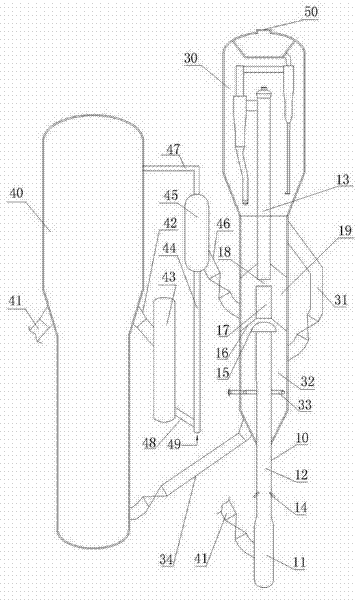

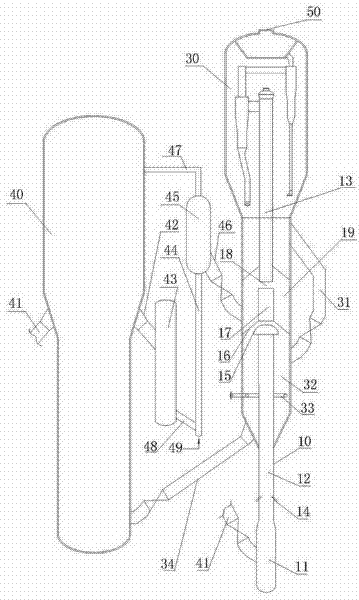

Catalytic cracking method and its apparatus

A catalytic cracking and catalyst technology, applied in the petrochemical field, can solve the problems of affecting the stripping effect, affecting the regeneration process, increasing investment, etc., and achieve the effects of reducing unfavorable secondary reactions, simple equipment manufacturing, and reducing thermal reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] figure 1 This is a schematic diagram of a catalytic cracking unit. The regenerated catalyst from the regenerator 40 enters the pre-lift section 11 at the bottom of the reactor 10 through the regeneration standpipe 41, and enters the first reaction zone 12 upward under the action of the pre-lifting medium, and passes through the feed nozzle 14 The incoming atomized feed oil is contacted, and the reaction temperature is 510℃, the reaction time is 0.8s, and the catalyst-to-oil ratio is 8 to participate in the catalytic reaction. The reaction mixture passes upwards through the splitter 15 to separate 80% of the catalyst, and the separated catalyst is directly Entering the stripping section 32, the remaining 20% of the catalyst and reaction oil and gas will enter the second reaction zone 13 upwards along the conveying pipe 17. At the same time, a part of the regenerated catalyst enters the catalyst cooler 43 to cool down to 540°C, thereby enhancing the effect of the steam 49...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com