Ti-Nb-Mo-O series high-damp alloy and preparation method thereof

A ti-nb-mo-o, high-damping alloy technology, applied in the field of high-damping alloys, can solve the problems of performance deterioration of other parts, deterioration of engine performance, fracture of fuselage materials, etc., to achieve good mechanical properties, enhance β phase Effects of stability, good damping characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

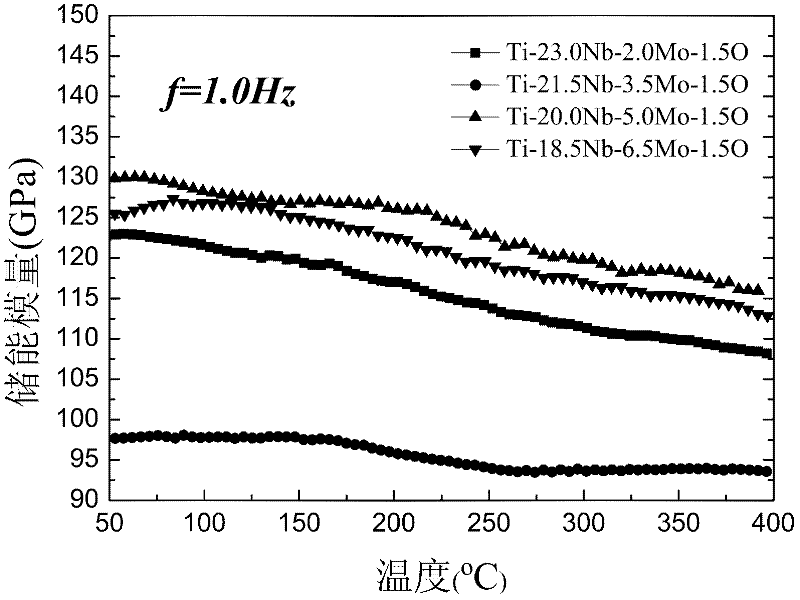

[0025] In order to provide good damping characteristics and mechanical properties, the present invention has taken the following measures:

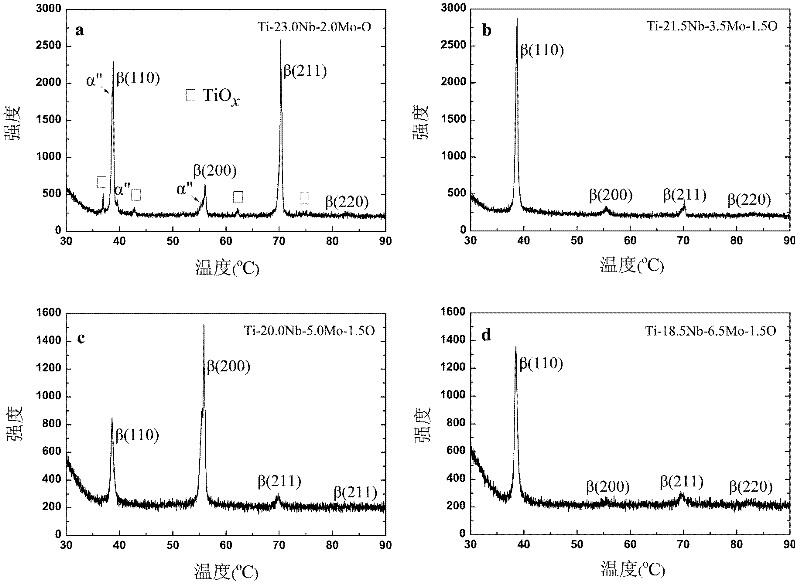

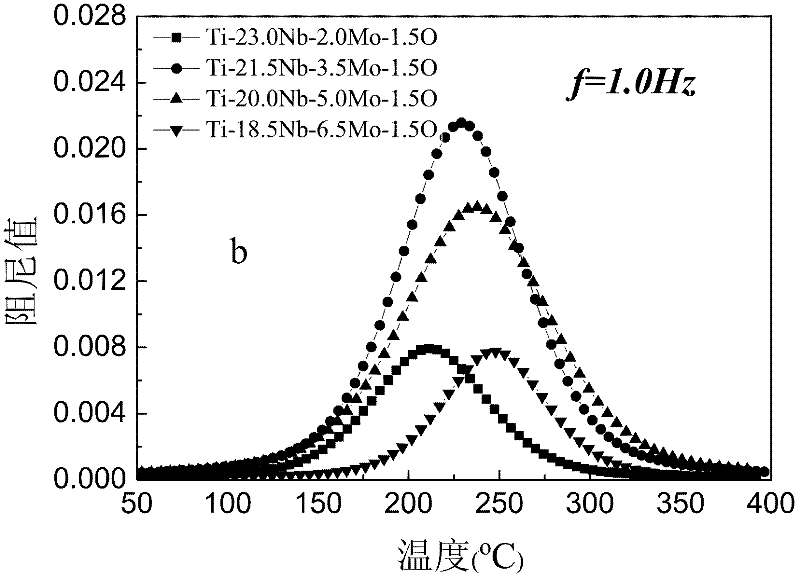

[0026] (1) Nb and Mo are β-phase stabilizing elements. The addition of Nb and Mo elements can significantly improve the stability of β-phase in titanium alloys, inhibit the generation of α-phase and martensitic phase, and ensure that the oxygen atom diffusion process can be realized.

[0027] (2) Strictly control the content of Mo element - not less than 2.0at.%, not more than 10.0at.% (8.0at.% in the original text, but 10.0at.% in the claim), when the content of Mo element is too low , the β-phase stabilization effect is small, and has no obvious effect on the alloy phase composition; when the content of Mo element is high, because the atomic radius of Mo element is much smaller than the atomic radius of Ti and Nb elements, too much Mo will cause the lattice constant to become smaller. Oxygen atom diffusion process is hindered.

[0028]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com