Low-cost high-strength high-modulus cast magnesium alloy and preparation method thereof

A technology for casting magnesium alloy, high strength and high modulus, applied in the field of metal material magnesium alloy, can solve the problems of high cost and difficult composition control of high modulus rare earth magnesium alloy, achieve low cost, reduce lattice constant, ensure strength and The effect of toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

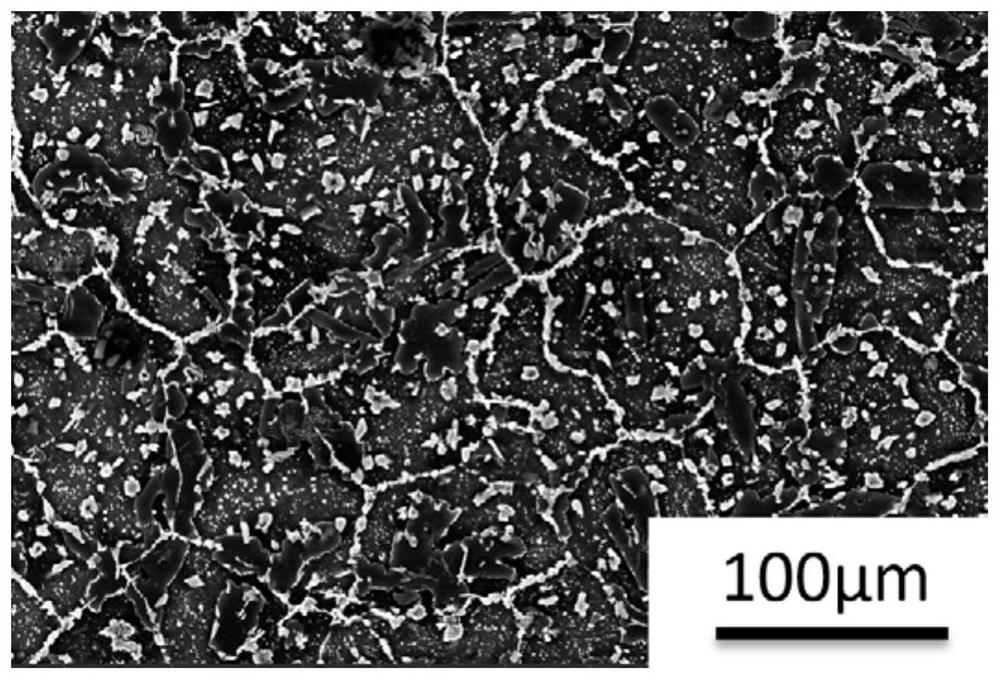

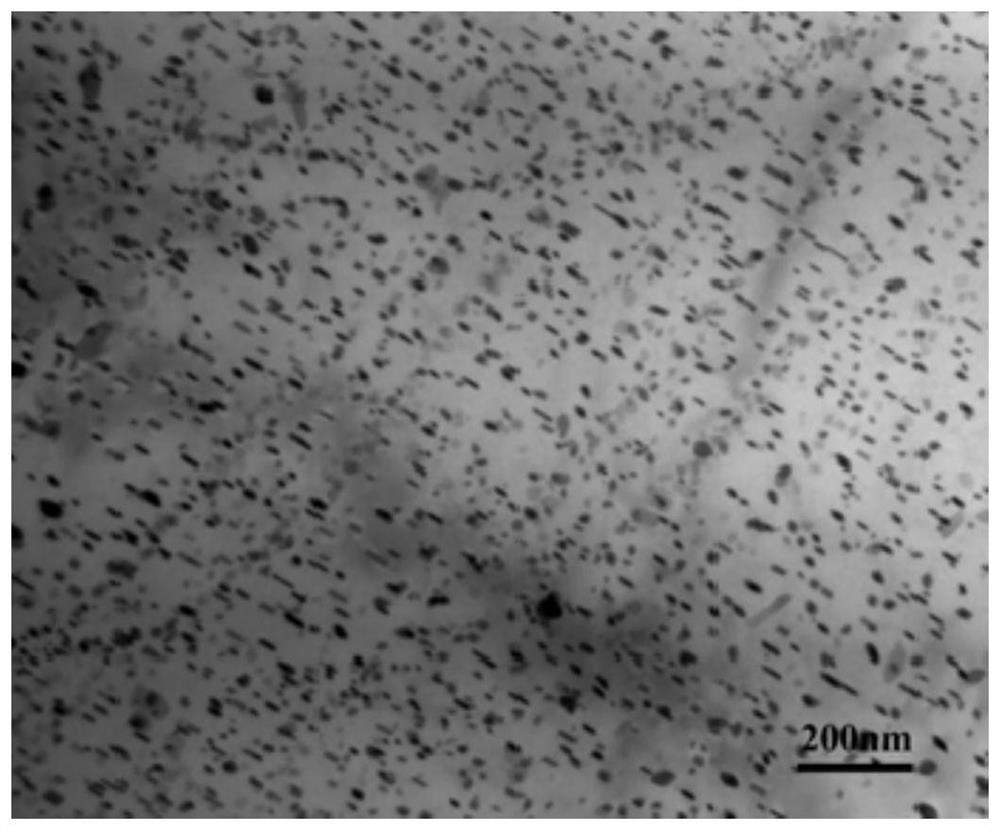

Image

Examples

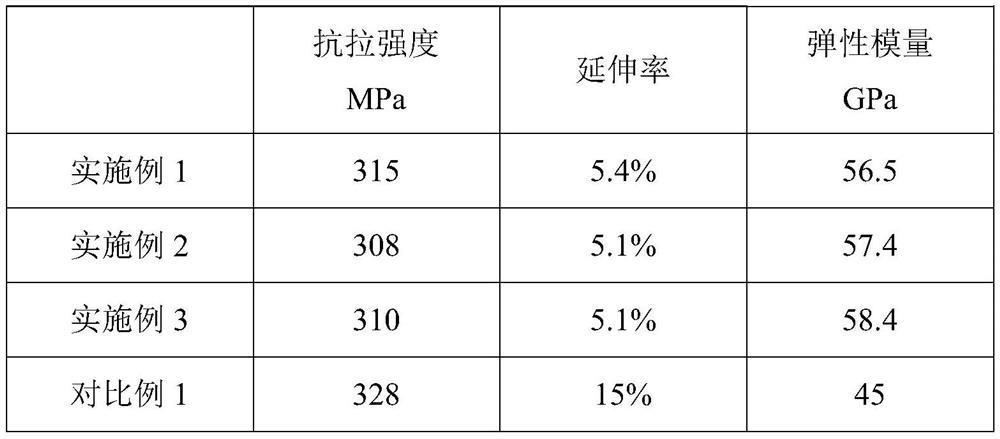

Embodiment 1

[0034] This embodiment provides a low-cost high-strength high-modulus cast magnesium alloy, which includes: 8.0% Zn, 7.0% li, 2.0% Al, 0.5% Mn, 0.5%. Cu, impurity element Fe 0.001%, impurity element Ni 0.0005%, and the remaining is Mg, i.e., the cast magnesium alloy is Mg-8Zn-7Li-2Al-0.5Cu-0.5 mn alloy.

[0035] The preparation method of the above MG-8ZN-7LI-2Al-0.5Cu-0.5Mn alloy includes:

[0036]S1: Pure Mg, Mg-20% li intermediate alloy, Mg-10% Mn intermediate alloy, pure Zn, pure Al and pure Cu bake at 150 ° C for 2 h;

[0037] S2: Pure Mg, Mg-20% li intermediate alloy, Mg-10% Mn MN, pure Zn, pure Al and pure Cu, in a vacuum sensitive smelting furnace crucible, and then the vacuum induction The smelting furnace crucible is placed in a vacuum inductive melting furnace. When the furnace is vacuum to the furnace, the vacuum is less than 1 Pa, and the furnace is charged with high purity argon to 0.4 atmospheric pressure, and then raise the vacuum to the furnace. The vacuum is less ...

Embodiment 2

[0046] This embodiment provides a low-cost high-strength high modulus cast magnesium alloy, and the difference from the first embodiment is that Cu is not included in the cast magnesium alloy of the present embodiment, and the total weight of the cast magnesium alloy. The cast magnesium alloy includes: 8.0% Zn, 7.0% li, 2.0% Al, 0.5% Mn, impurity element Fe 0.0009%, impurity element Ni 0.0004%, and the rest is Mg.

Embodiment 3

[0048] This embodiment provides a low-cost high-strength high modulus cast magnesium alloy, which includes: 7.0% Zn, 8.0% li, 4.0% Al, 0.5% Mn, impurity element. FE 0.0008%, the impurity element Ni is 0.0006%, the remaining is Mg, ie the cast magnesium alloy is Mg-7Zn-8Li-4Al-0.5 mn alloy.

[0049] The preparation method of the above Mg-7ZN-8Li-4Al-0.5 mn alloy is only in:

[0050] S4: Rhymes to the refined temperature of 750 ° C for refinement 12min; after the refining treatment is completed, in a metal mold having a diameter of 100 mm at 710 ° C, the alloy ingot is obtained.

[0051] S5: The alloy ingot was first solidified at 360 ° C for 48 h, and was quenched at 90 ° C to room temperature; then at 75 ° C for 4 h, it continued to heat up to 175 ° C for 24 h, air cooling to The MG-7ZN-8LI-4Al-0.5 mn alloy was obtained at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com