Ellipsoidal porous-structured lithium manganate or nickel lithium manganate positive electrode material and preparation method thereof

A technology of lithium nickel manganese oxide and positive electrode materials, applied in the field of new energy materials, can solve the problems of large specific surface area, achieve the effect of reducing lattice constant, suppressing deformation, and improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

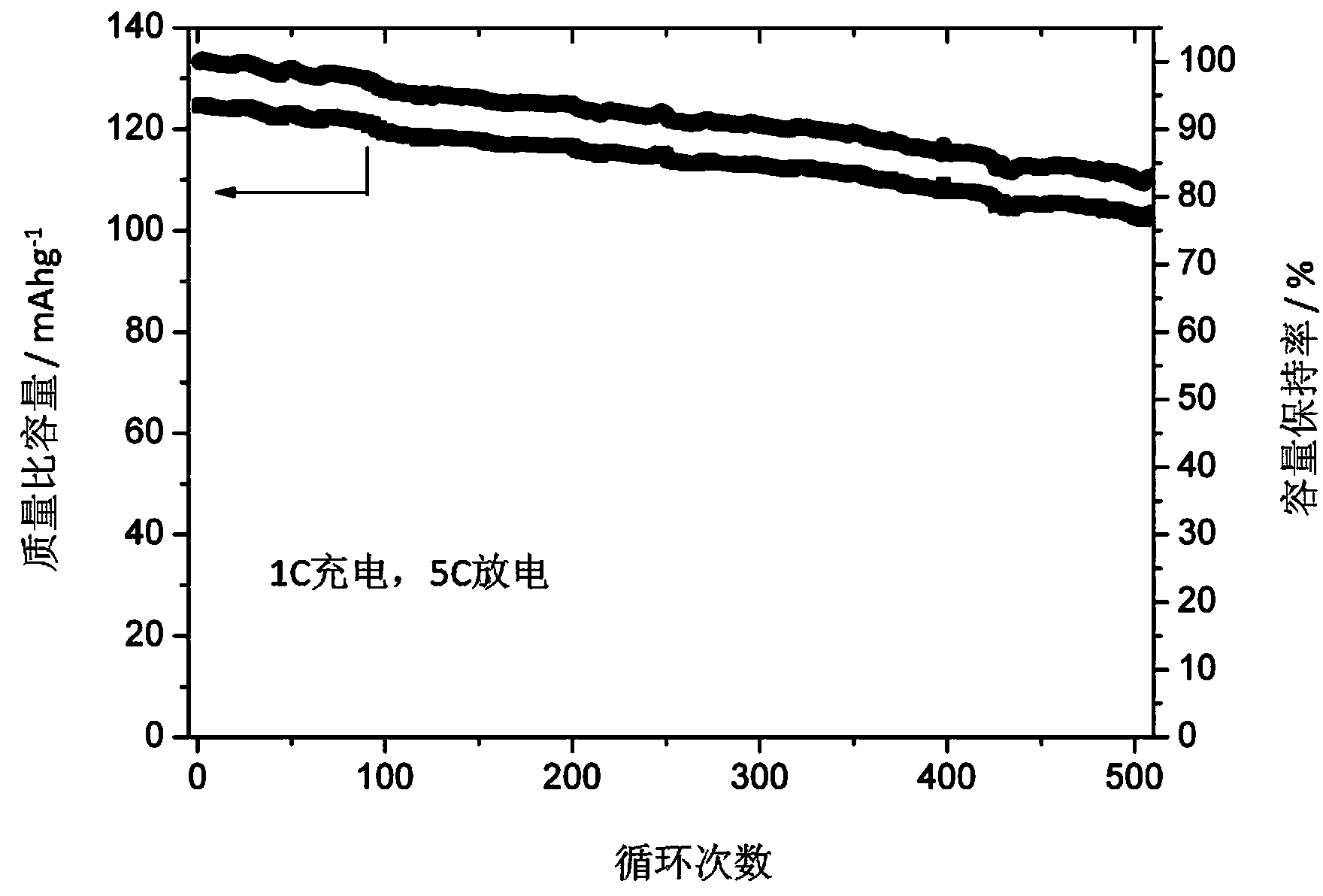

[0020] The ellipsoidal manganese carbonate was calcined at 350°C for 6 hours to obtain ellipsoidal manganese dioxide. Mix and dissolve 1.74g manganese dioxide and 0.44g lithium hydroxide monohydrate in 30g ethanol, stir evenly at room temperature, dry the alcohol after volatilization, and roast at 700°C for 20 hours to obtain porous ellipsoidal lithium manganate. After testing, the lithium manganate is porous ellipsoid, with a small amount of lumps, and the particle size is between 0.2 and 8 microns. Test results as a positive electrode material: Under the test conditions of 1C rate charge and 5C rate discharge, the initial discharge capacity is 60.3 mAh / g, and the capacity retention rate after 1000 cycles is 88.2%.

Embodiment 2

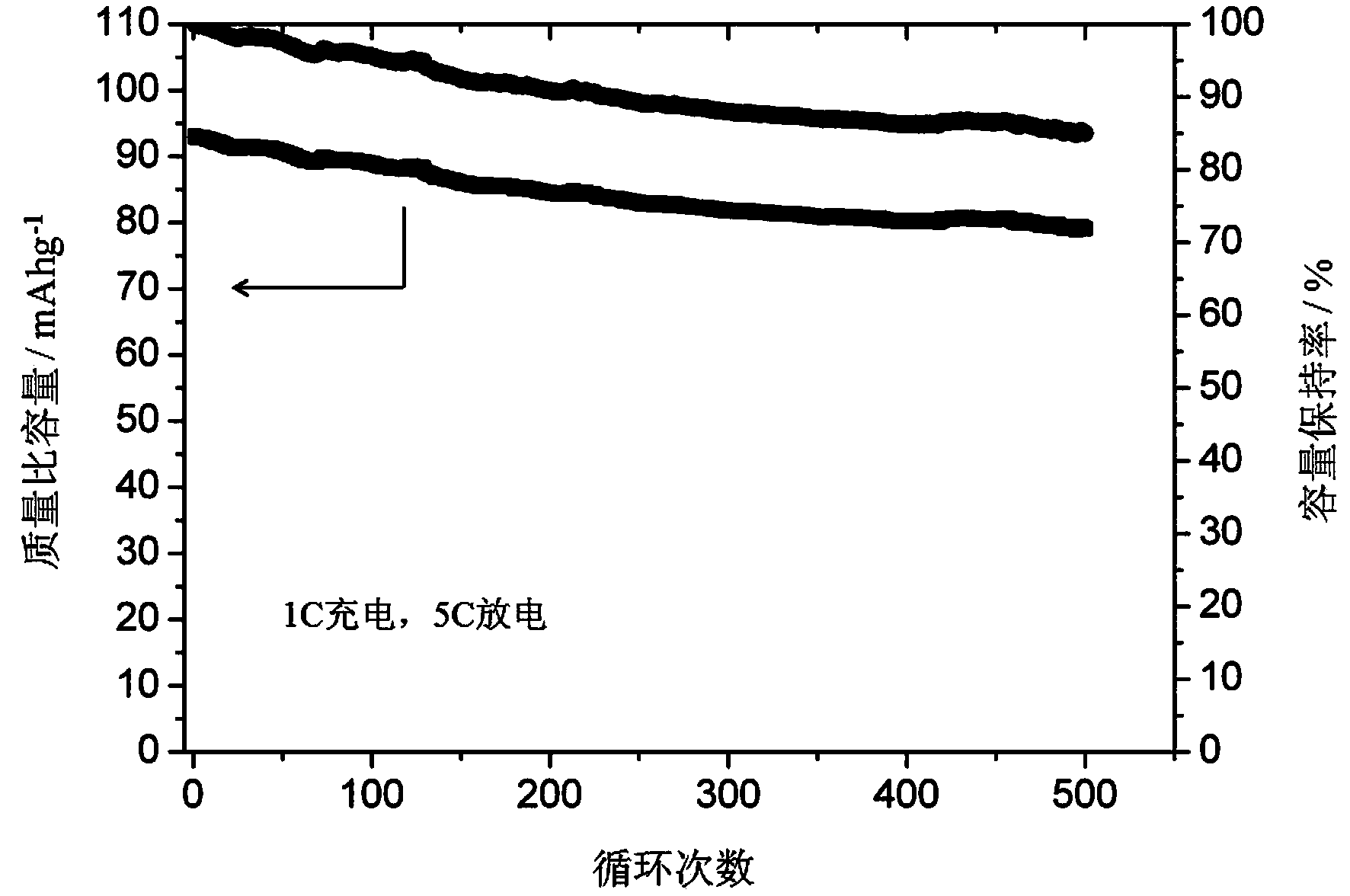

[0022] The ellipsoidal manganese carbonate was calcined at 300°C for 8 hours to obtain ellipsoidal manganese dioxide. Mix and dissolve 1.74g manganese dioxide and 0.44g lithium hydroxide monohydrate in 20g ethanol, stir evenly at room temperature with magnetic force, dry the alcohol after volatilization, and roast at 750°C for 10 hours to obtain porous ellipsoidal lithium manganate. After testing, the porous ellipsoidal lithium manganese oxide has a uniform shape and an average particle size of 3 microns. Test results as a positive electrode material: Under the test conditions of 1C rate charge and 5C rate discharge, the initial discharge capacity is 72.9 mAh / g, and the capacity retention rate after 500 cycles is 78.5%.

Embodiment 3

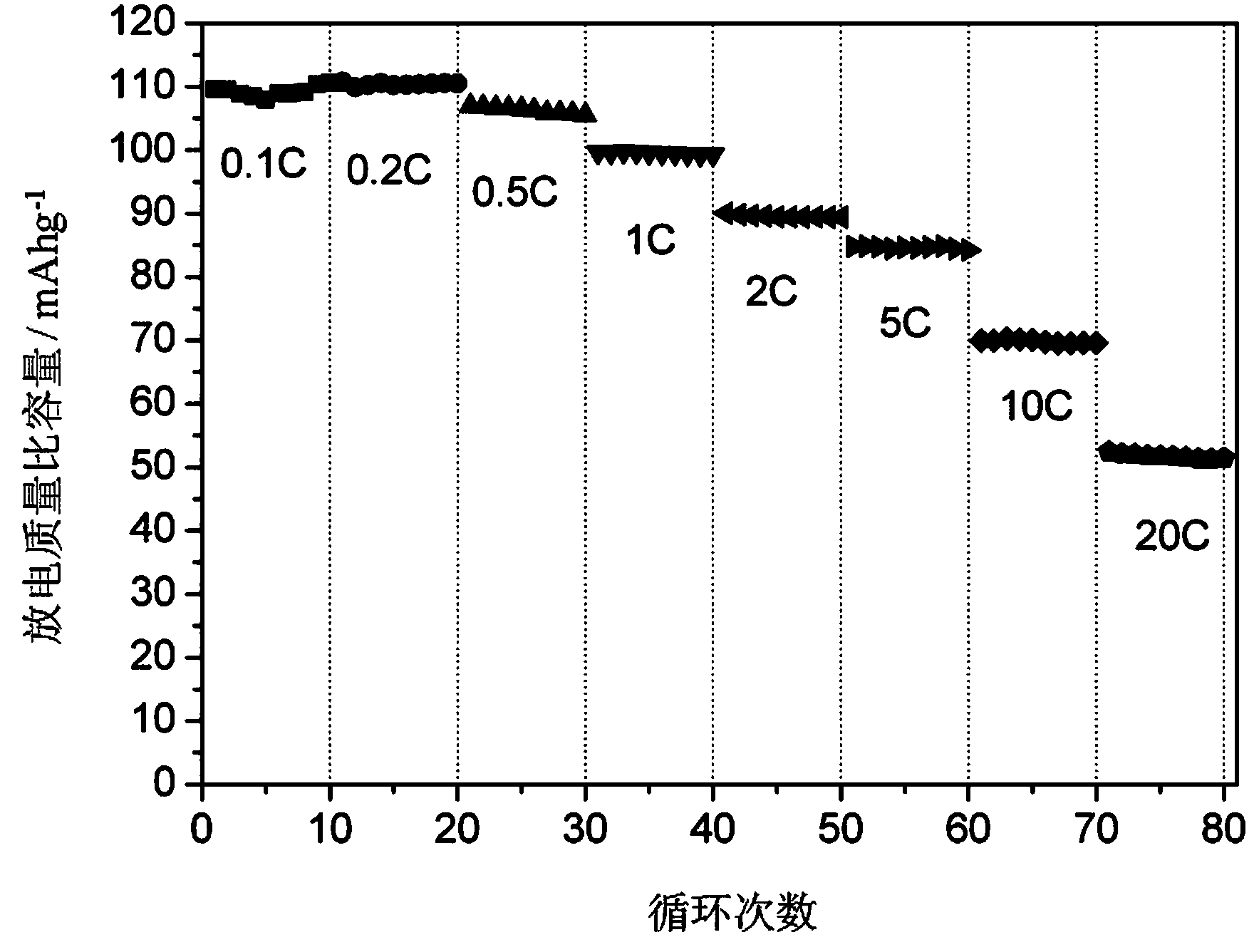

[0024] Roast rice-shaped manganese carbonate at 400°C for 4 hours to obtain ellipsoidal manganese dioxide. Mix and dissolve 1.74g manganese dioxide and 0.44g lithium hydroxide monohydrate in 20g ethanol, stir evenly at room temperature with magnetic force, dry the alcohol after volatilization, and roast at 800°C for 8 hours to obtain porous ellipsoidal lithium manganate. After testing, the lithium manganese oxide has a porous ellipsoid shape, uniform particle size distribution, and a particle size between 0.5 and 5 microns. As a positive electrode material test results: under the test conditions of 0.1C~20C rate charge and discharge, the 0.2C rate discharge capacity is 110.7 mAh / g, the 1C rate discharge capacity is 99.8 mAh / g, and the 5C rate discharge capacity is 84.8 mAh / g. The 10C rate discharge capacity is 70.3 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com