TiZrMnFe quaternary getter alloy material and preparation method and application thereof

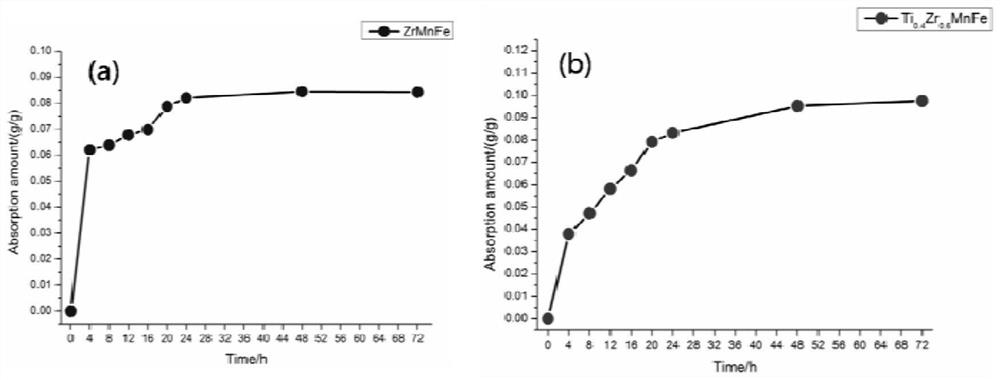

A technology of alloy materials and quaternary alloys, which is applied in the field of intermetallic compound getter materials, can solve the problems of single enhancement of getter performance such as stability, difficulty in determining the change of alloy structure composition, and long time of getter saturation. Achieve the effect of improving the adsorption rate and adsorption capacity, uniform alloy microstructure and high vacuum degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

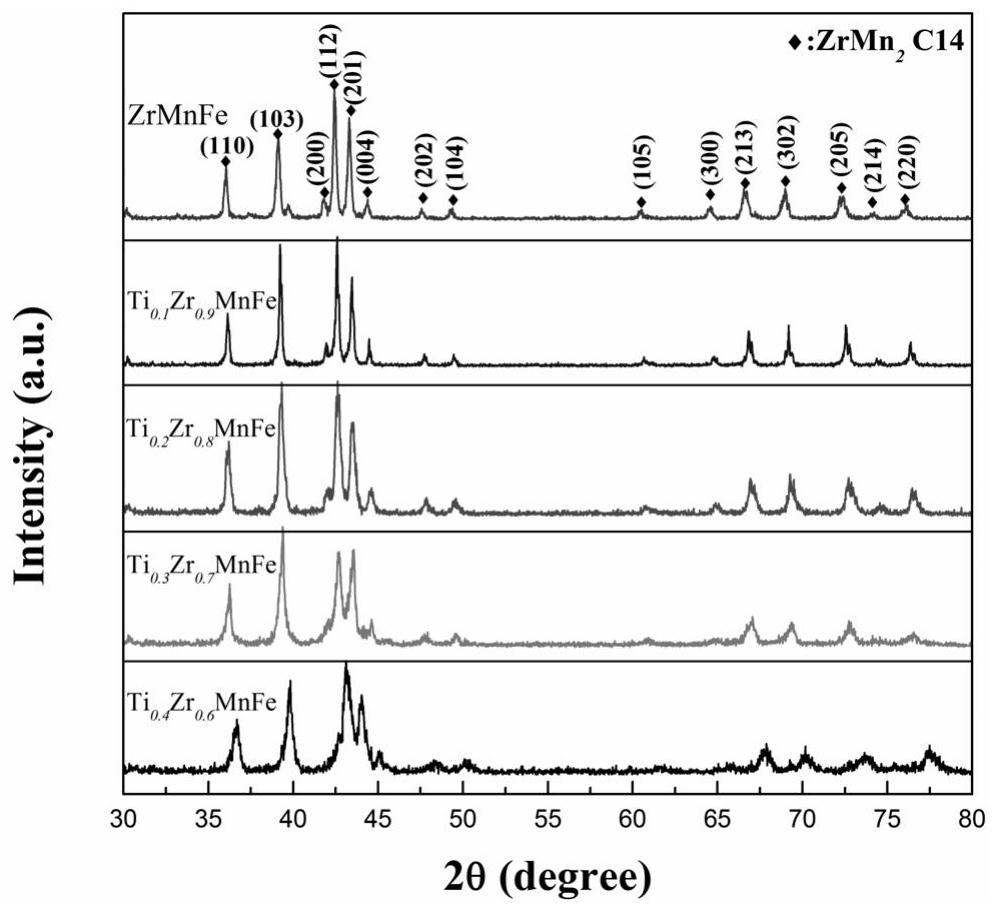

Embodiment 1

[0041] Weigh 12.1 g of high-purity titanium, 207.7 g of nuclear-grade pure zirconium, 164.0 g of electrolytic manganese, and 141.3 g of high-purity iron, polish the scale, ultrasonically clean and dry them, and seal them for future use. The sample is placed in a water-cooled copper crucible in a non-consumable vacuum arc melting furnace, ready for melting.

[0042] Pump the vacuum in the melting furnace to 5×10 -3 Pa, stop vacuuming, fill with 99.9% high-purity argon to 0.05MPa, and prepare for arc melting. During the arc melting process, the position of the arc torch is constantly adjusted to ensure uniform melting, and the alloy ingot is turned over 6 times to ensure the melting quality. After the smelting is completed, the sample is cooled and taken out to obtain a TiZrMnFe quaternary alloy ingot.

[0043] Put the alloy ingot into a high-temperature furnace, vacuumize and fill with argon, and anneal at 1000°C for 15h. After the annealing is completed, the alloy ingot is ...

Embodiment 2

[0048] 24.75 grams of high-purity titanium, 188.75 grams of nuclear-grade pure zirconium, 167.1 grams of electrolytic manganese, and 144.4 grams of high-purity iron were weighed, polished to scale, ultrasonically cleaned and dried, and sealed for future use. The sample is placed in a water-cooled copper crucible in a non-consumable vacuum arc melting furnace, ready for melting.

[0049] Pump the vacuum in the melting furnace to 5×10 -3 Pa, stop vacuuming, fill with 99.9% high-purity argon to 0.05MPa, and prepare for arc melting. During the arc melting process, the position of the arc torch is constantly adjusted to ensure uniform melting, and the alloy ingot is turned over 6 times to ensure the melting quality. After smelting, cool for about 1 hour, open the lid and take out the sample.

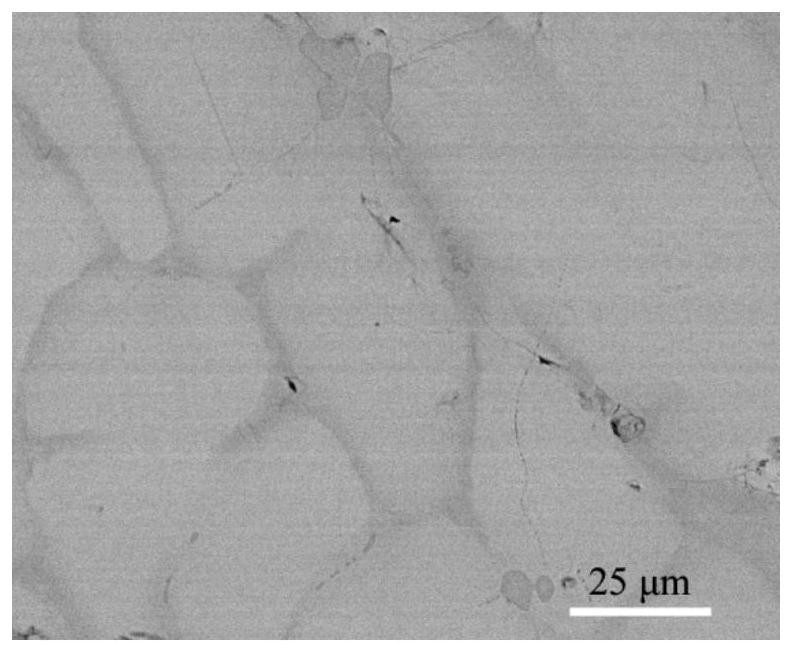

[0050] After the sample is broken, select the flat side, grind it flat on the pre-grinder at a low speed with alumina sandpaper, put it into the hot mounting machine to heat mount the sampl...

Embodiment 3

[0052] 38.0 grams of high-purity titanium, 168.95 grams of nuclear-grade zirconium, 170.35 grams of electrolytic manganese, and 147.7 grams of high-purity iron were weighed, polished to scale, ultrasonically cleaned and dried, and sealed for future use. The sample is placed in a water-cooled copper crucible in a non-consumable vacuum arc melting furnace, ready for melting.

[0053] Pump the vacuum in the melting furnace to 5×10 -3 Pa, stop vacuuming and fill with 99.9% high-purity argon to 0.05MPa, ready for arc melting. During the arc melting process, the position of the arc torch is constantly adjusted to ensure uniform melting, and the alloy ingot is turned over 6 times to ensure the melting quality. After smelting, cool for about 1 hour, open the lid and take out the sample.

[0054] After the sample was taken out, it was annealed at 1000°C for 18h under the protection of argon. After the annealing is completed, the sample is taken out, put into a vibrating crusher, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com