Lead-acid storage battery electrode group of which positive electrodes and negative electrodes have equal service life

A lead-acid battery, negative plate technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems that are not mentioned, different, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

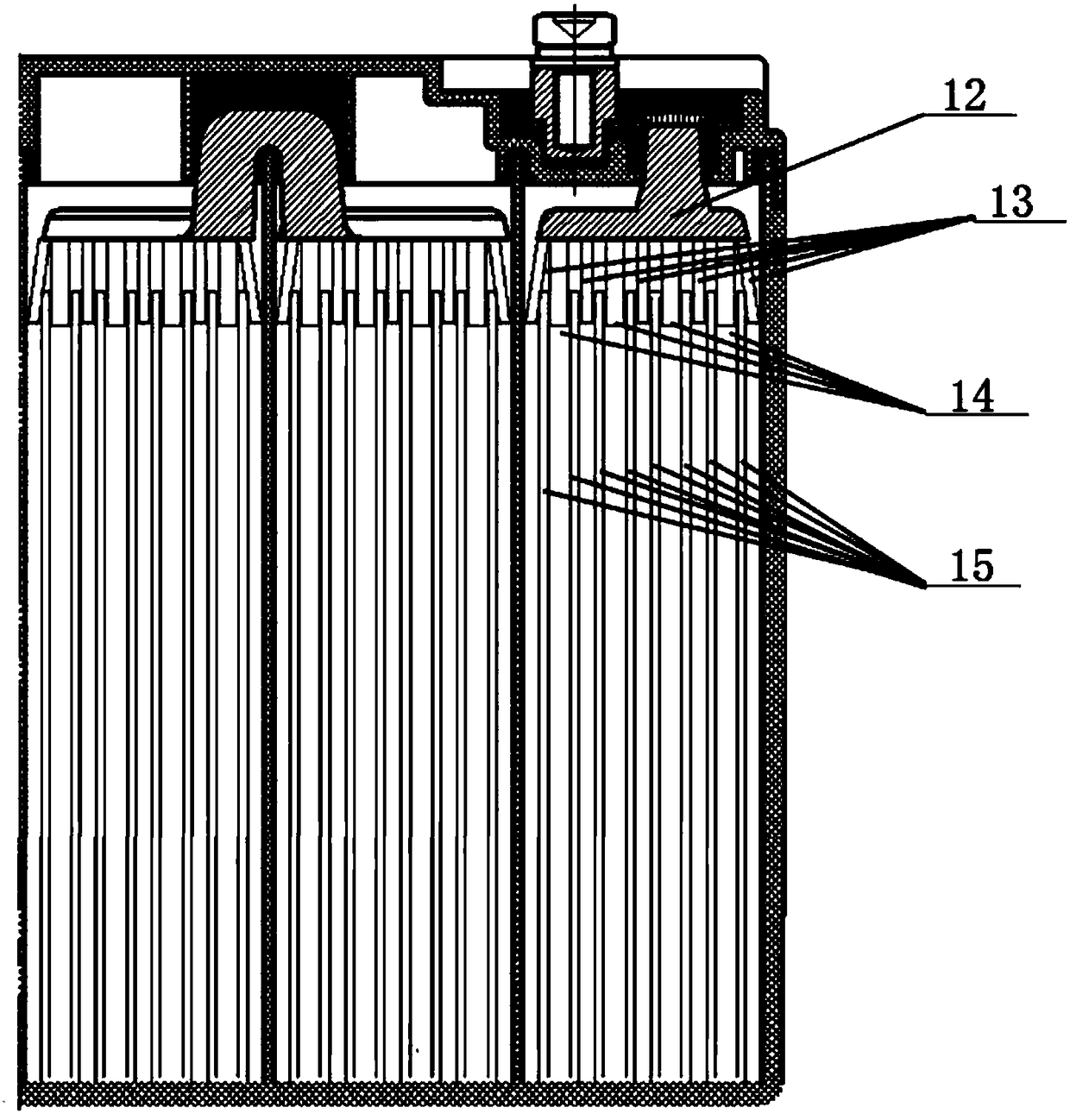

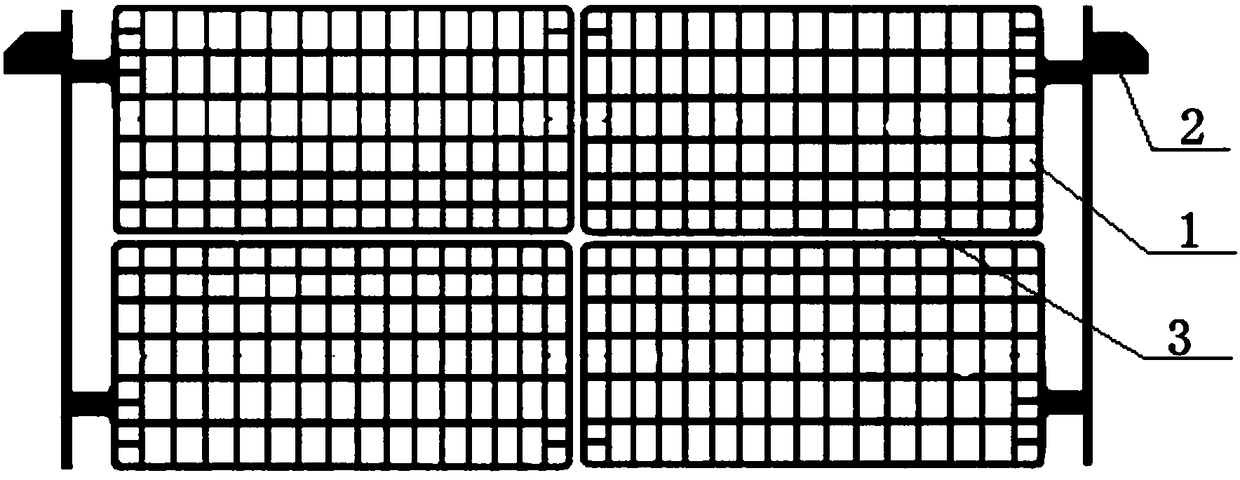

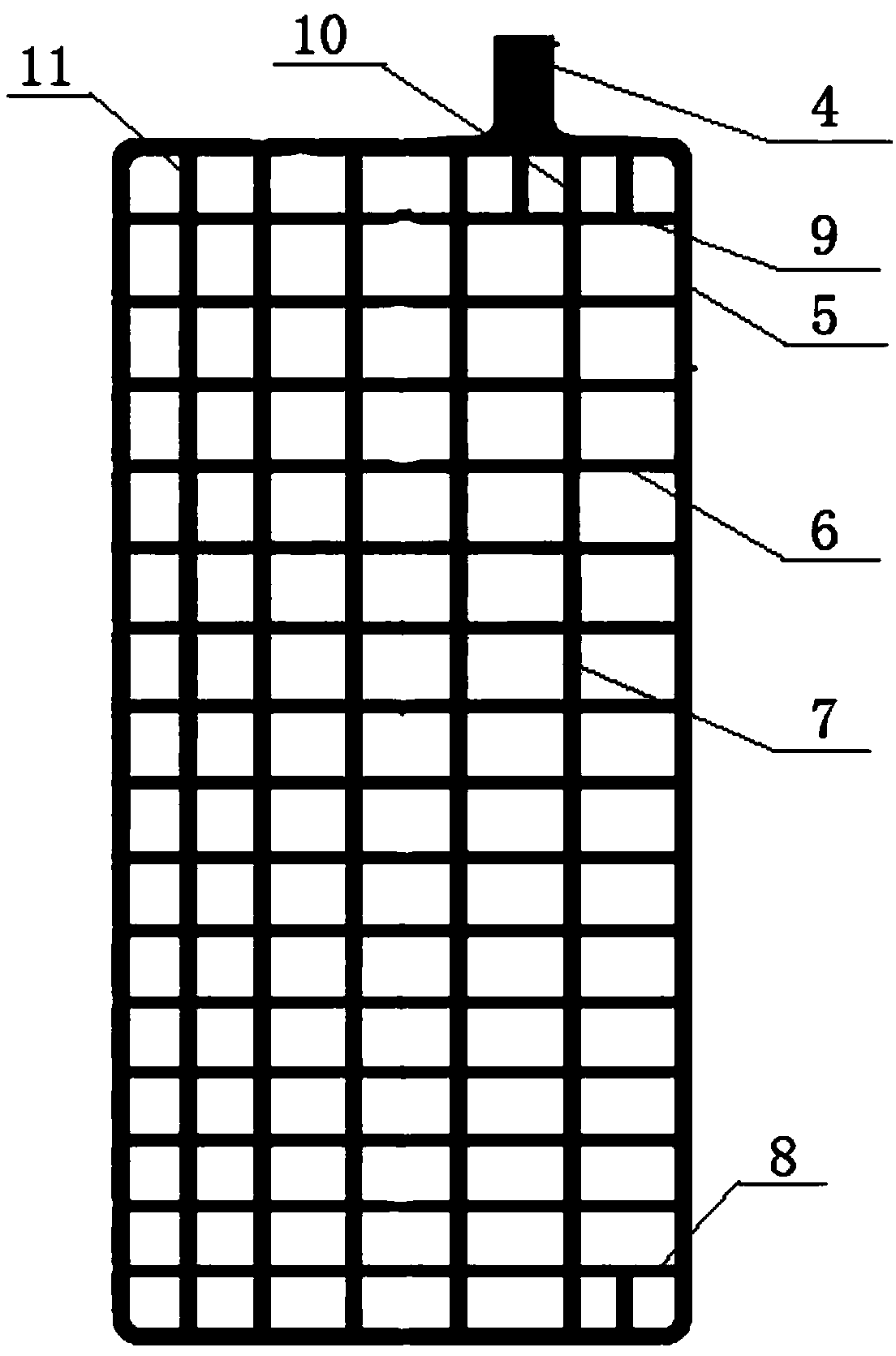

Embodiment 1

[0044]In this embodiment, the number of negative pole vertical ribs 7 is five, and the number of negative pole horizontal ribs 6 is sixteen. The distance between the negative pole vertical ribs 7 and the adjacent negative pole second vertical ribs is 9.5mm and 11mm respectively. , 12.5mm, 14mm, 15.5mm, the negative pole horizontal rib 6 is from the distance between the first negative pole horizontal rib 8 and the adjacent negative pole second horizontal rib to between the negative pole last horizontal rib 9 and its adjacent negative pole Nth horizontal rib The distances between consecutive adjacent negative pole transverse ribs 6 are: 6.46mm, 6.66mm, 6.86mm, 7.06mm, 7.26mm, 7.46mm, 7.66mm, 7.86mm, 8.06mm, 8.26mm, 8.36mm, 8.46mm , 8.56mm, 8.66mm, 8.76mm, 8.86mm. The width of the upper part of the negative electrode vertical rib 7 is 1.0 mm, and the width radiating downward to the bottom is 1.4 mm, with an even transition in the middle. After discharging, the negative electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com