S-type fluid bed

A fluidized bed and intermediate point technology, applied in the field of fluidized bed, can solve the problems of particle clogging wall, pressure loss, particle back-mixing, etc., and achieve the effect of reducing blockage, reducing pressure loss and reducing wall wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

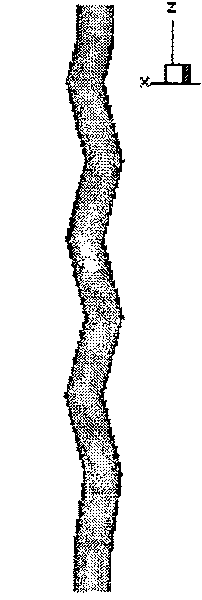

[0030] The present invention is applicable to the pneumatic conveying system of the straight pipe, and is more applicable to the circulating fluidized bed system.

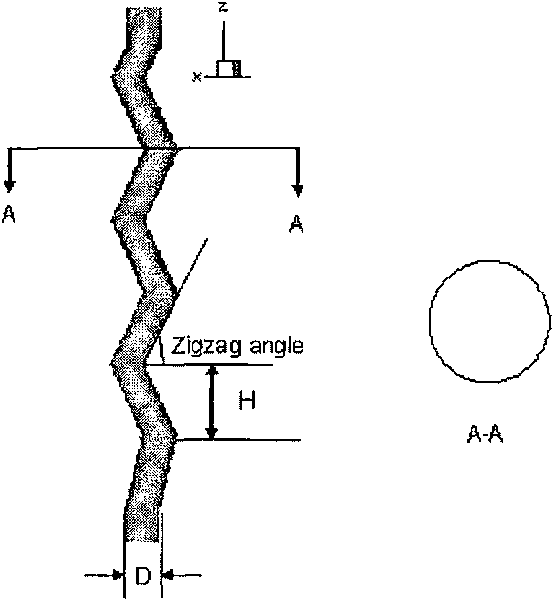

[0031] The cross-sectional shape of the S-type fluidized bed of the present invention is preferably a circle or a square, and may also be an ellipse, a rectangle or other regular polygons.

[0032] When the section of the S-type fluidized bed of the present invention is a regular polygon, said inner wall is composed of sides of the polygon, wherein at least two symmetrical inner walls are wavy.

[0033] When the section of the S-type fluidized bed of the present invention is a circle or an ellipse, the symmetrical inner wall surface is wavy.

[0034] In all S-type fluidized beds, the wavy inner walls preferably appear in pairs symmetrically and parallel to each other.

[0035] see Figure 1-4 , The axial height (H) of the S-type fluidized bed of the present invention refers to the distance from the middle point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com