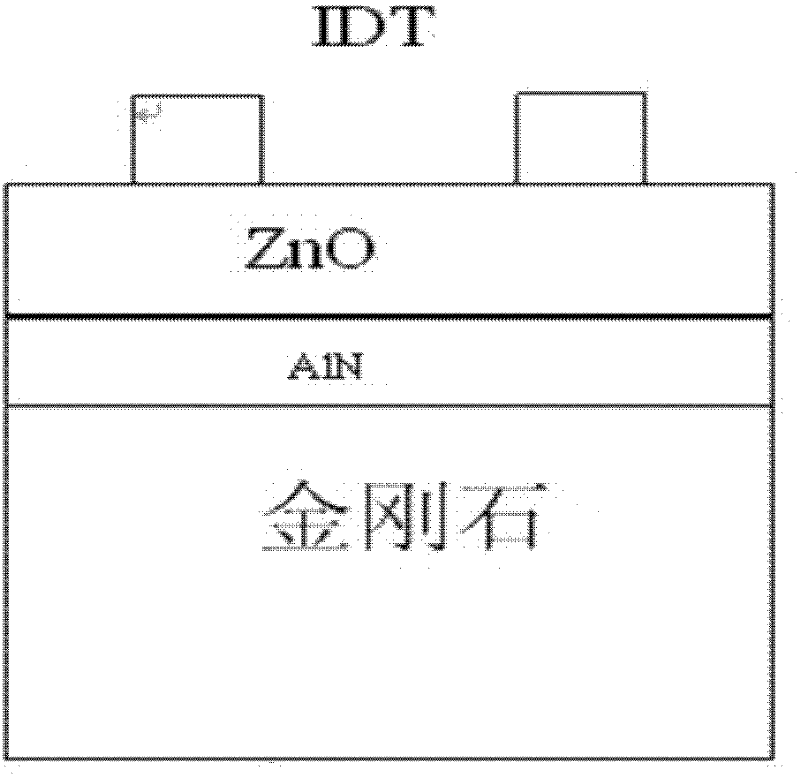

High frequency surface acoustic wave device with AlN (aluminum nitride) film as interlayer and preparation method thereof

A high-frequency surface acoustic wave and intermediate layer technology, applied in the direction of plating, coating, electrical components, etc. of superimposed layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The first step, the nano-diamond film substrate prepared by CVD method:

[0033] The technological parameter of adopting CVD method to prepare nano-diamond bottom layer is: carry out chemical vapor deposition in argon, hydrogen and methane mixed gas, the volume percent of argon, hydrogen and methane is 75%: 20%: 5%, mixing The gas flow is 500 sccm, the microwave power in the deposition chamber is 4500W, the pressure is 75Pa, the substrate temperature is 750°C, and the deposition time is 2 hours.

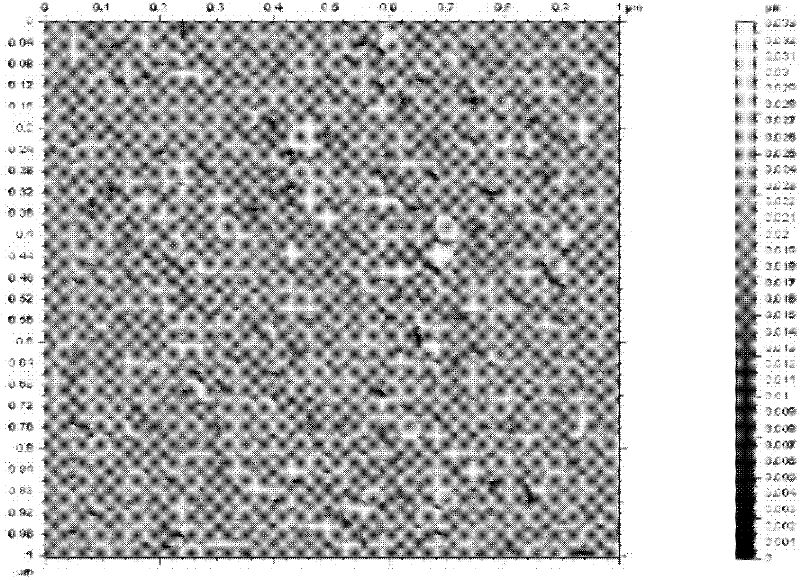

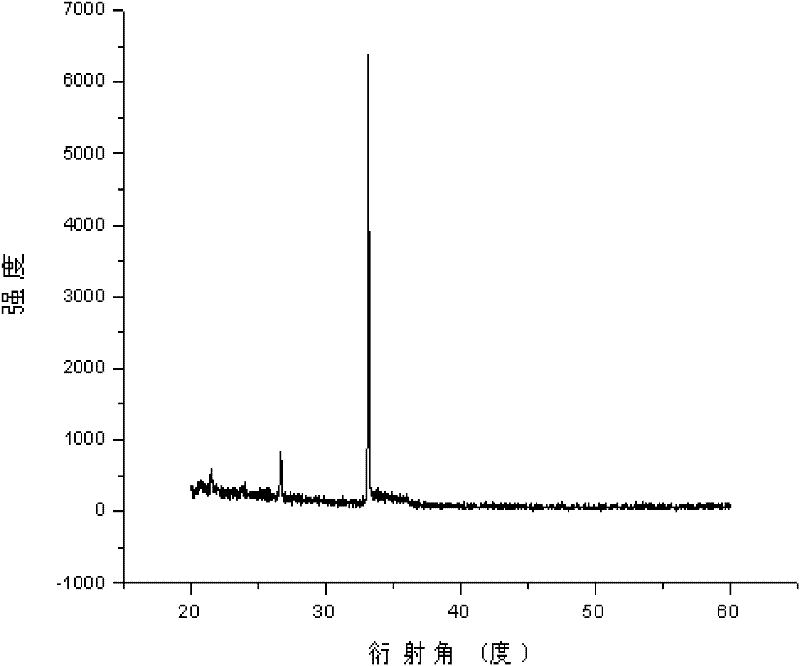

[0034] In the second step, in the high vacuum sputtering chamber, the Al target is used as the target material, and high vacuum magnetron sputtering is performed on the surface of the above-mentioned CVD diamond film terminated with hydrogen and mirror polished, and a layer of a-axis preferred orientation AlN is deposited and formed. Thin film, film thickness 0.30μm:

[0035]The reaction was carried out in a mixed gas of nitrogen and argon, the volume ratio of nitrogen and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com