A liquid heavy metal cooling natural circulation pool reactor auxiliary heating system

A liquid heavy metal, natural circulation technology, applied in reactors, cooling devices, reducing greenhouse gases, etc., can solve problems such as system failure, coolant solidification, unfavorable reactor treatment, etc., to improve economy and safety, prevent escape. dispersion, improved reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

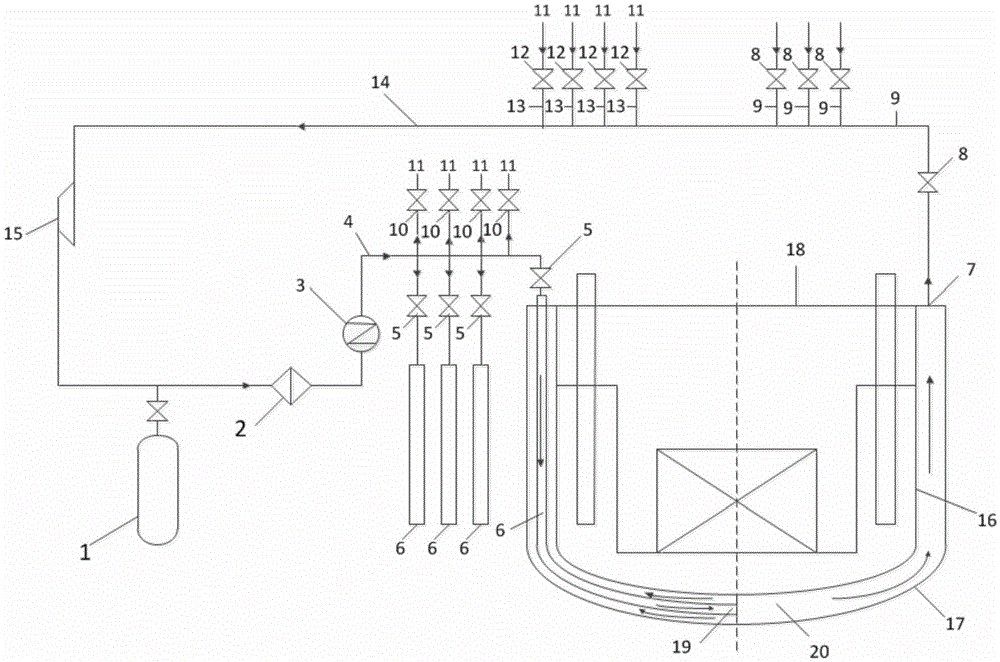

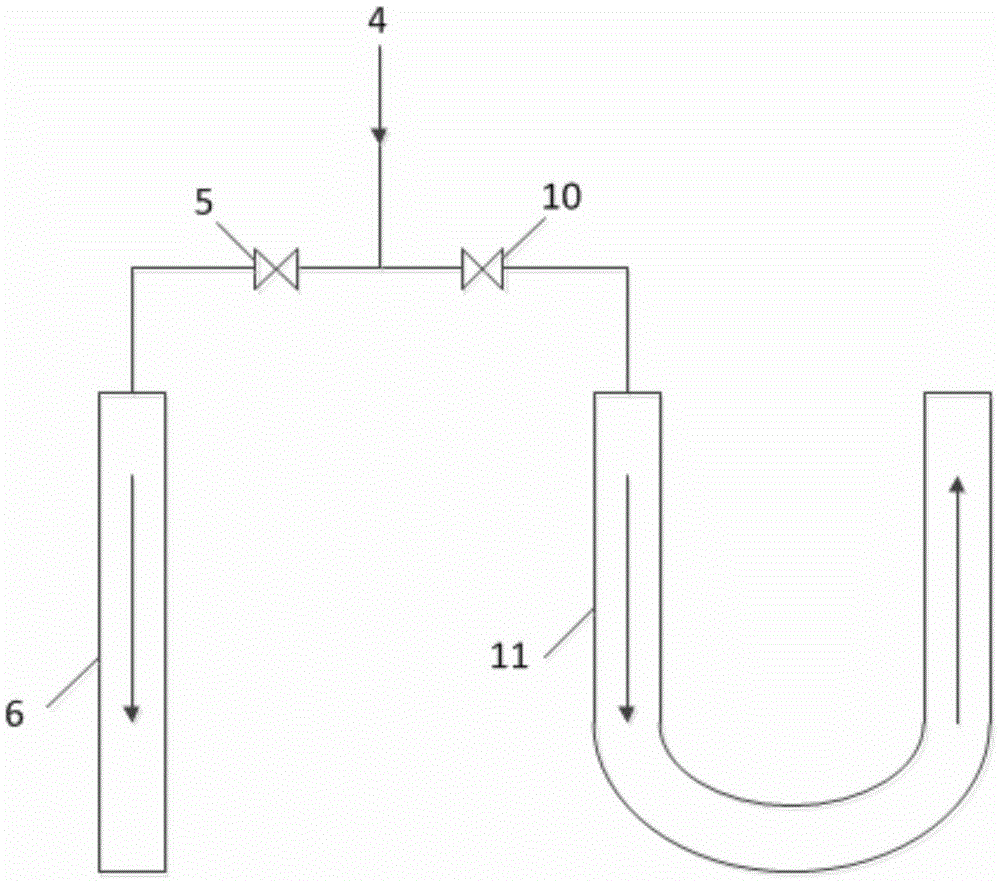

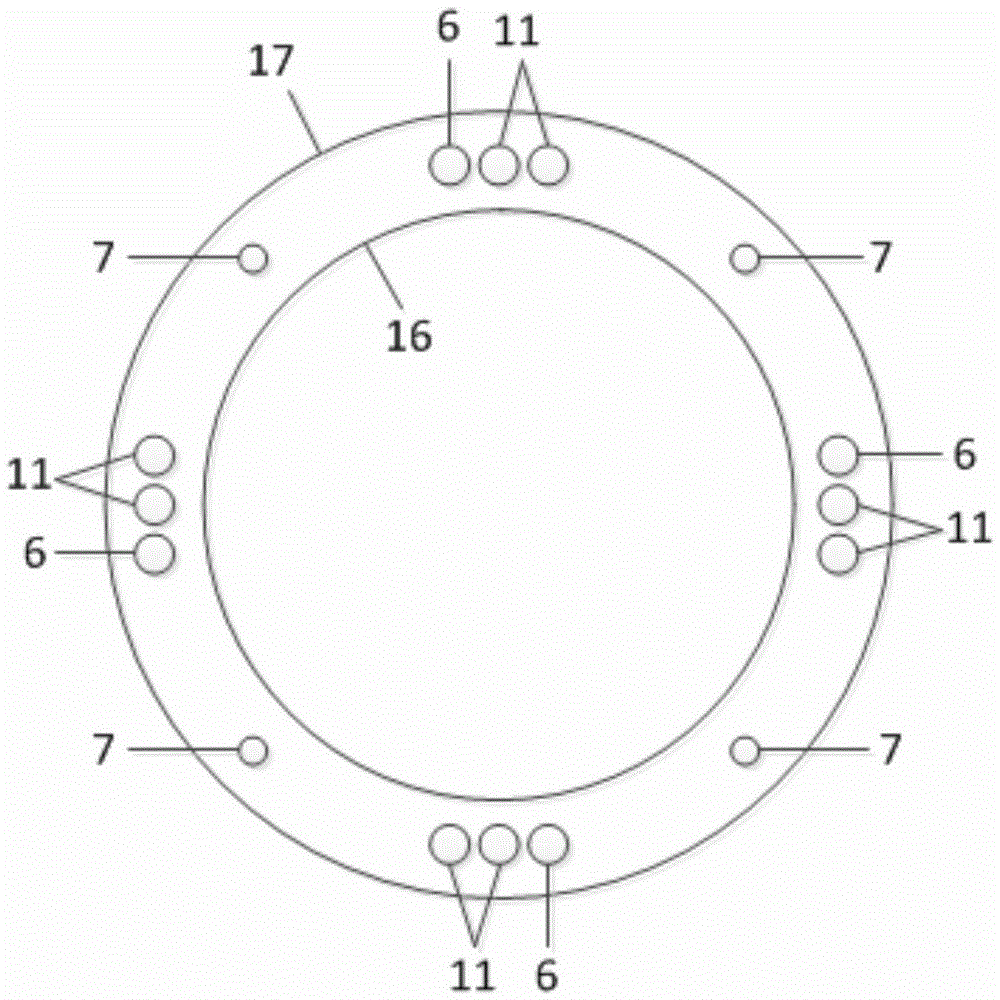

[0024] Such as figure 1 As shown, the present invention provides a liquid heavy metal cooling natural circulation pool reactor auxiliary heating system, the system consists of a gas storage tank 1, a filter 2, a gas heater 3, a gas input main pipe 4, a main gas input valve 5, a gas Main input pipe 6, air extraction port 7, gas main output valve 8, gas main output pipe 9 gas emergency input valve 10, gas emergency input pipe 11, gas emergency output valve 12, gas emergency output pipe 13, gas output main pipe 14, Air extractor 15 and the pipeline connected between the equipment and other valves are formed; wherein the main container 16 is located inside the safety container 17, and the upper ends of the main container 16 and the safety container 17 are all suspended on the stack top cover 18, and the main container 16 and the safety container 17 There is a certain gap between them, forming a ring cavity 20; each heating subunit in the system is independent of each other, and ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com