Catalytic cracking method and device

A catalytic cracking device and catalytic cracking technology, applied in the field of petrochemical industry, can solve the problems affecting the regeneration process, the large amount of transport medium, and the effect of stripping, so as to achieve the goals of reduced investment, simple engineering implementation, and reduced unfavorable secondary reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

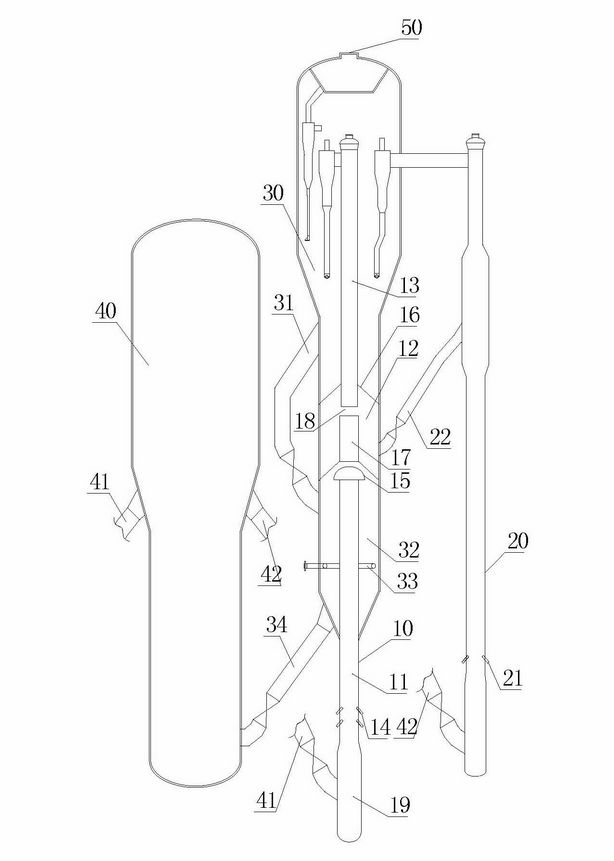

[0042] The design of a catalytic cracking unit in an oil refinery is as follows: figure 1 As shown, the heavy oil at 220°C is atomized through the nozzle 14, enters the first reaction zone 11 of the main riser reactor 10, mixes with the regenerated catalyst at about 640°C and gasifies, and flows upward along the first reaction zone 11 , and react continuously, the reaction time is 1.0s, and the reaction temperature is 520°C. After the reaction is completed, the mixture is separated from the catalyst through the splitter 15, and the oil and gas go upward along the delivery pipe 17 and enter the second reaction zone 13; meanwhile, from the auxiliary light raw material riser The spent catalyst drawn from the reactor 20 enters the catalyst replenishment zone 12 and enters the second reaction zone 13, contacts and mixes with the reaction oil and gas entering the second reaction zone 13 and continues to react. The reaction temperature is 510°C and the reaction time is 1.5s. Light g...

Embodiment 2

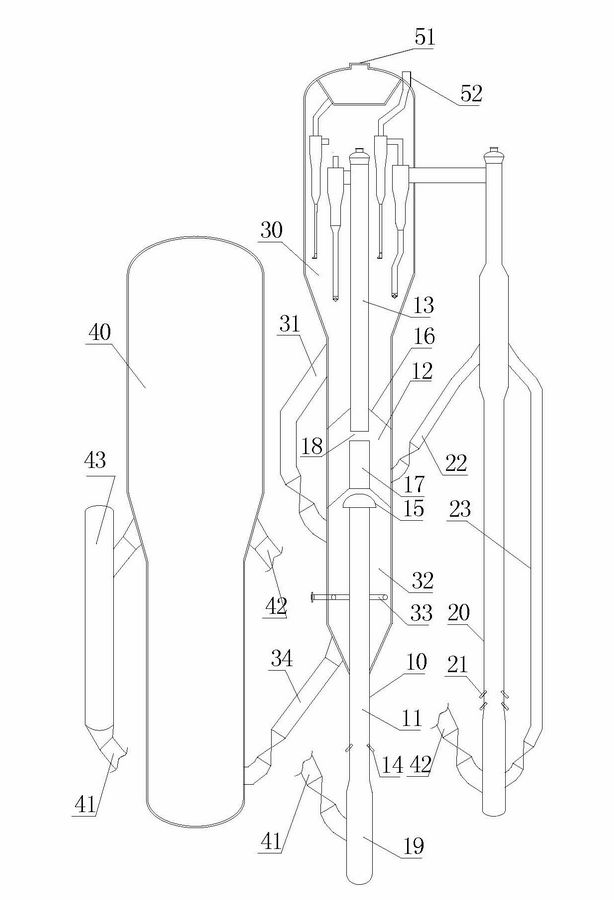

[0045] The design of a catalytic cracking unit in an oil refinery is as follows: figure 2 As shown, a catalyst cooler 43 is provided on the regeneration standpipe 41, and a catalyst return pipe 23 is provided in the auxiliary light raw material riser reactor 20; the reactor 20 shares the settler 30 with the main reactor 10, but does not share the gas-solid separator , the oil and gas in the two reactors are treated separately, and the rest of the device structure is the same figure 1 . In this embodiment, the heavy oil raw material and the regenerated catalyst at about 600° C. are contacted and reacted in the first reaction zone 11; the circulating amount of the ungenerated catalyst returned from the reactor 20 is controlled by the slide valve on the catalyst return pipe 23, and the returned amount is 40%; the reaction raw material of the reactor 20 is mixed C4 components. In this embodiment, the reaction temperature in the first reaction zone of the riser reactor 10 is 50...

Embodiment 3

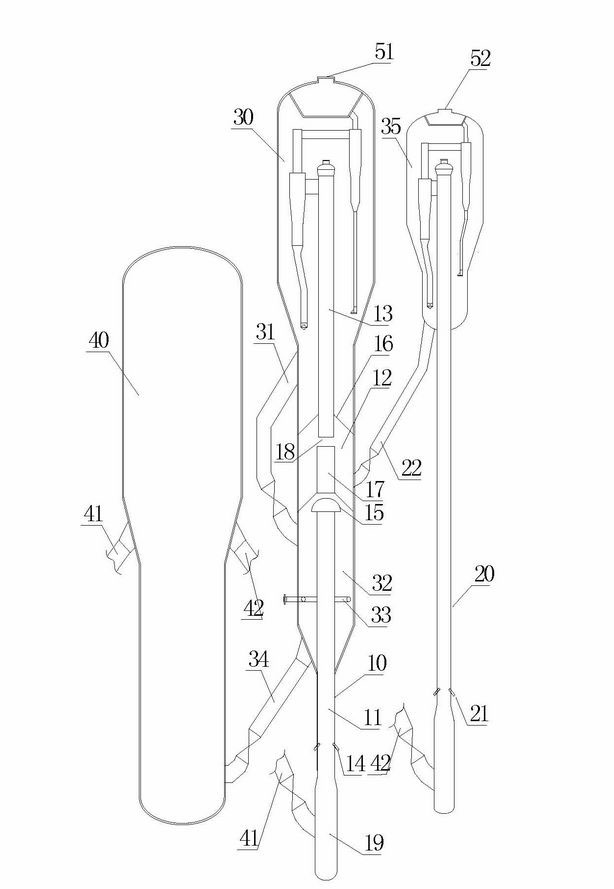

[0047] The design of a catalytic cracking unit in an oil refinery is as follows: image 3 As shown, the second settler 35 is separately set at the outlet of the auxiliary reactor 20; the unborn catalyst of the auxiliary reactor 20 is drawn from the second settler 35, and enters the second reaction zone 13 through the catalyst replenishment zone 12, and the oil and gas in the two reactors Treat them separately. The rest of the device structure is the same as figure 1 . In this embodiment, the reaction raw material of the riser reactor 20 is C4 component, and the reaction conditions of the riser reactor 10 are: the reaction temperature of the first reaction zone is 520° C., and the reaction time is 1.0s; the reaction temperature of the second reaction zone is 510° C. °C, the reaction time is 1.5s; the reaction temperature of the riser reactor 20 is 520 °C, and the reaction time is 2.5s; the total reaction liquid yield increases by about 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com