Preparation method of diamond wire cutting pulley piece

A technology of diamond wire cutting and pulleys, which is applied in the manufacture of tools, stone processing equipment, fine working devices, etc., can solve the problems of large steel wire cutting loss, short service life of pulleys, and low yield rate of cutting products, so as to reduce steel Reduce wire cutting loss, improve cutting service life, and improve man-machine cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

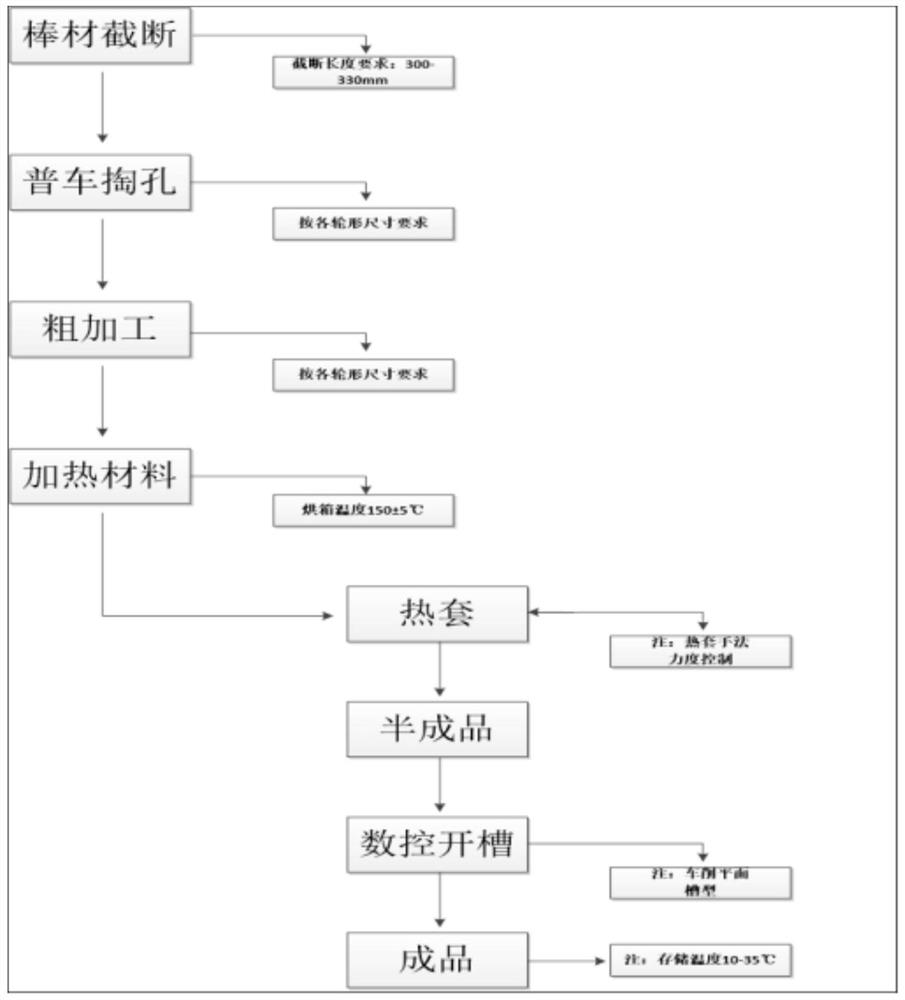

[0021] The preparation method of a diamond wire cut pulley provided in this embodiment has a structure such as figure 1 As shown, it includes the following process: bar cutting - common car hole - rough machining - heating material - heat sleeve - semi-finished product - CNC slotting - finished product, of which:

[0022] (1) First cut and cut the polyethylene rod in sections according to the size requirements, turn the outer circle, and bore the inner circle to obtain the polyethylene ring;

[0023] (2) The obtained polyethylene ring is heated in an oven to soften and expand;

[0024] (3) Install the softened and expanded polyethylene ring on the nylon frame. After natural cooling, the polyethylene ring condenses and shrinks and cooperates with the nylon frame to form a semi-finished pulley piece;

[0025] (4) Use a CNC lathe to remove the margins on both sides and the outer circle of the polyethylene semi-finished product, and then groove the surface of the semi-finished pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com