Continuous homogenizing mixing reactor

A technology for mixing reactors and containers, applied in the field of continuous homogeneous mixing reactors, can solve problems such as high requirements for preventing sedimentation and small concentration fluctuations, and achieve the effects of avoiding sedimentation or agglomeration, large production capacity, and saving production workshops.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

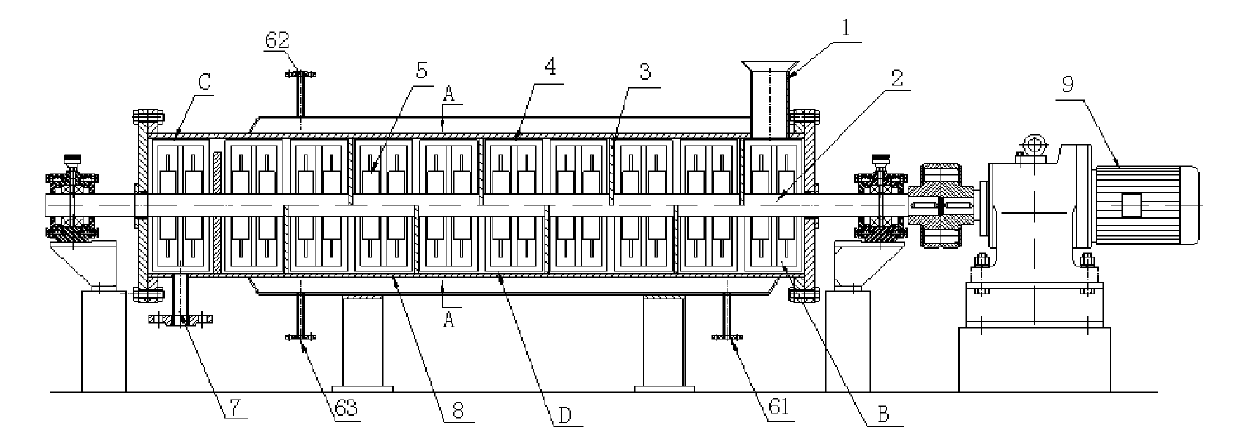

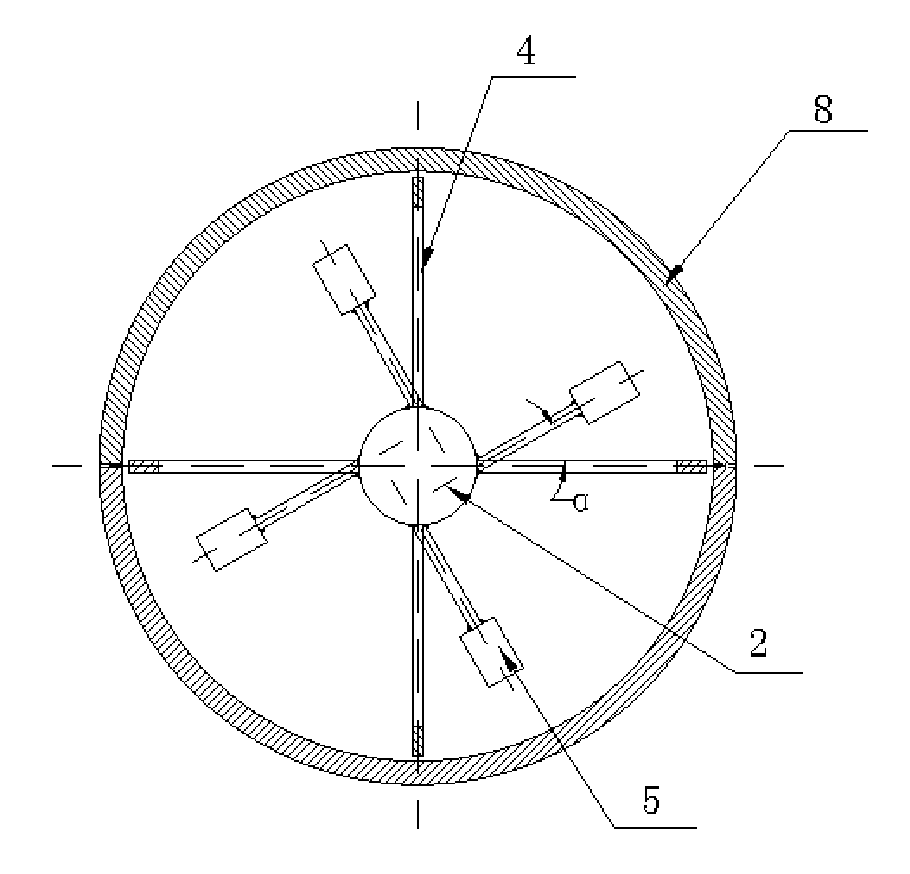

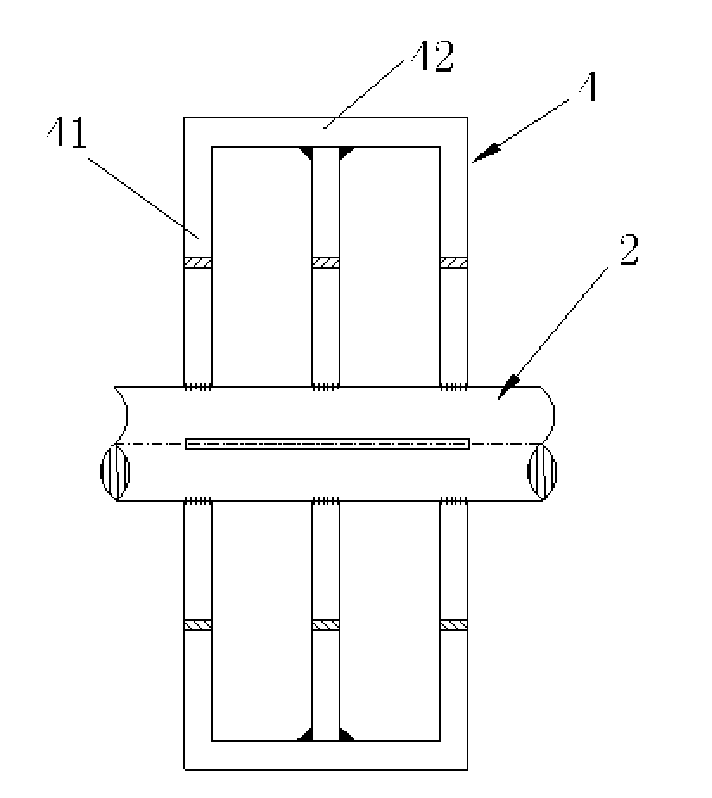

[0041] Examples of the present invention are Figure 1 to Figure 4 As shown, the mixing reactor in this embodiment is a horizontal continuous homogeneous mixing reactor, and the vertical continuous homogeneous mixing reactor is the same as this structure. The continuous homogeneous mixing reactor includes a cylindrical container 8, a mixing device arranged in the cylindrical container 8, a driving system connected to the mixing device, an electrical control system connected to the driving system, and a cylindrical container 8 is cylindrical, with a jacket 6 outside. The bottom and top of the jacket 6 are respectively provided with an inlet 61 and an outlet 62. The bottom of the jacket 6 is also provided with an emptying port 63, which can circulate heat or refrigerant. Used to heat or cool materials. A material inlet 1 is provided above a section of the cylindrical container 8 close to the drive system, and a material outlet 7 is provided below the other end.

[0042] On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com