Catalytic cracking reaction device fed with combination of light raw materials and heavy oil

A catalytic cracking and reaction device technology, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve problems such as easy channeling, achieve the effect of improving contact efficiency, promoting catalytic cracking reaction, and improving single-pass conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

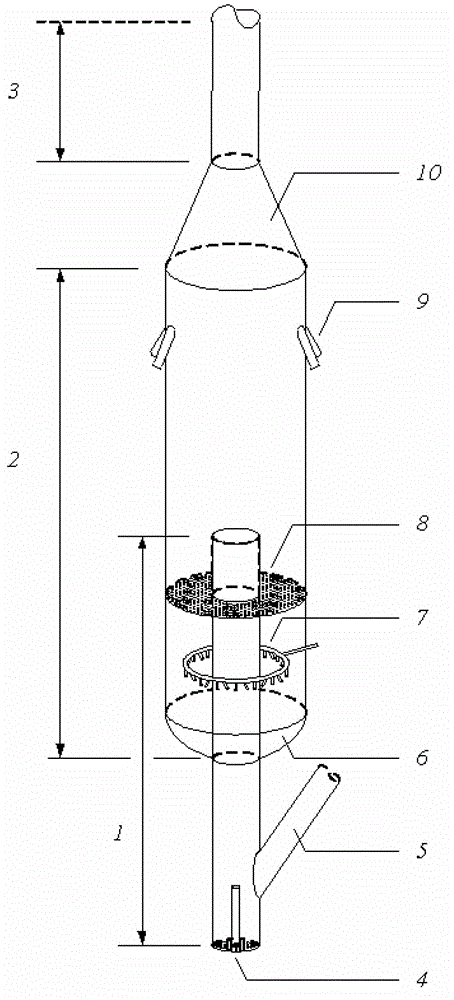

[0040] Such as figure 1 As shown, a catalytic cracking reaction device for combined feeding of light raw materials and heavy oil, including a pre-riser 1, a diameter-expanding dense-phase fluidization section 2, a riser reactor 3 and a regeneration inclined tube 5, the pre-riser 1 and The riser reactor 3 is on the same axis, and the pre-riser 1 and the riser reactor 3 are respectively located at the upper and lower parts of the enlarged diameter dense-phase fluidized section 2; the diameter of the pre-riser 1 is smaller than that of the enlarged diameter dense-phase fluidized section 2 The upper part of the pre-lift pipe 1 is located in the diameter-expanding dense-phase fluidization section 2, from the outlet of the upper port of the pre-lift pipe 1 to the bottom of the diameter-expanding dense-phase fluidization section 2, from top to bottom in the diameter expansion A distribution plate 8 and an annular feed pipe 7 are arranged in sequence in the dense phase fluidization se...

Embodiment 2

[0052] This embodiment adopts the catalytic cracking reaction device of light raw material and heavy oil combined feed described in Example 1 to carry out catalytic cracking of heavy oil and light raw material to produce propylene, and the light raw material and heavy oil are respectively fed from the nozzle, The heavy oil nozzle enters the diameter-expanding dense-phase fluidization section, contacts with the catalyst, and enters the riser reactor for catalytic reaction.

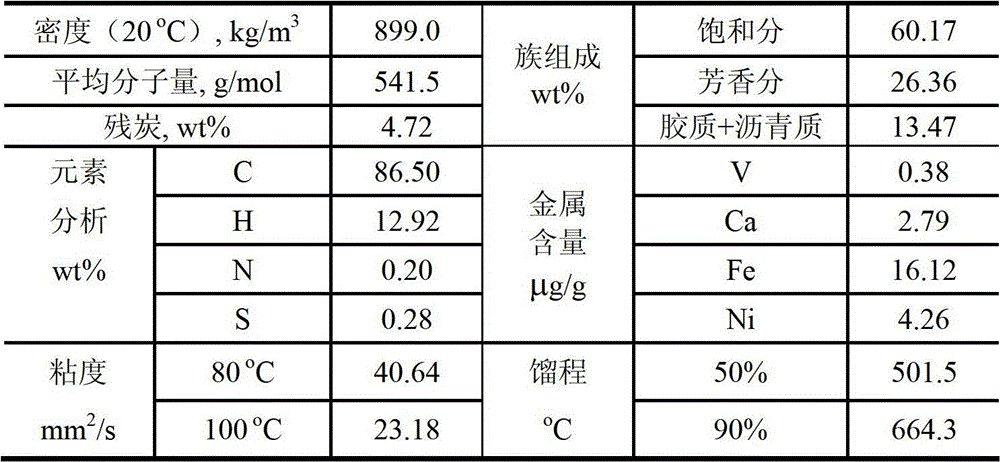

[0053] Among them, the properties of the heavy oil raw material used in this example are shown in Attached Table 1: the hydrogen content is high, close to 13wt%, and the content of residual carbon, Ni and V is not high, so it is an ideal raw material for catalytic cracking and propylene production.

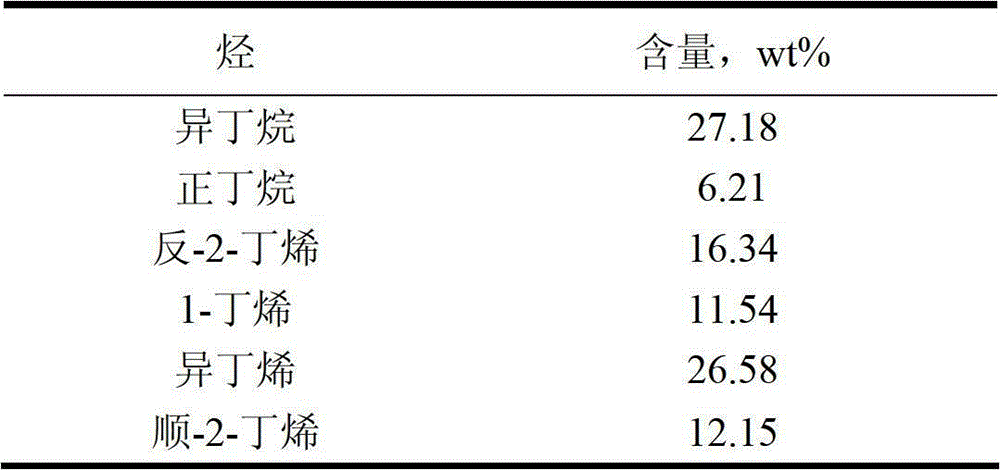

[0054] The light raw material used in this embodiment is mixed C4, and its composition is shown in attached table 2, wherein the butene content is more than 66wt%.

[0055] The catalyst used in this example is ...

Embodiment 3

[0058] The light raw material of this embodiment uses light gasoline, and its components are shown in Table 3, and the reaction conditions are shown in Table 5, and other raw materials, reaction devices, etc. are all the same as in Example 2.

[0059] The light gasoline used in this example has a relatively high olefin content, reaching 75 wt%, and most of the olefins are pentene. The light gasoline contains substantially no aromatics.

[0060] The resulting product distribution and conversions are shown in Table 5B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com