A kind of alkane catalytic dehydrogenation or catalytic cracking to olefin circulating fluidized bed reactor

A reaction device and catalytic dehydrogenation technology, applied in the fields of hydrocarbon cracking, organic chemistry, chemical recovery, etc., can solve the problems of difficult disposal of spent catalysts, environmental pollution, etc., and achieve the effects of simple structure, flexible layout, and convenient equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] On the other hand, the preparation method of alkane dehydrogenation to olefins by using the above-mentioned reaction device for alkane dehydrogenation or catalytic cracking to olefins includes the following steps, the raw material enters the reaction section from the feed distributor, and the raw material and the catalyst flow upward together, The two contact to carry out catalytic reaction, wherein, in the dense-phase conveying section, the superficial gas velocity of the gas is controlled at 0.1-5.0m / s, the reaction temperature is preferably controlled between 500-730°C, and the mass space time of the reaction is 0.5~10h. In some embodiments, in the dense-phase conveying section where the catalytic dehydrogenation occurs, the reaction temperature is controlled between 550°C and 630°C.

[0075] In some embodiments, in the dense-phase conveying section where the catalytic dehydrogenation occurs, the mass space time of the reaction is 1.5-5.0 h.

[0076] In some embodimen...

Embodiment 1

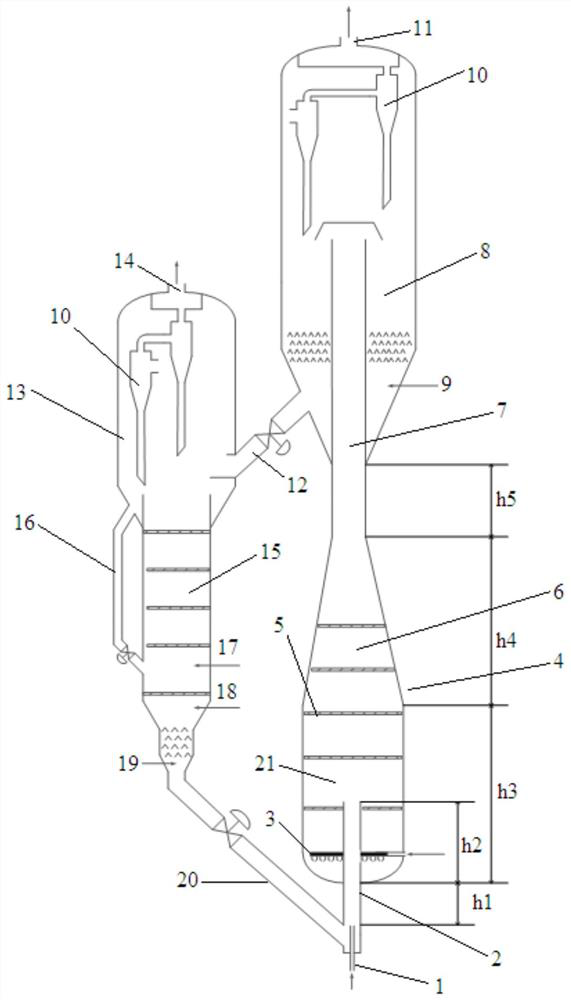

[0086] This embodiment refers to the attached figure 1 As shown, the reaction device for the catalytic dehydrogenation of alkanes or catalytic cracking to olefins provided by this application is used in conjunction with the catalyst regeneration device. These two sets of devices can be used separately, and respectively used in combination with other reaction devices or catalyst regeneration devices in the prior art.

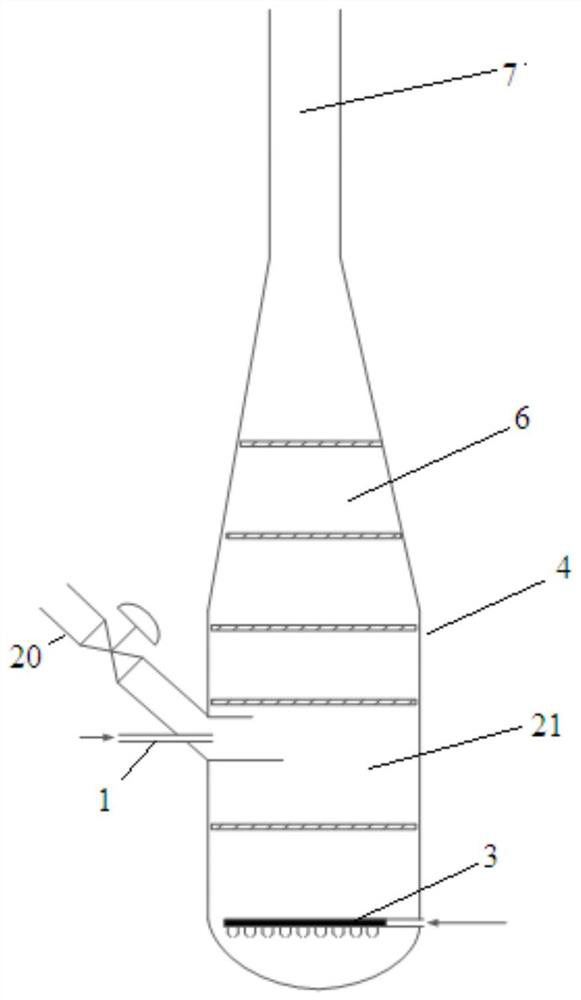

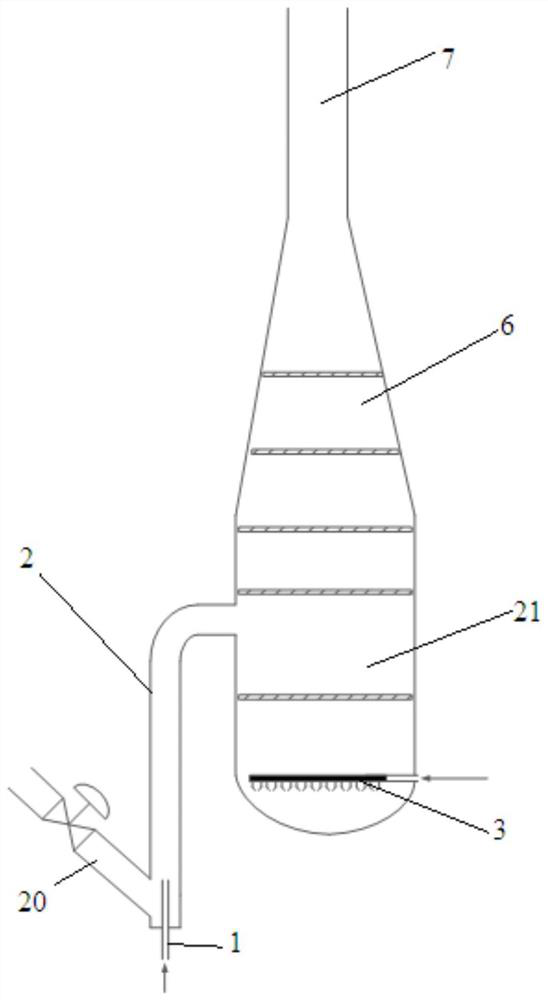

[0087] The reaction device for catalytic dehydrogenation of alkanes or catalytic cracking to produce olefins includes a reactor 4 and a settling section 8 of the reactor. The settling section 8 of the reactor is located at the upper part of the reactor 4 . The reaction section 10 includes a dilute-phase conveying section 7 , a diameter-reducing section 6 and a dense-phase conveying section 21 , the dense-phase conveying section 21 is located below the diameter-reducing section 6 , and the dilute-phase conveying section 7 is located above the diameter-reducing sec...

Embodiment 2

[0100] Compared with Embodiment 1, this embodiment has different arrangements of different catalyst risers. In this embodiment, the inclined regeneration pipe 20 extends into the reactor 4 from the side of the dense-phase conveying section 21 , and the lifting medium pipe 1 is arranged in the inclined regeneration pipe 20 inserted into the reactor 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com