Copper-based thick-wall Nb3Sn thin film superconducting cavity and preparation method thereof

A superconducting cavity, thin film technology, applied in the field of superconductivity, can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

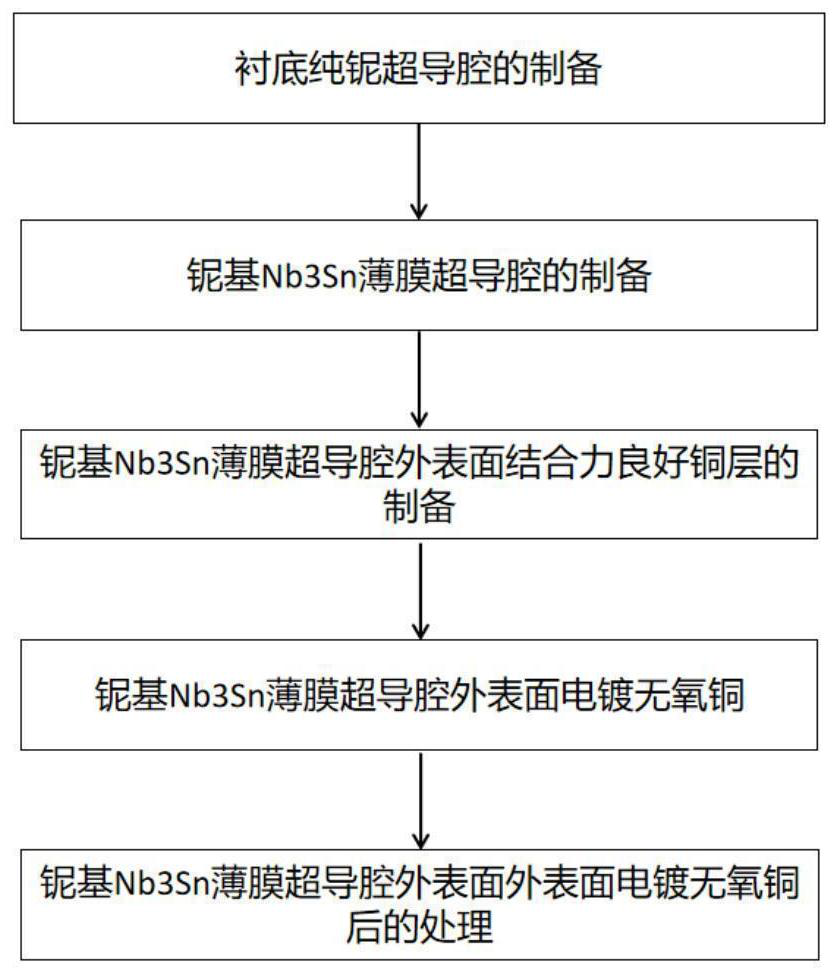

[0056] Embodiment 1, copper-based thick-walled Nb 3 Fabrication of Sn Thin Film Superconducting Cavities

[0057] 1. Niobium-based Nb 3 Fabrication of Sn Thin Film Superconducting Cavities

[0058] (1) Prepare a pure niobium superconducting cavity processed from a high-purity niobium plate with RRR>300 and a thickness of 2.0mm; the pure niobium superconducting cavity is prepared according to the method in the following literature: The International Linear ColliderTechnical Design Report 2013, Volume 3.I: Accelerator R&D;

[0059] (2) Carry out vacuum leak detection to the pure niobium superconducting cavity in step (1);

[0060] The pump set used for leak detection must be an oil-free pump set, and the leak rate of each sealing flange and weld of the pure niobium superconducting cavity must be lower than 1×10 -10 mbar L / s; this step of leak detection is to ensure that there are no leaks in the pure niobium superconducting cavity weld seam and each flange surface, to ensure...

Embodiment 2

[0100] Embodiment 2, copper-based thick-walled Nb 3 Performance Test of Sn Thin Film Superconducting Cavity

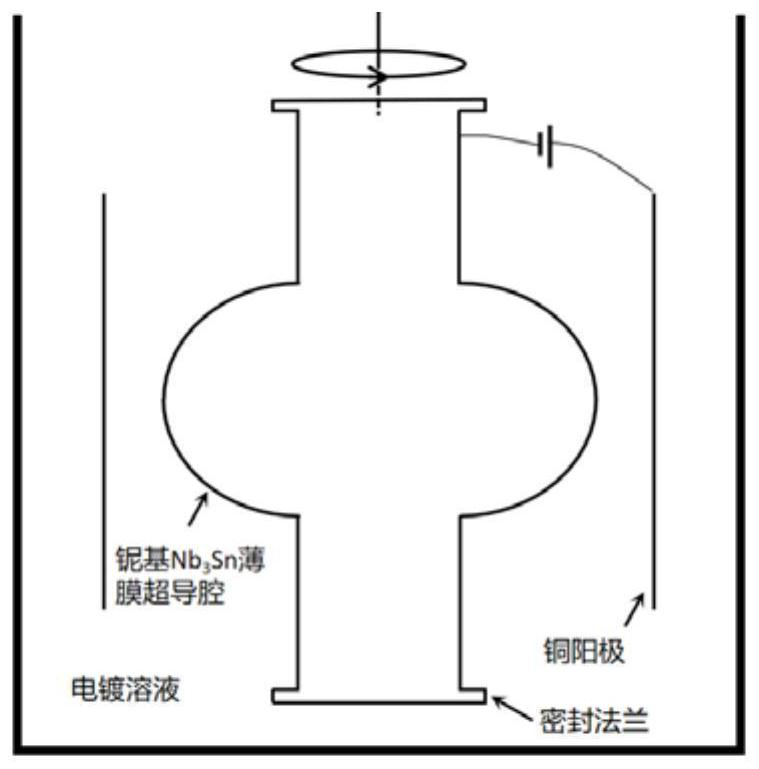

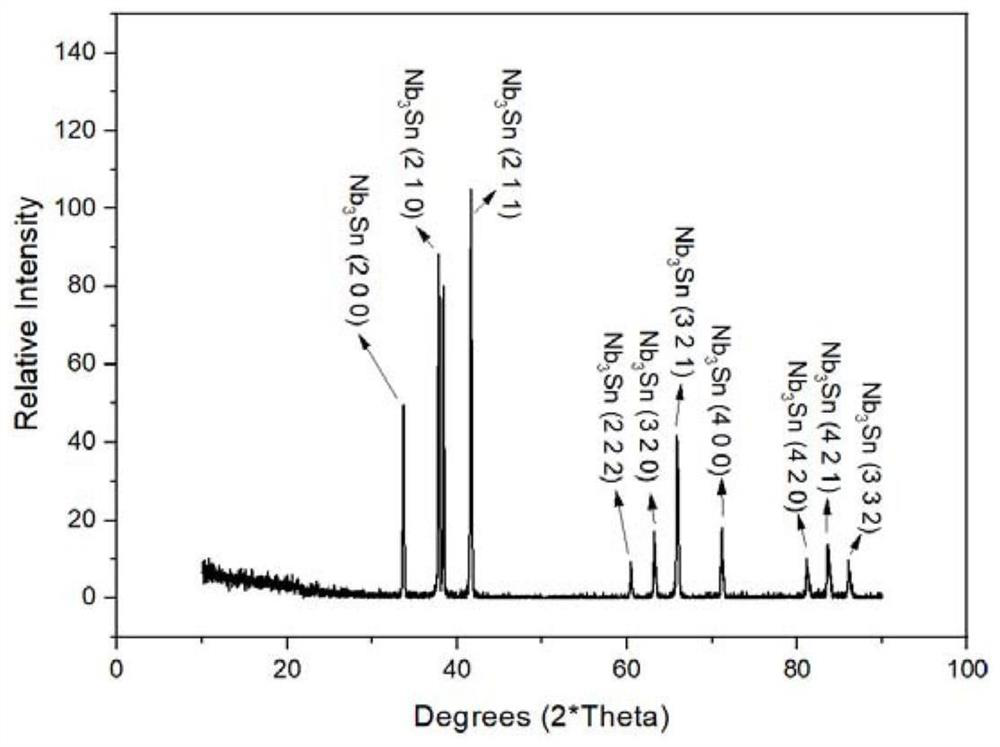

[0101] The copper-based thick-walled Nb prepared in Example 1 3 The Sn thin film superconducting cavity has been tested as follows: 1. X-ray diffraction (see image 3 ) analysis showed that the grown Nb 3 Sn thin films contain only highly pure Nb 3 The Sn phase, without any other impurity phase, exhibits the high quality of the film. 2.4.2K~2K RF performance test at low temperature: 1. The test found that the Lorentz detuning coefficient LFD before the copper plating layer was -2.7182Hz / (MV / m) 2 , the influence of liquid helium pressure fluctuations on its frequency is df / dp=-102.77Hz / mbar, when its outer surface is electroplated with a copper layer with a thickness of 9mm, its Lorentz detuning coefficient is reduced to -0.6368Hz / (MV / m) 2 , df / dp=-18.7Hz / mbar, the mechanical stability is significantly improved (see Figure 4 ); 2. After electroplating the coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com