Patents

Literature

33results about How to "Reduce heat response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

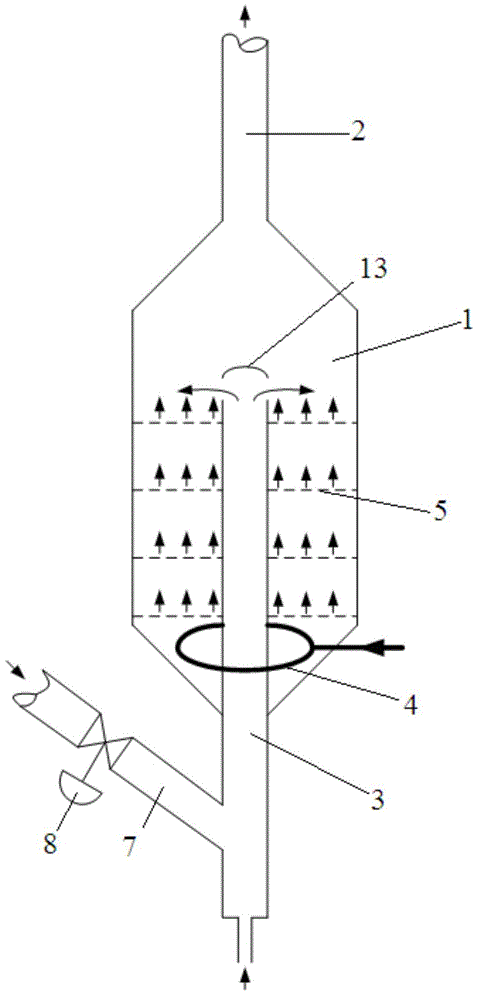

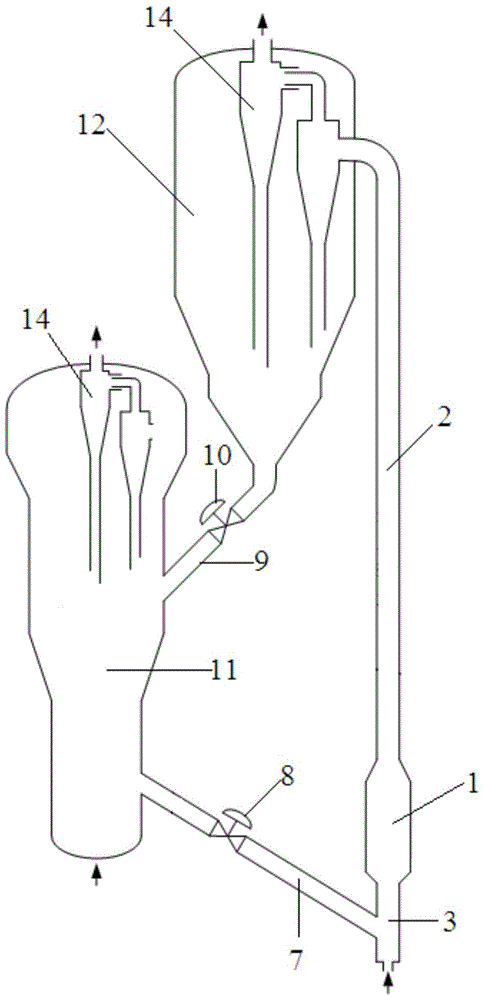

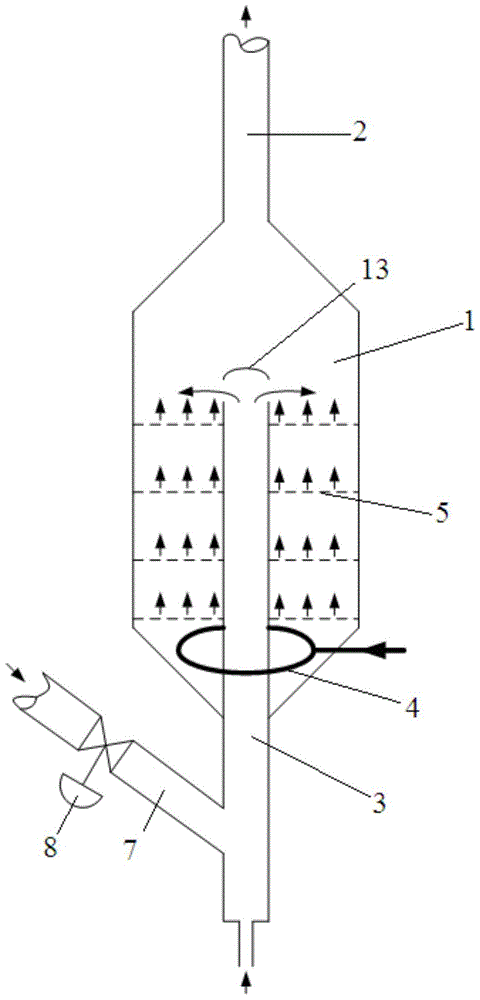

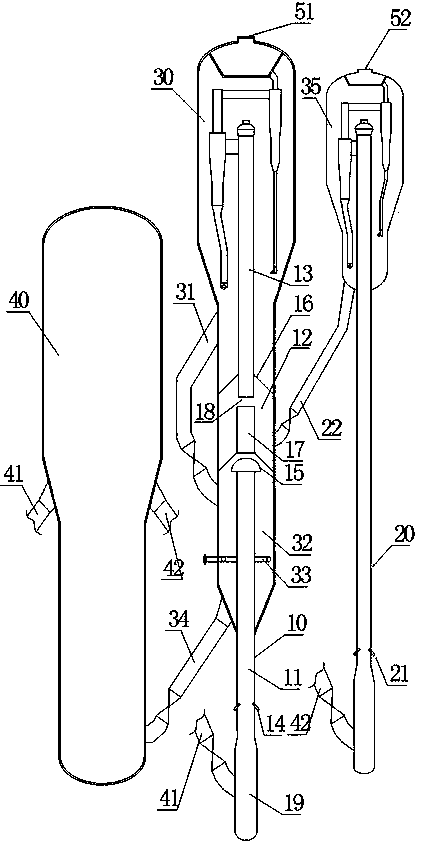

Fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO)

InactiveCN104437274AImprove contact reaction efficiencyHigh selectivityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedAlkene

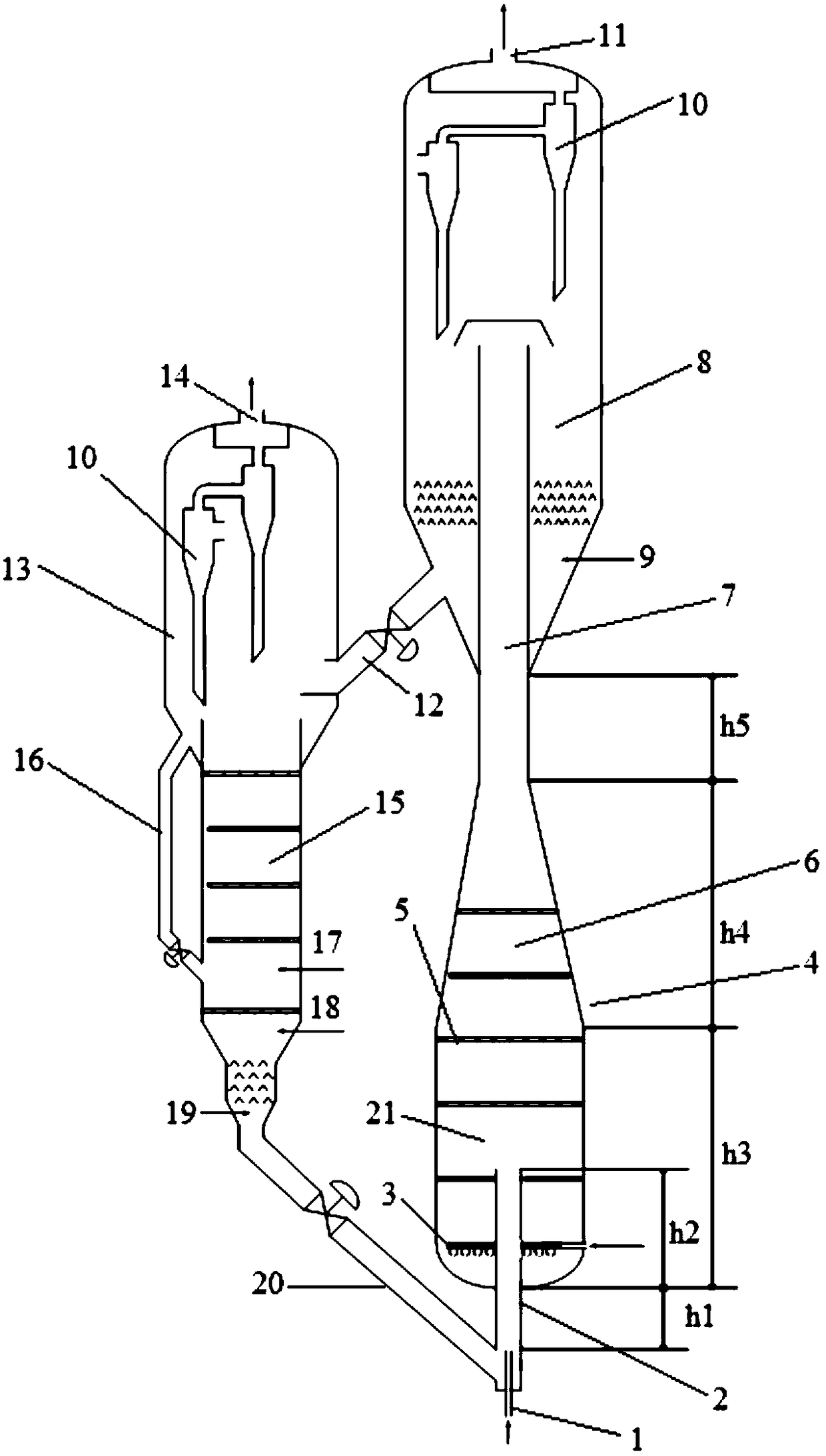

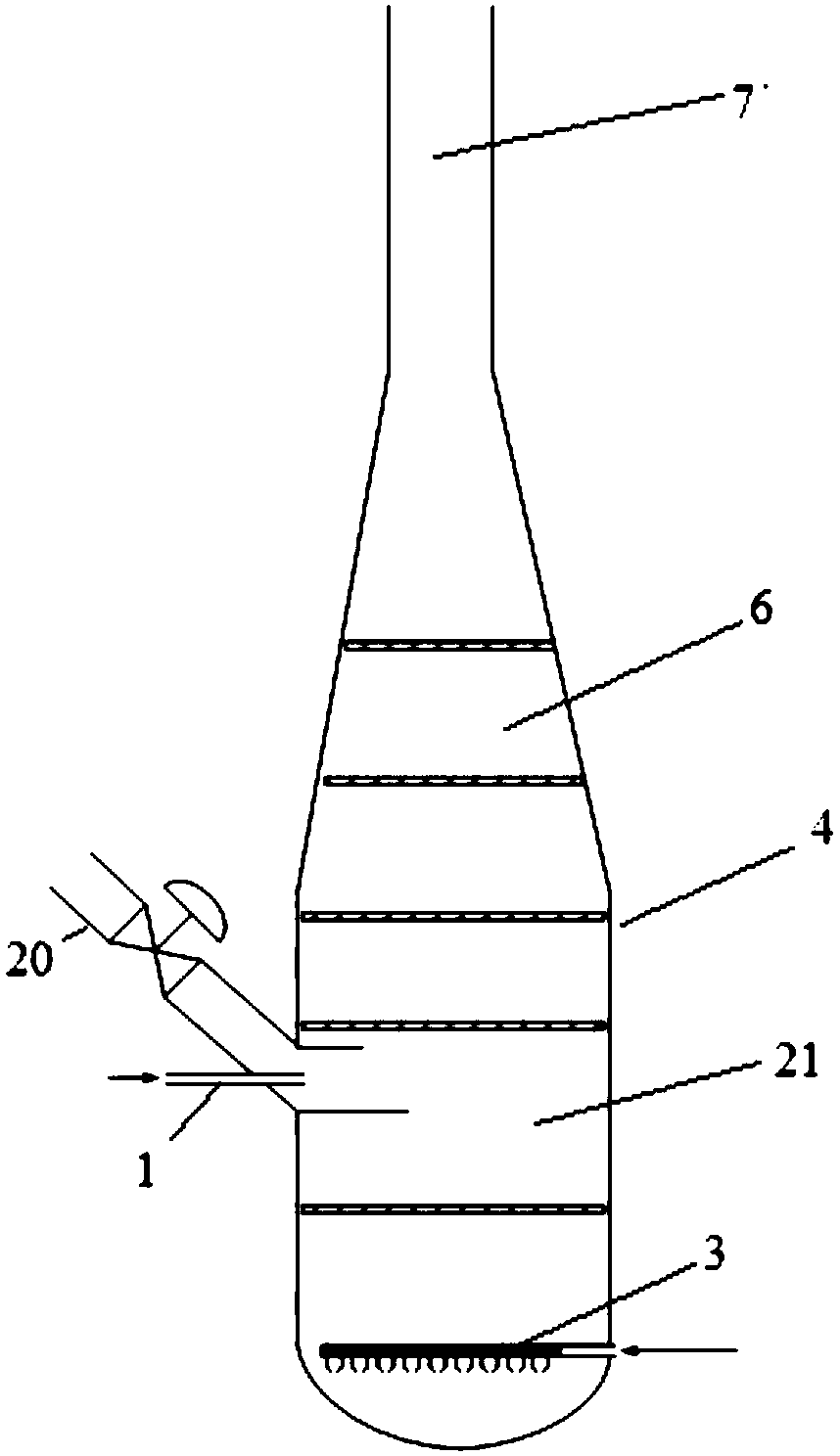

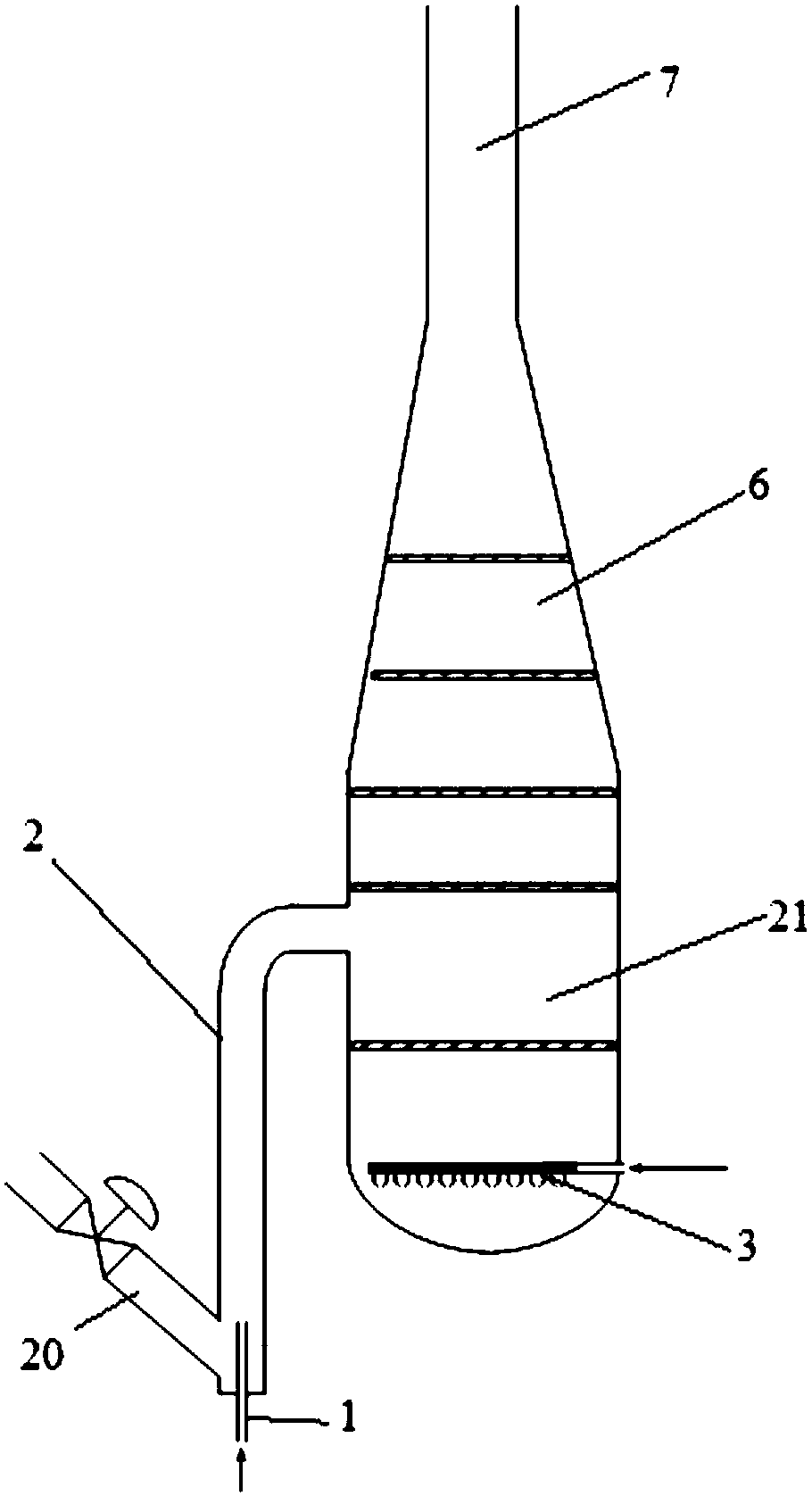

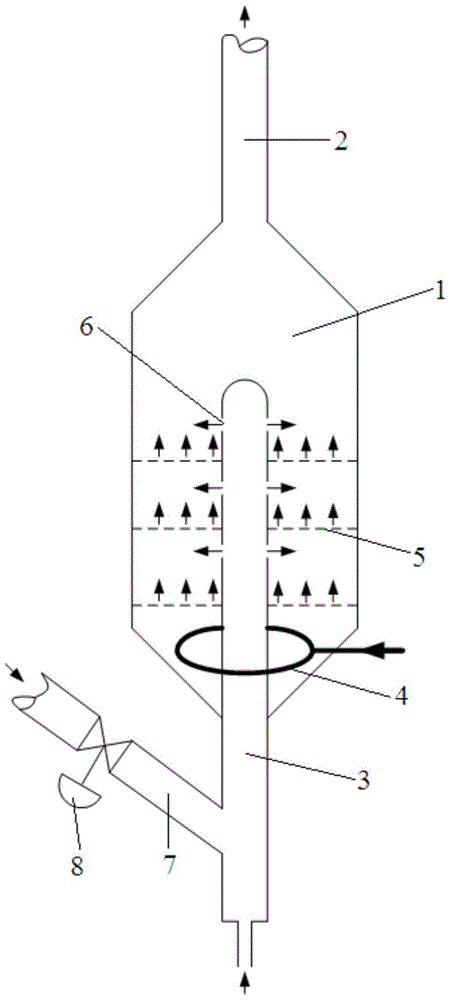

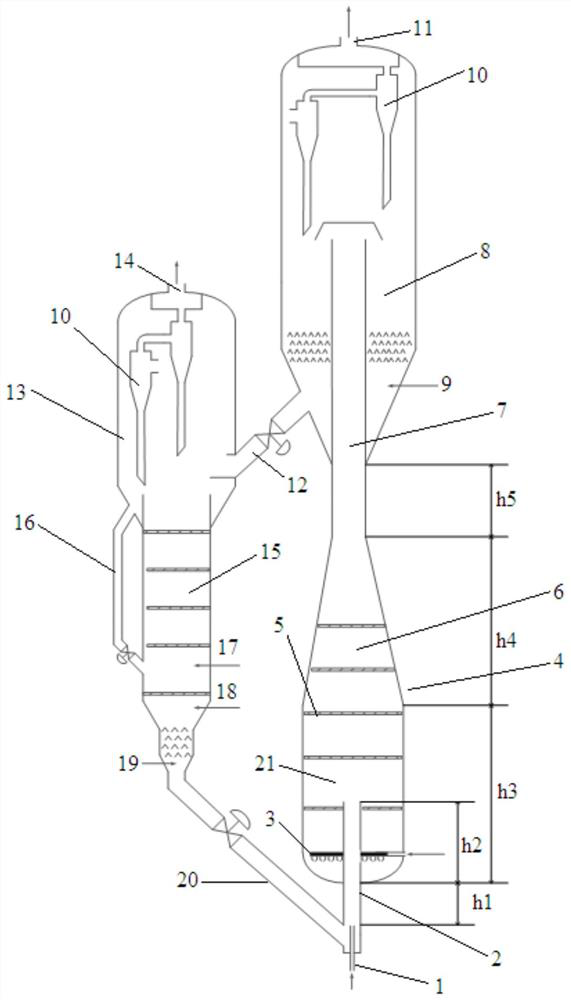

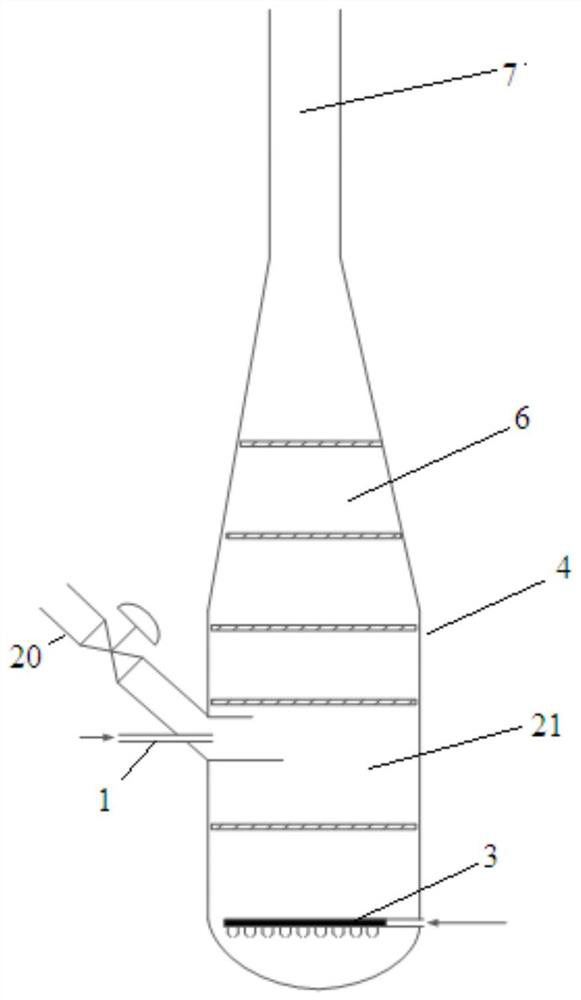

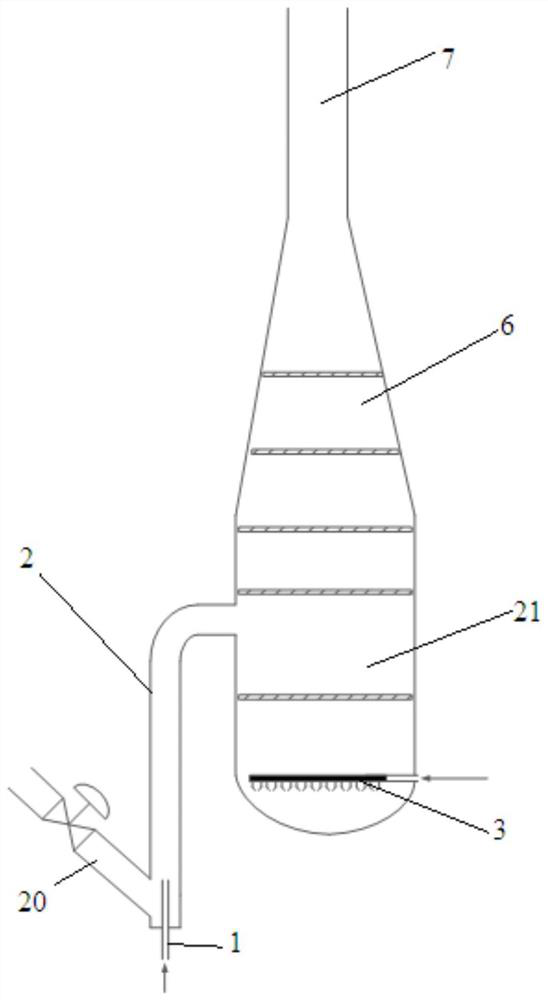

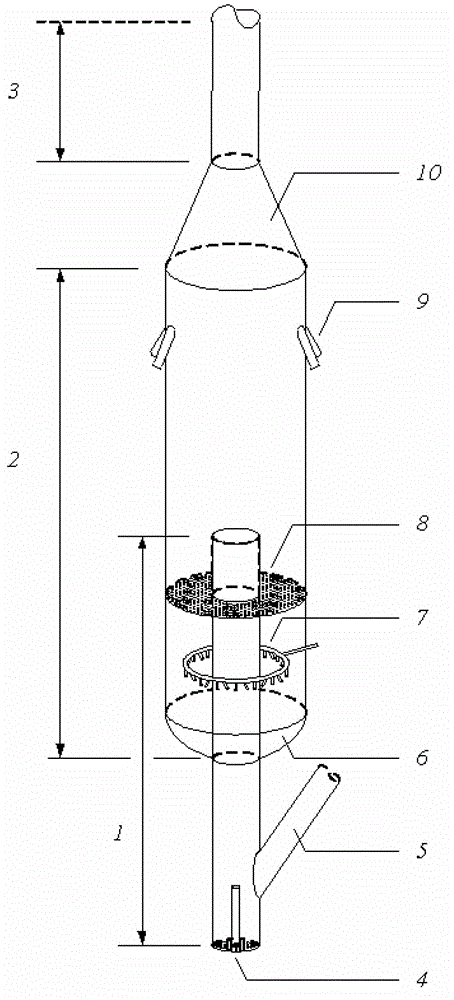

The invention discloses a fluidized bed reactor used for light olefin cracking and Methanol To Olefin (MTO), which comprises a reactor and a pre-riser; the reactor comprises a dense phase fluidized bed reactor and a dilute phase conveying reactor which are positioned at same axis, the pre-riser and the dilute phase conveying reactor are respectively positioned at upper part and lower part of the dense phase fluidized bed reactor; diameter of the pre-riser is smaller than diameter of the dense phase fluidized bed reactor, the upper part of the pre-riser extends into the dense phase fluidized bed reactor; an upper end port of the pre-riser in the dense phase fluidized bed reactor is sealed, and a perforate is provided on the tube wall of the pre-riser in the dense phase fluidized bed reactor; or the perforate is provided on the upper end of the pre-riser in the dense phase fluidized bed reactor, and a baffle plate is arranged over the perforate. The reactor is capable of increasing gas-solid contact efficiency, the backmixing degree of oil gas and a catalyst is less, and conversion rate of one way of the light olefin cracking and Methanol To Olefin (MTO) reactions can be greatly improved, and the target product micromolecule olefin selectivity can be greatly improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

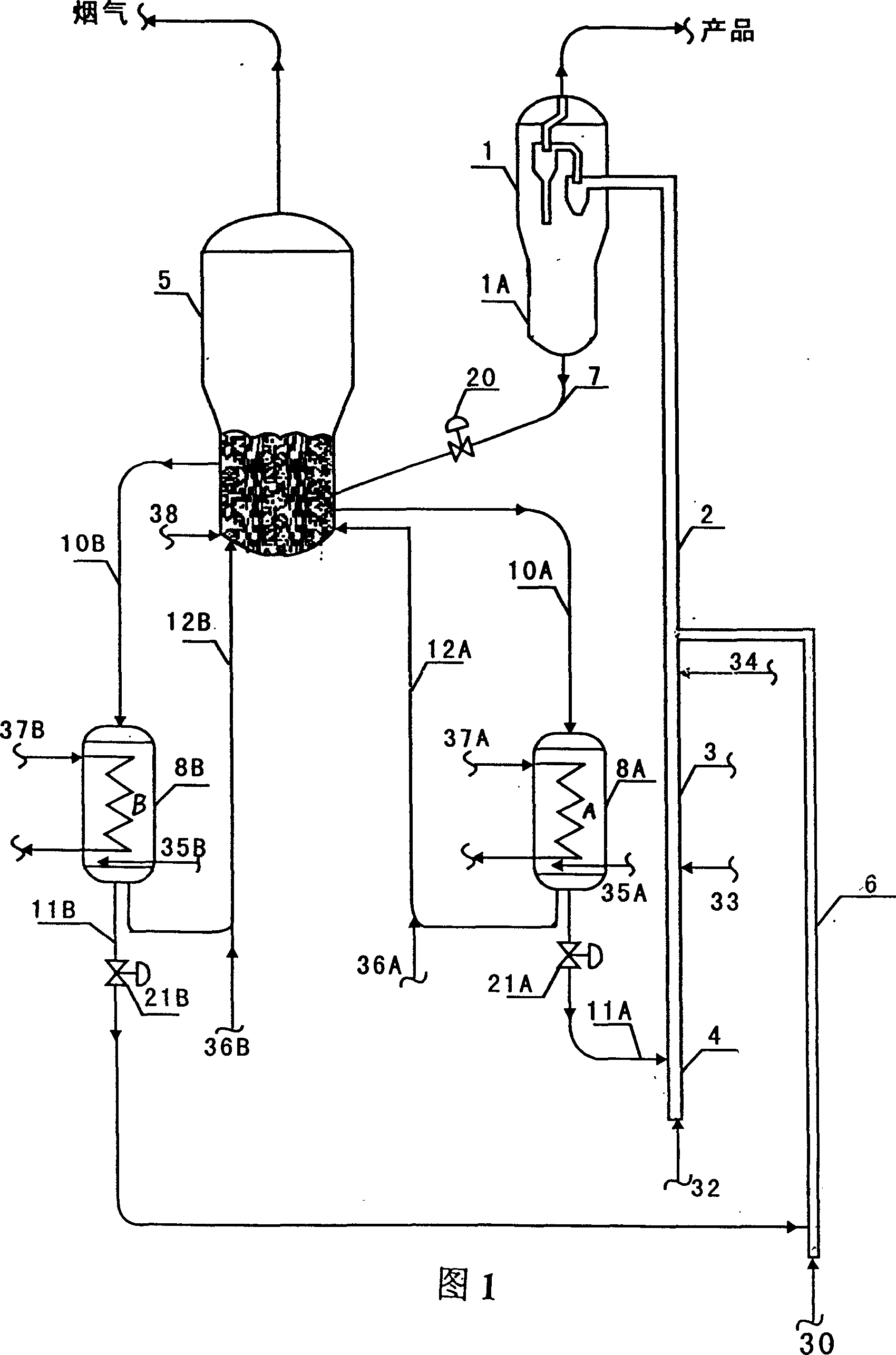

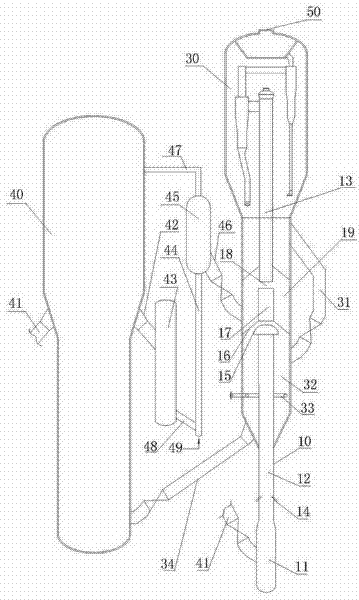

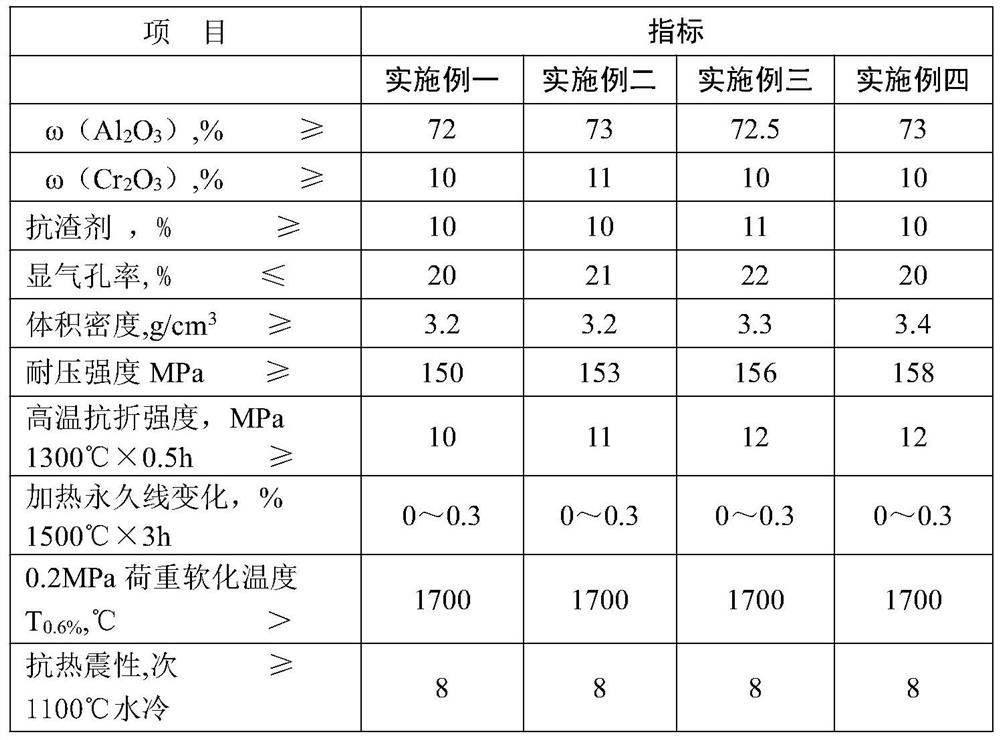

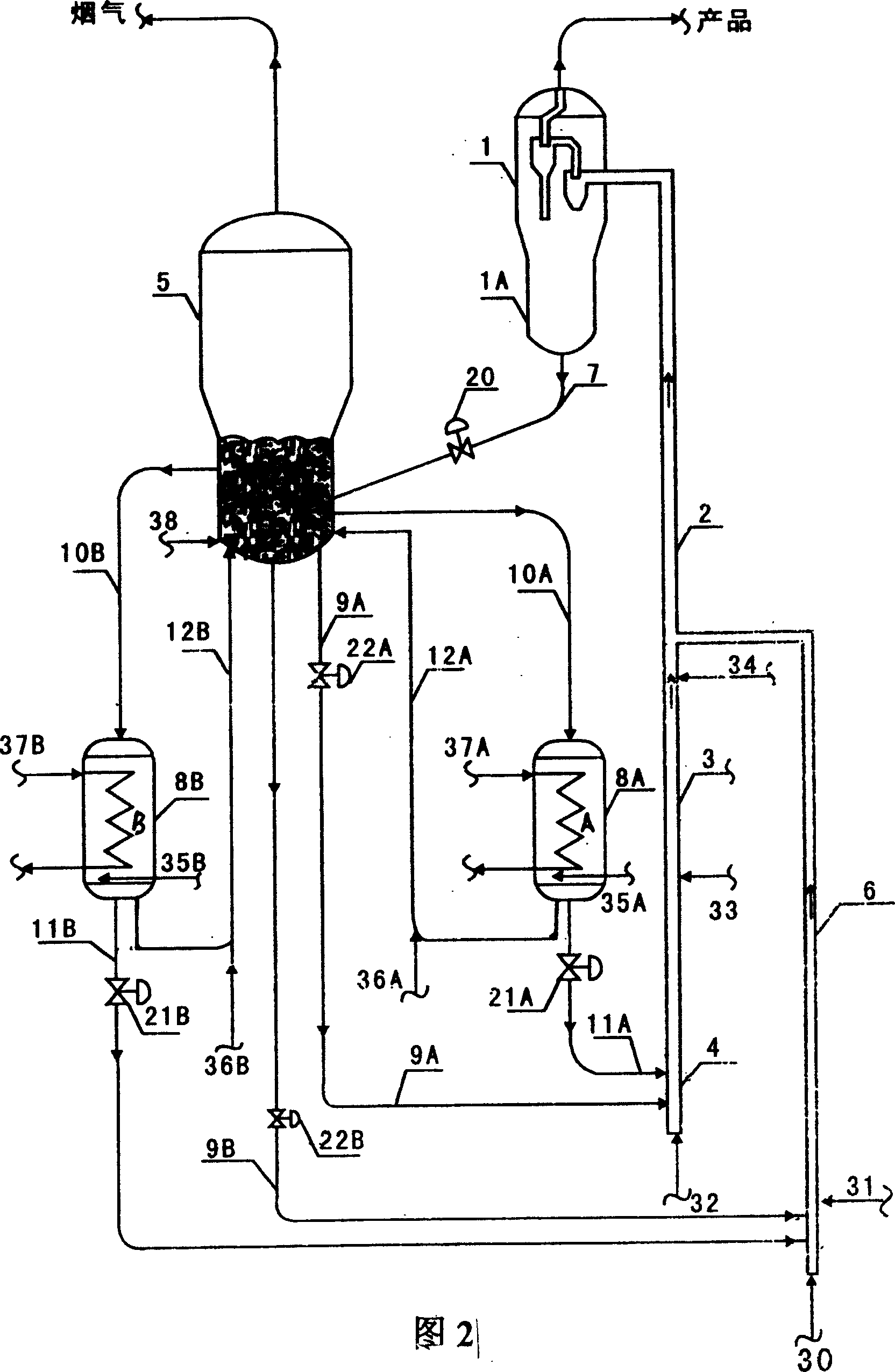

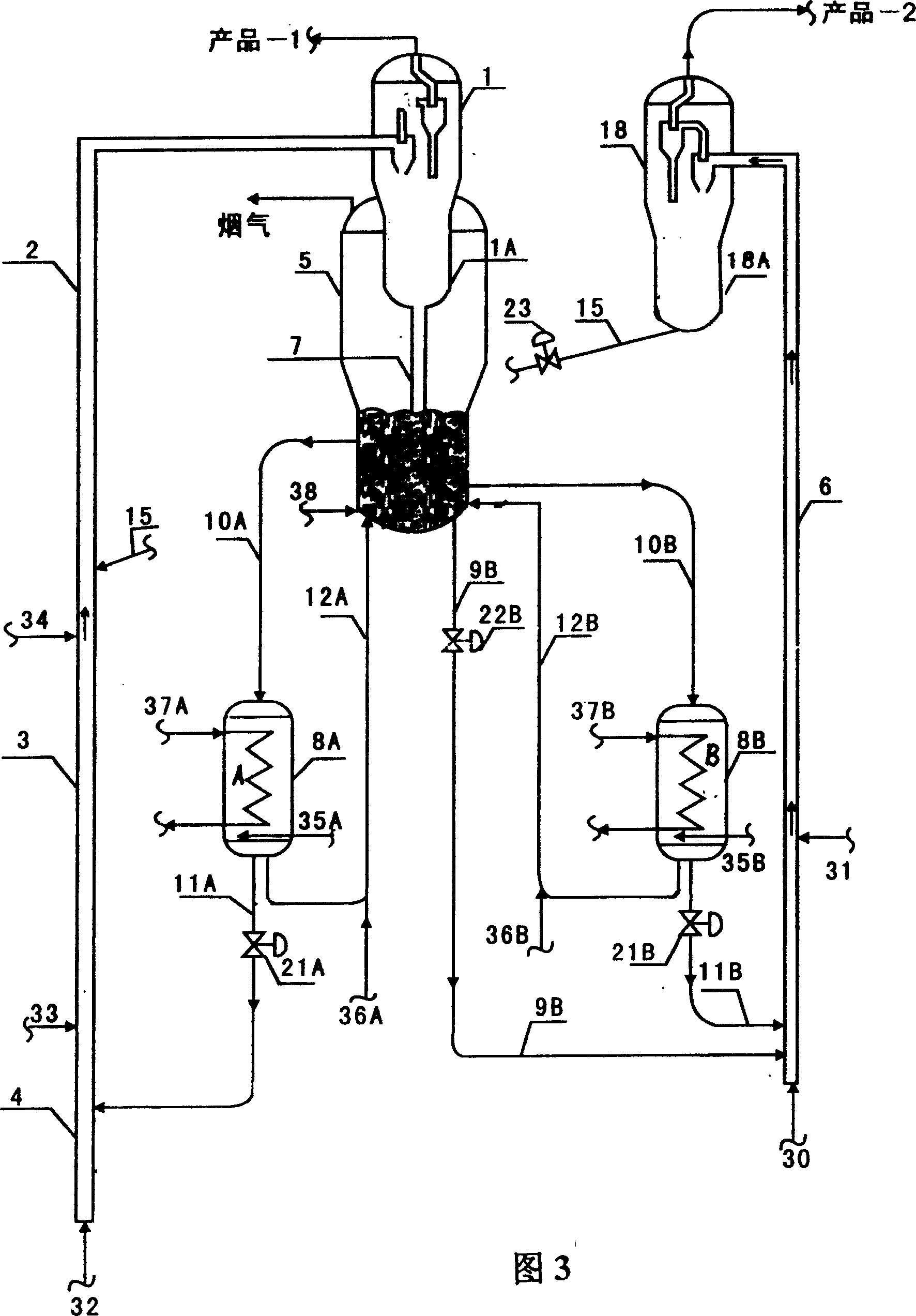

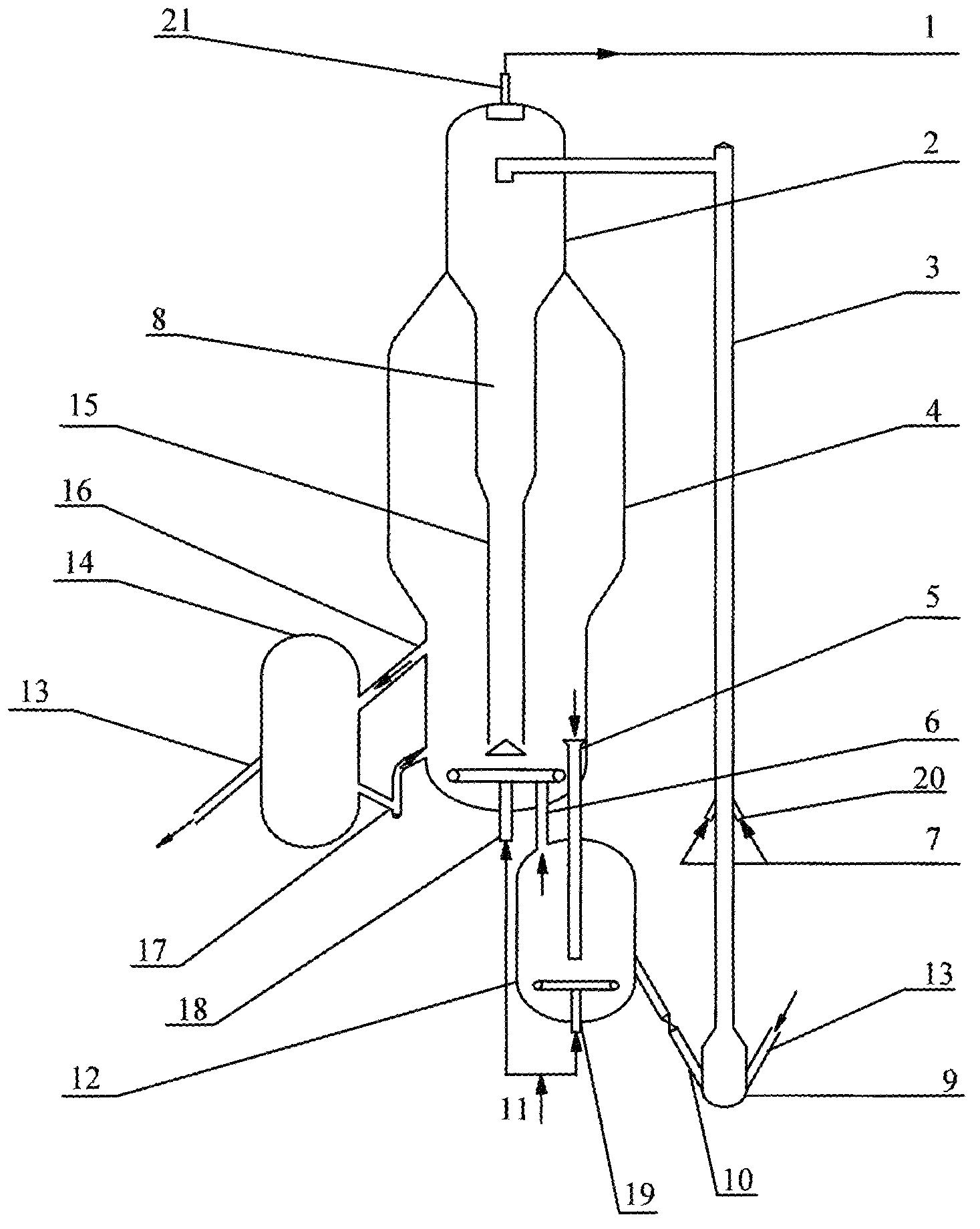

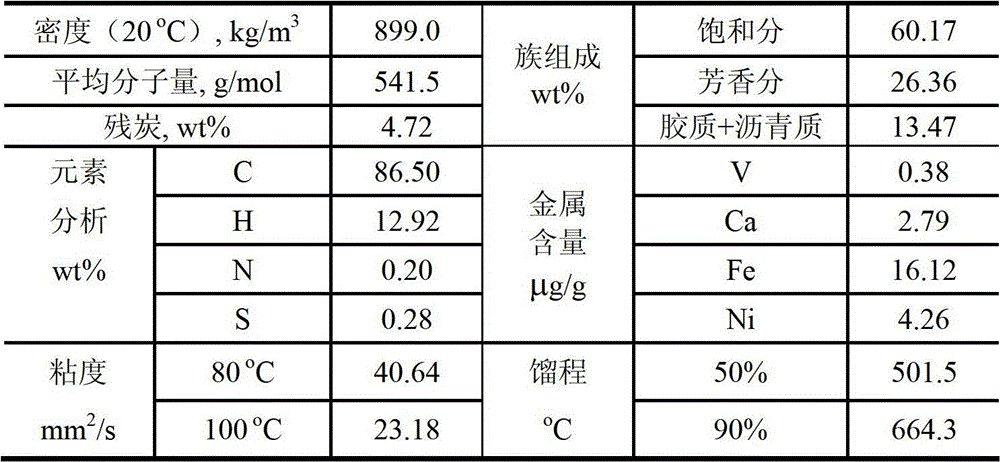

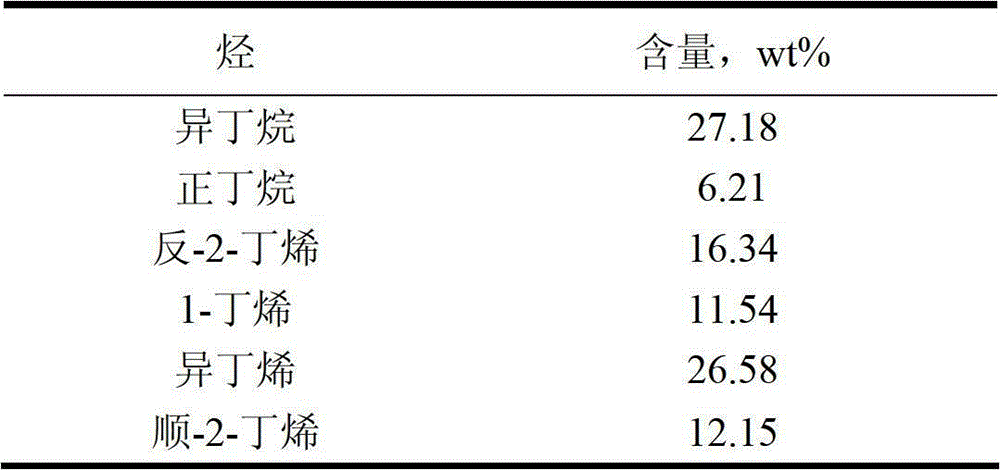

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1664074ARaise the preheat temperaturePromote atomizationTreatment with plural serial stages onlyCatalytic transformationPtru catalyst

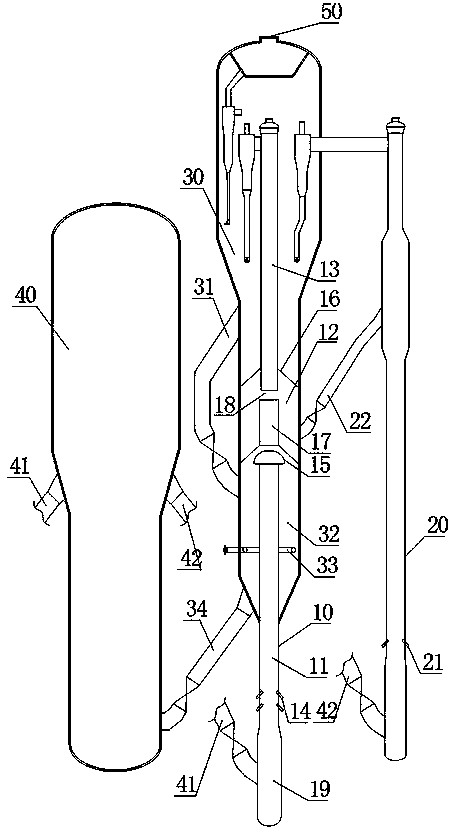

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

Nutritional breakfast and preparation method beneficial to calcium supplement and stomach nourishing of the elderly

The invention involves a nutritional breakfast beneficial to calcium supplement and stomach nourishing of the elderly. The raw materials include totally 30 food materials in six kinds of grain, beans, fruit, vegetables, nuts and fiber. The specific form is nutrition rice slice and fruit and vegetable particle. The invention also refers to the preparation of the nutritional breakfast beneficial to calcium supplement and stomach nourishing of the elderly. The described nutritional breakfast is of comprehensive nutrition easy to absorb and convenient to carry with and blew. The effect to replenish calcium and strengthen the bone is achieved by adding the rice, soybeans, red beans and red dates which are rich in calcium. The breakfast also has the effect of nourishing stomach, enhancing the heart, reinforcing the vitality and reducing the blood pressure and cholesterol by adding the millet, barley, pumpkin, oats, buckwheat, potato, carrot, lotus seed, banana, grapes, broccoli, pearl barley and gorgon fruit, etc.

Owner:湖南益百年健康科技有限公司

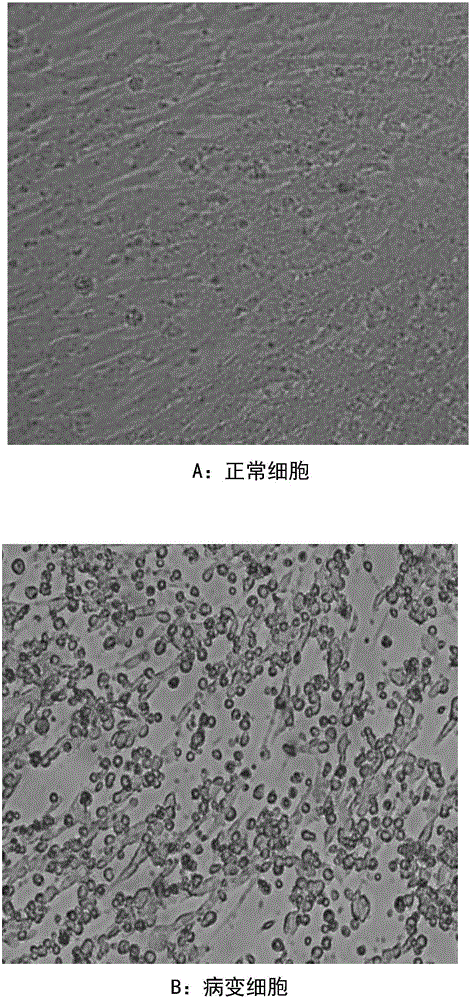

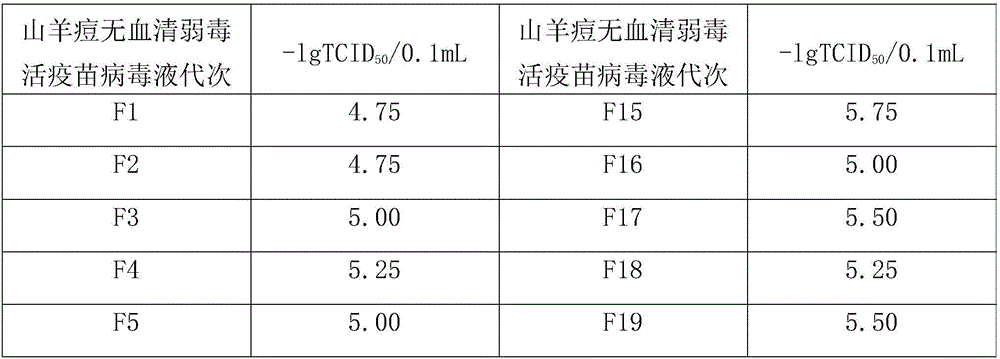

Method for preparing heat-resisting attenuated virus live vaccine for goatpox by using BHK21-C13 passage cell

InactiveCN106282129AAvoid pollutionStrong process controllabilityPowder deliveryViral antigen ingredientsHeterologousImmunogenicity

The invention discloses a method for preparing a heat-resisting attenuated virus live vaccine for goatpox by using a BHK21-C13 passage cell. Based on the existing attenuated virus AV41 for goatpox, which has excellent immunogenicity, the method comprises the following steps: culturing 25-28th generations of virus solution with a heterologous BHK21 cell, and then adding an appropriate heat-resisting freeze-drying protective additive to obtain the heat-resisting attenuated virus live vaccine for goatpox. The passage cell vaccine used by the method is superior to the primary cell vaccine in the aspects of virus yield, homogeneity, purity and the like, not only guarantees the effective level of the vaccine and has a better heat-resisting protection effect, but also can ensure the safety of a purebred pregnant goat. As the existing BHK21 cell adopts a mature suspension culture process, the exploration of various parameters of adherent culture lays a solid foundation for the next promotion of suspension process.

Owner:JINYUBAOLING BIO PHARMA CO LTD

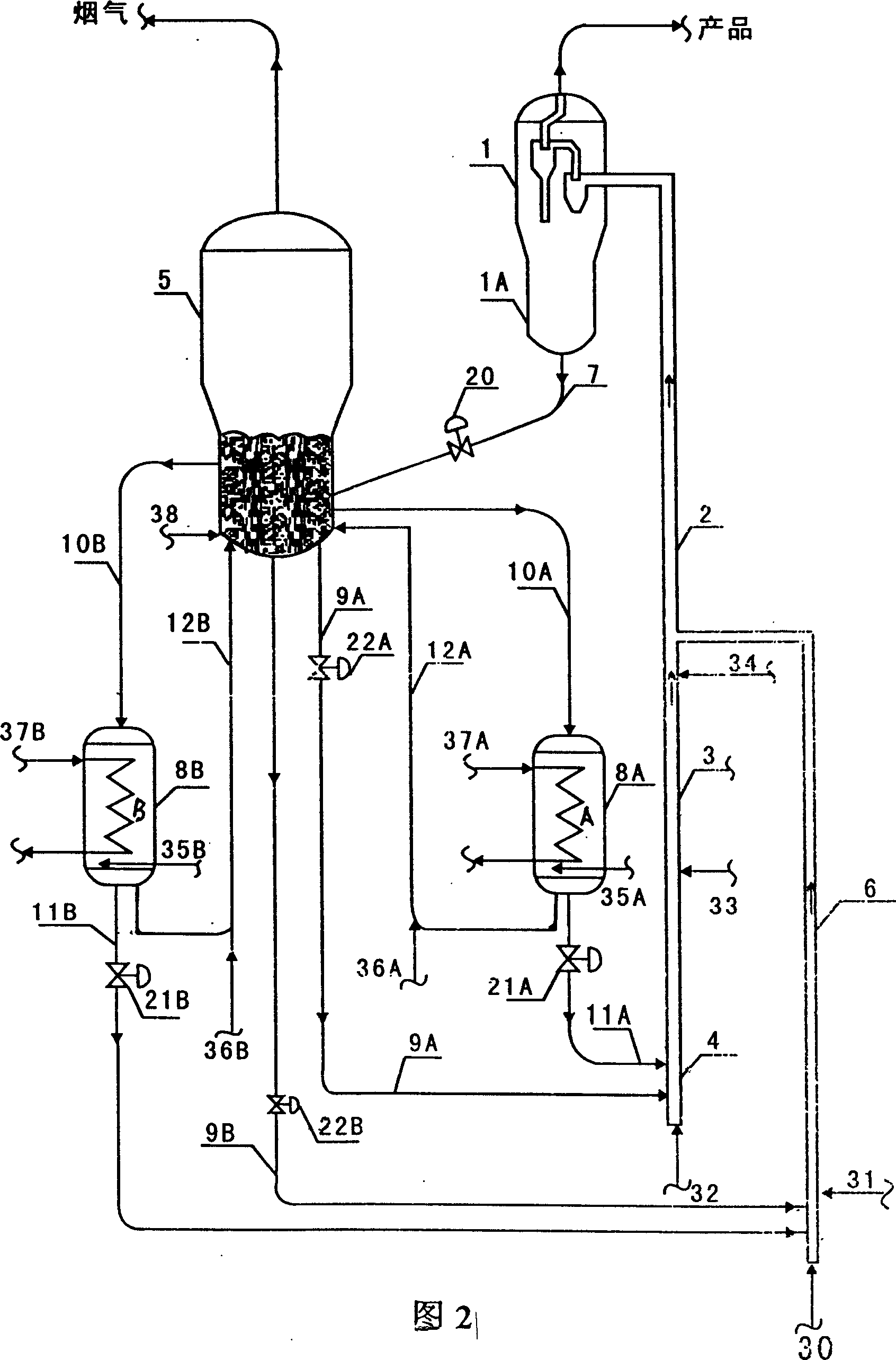

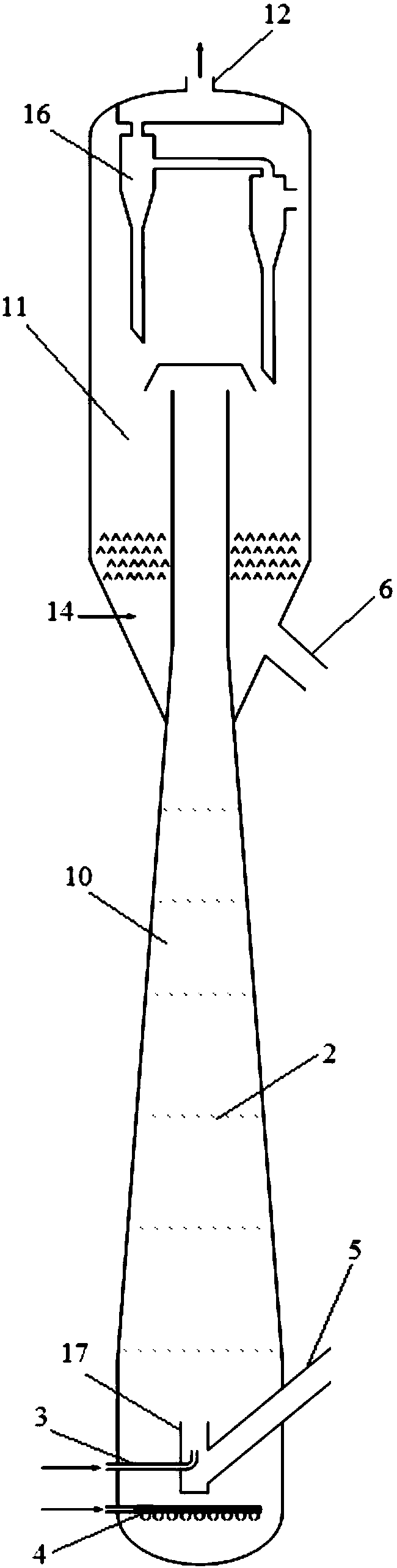

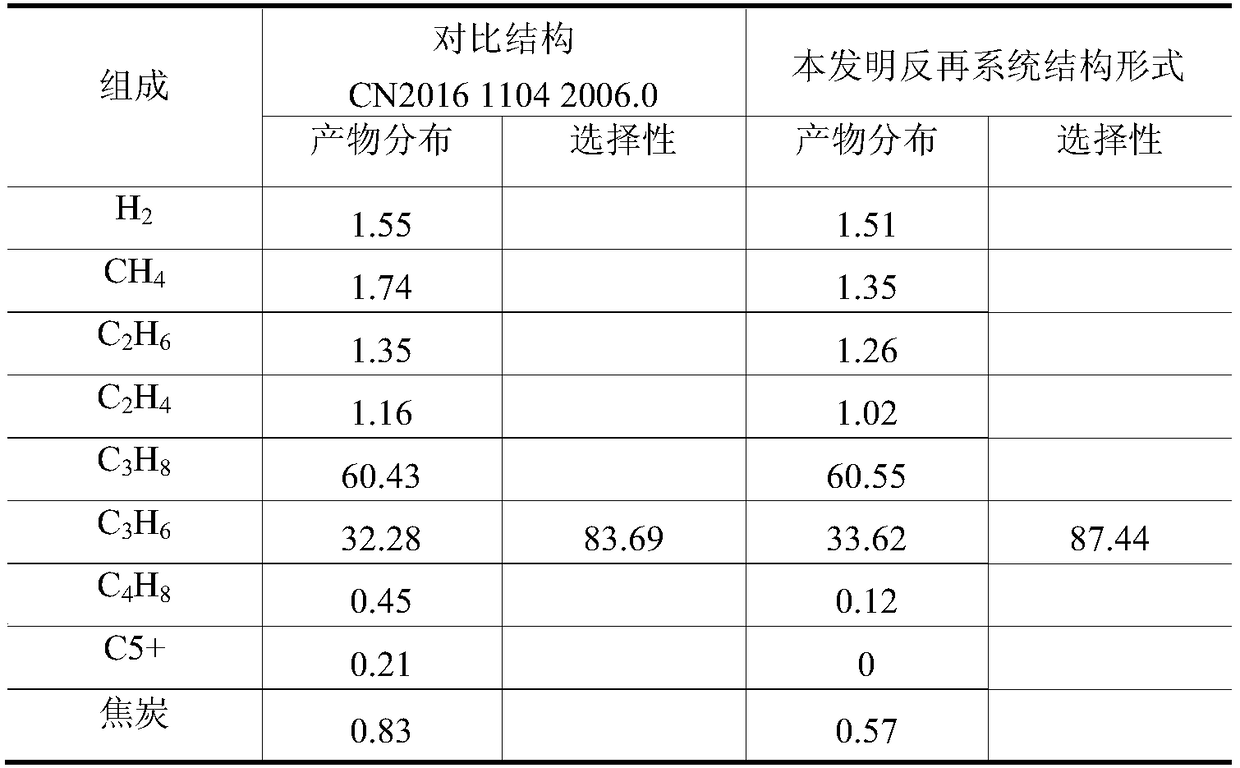

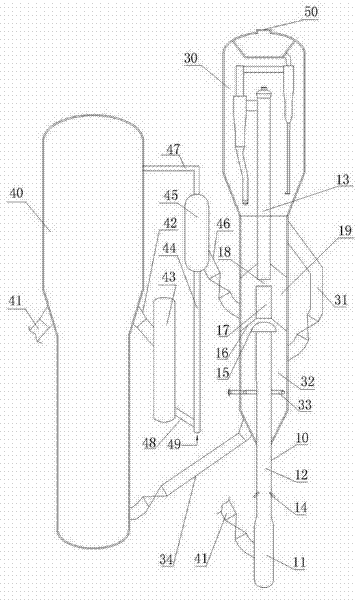

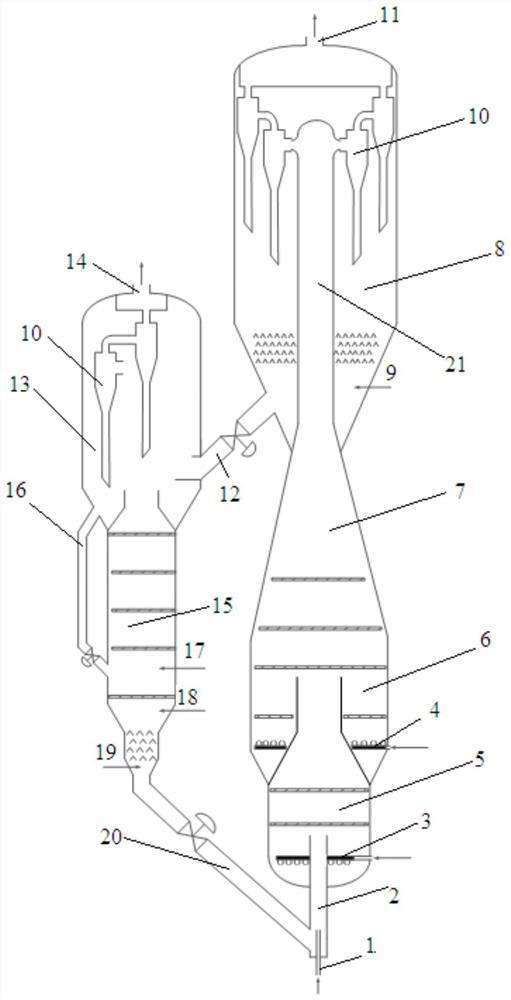

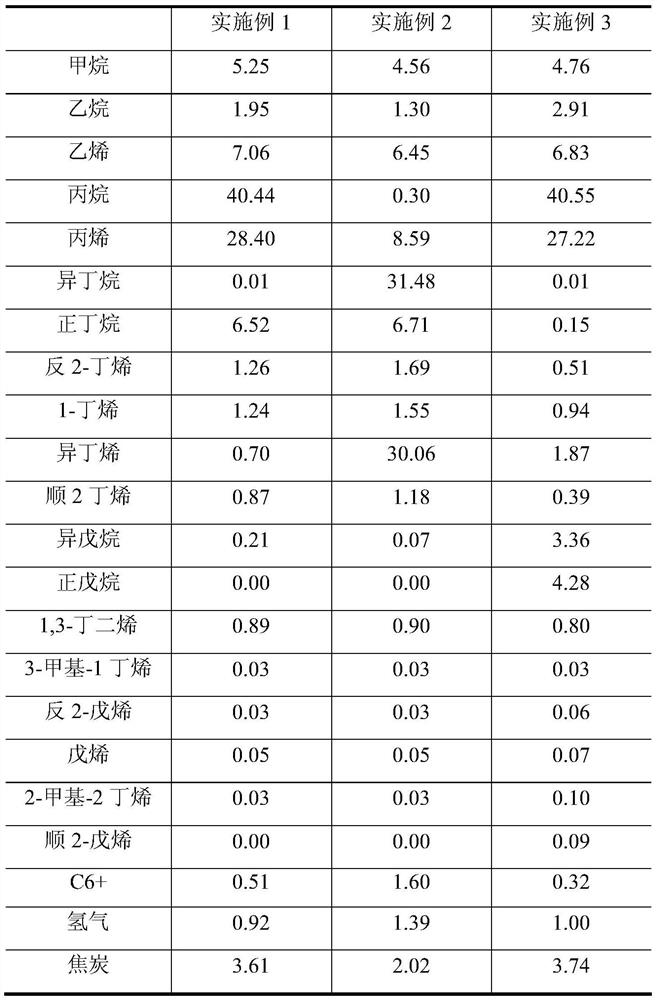

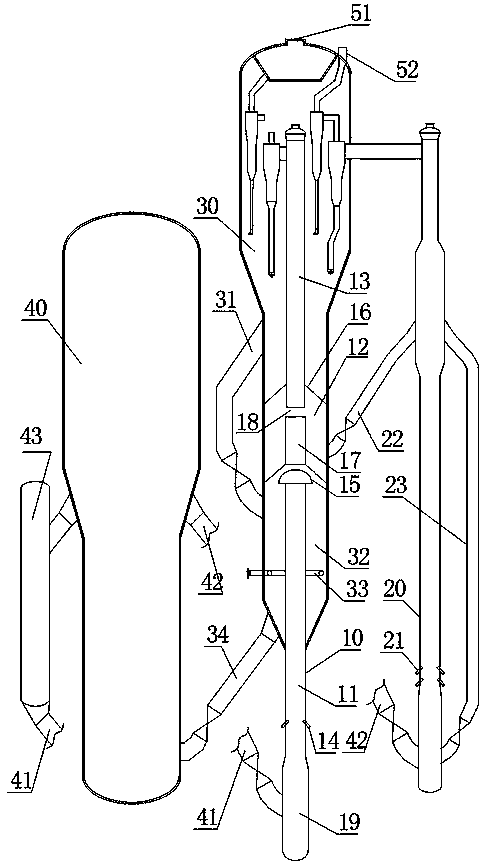

Circulating fluid bed reaction device for preparing olefin from alkane through catalytic dehydrogenation or catalytic cracking

ActiveCN109499486AReduce secondary conversionsTake advantage ofHydrocarbonsChemical recyclingAlkaneDehydrogenation

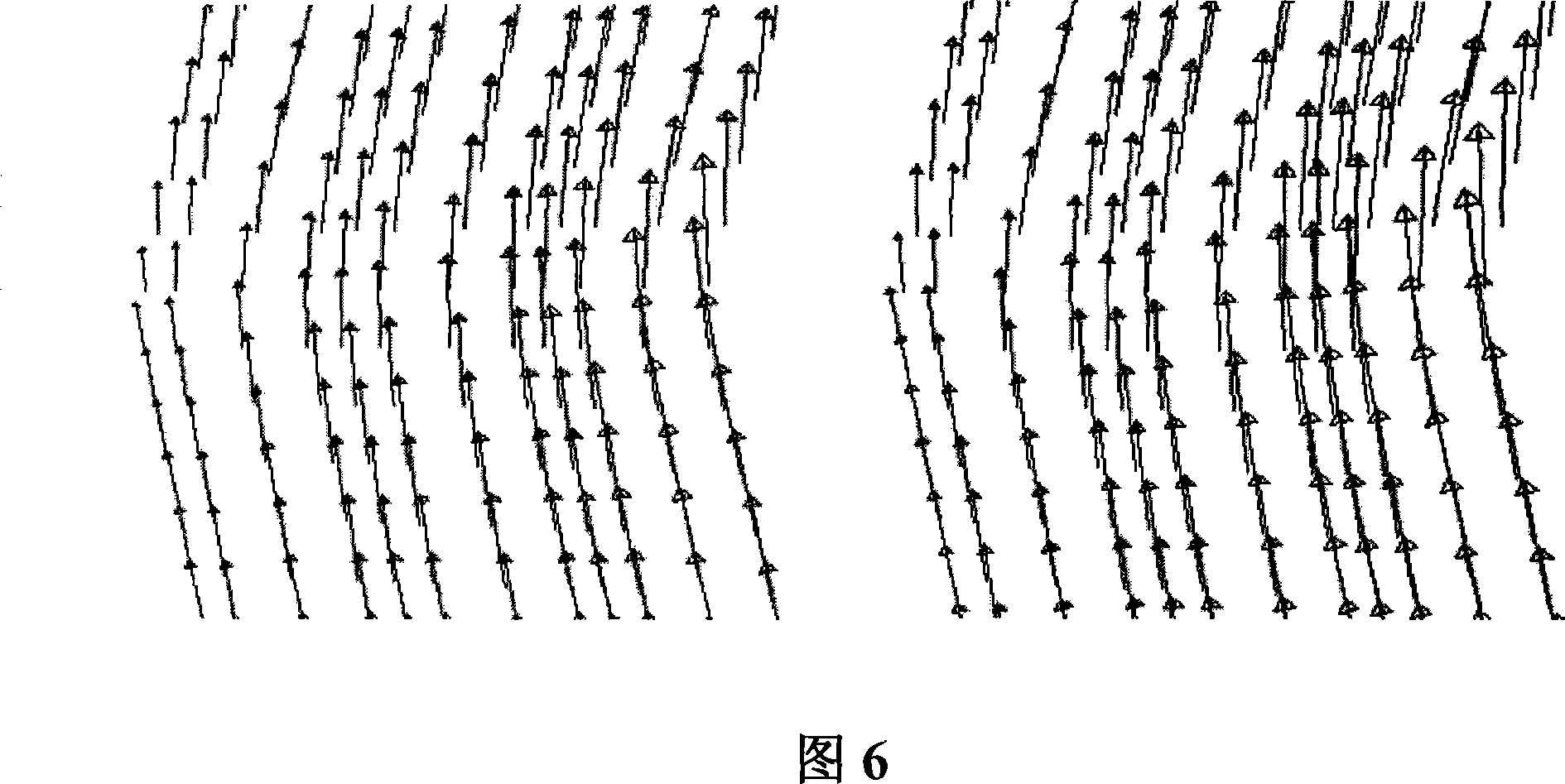

The invention provides a circulating fluid bed reaction device for preparing olefin from alkane through catalytic dehydrogenation or catalytic cracking. The device comprises a reactor and a reactor sedimentation section, wherein the reactor sedimentation section is positioned at the upper part of the reactor; the reactor comprises a diameter shrinkage section; the cross section diameter of the diameter shrinkage section is gradually decreased from bottom to top; a lifting pipe extends into the reactor from the lower part of the reactor; a catalyst regeneration inclined pipe is connected with the lifting pipe outside the reactor. The reaction device realizes the gradual diameter shrinkage along the fluid flowing direction; the secondary conversion of of olefin due to returning and mixing isreduced. Reactants and catalysts in the reactor realize the flow merging and upward flowing; the uniform distribution of temperature in the reactor can be effectively improved; the local high temperature is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

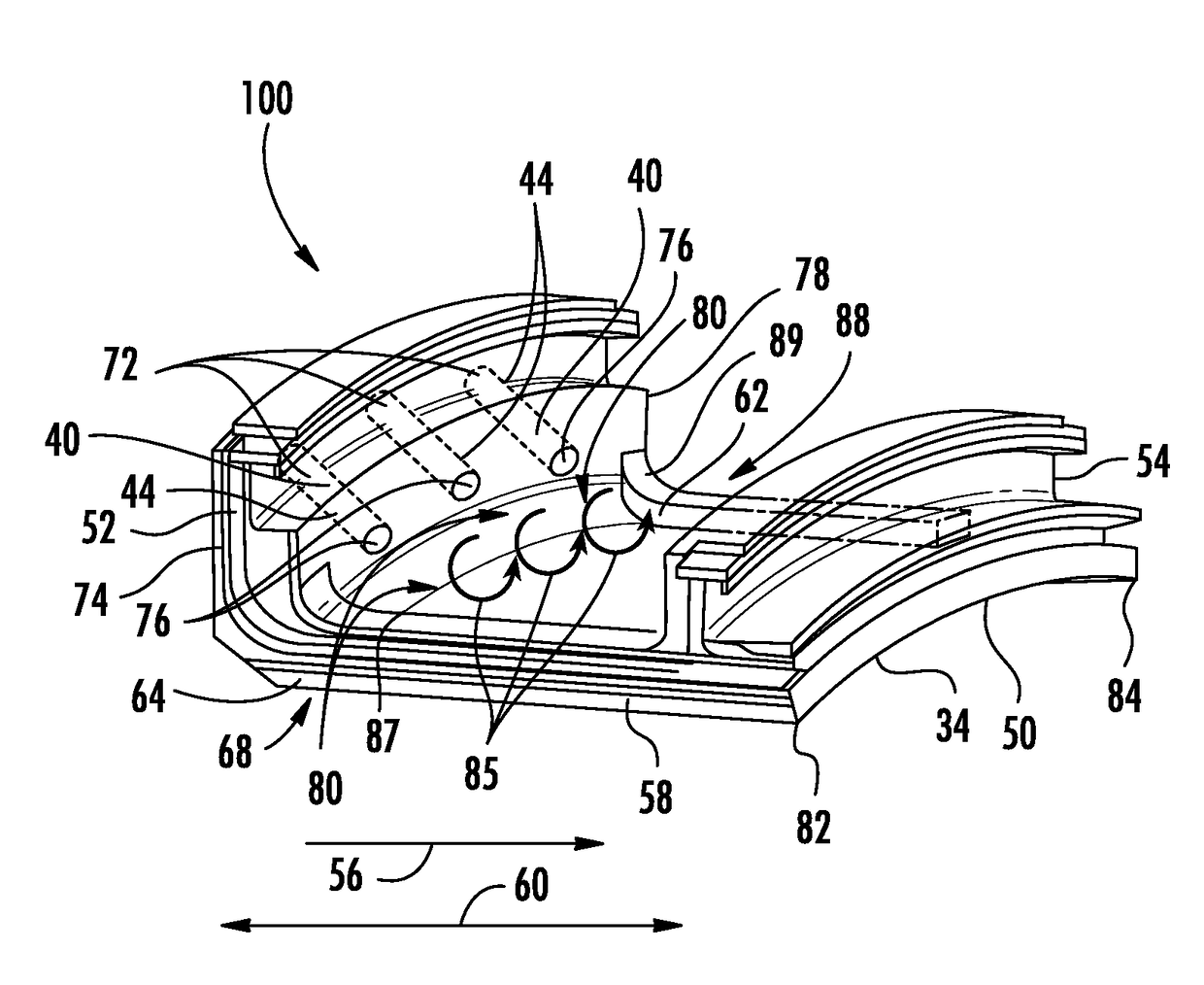

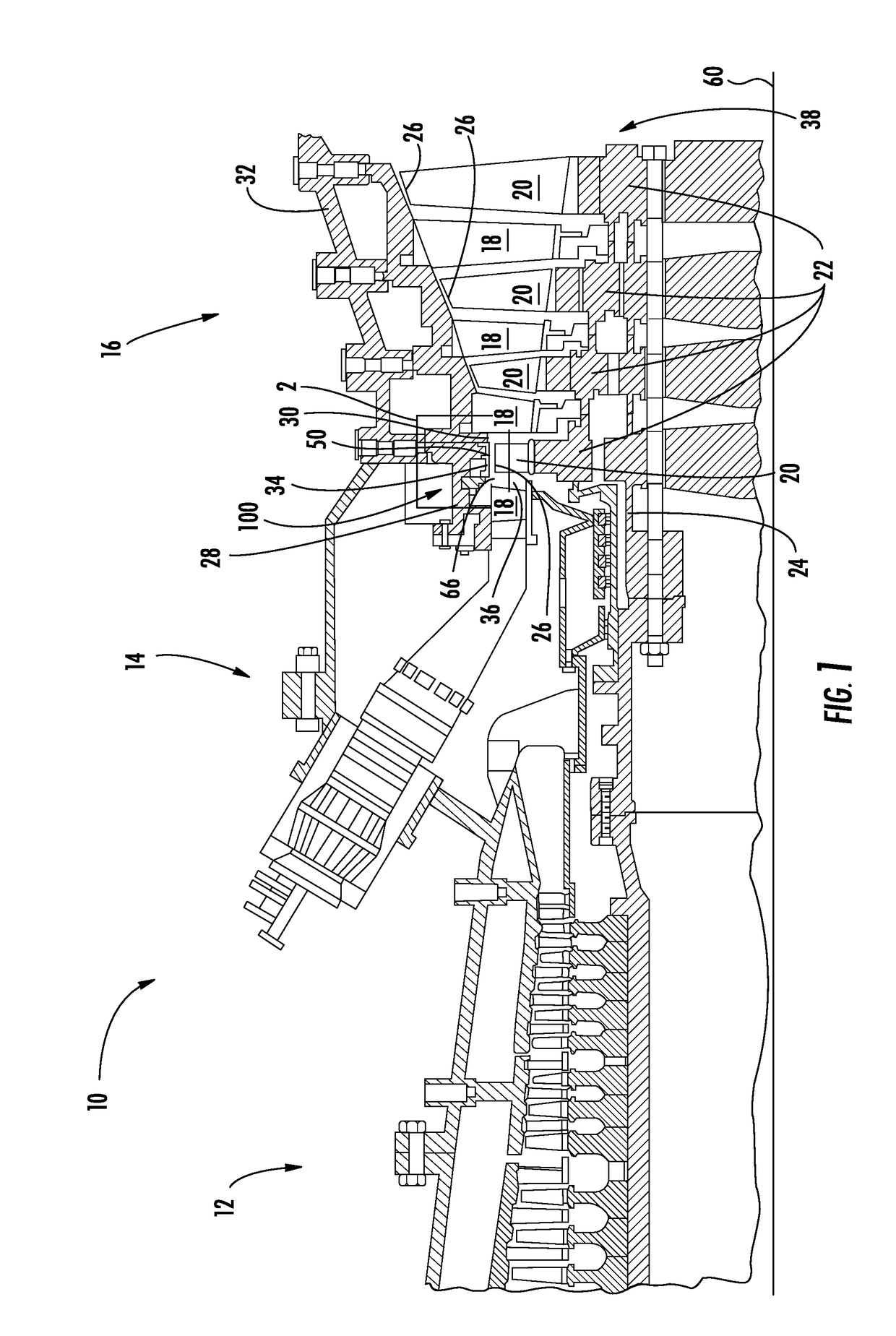

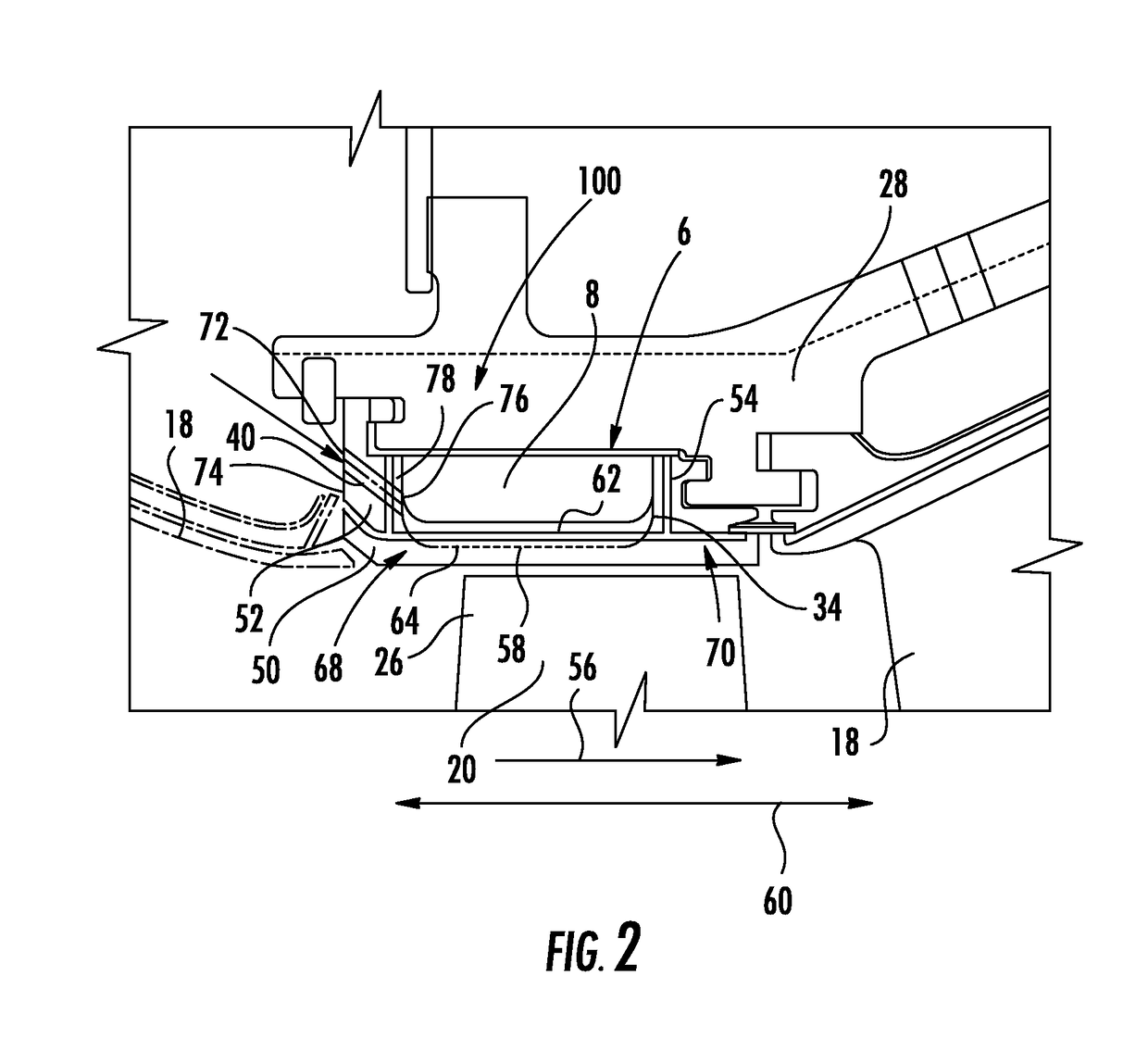

Shroud cooling system for shrouds adjacent to airfoils within gas turbine engines

InactiveUS20170183978A1Improve cooling efficiencyImprove cooling effectEngine fuctionsLeakage preventionTurbine bladeCooling fluid

A shroud cooling system (100) configured to cool a shroud (50) adjacent to an airfoil within a gas turbine engine (10) is disclosed. The turbine engine shroud (50) may be formed from shroud segments (34) that include a plurality of cooling air supply channels (40) extending through a forward shroud support (52) for impingement of cooling air onto an outer radial surface of the shroud segment (34) with respect to the inner turbine section of the turbine engine (10). The channels (40) may extend at various angles (42) to increase cooling efficiency. The backside surface (62) may also include various cooling enhancement components configured to assist in directing, dispersing, concentrating, or distributing cooling air impinged thereon from the channels (40) to provide enhanced cooling at the backside surface (62). The shroud cooling system (100) may be used to slow down the thermal response by isolating a turbine vane carrier (28) from the cooling fluids while still providing efficient cooling to the shroud (50).

Owner:SIEMENS AG

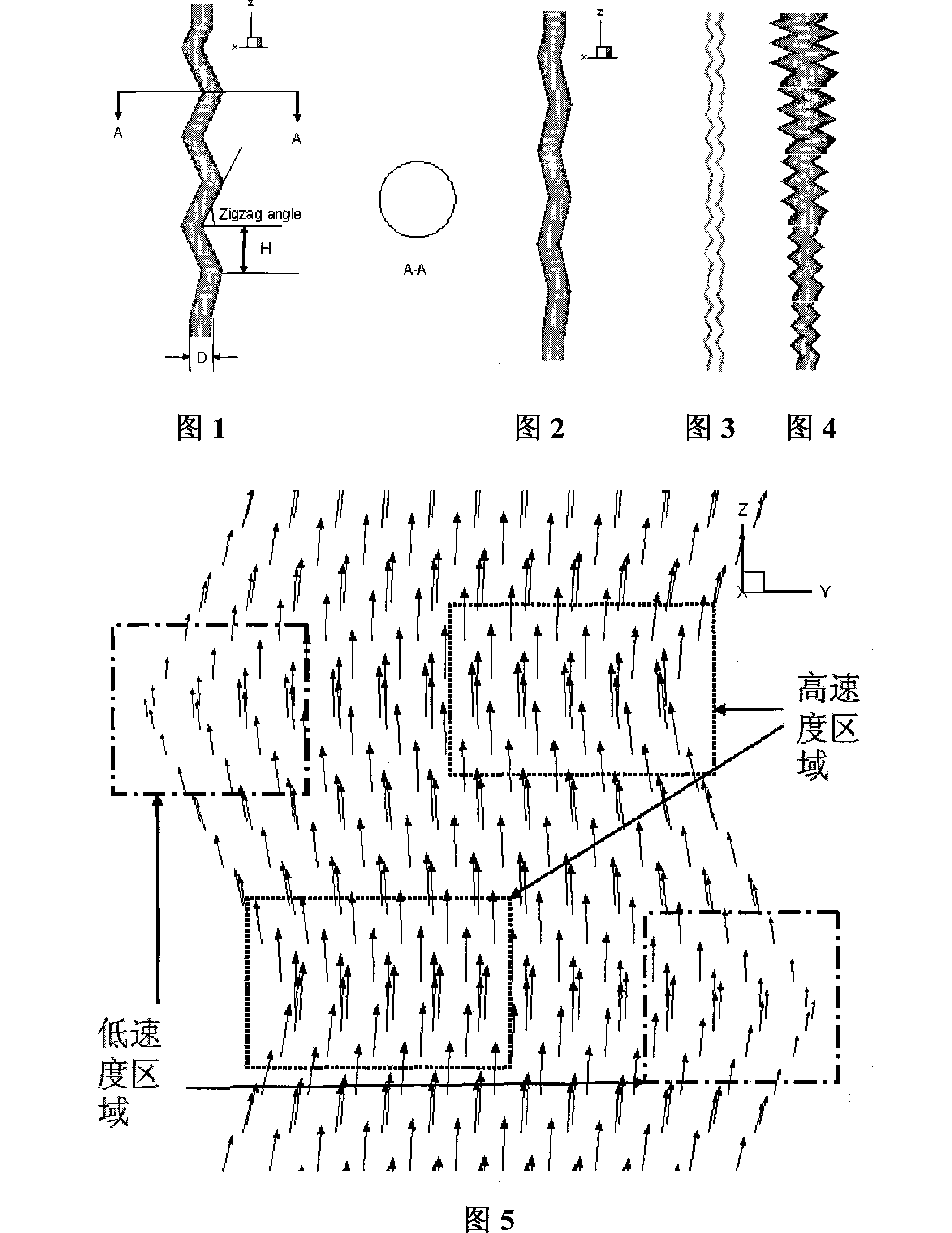

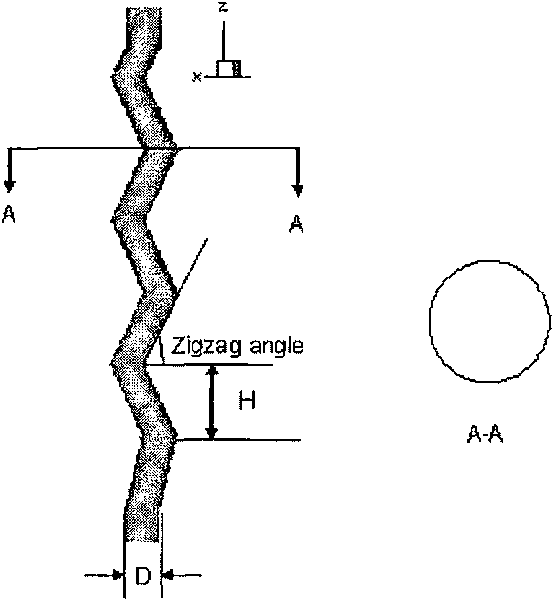

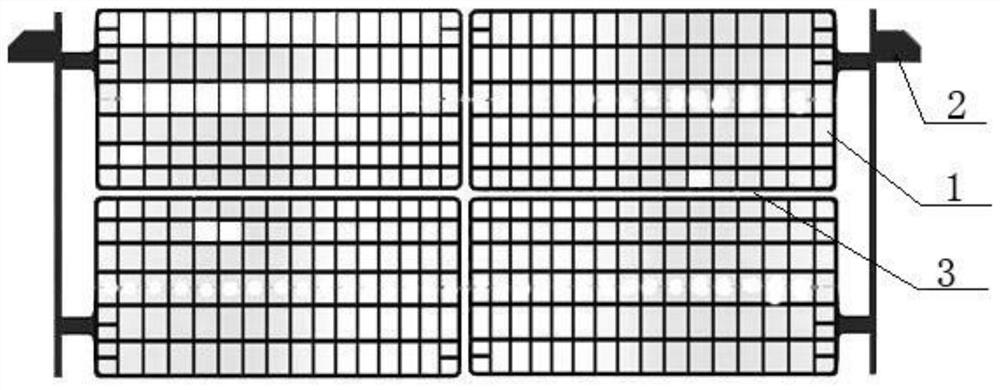

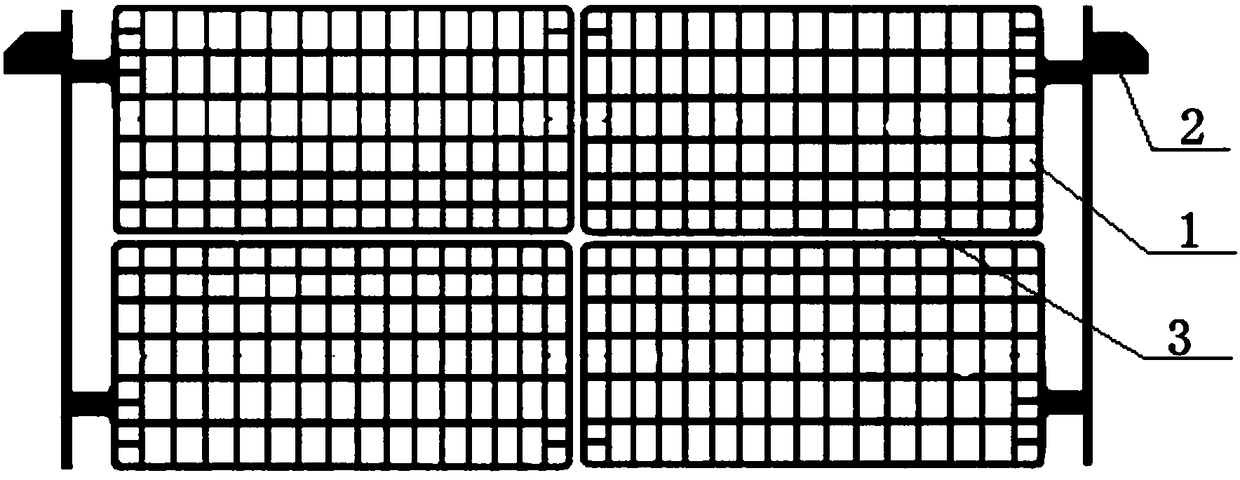

S-type fluid bed

InactiveCN101219356AAvoid backmixingFacilitate catalytic reactionsChemical/physical processesFluidized bedWave shape

The invention relates to an S-shape fluidized bed with the main technical solving proposal that the inner wall surface of the fluidized bed shows the wave shape along the direction of a long axle. The invention aims at solving the problems of the fluidized bed such as pressure loss, granules mixing, granules build-up and serious wall surface abrasion caused by the phenomenon of 'center-wall pipe flow' in the background technology, providing the S-shape fluidized bed which has even distribution of flow phase speed, solid granules phase speed and concentration.

Owner:褚开维 +1

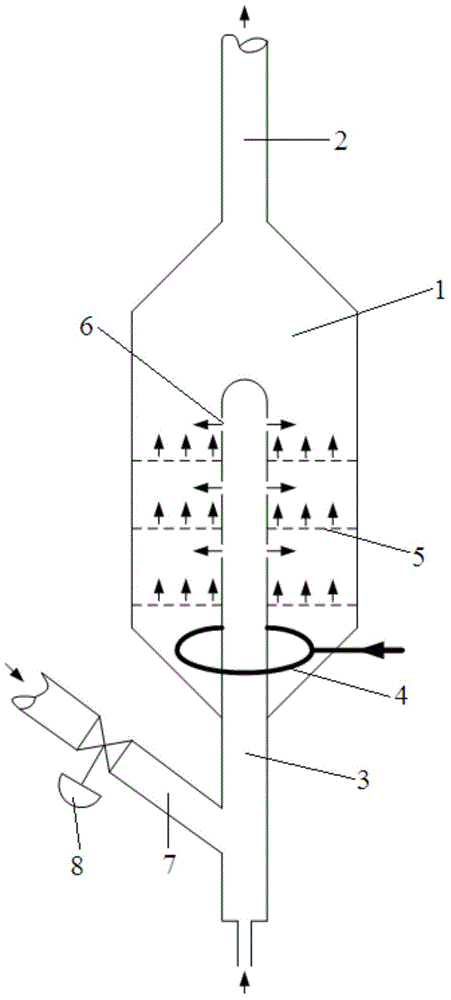

Reactor capable of reducing back mixing for preparing alkenes by dehydrogenation of alkanes and preparation method

ActiveCN108654526ATake advantage ofHigh selectivityHydrocarbonsChemical recyclingDehydrogenationAlkene

The invention relates to reaction apparatus for catalytic dehydrogenation of alkanes. The reaction apparatus comprises a reaction section and a reactor sedimentation section; the reactor sedimentationsection is positioned on the upper part of the reaction section; the diameter of the reaction section is gradually decreased from top to bottom; a catalyst regeneration tube aslant stretches into thereaction section, and the outlet end of the catalyst regeneration slant tube is positioned at the lower part of the reaction section; and a feeding distribution device is positioned below the outletend of the catalyst regeneration slant tube in the reaction section. The reactants and the catalyst in the reactor flow concurrently upwards, so that the uniformity of the temperature distribution inthe reactor can be effectively improved, local high temperature can be avoided, and then the thermal reaction is reduced. In addition, the diameter of the reactor is gradually decreased along the flowing direction of the fluid, and the secondary conversion of the alkenes caused by back mixing is reduced, so that the yield and the selectivity of alkenes are improved. A high-temperature regeneratoris directly sprayed into the bottom of the dense-phase bed of the reactor, so that rapid mixing of the high-temperature catalyst with the catalyst in the reactor is facilitated, and local high temperature in the bed layer is avoided. The dense-phase fluidized catalyst is beneficial to the ending of the transmission of free radicals, so that the thermal reaction is reduced, and the selectivity of preparing alkenes by the dehydrogenation of alkanes is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Children's intelligence and vision development promoting fully nutritious breakfast and preparation method thereof

The present invention relates to children's intelligence and vision development promoting fully nutritious breakfast. The breakfast comprises the following six varieties of raw materials of cereals, beans, fruits, vegetables, nuts and fibers, a total of 31 edible materials. The specific form of the fully nutritious breakfast is nutritious rice slices and fruit and vegetable particles. The present invention also relates to a preparation method of the children's intelligence and vision development promoting fully nutritious breakfast. The fully nutritious breakfast is comprehensive in nutrition, easy to digest and absorb, and also easy to carry and convenient to brew. Besides, by adding carrots, grapes, blueberries and other edible materials, the breakfast supplements children needed anthocyanins, carotene, vitamin C and B family, and reaches the effects of protecting eyes and enhancing vision. By adding walnut kernels, millet, shii-take, red dates, bananas and other edible materials, the breakfast can reach a certain function of supplementing and tonifying brains.

Owner:湖南益百年健康科技有限公司

Nutritional breakfast beneficial for working personnel to protect eyes, keep fit and strengthen spleen and stomach, and preparation method thereof

The invention relates to a nutritional breakfast beneficial for working personnel to protect eyes, keep fit and strengthen the spleen and the stomach. Raw materials of the nutritional breakfast include 30 food materials in six categories of cereals, beans, fruits, vegetables, nuts and fibers. The concrete form of the nutritional breakfast is nutritional rice slices and fruit and vegetable particles. The invention also relates to a preparation method of the nutritional breakfast beneficial for the working personnel to protect the eyes, keep fit and strengthen the spleen and the stomach. The nutritional breakfast disclosed by the invention is comprehensive in nutrition, easy to digest and absorb and convenient to carry and brew; the effects of protecting the eyes and enhancing vision are achieved through addition of blueberries, strawberries, applies, grapes and carrots; the effects of keeping fit and slimming are achieved through addition of apples, carrots, lentinus edodes, pumpkins, oats, buckwheat and sweet potatoes; and the effect of nourishing the spleen and the stomach is achieved through addition of rice, millet, barley, triticum aestivum, semen nelumbinis, pisum sativum, bananas, broccoli and brassica rapa.

Owner:湖南益百年健康科技有限公司

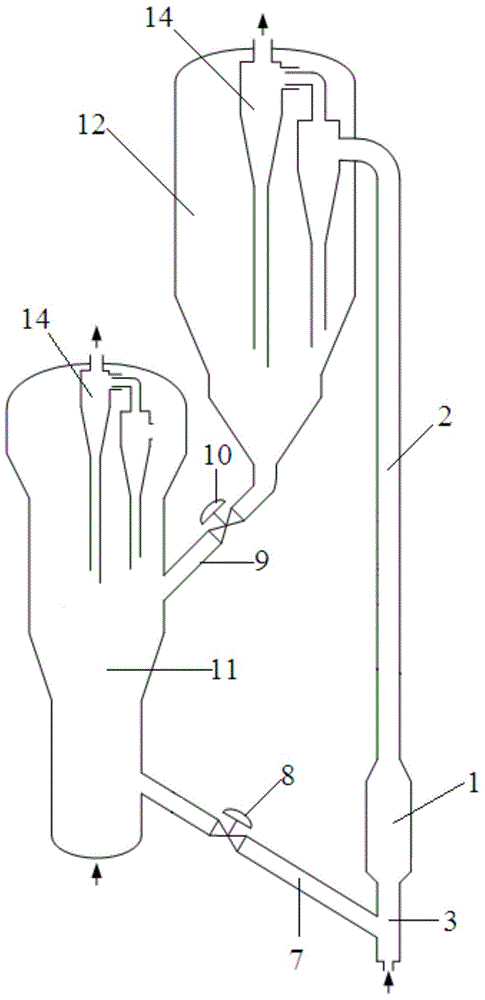

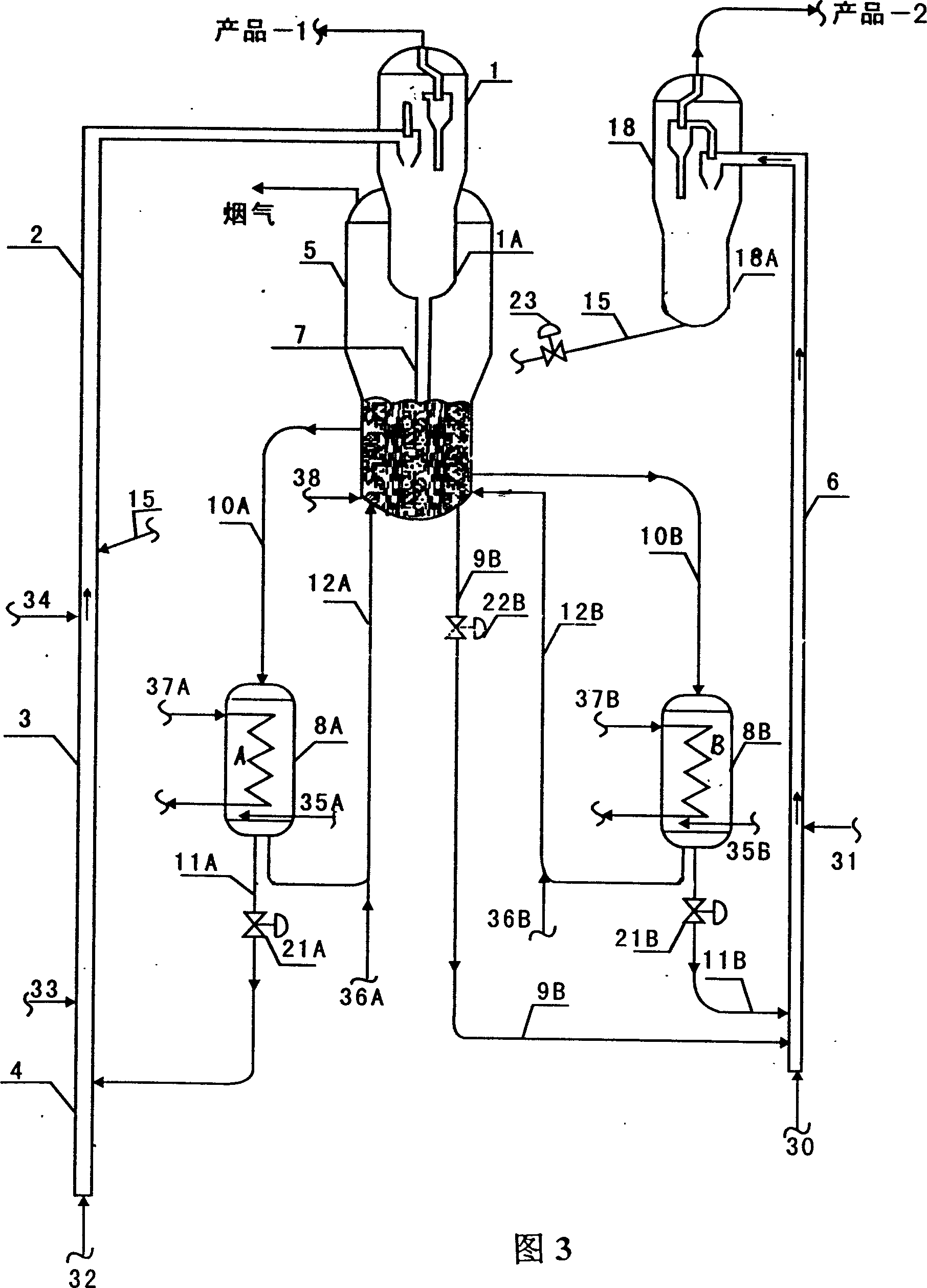

Catalytic cracking method and its apparatus

InactiveCN102477311ASeparation ratio controlFully contactedTreatment with plural serial cracking stages onlyTreatment with plural serial stages onlyFractionationReaction zone

The invention discloses a catalytic cracking method and its apparatus, which belongs to the petrochemical technical field. The process of catalytic cracking is carried out in a reactor which is at least provided with a first reaction zone, a conveyer pipe and a second reaction zone, a regenerated catalyst from a regenerator is contacted and reacted with raw oil in the first reaction zone of the reactor, a reaction mixture is flowed upwards and separated to a catalyst through a diverter, the separated catalyst directly flows into a stripping stage, the reaction oil gas flows upwards along the conveyer pipe and is introduced in the second reaction zone of the reactor, a part of cooling regenerated catalyst is introduced in a catalyst additional area, and then introduced in the second reaction zone from the catalyst additional area, mixed with reaction oil gas from the first reaction zone, thereby oil gas is continuously reacted, the separated oil gas after finishing the reaction is conveyed to a subsequent fractionation system, the catalyst flows into the stripping stage, combined with the separated catalyst through the diverter in the first reaction zone, stripped and then introduced in the regenerator for regeneration. The catalytic cracking method and its apparatus reinforce the selectivity of the catalytic reaction in the reactor, and the investment can be reduced by sharing stripping.

Owner:石宝珍

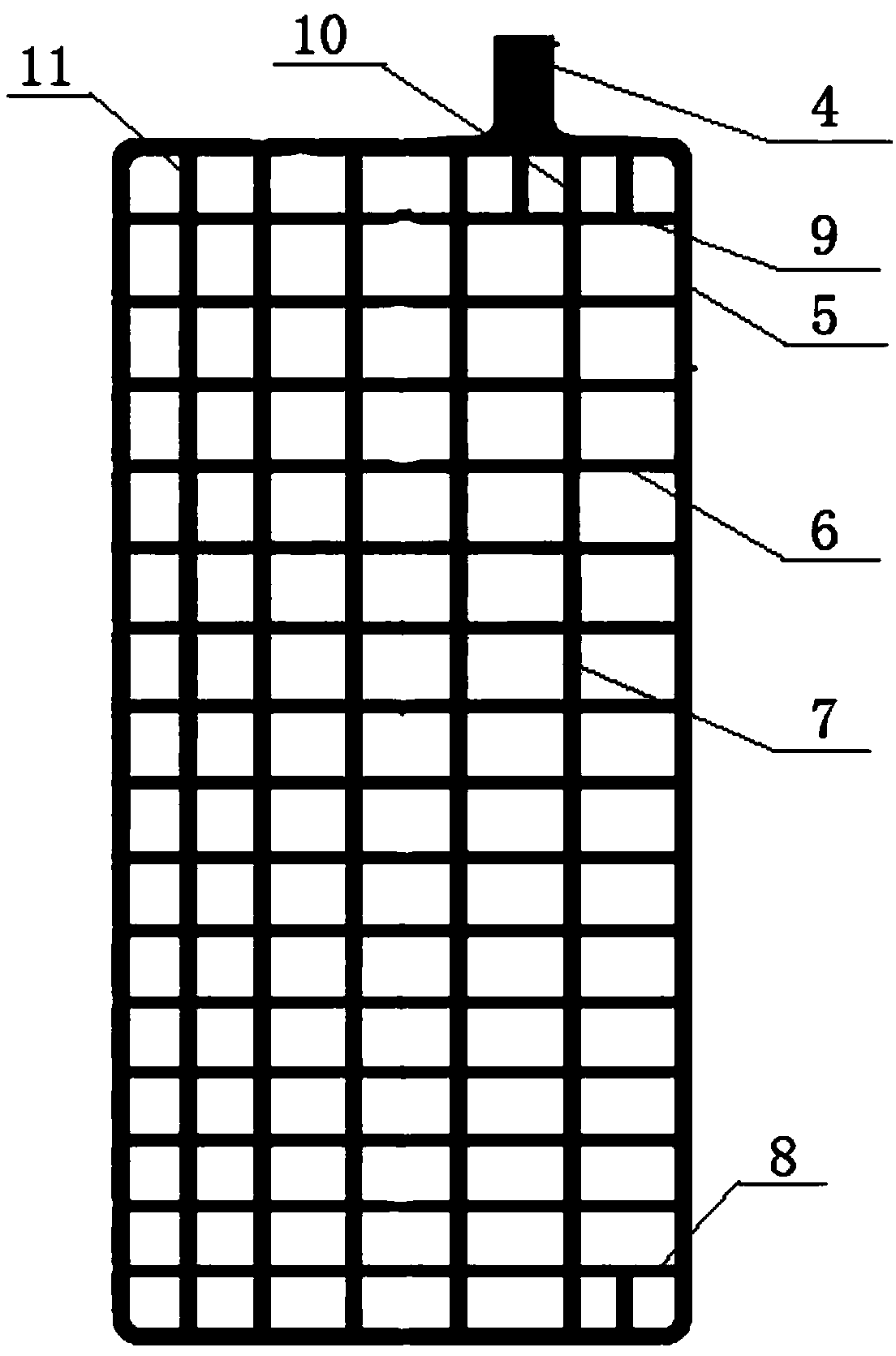

A fluidized bed reactor for light olefin cracking and methanol to olefin

InactiveCN104437274BHigh fluidized densityHigh selectivityHydrocarbon from oxygen organic compoundsEthylene productionFluidized bedMethanol

The invention discloses a fluidized bed reactor for light olefin cracking or methanol to olefin, including a reactor, a pre-riser, etc.; the reactor includes two parts: a dense-phase fluidized-bed reactor and a dilute-phase conveying Or on the same axis, the pre-riser and the dilute phase transfer reactor are respectively located above and below the dense-phase fluidized bed reactor; the diameter of the pre-riser is smaller than the diameter of the dense-phase fluidized bed reactor, and the upper Partially extending into the dense-phase fluidized bed reactor; the upper port of the pre-riser pipe located in the dense-phase fluidized bed reactor is sealed, and the pipe wall of the pre-riser pipe extending into the dense-phase fluidized bed reactor Or, the upper end of the pre-riser pipe located in the dense phase fluidized bed reactor is an opening, and a baffle is arranged above the opening. The reactor improves the gas-solid contact efficiency, the degree of oil gas and catalyst back-mixing is small, and can greatly improve the conversion rate of light hydrocarbon cracking and methanol-to-olefin reaction and the selectivity of the target product small molecule olefin.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Coking coal modifier

The invention discloses a coking coal modifier. The coking coal modifier mainly comprises the raw materials as follows according to weight percent: 40% to 70% of boric acid, 10% to 20% of antimony oxide and 20% to 40% of moderate-temperature modified asphalt, and the coking coal modifier is prepared by mixing the raw materials. When the coking coal modifier provided by the invention is added during the coking process of coking coal, the reactivity of coke can be reduced effectively, and the strength of reacted coke can be improved; when the coking coal modifier provided by the invention is used during coal injection of coking, the use amount of coking coal, rich coal and other high-quality coking coal can be reduced greatly, the use amount of lean coal, gas coal and other coal with poor caking performance can be increased, even the use amount of non-caking coal can be increased, and high-quality and qualified coke can be obtained, so that the cost of coking can be reduced remarkably. The coking coal modifier provided by the invention can effectively change the molecular structure of coal to achieve the purposes that coke has good coking effect and high coking density and strength, the thermal response of coke can be reduced effectively and the thermal intensity of coke can be improved; and by adoption of the coking coal modifier provided by the invention, the use amount of high-quality coking coal can be reduced, and energy can be saved. Therefore, the coking coal modifier has remarkable economic benefits and social benefits.

Owner:曹金贵

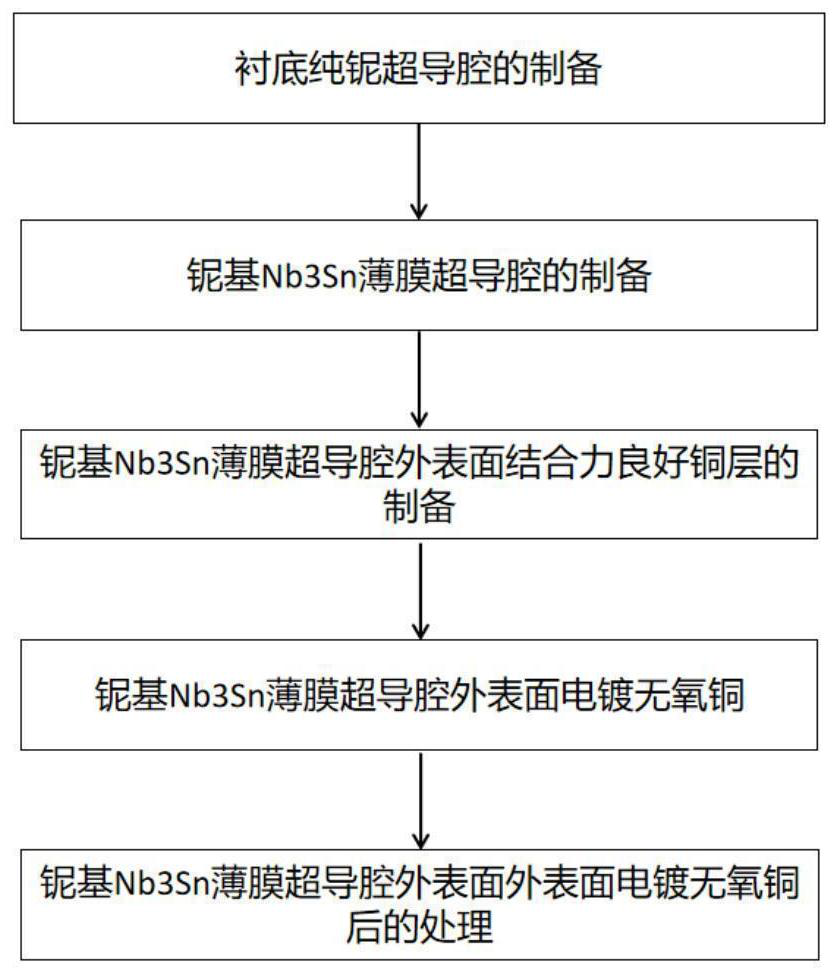

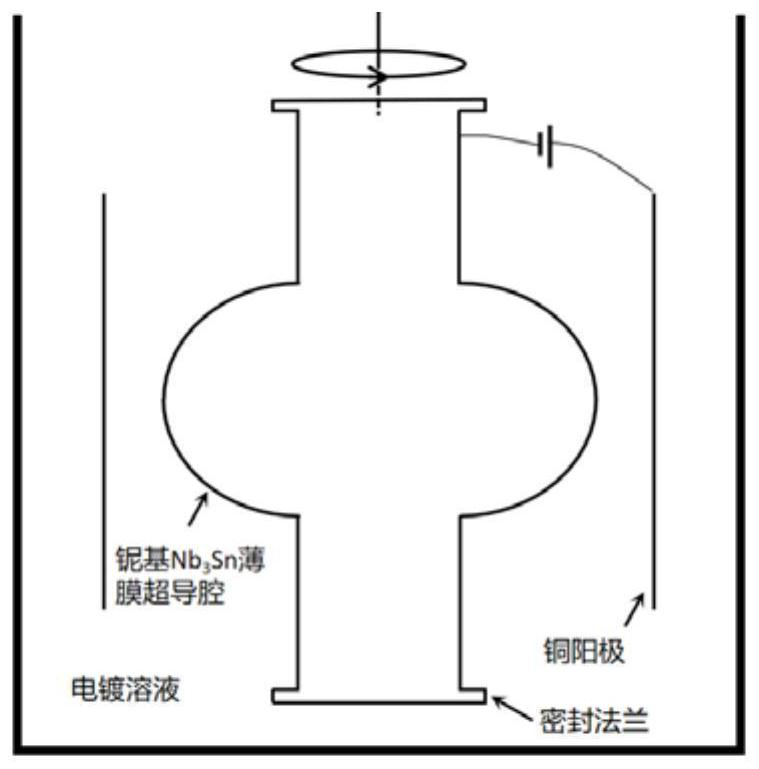

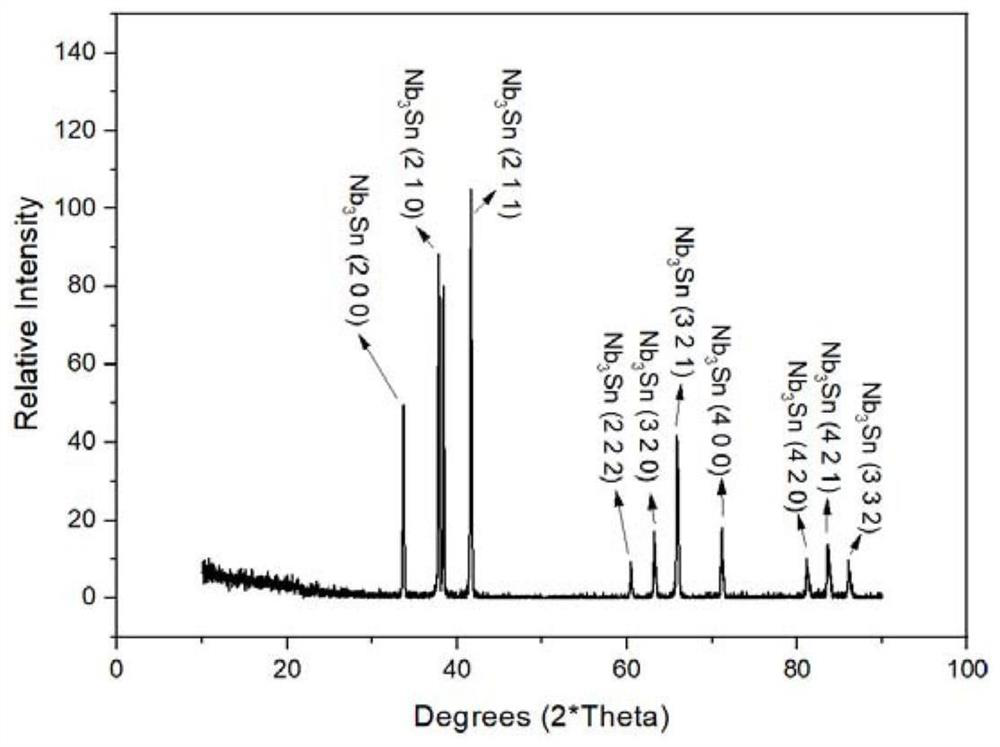

Copper-based thick-wall Nb3Sn thin film superconducting cavity and preparation method thereof

ActiveCN113373404AImprove mechanical stabilityImprove thermal stabilityMolten spray coatingSolid state diffusion coatingPorosityNiobium

The invention discloses a copper-based thick-wall Nb3Sn thin film superconducting cavity and a preparation method thereof, and belongs to the technical field of superconducting. The invention discloses the preparation method of the copper-based thick-wall Nb3Sn thin film superconducting cavity, which comprises the following steps: (1) preparing a niobium-based Nb3Sn thin film superconducting cavity from a pure niobium superconducting cavity by adopting a tin vapor diffusion method; (2) depositing a copper layer on the outer surface of the niobium-based Nb3Sn thin film superconducting cavity; and (3) electroplating oxygen-free copper on the outer surface of the niobium-based Nb3Sn thin film superconducting cavity deposited with the copper layer to obtain the copper-based thick-wall Nb3Sn thin film superconducting cavity. According to the preparation method of the invention, the copper-based thick-wall Nb3Sn thin film superconducting cavity is prepared on the outer surface of the niobium-based Nb3Sn thin film superconducting cavity in a mode of electroplating oxygen-free copper, and the defect that a high-quality Nb3Sn thin film cannot be generated due to the low melting point of copper is successfully overcome; and the electroplated oxygen-free copper is high in density, low in porosity and small in thermal reaction.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

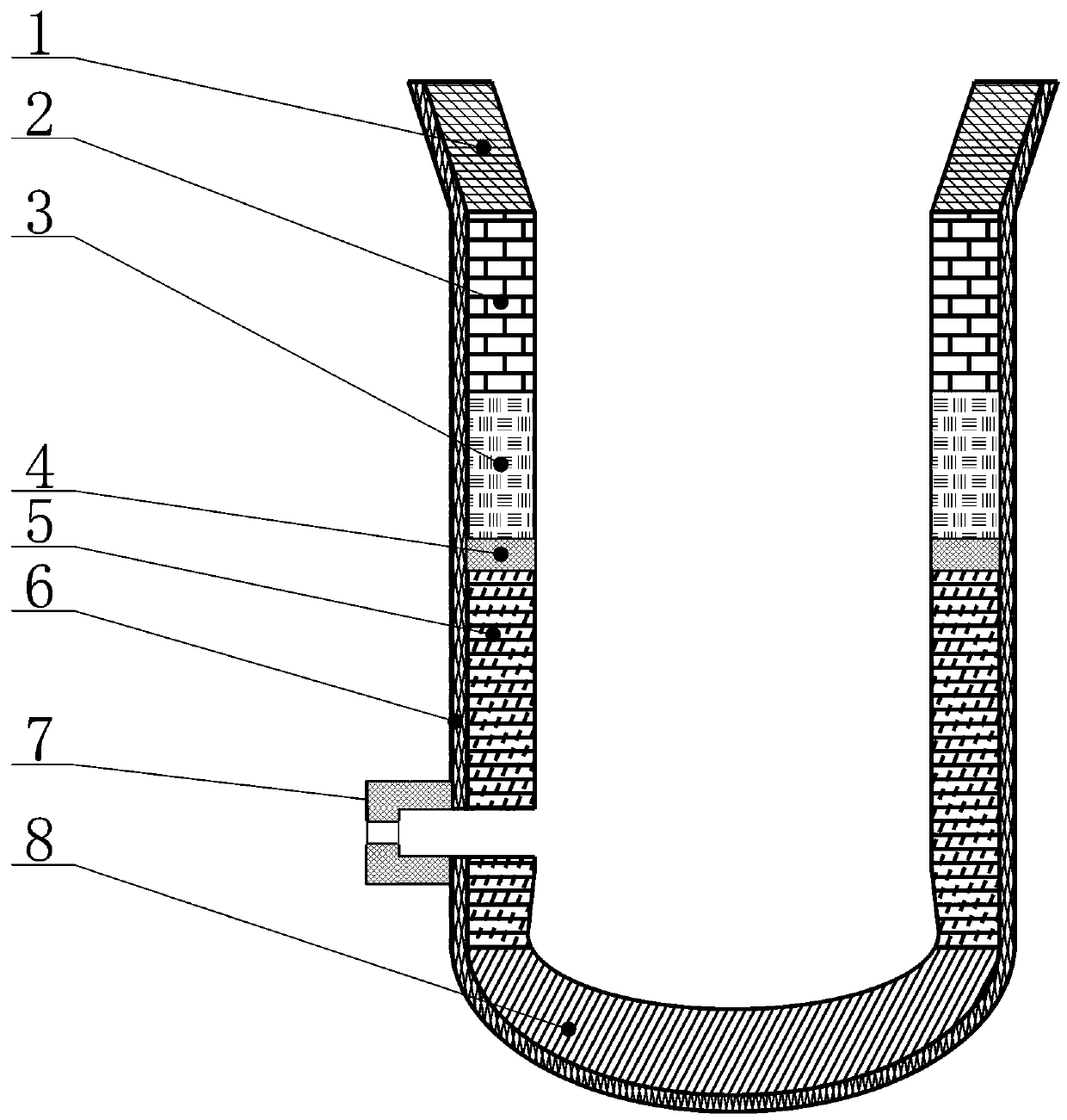

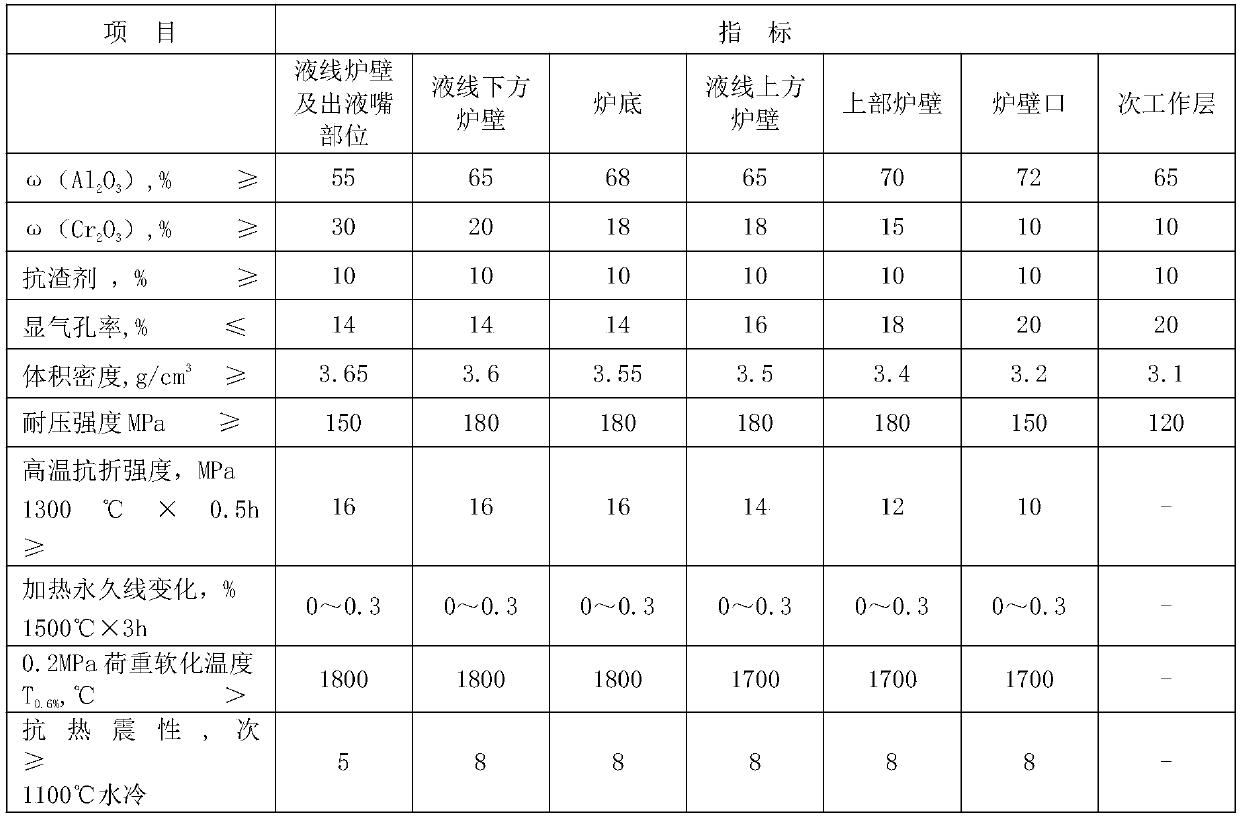

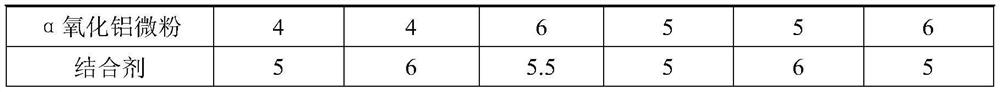

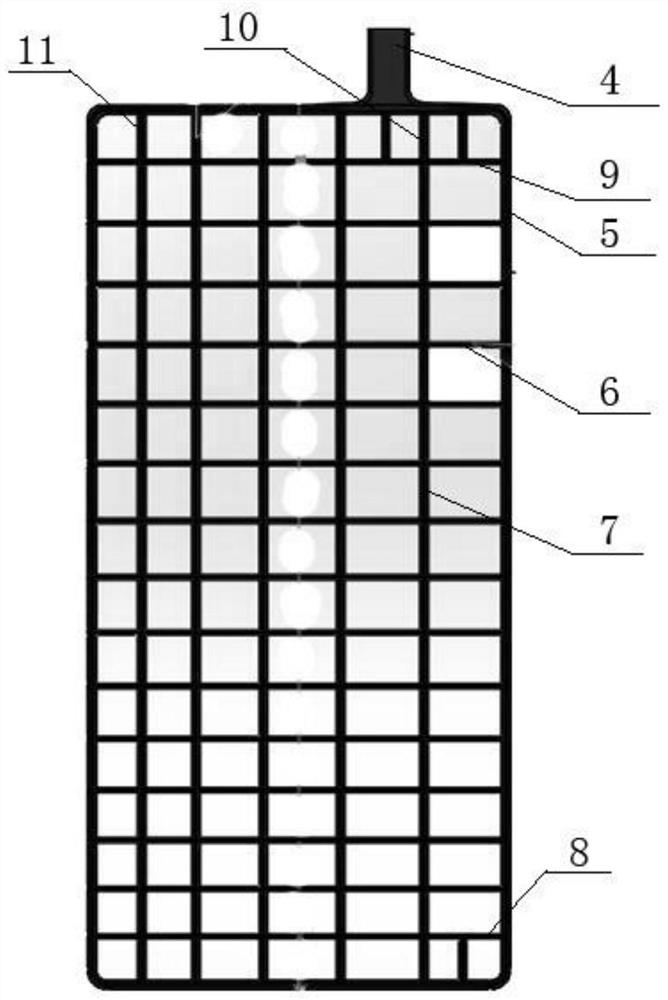

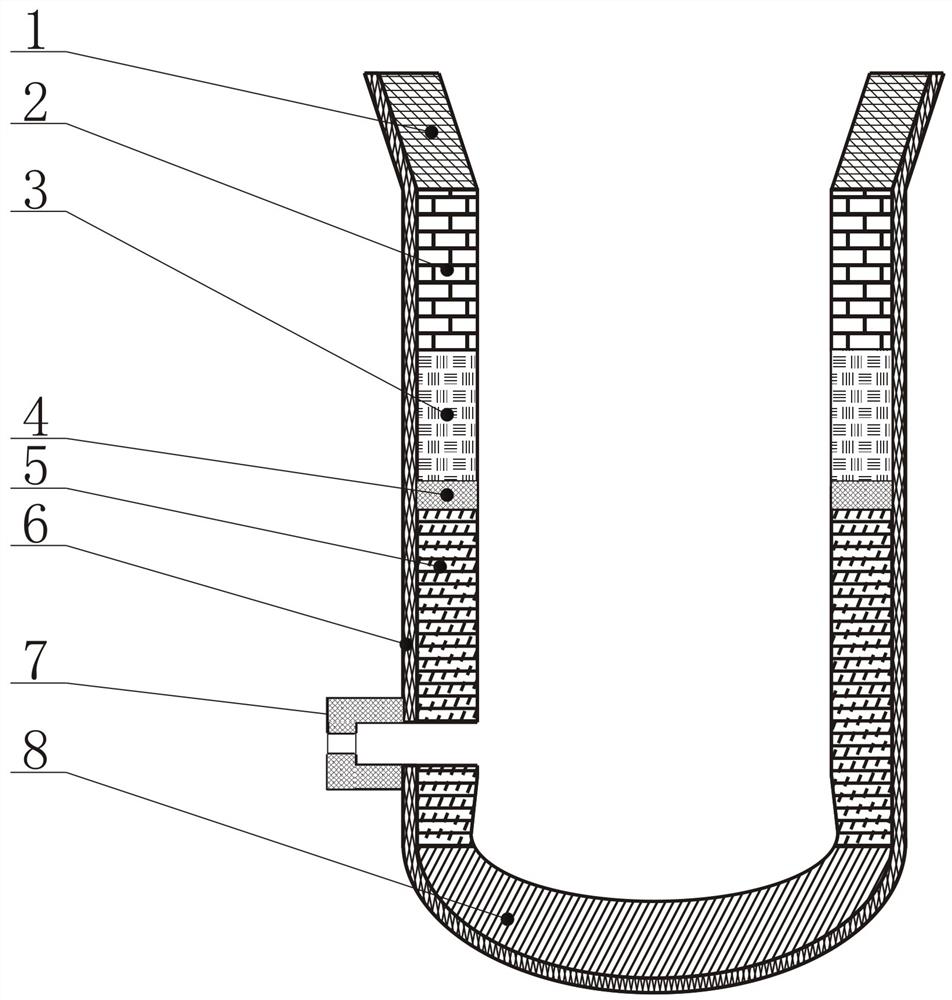

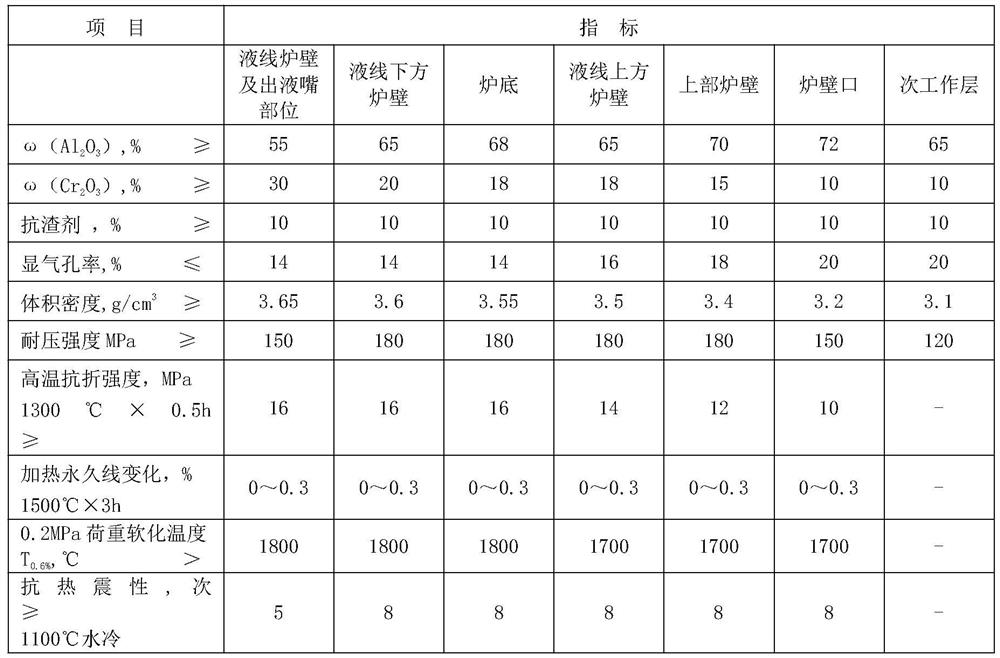

High-strength fusion smelter for colored strengthening smelting

ActiveCN109650856AReduce decomposition reactionsReduce heat responseCharge treatment typeFurnace liningsLiquid lineThermal shock

The invention relates to a high-strength fusion smelter for colored strengthening smelting. The smelter comprises a smelter wall port, an upper smelter wall, a smelter wall above a liquid line, a liquid line smelter wall, a smelter wall below the liquid line, a secondary working layer, a liquid outlet nozzle and a smelter bottom. All the parts of the smelter are made of fire-resistance materials,by analyzing working conditions of different parts of the high-strength fusion smelter for colored strengthening smelting, different kinds of fire-resistance material brasque are used as the corresponding parts, one or more properties of the erosion resistance, thermal shock resistance, washing resistance and permeability resistance of the brasque at the part are improved, the service life of thebrasque is greatly improved, frequent repairing and brasque replacement are avoided, and a large number of human resources and financial resources are saved.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

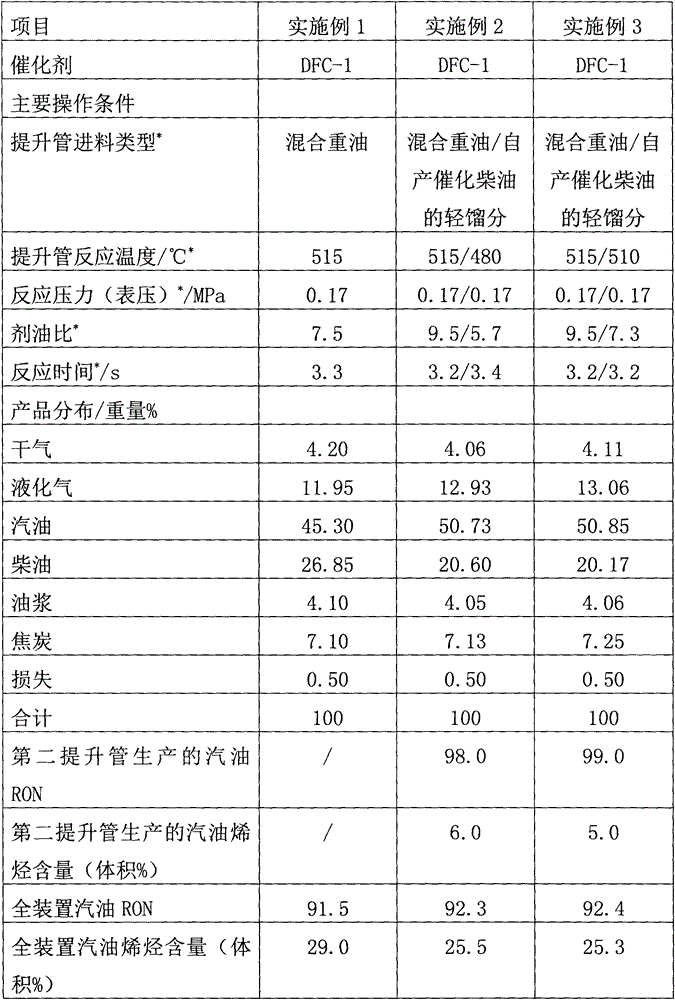

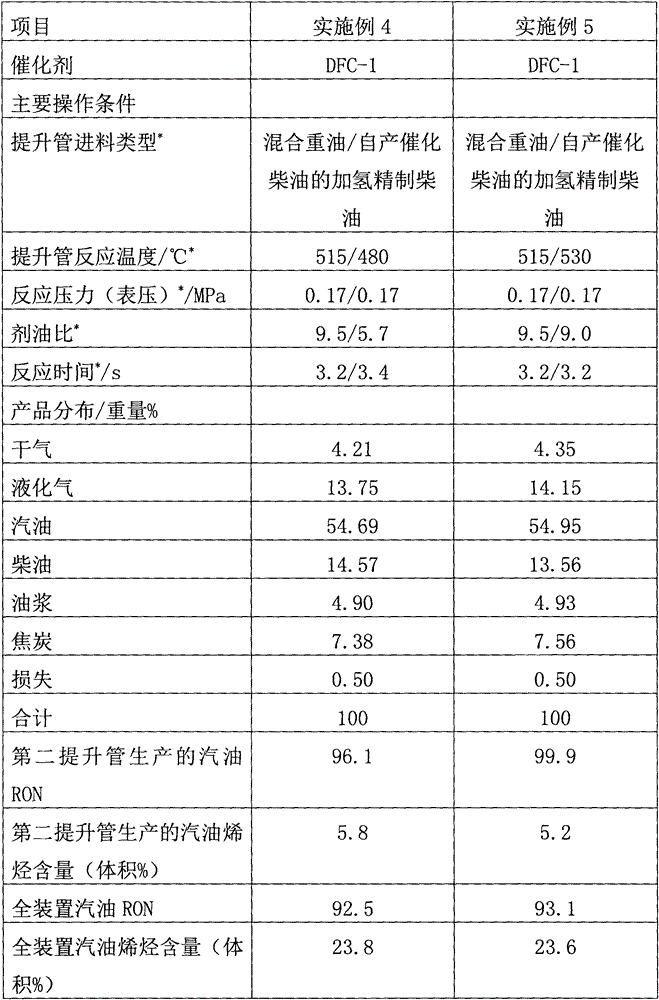

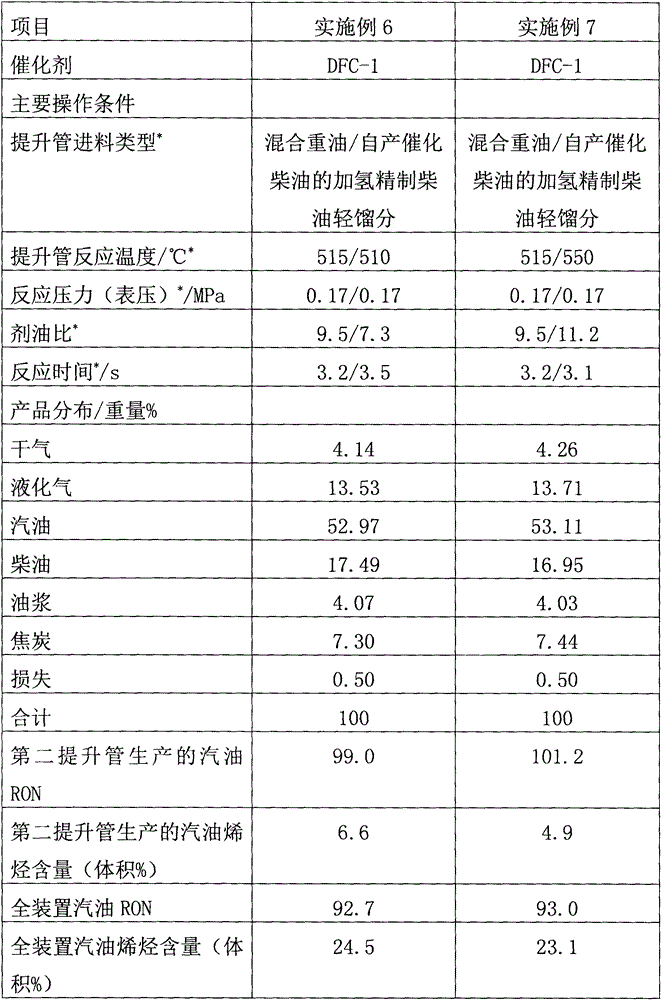

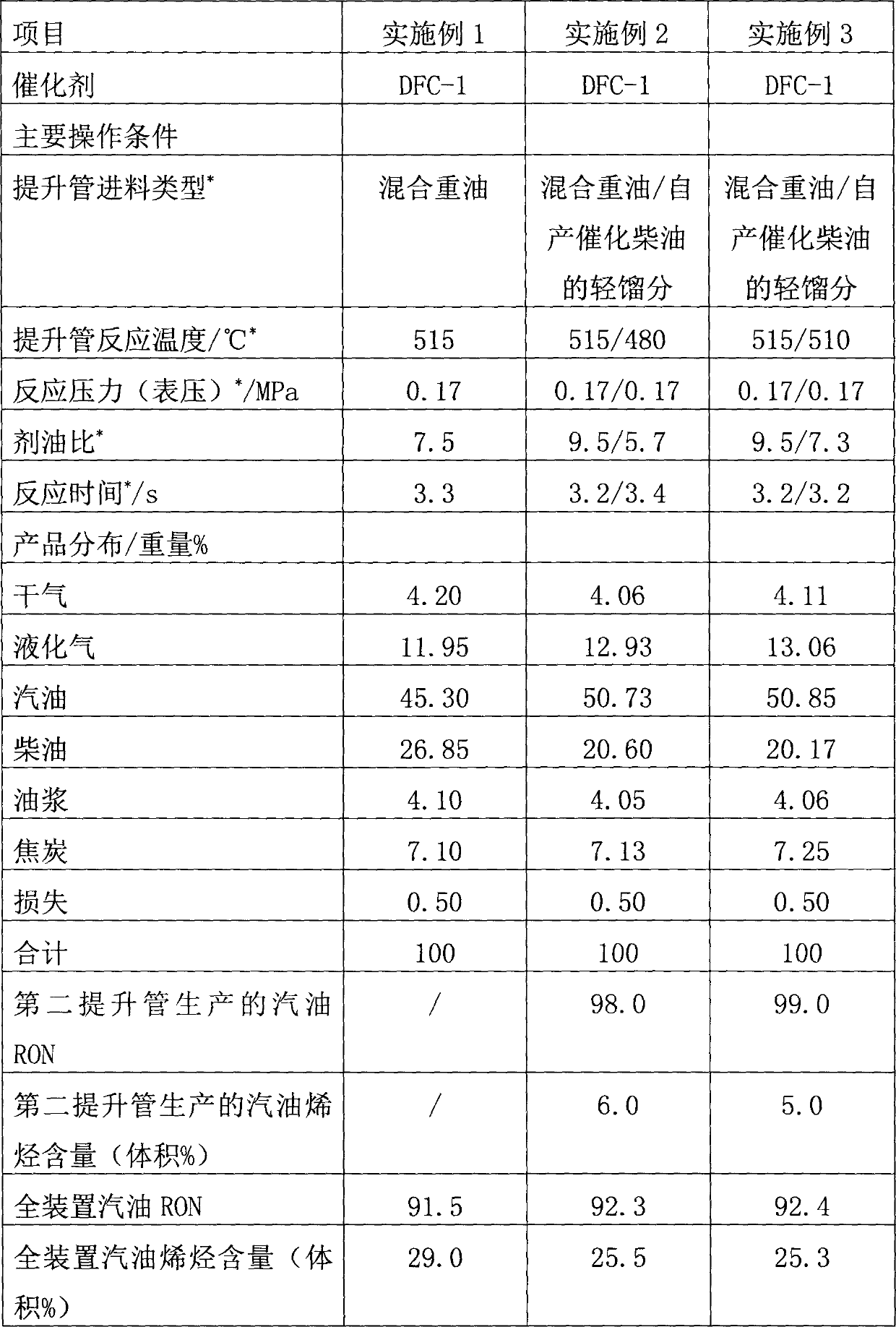

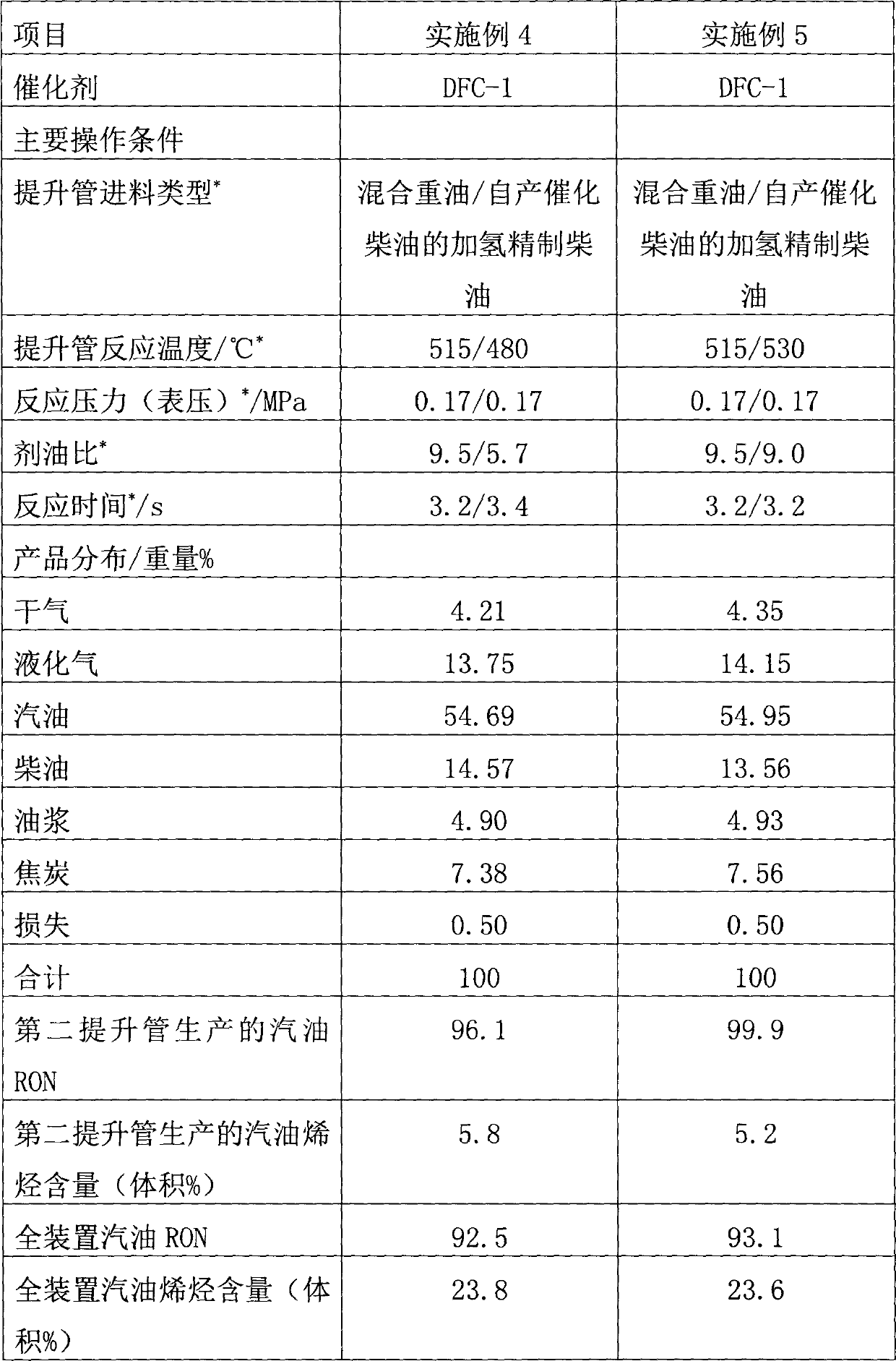

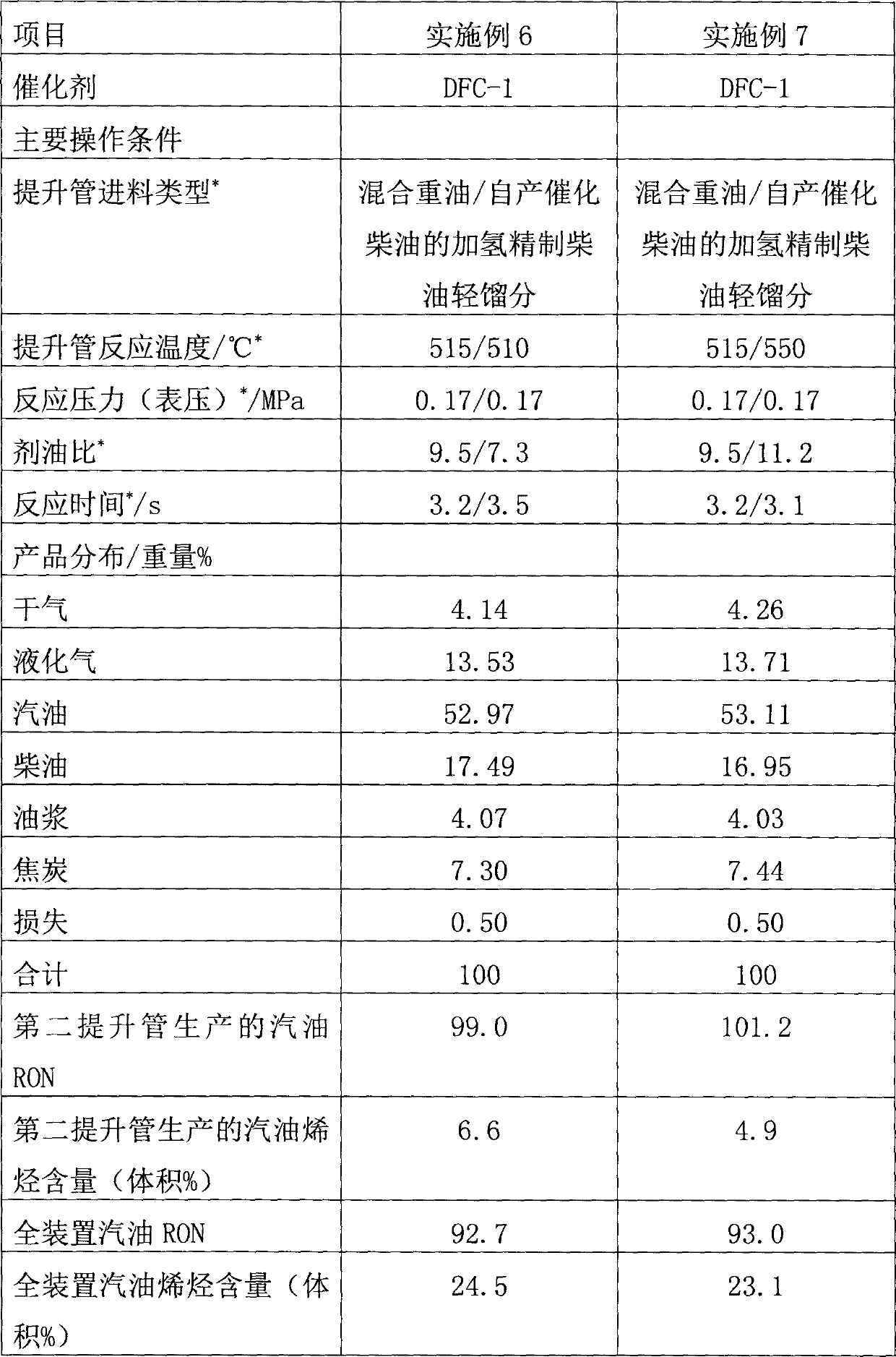

Catalytic cracking method of increasing gasoline yield

ActiveCN104974787AReduce the temperatureReduce contact reactionTreatment with plural serial stages onlyProcess engineeringDirect production

The invention discloses a catalytic cracking method of increasing gasoline yield, which comprises the following steps: (A) feeding raw material oil to the lower part of a first lifting tube reactor and carrying out a contact reaction to the raw material oil with a catalyst from a pre-lifting mixer; (B) feeding a to-be-regenerated catalyst from the first lifting tube reactor into a steam stripping part of a main precipitator, performing steam stripping and regenerating the catalyst in a regenerator; (C) feeding catalytic diesel or hydrotreated catalytic diesel into the lower part of a second lifting tube reactor and carrying out a contact reaction with the catalyst from the regenerator; (D) feeding the to-be-regenerated catalyst from the second lifting tube reactor into a steam stripping part of a sub precipitator; (E) performing air stripping to the to-be-regenerated catalyst from the steam stripping part of the sub precipitator, feeding one part of the catalyst into the regenerator and regenerating the catalyst, and feeding the other one part of the catalyst into the pre-lifting mixer and mixing the catalyst with the regenerated catalyst from the regenerator; and (F) feeding the mixed catalyst into the lower part of the first lifting tube reactor and carrying out a contact reaction with the raw material oil. By means of the method, the catalytic cracking device is increased by 3-20% in gasoline yield, is increased by more than 0.5 units in RON of gasoline and is reduced in the content of olefin by more than 3% by volume. The gasoline directly produced in the second lifting tube reactor is higher than 96 in RON and is less than 10% in the content of olefin.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

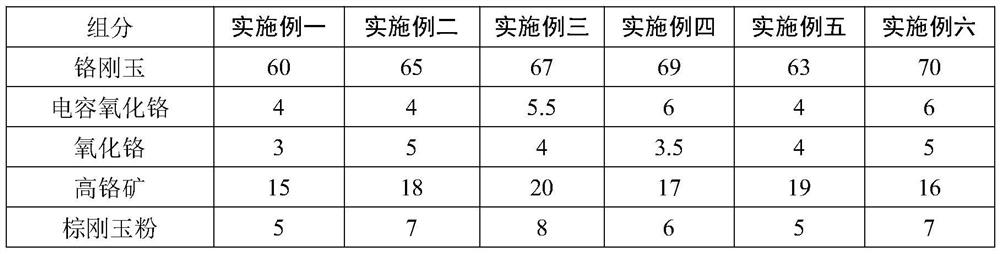

A kind of refractory material for upper furnace wall of non-ferrous smelting melting furnace and preparation method thereof

A refractory material for the upper furnace wall of a non-ferrous smelting melting furnace, which is suitable for the upper furnace wall of a non-ferrous smelting melting furnace. powder, α-alumina micropowder and binder. This technical solution uses chromium corundum, fused chromium oxide, chromium oxide, high chromium ore, brown corundum powder, and α-alumina micropowder as raw materials, which reduces the content of MgO, so that the dissolution and subsequent decomposition of MgO in the refractory material The reaction is greatly reduced, the related thermal reaction is reduced, and the refractory structure is prevented from being damaged by frequent reactions.

Owner:中钢洛耐科技服份有限公司

S-type fluid bed

InactiveCN101219356BAvoid backmixingFacilitate catalytic reactionsChemical/physical processesFluidized bedWave shape

Owner:褚开维 +1

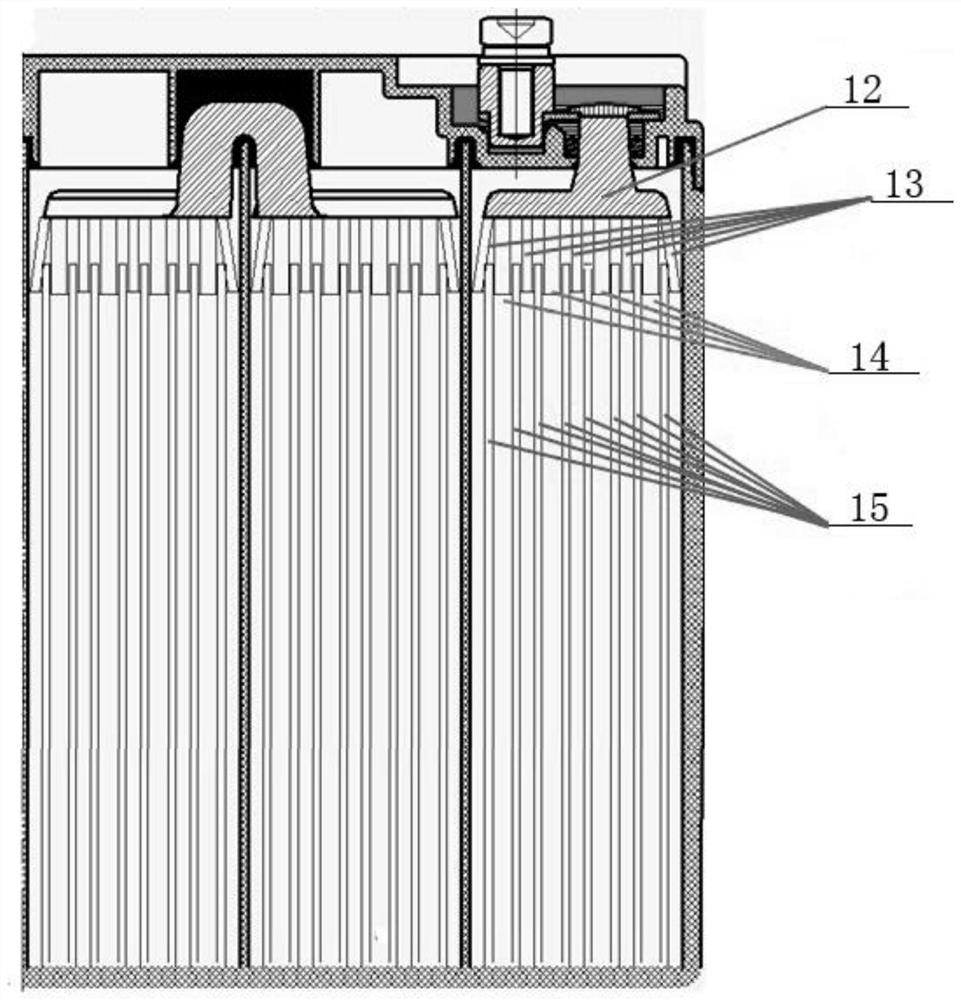

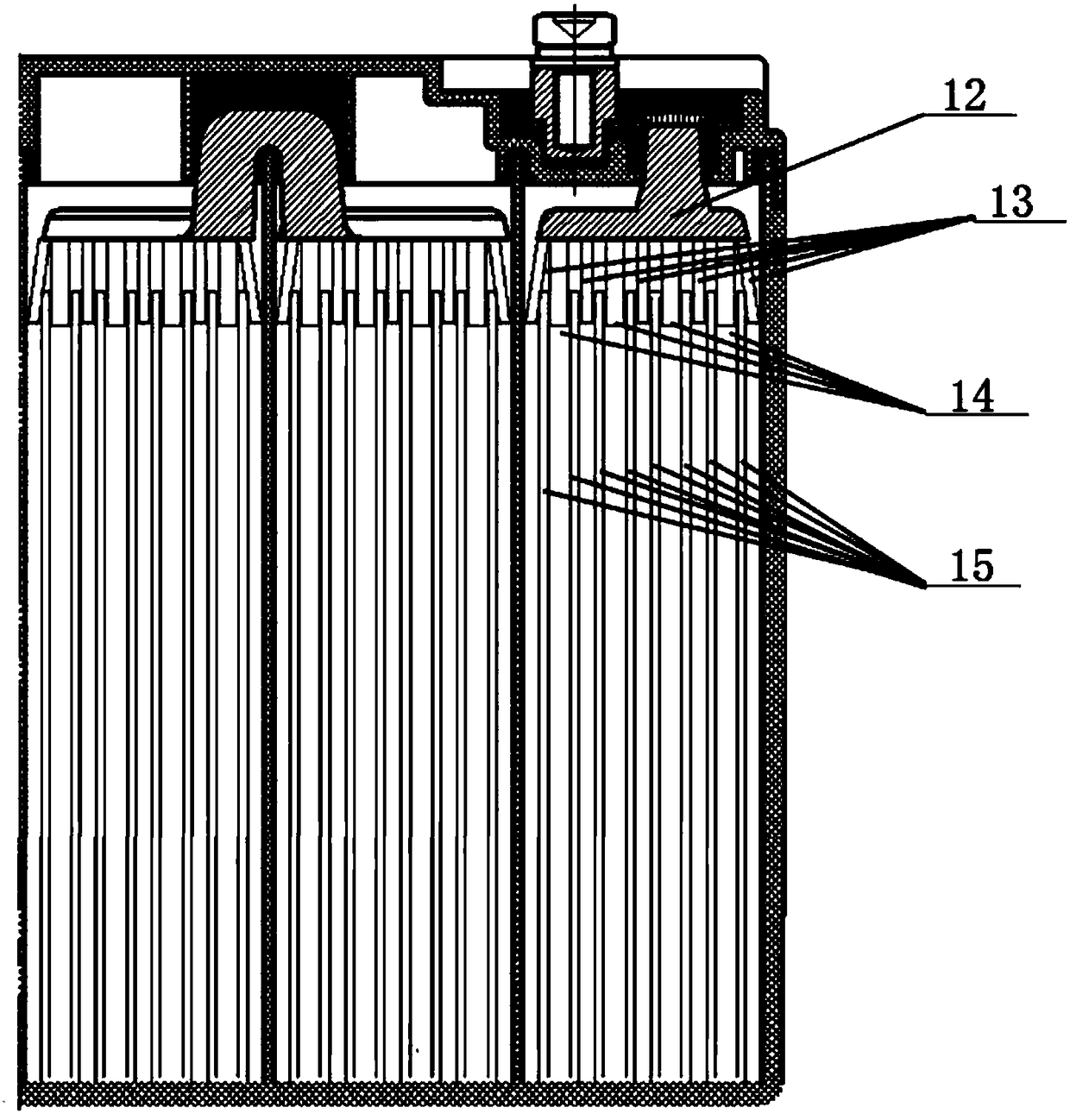

A lead-acid battery positive and negative plates and other life pole groups

ActiveCN108461701BExacerbate corrosionHigh densityCell component detailsElectric current flowCharge and discharge

The invention belongs to the technical field of storage battery production, and in particular relates to life-span pole groups such as positive and negative plates of lead-acid storage batteries. A lead-acid storage battery with positive and negative plates and other life-span pole groups, including a plurality of series-connected pole plate groups, each pole plate group is connected in parallel by positive pole plates and negative pole plates, and the adjacent pole plate groups are provided with There is an AGM separator, and the negative electrode plate is connected to the electrode plate connection bus bar. According to the different reaction mechanisms of the positive and negative plates in the charging and discharging process of the battery, the electrode group provided by the invention can promote the current flow of the battery to follow the requirements in the process of charging and discharging by adjusting the structure of the current-collecting ribs of the positive and negative grid sheets. Reasonable distribution on the positive and negative plates, so as to ensure that the active materials on the positive and negative plates close to the current collector and away from the current collector release energy at the same time, so as to achieve the purpose of the life of the positive and negative plates.

Owner:TIANNENG GRP HENAN ENERGY TECH

A kind of refractory material for furnace wall port of non-ferrous smelting melting furnace and preparation method thereof

The invention discloses a refractory material for the furnace wall opening of a nonferrous smelting melting furnace, which is suitable for the position of the furnace wall opening of a nonferrous smelting melting furnace. The refractory material is composed of fused chromium corundum, chromium oxide and gel binder. The invention uses fused chromium corundum and chromium oxide as raw materials, reduces the content of MgO, greatly reduces the dissolution of MgO in the refractory material and subsequent decomposition reactions, reduces related thermal reactions, and avoids frequent damage to the refractory material structure. ground reaction damage. Fused chromium corundum makes the refractory material have excellent high temperature performance, good thermal shock stability and good corrosion resistance. The addition of chromium oxide makes the refractory material resistant to penetration.

Owner:中钢洛耐科技服份有限公司

Method for catalytic conversion of heavy oil and device thereof

ActiveCN1324116CRaise the preheat temperaturePromote atomizationCatalytic crackingTreatment with plural serial stages onlyCatalytic transformationGasoline

The invention provides a method of heavy raw material catalytic conversion and the device, comprising: the heavy hydrocarbon raw material passing through the first and second reaction area of the raiser reactor and contacting with catalyst for first reaction and second reaction, the reactants entering into the settler for the separation of catalyst and oil gas, steam stripping the separated catalyst through stripping section and introducing it to the reactivator for carbon burning reactivation, the reactivated catalyst returning to the raiser reactor after cooled or directly to the raiser reactor for reuse. After the heavy oil passing through the device said above, the volume content of olefin decreases by 10~40%, octane value increases 0.5~1 units, sulfur content in petrol decreases 10~30% by weight. After the poor petrol passing through the device said above, the volume content of olefin decreases by 10~60%, octane value increases 0.5~40 units, sulfur content in petrol decreases 10~50% by weight.

Owner:LUOYANG WEIDA PETROCHEMICAL ENG CO LTD

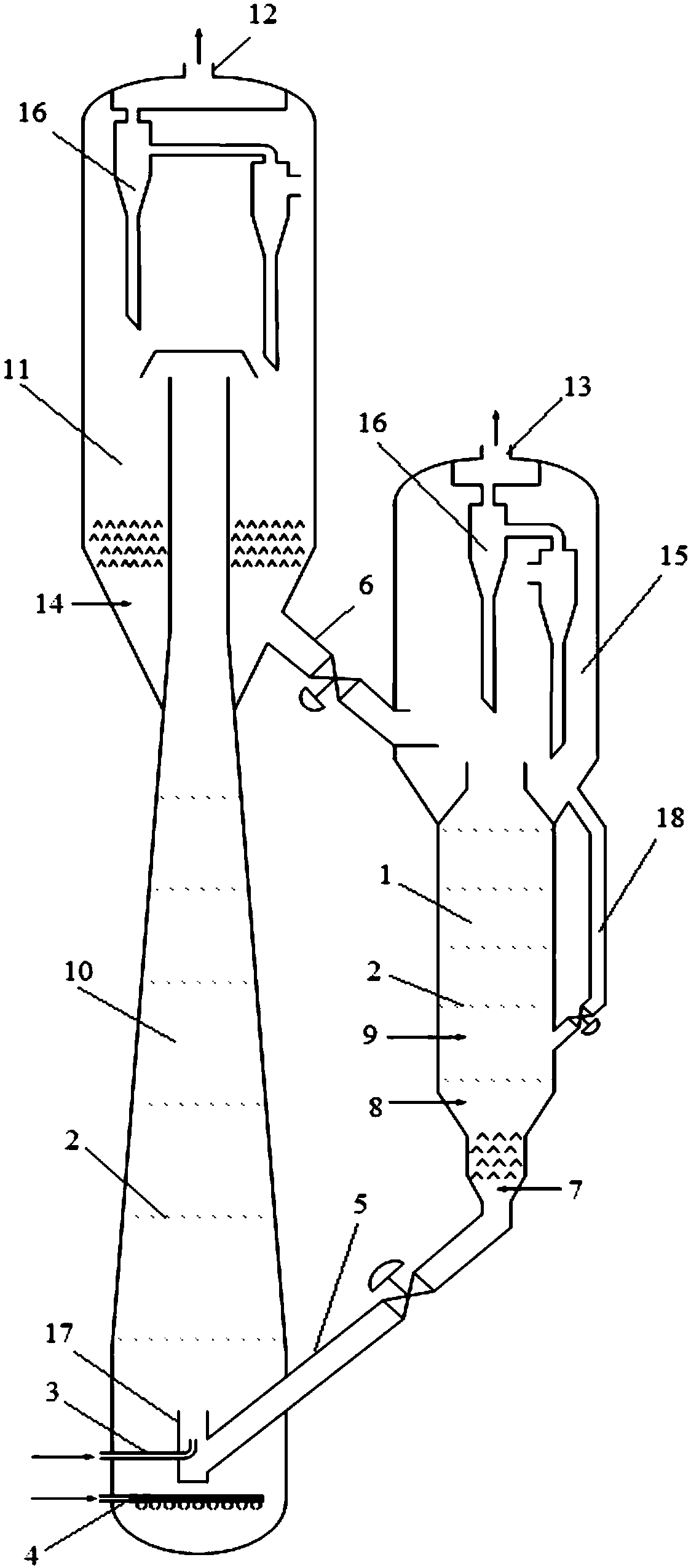

A circulating fluidized bed reaction device for alkane dehydrogenation-cracking to olefins

ActiveCN109499485BNot limited by sizeLow reaction temperatureHydrocarbonsChemical recyclingAlkanePtru catalyst

A reaction device for catalytic dehydrogenation-cracking of alkanes to produce olefins, comprising a reactor for catalytic dehydrogenation-cracking and a settling section of the reactor, the settling section of the reactor is located on the upper part of the reactor, wherein the reactor includes a dehydrogenation tank A phase reaction section and a cracking reaction section, the cracking reaction section is located below the dehydrogenation dense phase reaction section, and the diameter of the cross section of the cracking reaction section is smaller than the diameter of the cross section of the dehydrogenation dense phase reaction section. The reaction device combines dehydrogenation cracking and catalytic dehydrogenation, and the overall reaction temperature and catalyst regeneration temperature are greatly reduced. The diameter of the reaction device gradually shrinks along the fluid flow direction to reduce the secondary conversion of olefins caused by back-mixing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of catalytic cracking method of prolific gasoline

ActiveCN104974787BReduce the temperatureReduce contact reactionTreatment with plural serial stages onlyGasolineDirect production

The invention discloses a catalytic cracking method for producing gasoline. The steps are: the feedstock oil enters the lower part of the first riser reactor to contact and react with the catalyst from the pre-lift mixer, the raw catalyst in the first riser reactor enters the stripping section of the main settler for stripping, and then enters the regenerator for regeneration. Catalyzed diesel or hydrotreated catalytic diesel enters the lower part of the second riser reactor to contact and react with the catalyst from the regenerator, and the ungenerated catalyst in the second riser reactor enters the stripping section of the secondary settler After being stripped, part of the spent catalyst enters the regenerator for regeneration, and the other part enters the pre-lift mixer to mix with the regenerated catalyst from the regenerator, and the mixed catalyst enters the lower part of the first riser reactor to contact with the raw material oil for reaction. By using the method of the invention, the gasoline yield of the catalytic cracking unit can be increased by 3-20 percentage points, the gasoline RON can be increased by more than 0.5 units, and the gasoline olefin content can be reduced by more than 3 volume percentage points. The RON of gasoline directly produced in the second riser reactor is above 96, and the volume content of olefins is below 10%.

Owner:SINOPEC LUOYANG PETROCHEM ENG CORP +1

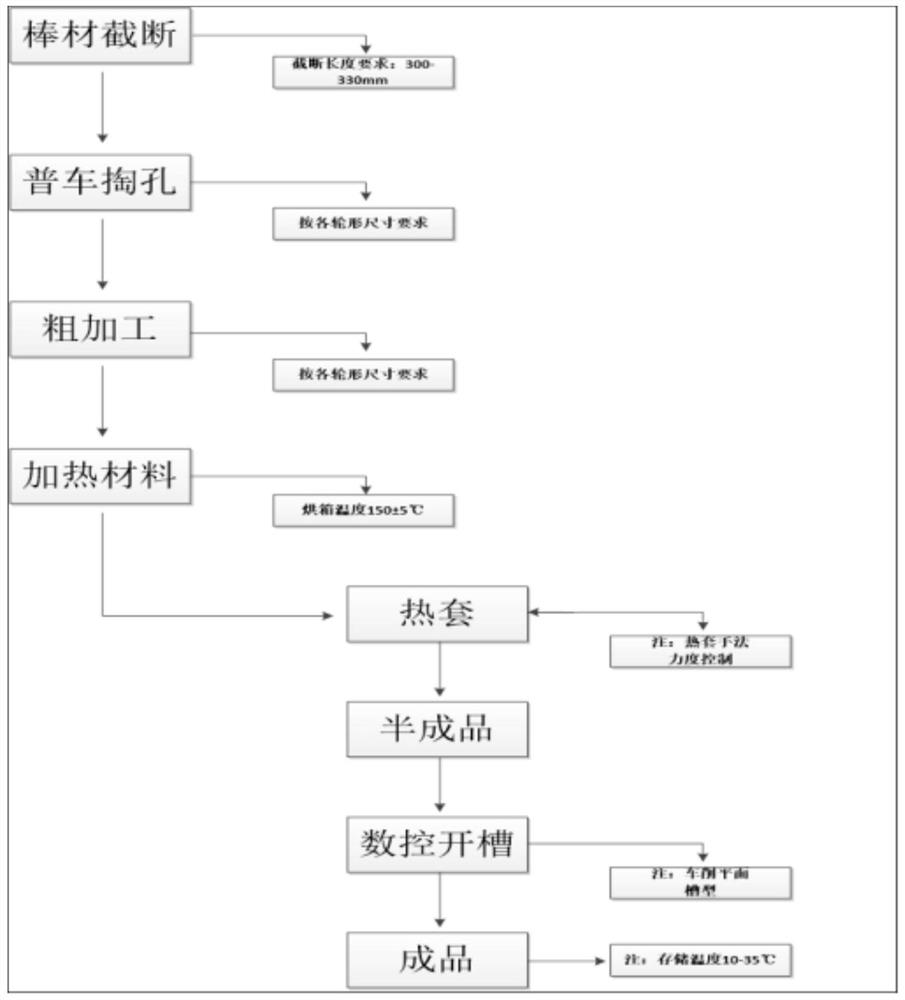

Preparation method of diamond wire cutting pulley piece

InactiveCN111645211AReduce disconnection ratioReduce wire cutting lossFine working devicesWire cuttingSilicon chip

The invention discloses a preparation method of a diamond wire cutting pulley piece. The preparation method comprises the steps of bar cutting, general lathing and hole forming, rough machining, material heating, hot sleeving, obtaining of a semi-finished product, numerically controlled slotting and obtaining of a finished product, wherein: (1) firstly, a polyethylene bar is cut in sections, the outer circle is turned, and the inner circle is bored, so as to obtain a polyethylene ring; (2) the obtained polyethylene ring is softened and expanded in the form of oven heating; (3) a softened and expanded polyethylene ring is installed on a nylon frame, and after natural cooling, the polyethylene ring condenses, shrinks and is in interference fit with the nylon frame to form a semi-finished pulley piece; and (4) a CNC lathe is used to remove margins on both sides and on the outer circle of the polyethylene semi-finished product, and then the finished product is obtained after the surface ofthe semi-finished product is slotted through the movement of a slotting tool along the X---Z axis. The prepared pulley effectively reduces the proportion of wire breakage caused by the winding and unwinding of a diamond wire during the silicon wafer cutting process, reduces the cutting loss of the diamond wire, prolongs the service life of the pulley, improves the yield of cutting products, and improves the efficiency of man-machine cutting.

Owner:江苏美科太阳能科技股份有限公司

A kind of alkane catalytic dehydrogenation or catalytic cracking to olefin circulating fluidized bed reactor

ActiveCN109499486BSimple structureEasy to manufactureHydrocarbonsChemical recyclingAlkanePtru catalyst

A circulating fluidized bed reaction device for catalytic dehydrogenation of alkanes or catalytic cracking to olefins, comprising a reactor and a settling section of the reactor, the settling section of the reactor is located at the upper part of the reactor, wherein the reactor includes a diameter-reducing section, and the The cross-sectional diameter of the diameter-reducing section decreases gradually from bottom to top, and the riser extends into the reactor from the bottom of the reactor, and outside the reactor, the catalyst regeneration inclined pipe is connected with the riser. The diameter of the reaction device gradually shrinks along the direction of fluid flow, reducing the secondary conversion of olefins caused by back-mixing. The reactant and catalyst in the reactor flow together and upward, which can effectively improve the uniformity of temperature distribution in the reactor and avoid local high temperature.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Catalytic cracking method and device

InactiveCN102465006BEnhanced catalytic reaction selectivityHigh activityTreatment with plural serial stages onlyPetrochemicalReaction zone

The invention discloses a catalytic cracking method and a device for realizing the method, belonging to the technical field of the petrochemical industry. Catalytic cracking is carried out in a main reactor and an auxiliary light raw material reactor, a regenerated catalyst from a regenerator is subjected to contact reaction with a raw oil in a first reaction zone of the main reactor, and a reaction mixture is upwards fed to a flow divider so as to separate out the catalyst; the separated catalyst directly flows into a stripping section, and reaction oil gas is upwards fed into a second reaction zone of the main reactor along a delivery pipe; a spent catalyst from the auxiliary light raw material reactor is firstly fed into a catalyst replenishing zone and then is upwards fed into the second reaction zone of the main reactor from the catalyst replenishing zone so as to be mixed with the reaction oil gas from the first reaction zone and make the oil gas subjected to continuous reaction; and after the reaction is finished, the oil gas and the catalyst are separated, the oil gas is led out and then fed into a subsequent fractionating system through an oil gas outlet pipeline, the catalyst flows into the stripping section and is stripped and fed into the regenerator for regeneration, together with the catalyst separated out by the flow divider in the first reaction zone.

Owner:石宝珍

Lead-acid storage battery electrode group of which positive electrodes and negative electrodes have equal service life

The invention belongs to the technical field of production of storage batteries, and particularly relates to a lead-acid storage battery electrode group of which positive electrodes and negative electrodes have equal service life. The lead-acid storage battery electrode group comprises multiple electrode plate groups which are in series connection, each electrode plate group is formed by positiveelectrode plates and negative electrode plates which are in parallel connection, AGM clapboards are arranged between every two adjacent electrode plate groups, and the negative electrode plates are connected with electrode plate link busbars. By means of the lead-acid storage battery electrode group, according to different reaction mechanisms of the positive electrode plates and negative electrodeplates in the charging and discharging process of a storage battery, by adjusting structures of current collecting ribs of plate grids of the positive electrodes and negative electrodes, current is reasonably distributed at all the positive electrode plates and the negative electrode plates as required in the charging and discharging process of the storage battery to guaranteed that active substances, close to current collectors and away from the current collectors, on the positive electrode plates and the negative electrode plates release energy simultaneously, and the purpose that the positive electrode plates and the negative electrode plates have the equal service life is achieved.

Owner:TIANNENG GRP HENAN ENERGY TECH

Catalytic cracking technology and device

InactiveCN104046387AReduce the temperatureAbundant means of temperature adjustmentCatalytic crackingTreatment with plural serial stages onlyFlue gasGasoline

The invention discloses a catalytic cracking technology and a device. Raw oil contacts and reacts with a catalyst from a catalyst pre-stripping mixer; after the reaction, oil gas is separated from a spent catalyst; separated reaction oil gas enters a fractionating tower for fractionation; the separated spent catalyst undergoes stripping and then is completely regenerated; a part of regenerant enters a catalyst heat-exchanger to undergo heat exchanged with part of prevailing wind and then enters the catalyst pre-stripping mixer; another part of the regenerant enters an external heat removal device for heat remove and cooling; and a part of a cooling regenerant returns to a regenerator and another part enters the catalyst pre-stripping mixer to be mixed with the regenerant from the catalyst heat-exchanger, and the mixture is recycled to a riser reactor. By the use of the technology, catalyst / oil ratio of the catalytic cracking device can be raised; dry gas and coke yield of the catalytic cracking device is reduced; total liquid yield is raised; and olefin content in gasoline and SOX emission in catalytic flue gas are simultaneously reduced.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

A high-strength melting furnace for non-ferrous intensified smelting

ActiveCN109650856BReduce decomposition reactionsImprove high temperature performanceCharge treatment typeFurnace liningsLiquid lineRefractory

A high-strength melting furnace for non-ferrous intensified smelting, including a furnace wall opening, an upper furnace wall, a furnace wall above the liquid line, a liquid line furnace wall, a furnace wall below the liquid line, a secondary working layer, a liquid outlet nozzle, a furnace bottom, and various parts of the furnace They are all made of refractory materials. By analyzing the working conditions of different positions of high-strength melting furnaces for non-ferrous intensified smelting, different refractory material linings are used at corresponding positions to improve the erosion resistance, thermal shock resistance and erosion resistance of the furnace lining at this position. 1. One or more performances in the impermeability greatly prolong the service life of the furnace lining, avoid frequent repairs and replacement of the furnace lining, and save a lot of manpower and financial resources.

Owner:REFRACTORY MATERIAL OF SINOSTEEL CORP

Catalytic cracking reaction device fed with combination of light raw materials and heavy oil

ActiveCN102827629BIncrease conversion rate per passImprove contact efficiencyCatalytic crackingFuel oilReaction system

Disclosed is a catalytic cracking reaction device fed with combination of light raw materials and heavy oil. The light raw materials and the heavy oil are fed into a riser reactor with an expanding dense-phase fluidizing section from different positions, are in contact with catalysts and are reacted with the catalysts, oil gas is separated from the catalysts in an upper precipitator of a riser by a cyclone separator, and is exhausted from a reaction system, and deactivated catalysts are fed into a regenerator via a spent inclined tube, are burned and regenerated, then are fed into a pre-riser via a regenerated inclined tube, are lifted by pre-rising media and are fed into the dense-phase fluidizing phase again. A part of the pre-riser is inserted into the expanding dense-phase fluidizing section and is positioned on the same axis with the riser reactor. Heavy oil nozzles are arranged above an outlet at the upper end of the pre-riser, and a distributing plate and an annular feeding tube are sequentially arranged in space between the outlet and the bottom of the expanding dense-phase fluidizing section from top to bottom. The device is used for catalytic cracking reaction of light oil and heavy oil, is beneficial to improving contact of the oil gas and the catalysts, and is high in catalytic conversion efficiency, generated cracking dry gas is reduced, and yield of propylene is increased.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com