A lead-acid battery positive and negative plates and other life pole groups

A lead-acid battery, negative plate technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems that are not mentioned, different, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

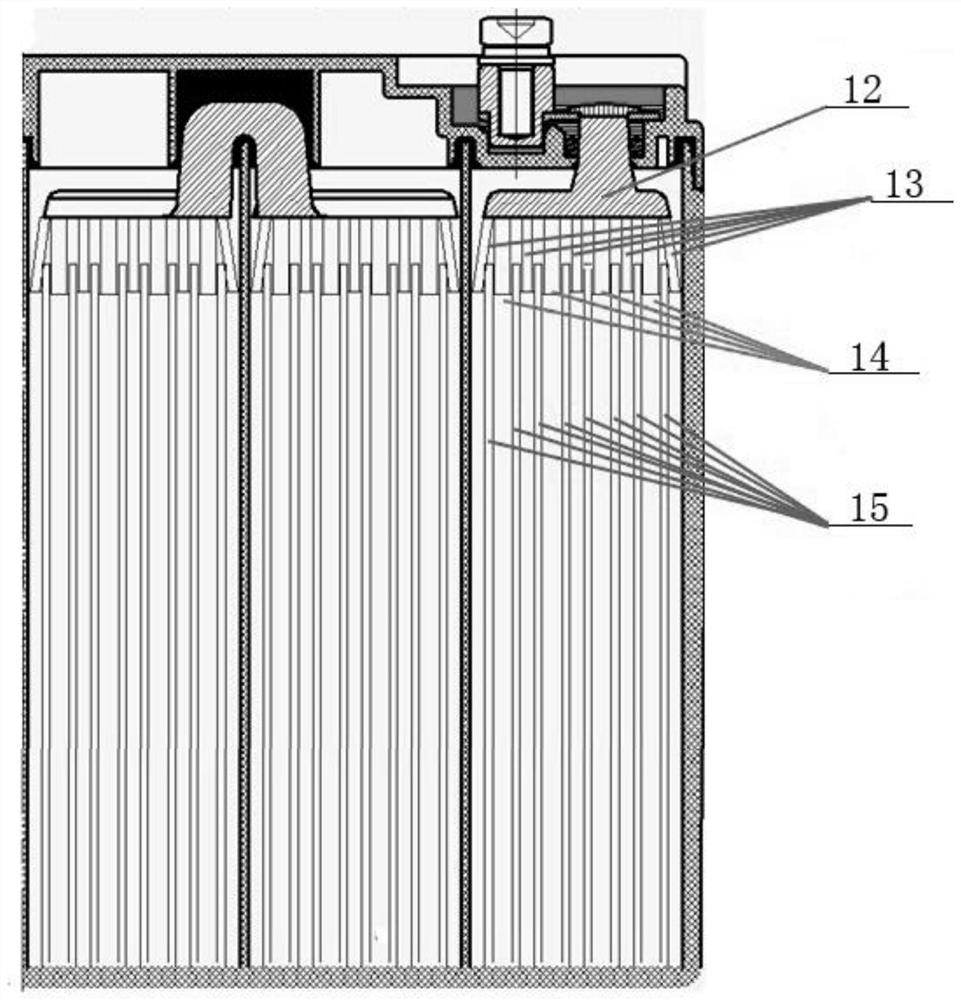

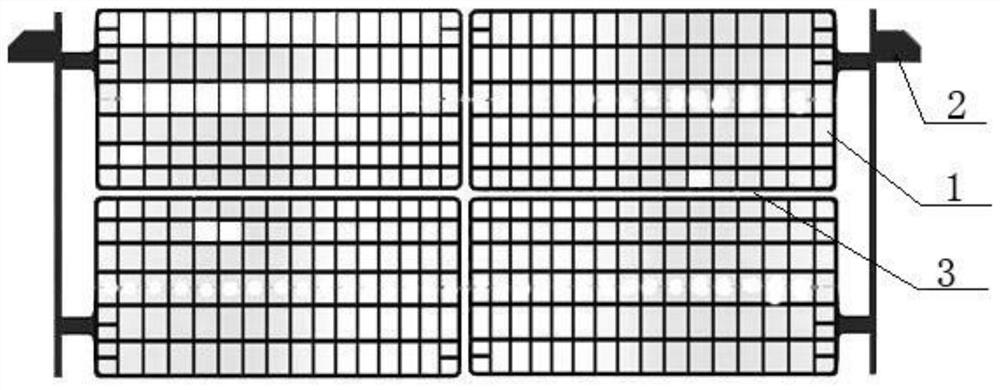

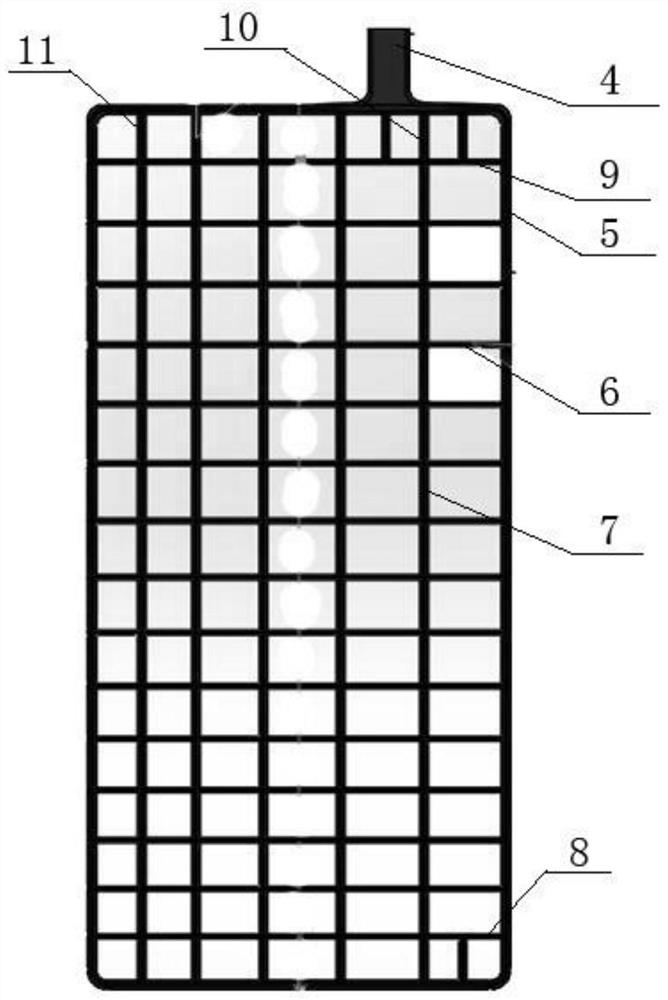

[0044]In this embodiment, the number of negative pole vertical ribs 7 is five, and the number of negative pole horizontal ribs 6 is sixteen. The distance between the negative pole vertical ribs 7 and the adjacent negative pole second vertical ribs is 9.5mm and 11mm respectively. . The distances between consecutive adjacent negative electrode transverse ribs 6 are: 6.46mm, 6.66mm, 6.86mm, 7.06mm, 7.26mm, 7.46mm, 7.66mm, 7.86mm, 8.06mm, 8.26mm, 8.36mm, 8.46mm , 8.56mm, 8.66mm, 8.76mm, 8.86mm. The width of the upper part of the negative electrode vertical rib 7 is 1.0 mm, and the width radiating downwards to the bottom is 1.4 mm, with an even transition in the middle. After discharging, the negative electrode grid provided by this embodiment was tested for PbSO4 content in different positions. The discharged product was uniform and met the set requirements. The cycle life curve of the battery produced by using this negative electrode grid is shown in the table below.

[0045] I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com