Gas-liquid two-phase palmitic acid-based imidazoline corrosion inhibitor and its preparation and use method

A technology of palmitic acid-based imidazoline and corrosion inhibitor, which is applied in the field of oil and gas field chemistry, can solve the problems of difficulty in inhibiting the corrosion of the top of oil and gas pipes, difficult to inhibit liquid phase corrosion of oil and gas pipes, and difficult to prevent corrosion, and achieves great economic and social benefits, The effect of inhibiting metal corrosion and forming dense film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

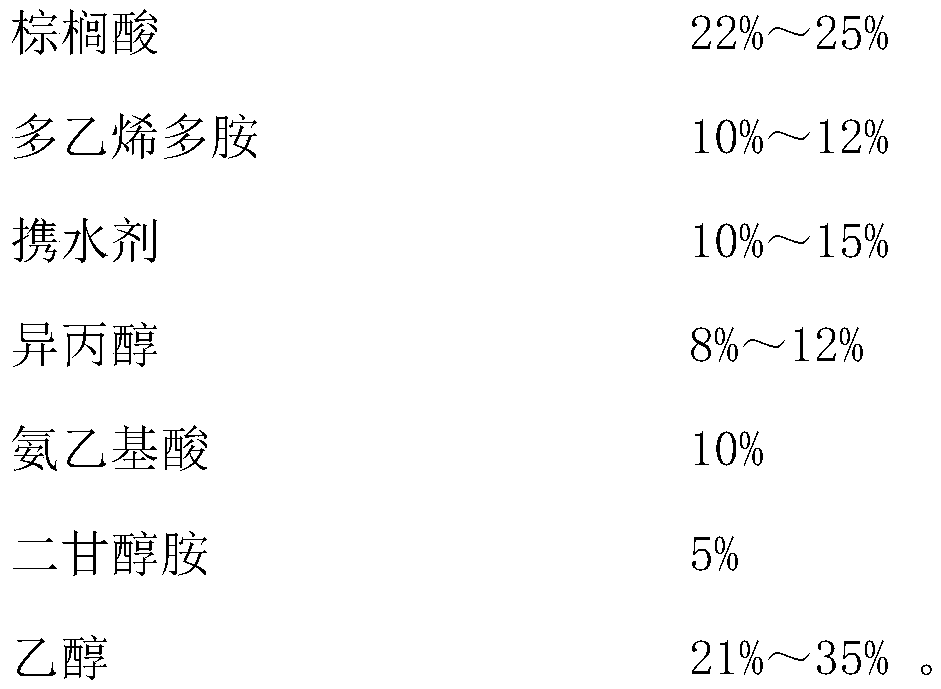

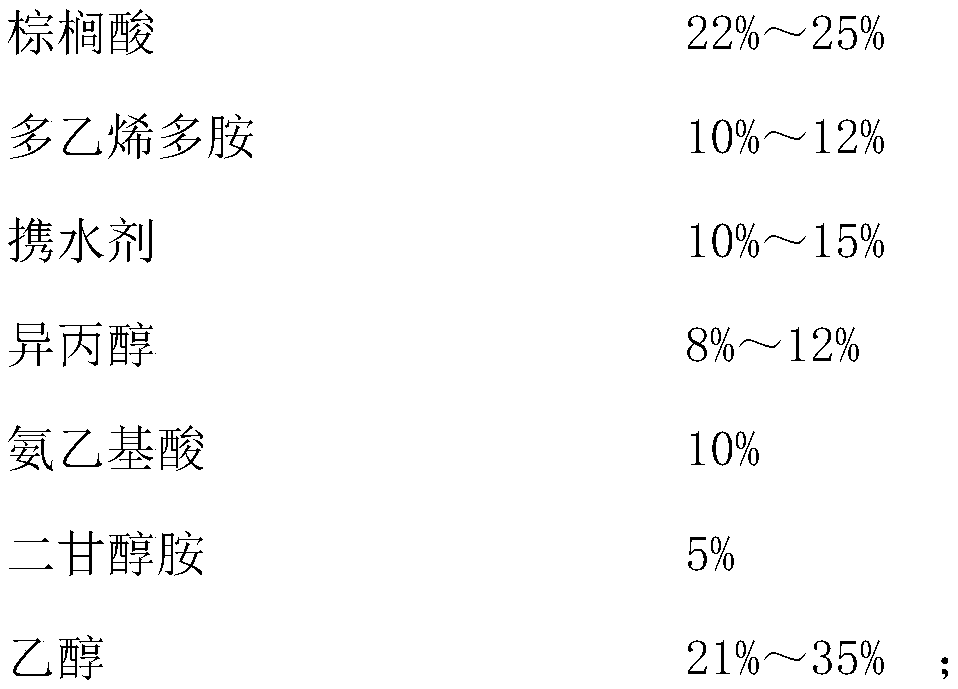

[0032] This embodiment provides a gas-liquid two-phase palmitic acid-based imidazoline corrosion inhibitor, which includes a main agent, several auxiliary agents and a solvent, and is formed by mixing the main agent, auxiliary agents and solvents.

[0033] The main agent is an imidazoline derivative prepared from palmitic acid, polyethylene polyamine, and a water-carrying agent; the auxiliary agent includes isopropanol, aminoethyl acid, and diglycolamine; and the solvent is ethanol. In this embodiment, preferably, polyethylene polyamine is selected from triethylenetetramine; water carrier is selected from xylene.

[0034] The present embodiment provides the preparation method of this gas-liquid biphasic palmitic acid base imidazoline corrosion inhibitor, comprises the following steps:

[0035] Step 1, the preparation of imidazoline derivatives

[0036] Put 100kg of the raw material triethylenetetramine and 100kg of the water-carrying agent xylene into the reactor, start stirr...

Embodiment 2

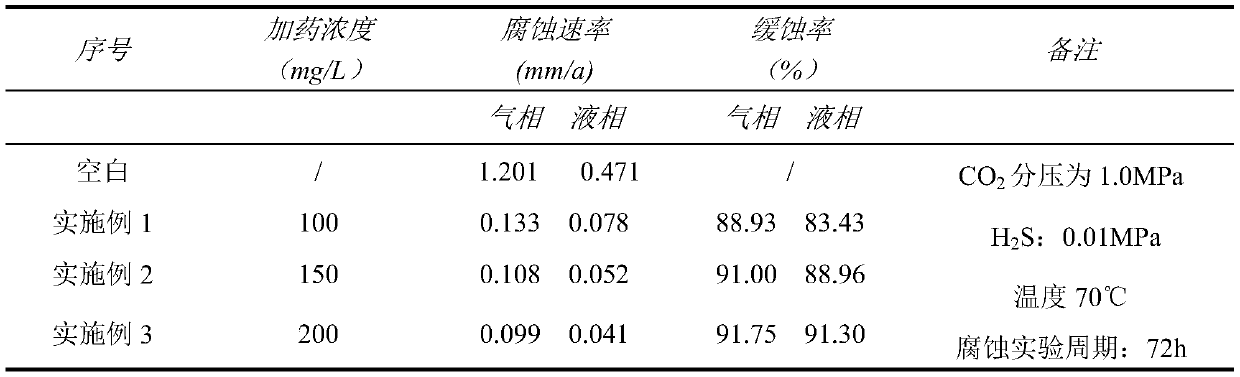

[0044] On the basis of Example 1, this example provides a preferred formulation of a gas-liquid biphasic palmitic acid-based imidazoline corrosion inhibitor. In terms of weight percent, the proportion of the feeding amount of each component is: palmitic acid 240kg, 110kg of triethylenetetramine, 120kg of water-carrying xylene; 100kg of isopropanol, 100kg of aminoethyl acid, 50kg of diglycolamine; 280kg of solvent ethanol.

[0045] For the preparation method and application method of the gas-liquid biphasic palmitic acid-based imidazoline corrosion inhibitor, see Example 1. The difference from Example 1 is that the gas-liquid biphasic palmitic acid-based imidazoline corrosion inhibitor is used at a concentration of 150 mg / L.

Embodiment 3

[0047] On the basis of Example 1, this example provides a preferred formulation of a gas-liquid biphasic palmitic acid-based imidazoline corrosion inhibitor. In terms of weight percent, the proportion of the feeding amount of each component is: palmitic acid 250kg, 120kg of triethylenetetramine, 150kg of water-carrying xylene; 120kg of isopropanol, 100kg of aminoethyl acid, 50kg of diglycolamine; 210kg of solvent ethanol.

[0048] For the preparation method and application method of the gas-liquid biphasic palmitic acid-based imidazoline corrosion inhibitor, see Example 1. The difference from Example 1 is that the gas-liquid biphasic palmitic acid-based imidazoline corrosion inhibitor is used at a concentration of 200 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com