Patents

Literature

61results about How to "Excellent frequency temperature characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS20070080611A1Improve featuresHigh crystallinityPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesRocking curveComposite film

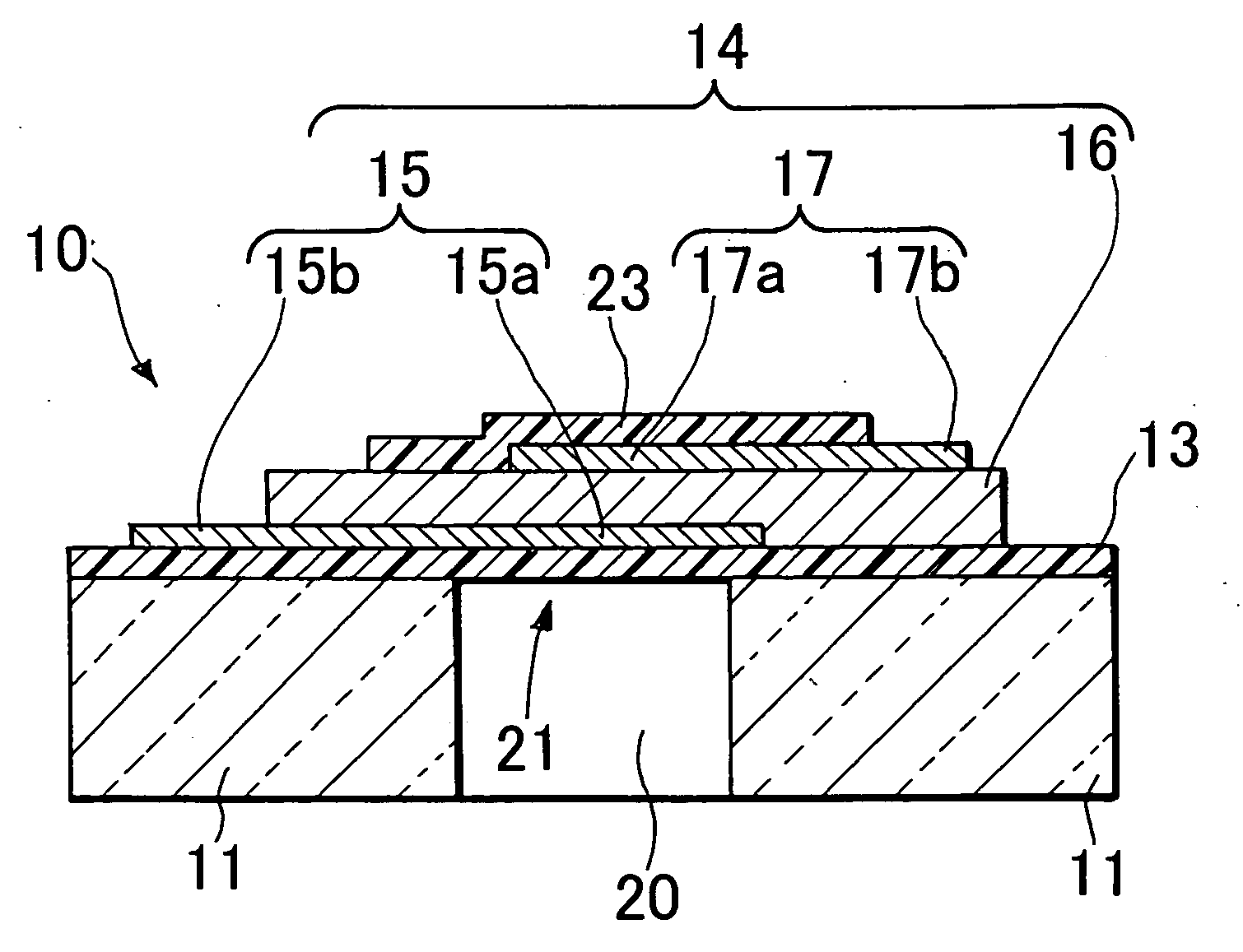

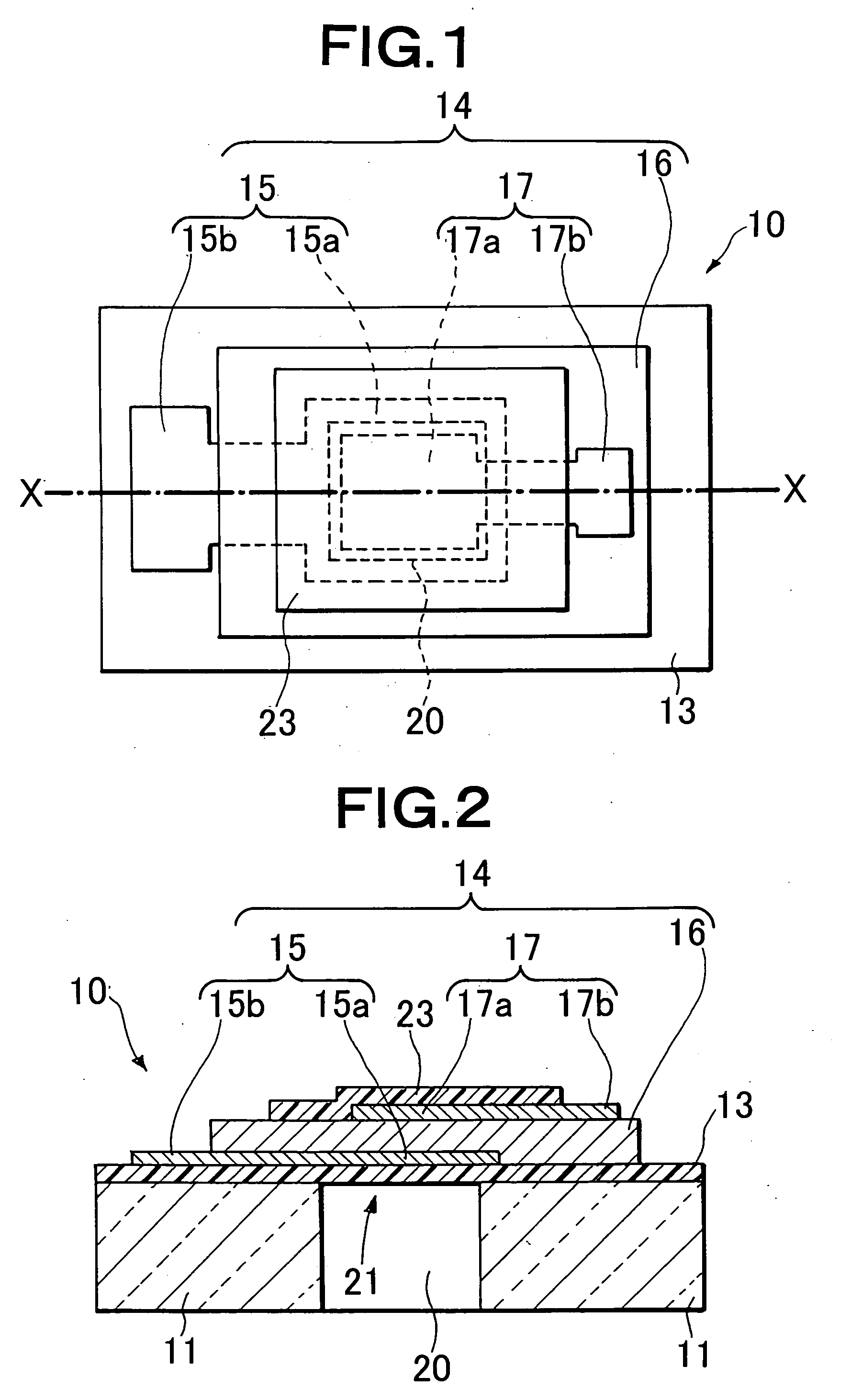

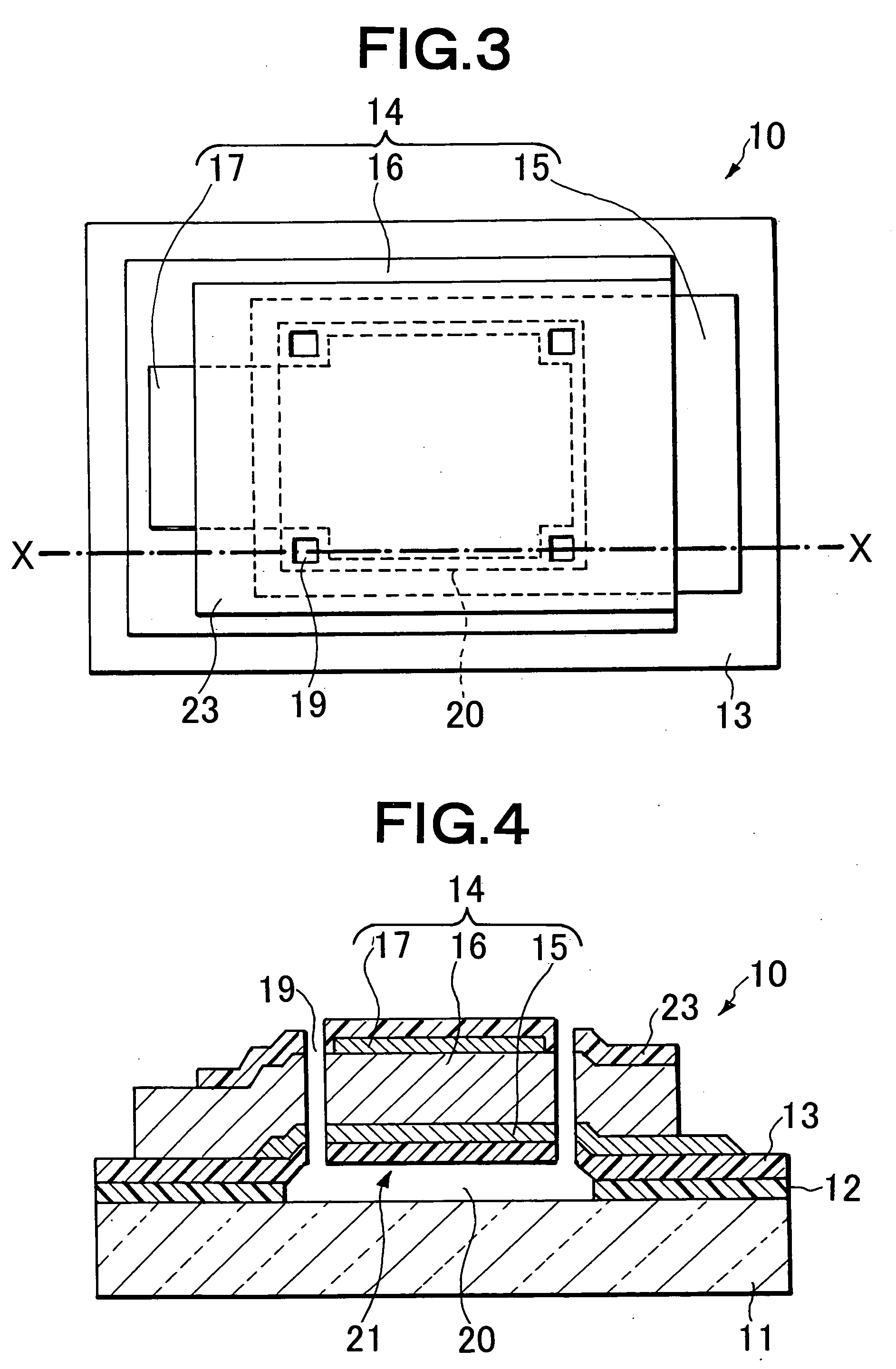

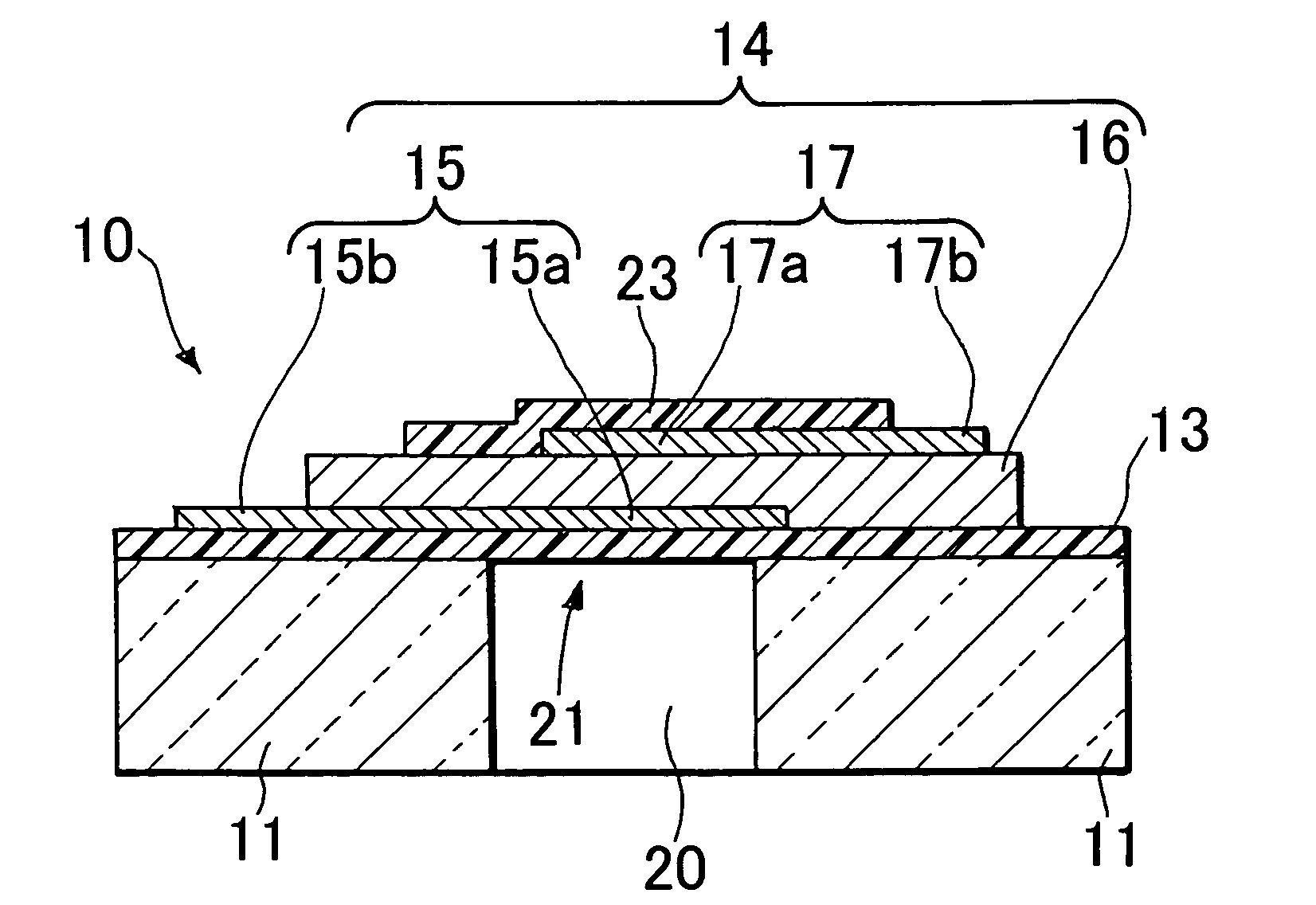

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

Aluminum nitride thin film, composite film containing the same and piezoelectric thin film resonator using the same

ActiveUS7482737B2Improvement factorImprove sound qualityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksRocking curveComposite film

A piezoelectric thin film resonator has a substrate and a piezoelectric layered structure including a lower electrode, piezoelectric aluminum nitride thin film with c-axis orientation and upper electrode formed on the substrate in this order. The lower electrode are made of a metal thin film including a layer containing ruthenium as a major component having a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of ruthenium of 3.0° or less. The piezoelectric aluminum nitride thin film formed on the lower electrode has a full-width half maximum (FWHM) of a rocking curve of a (0002) diffraction peak of 2.0° or less.

Owner:MEMS SOLUTIONS INC

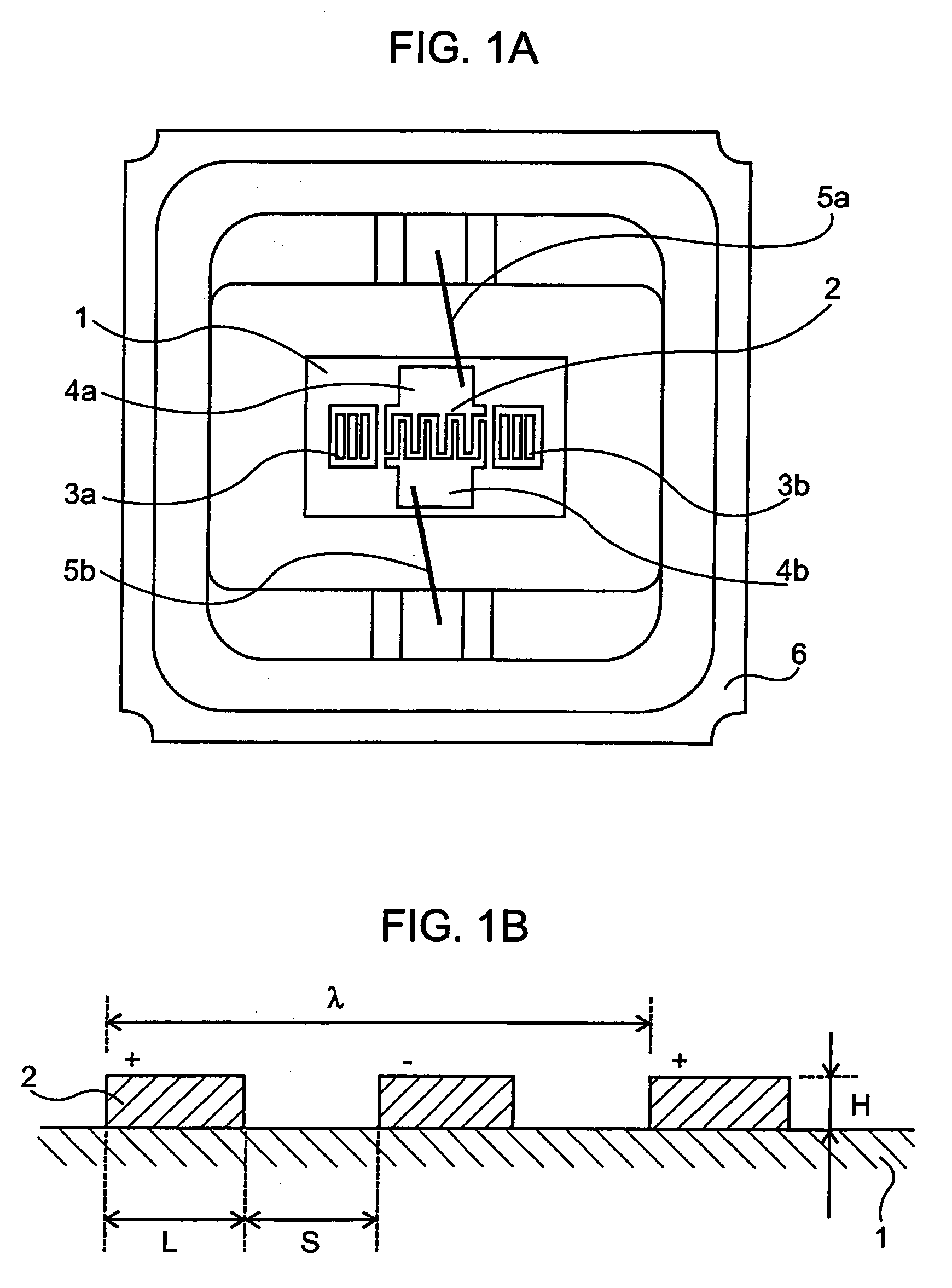

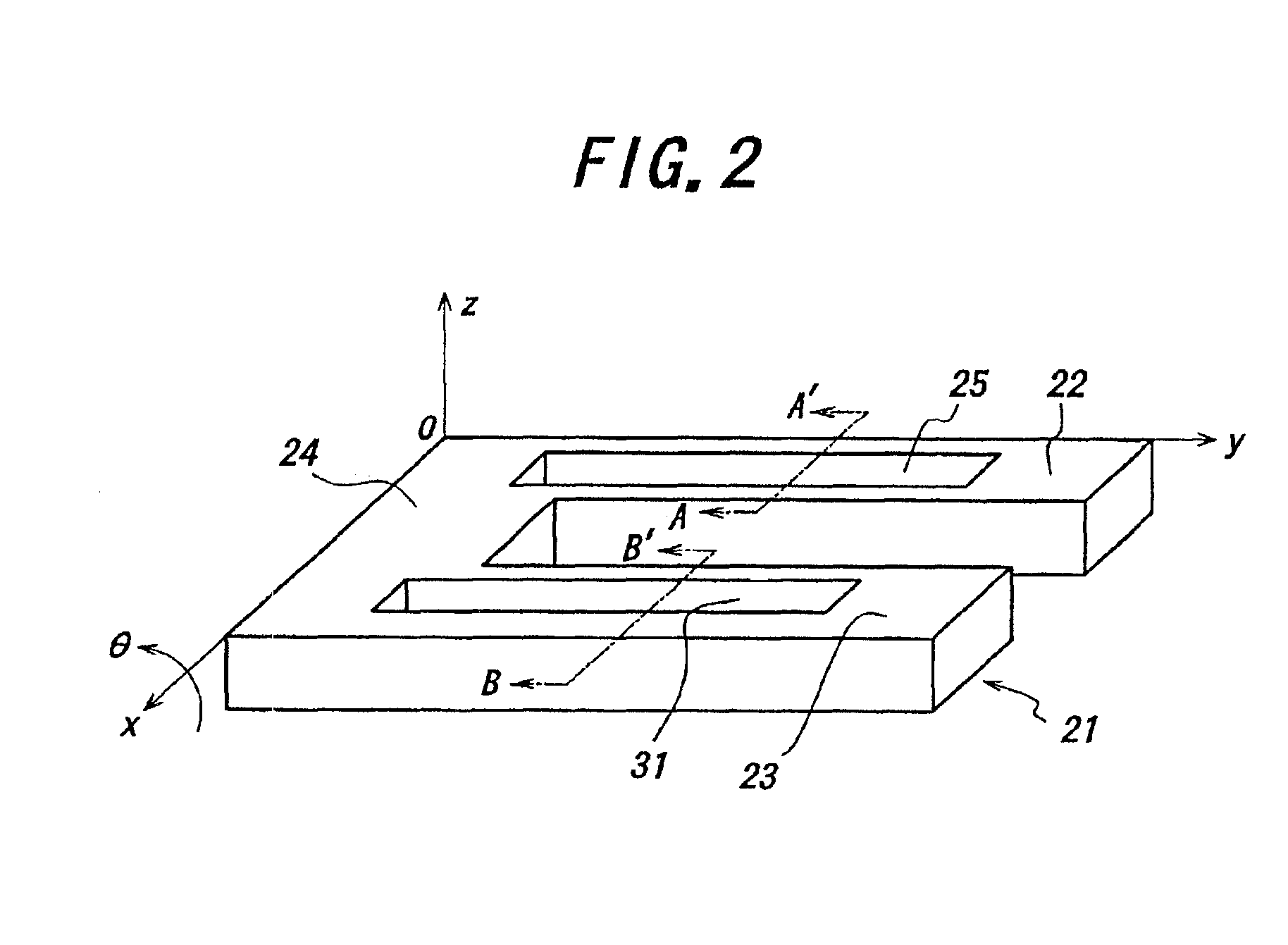

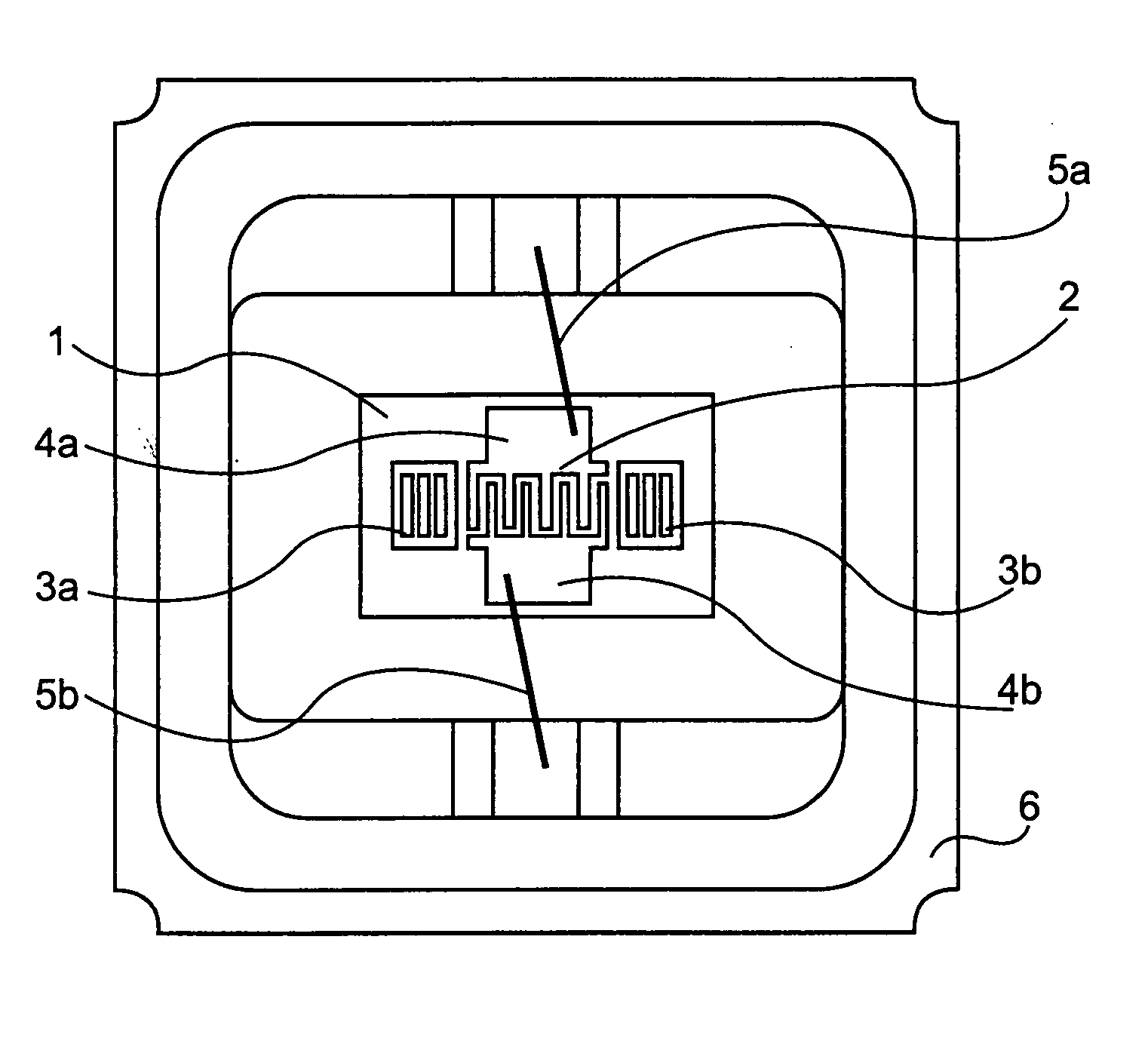

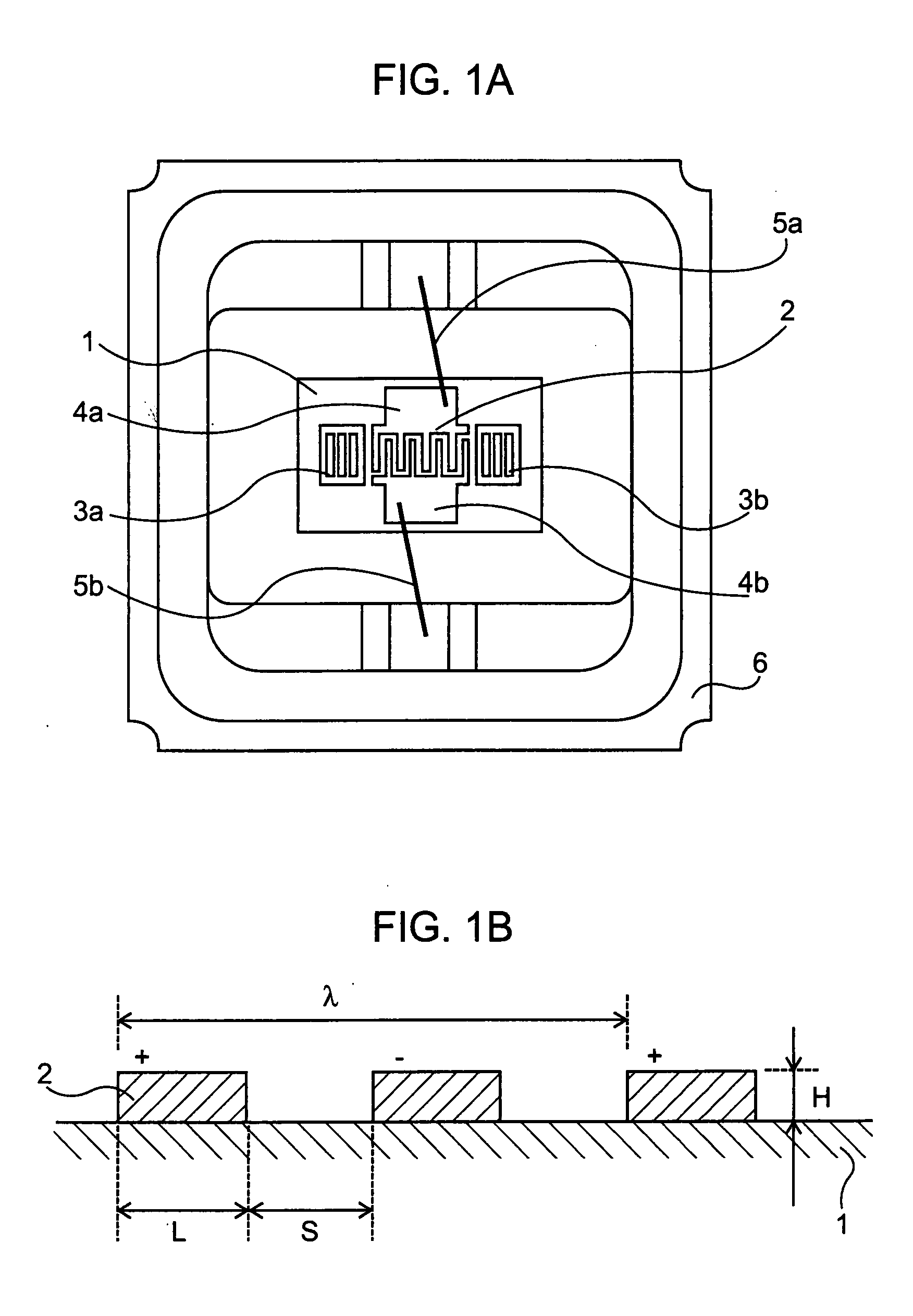

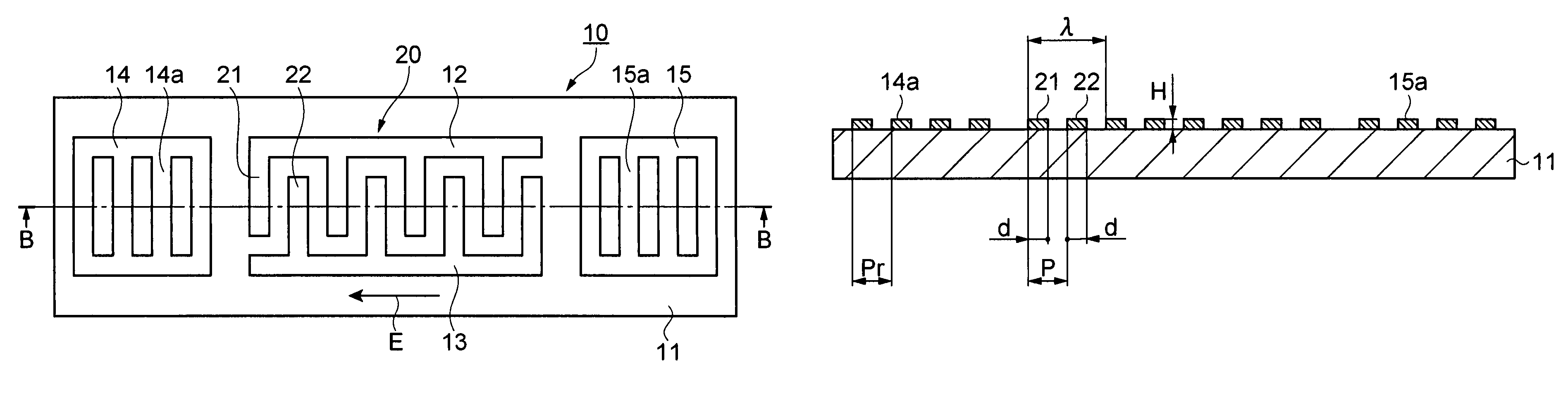

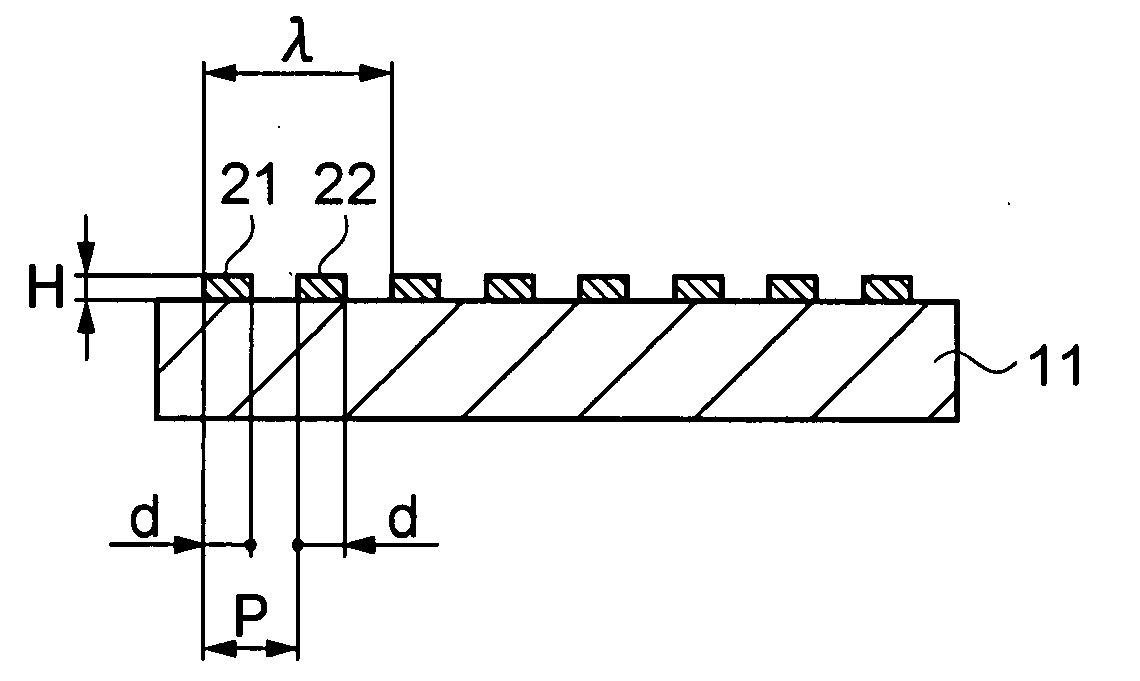

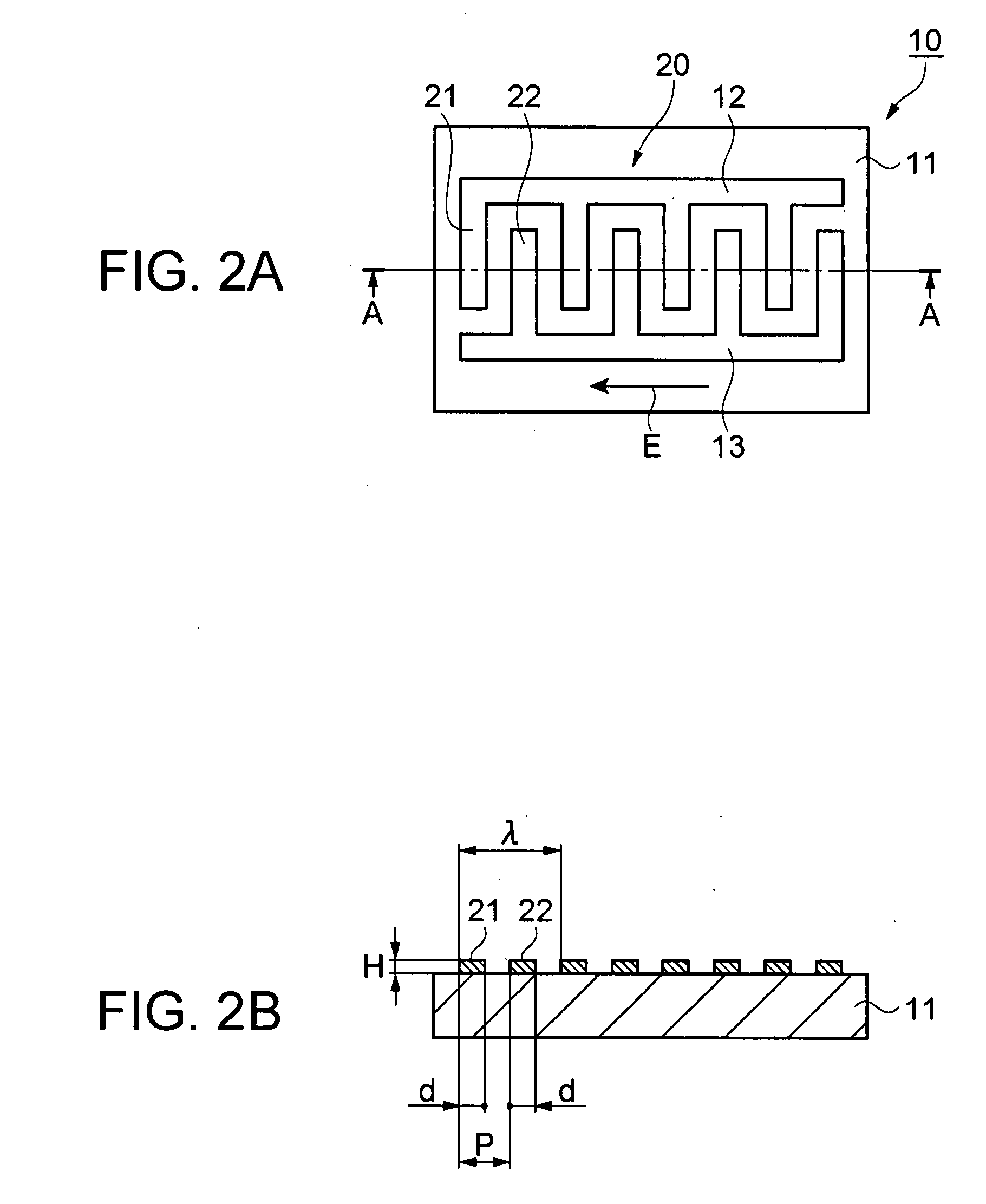

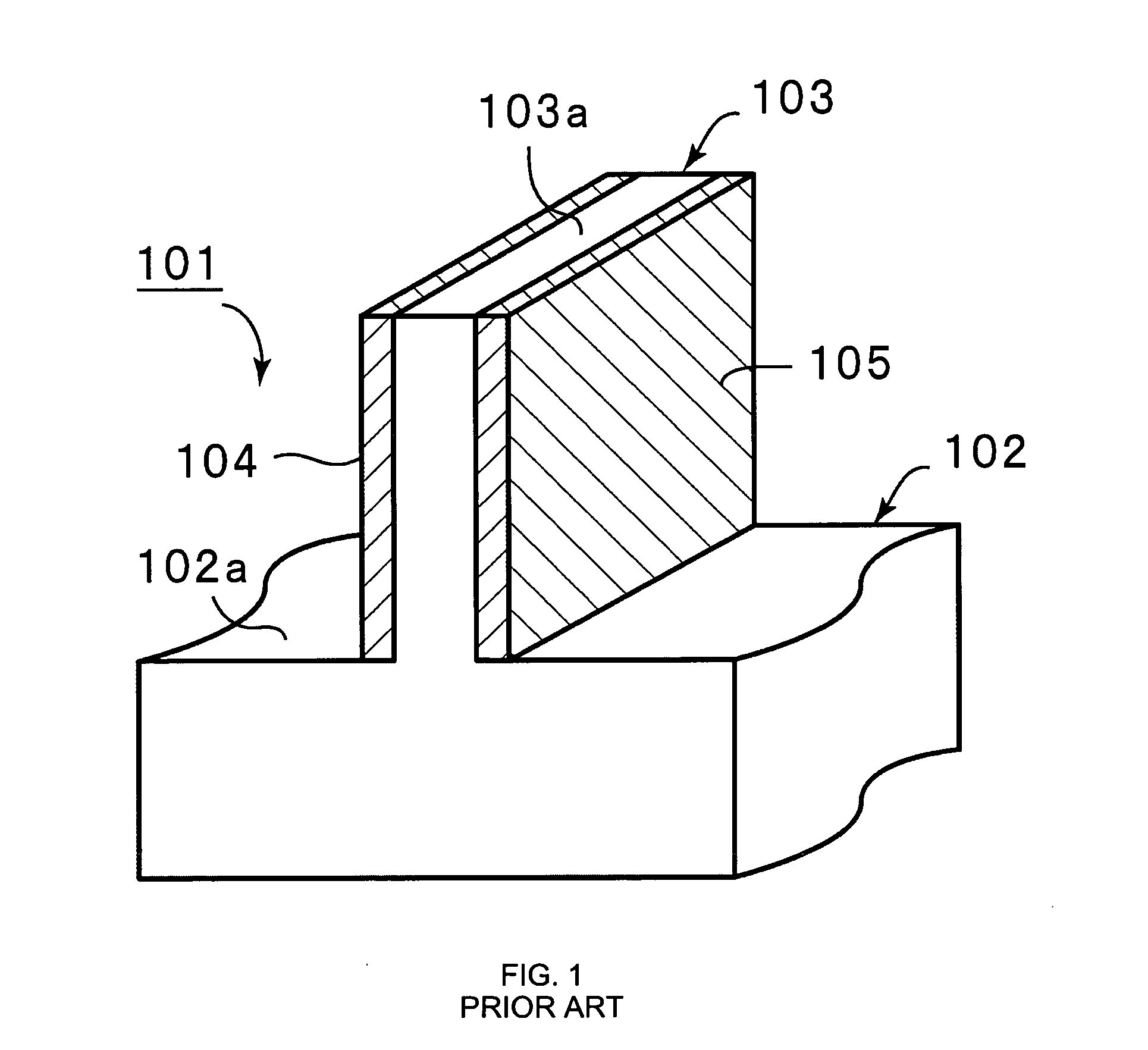

Surface acoustic wave device

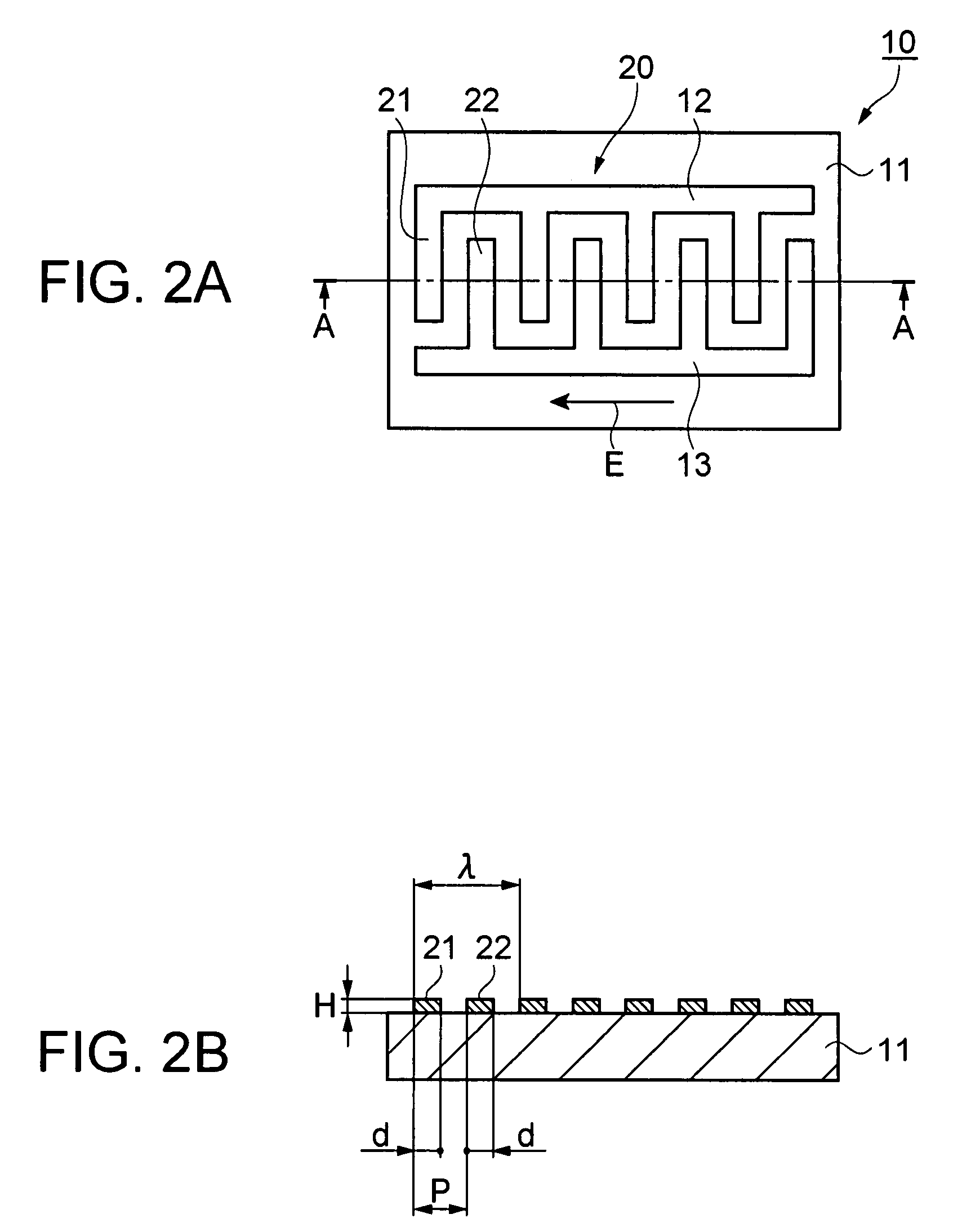

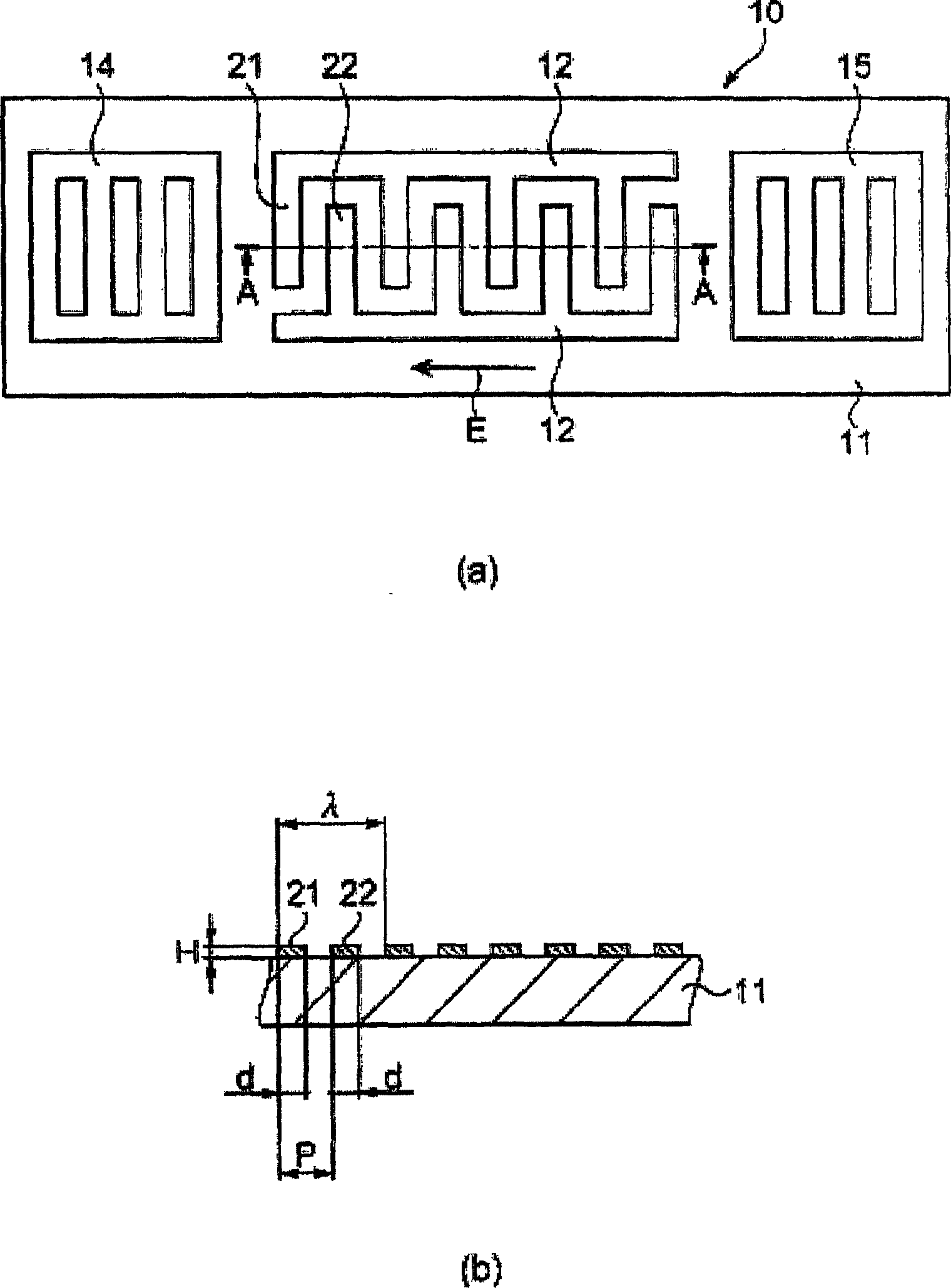

ActiveUS20060145568A1Improve control performanceSuppress frequency variationImpedence networksPiezoelectric/electrostriction/magnetostriction machinesPhysicsOccupancy rate

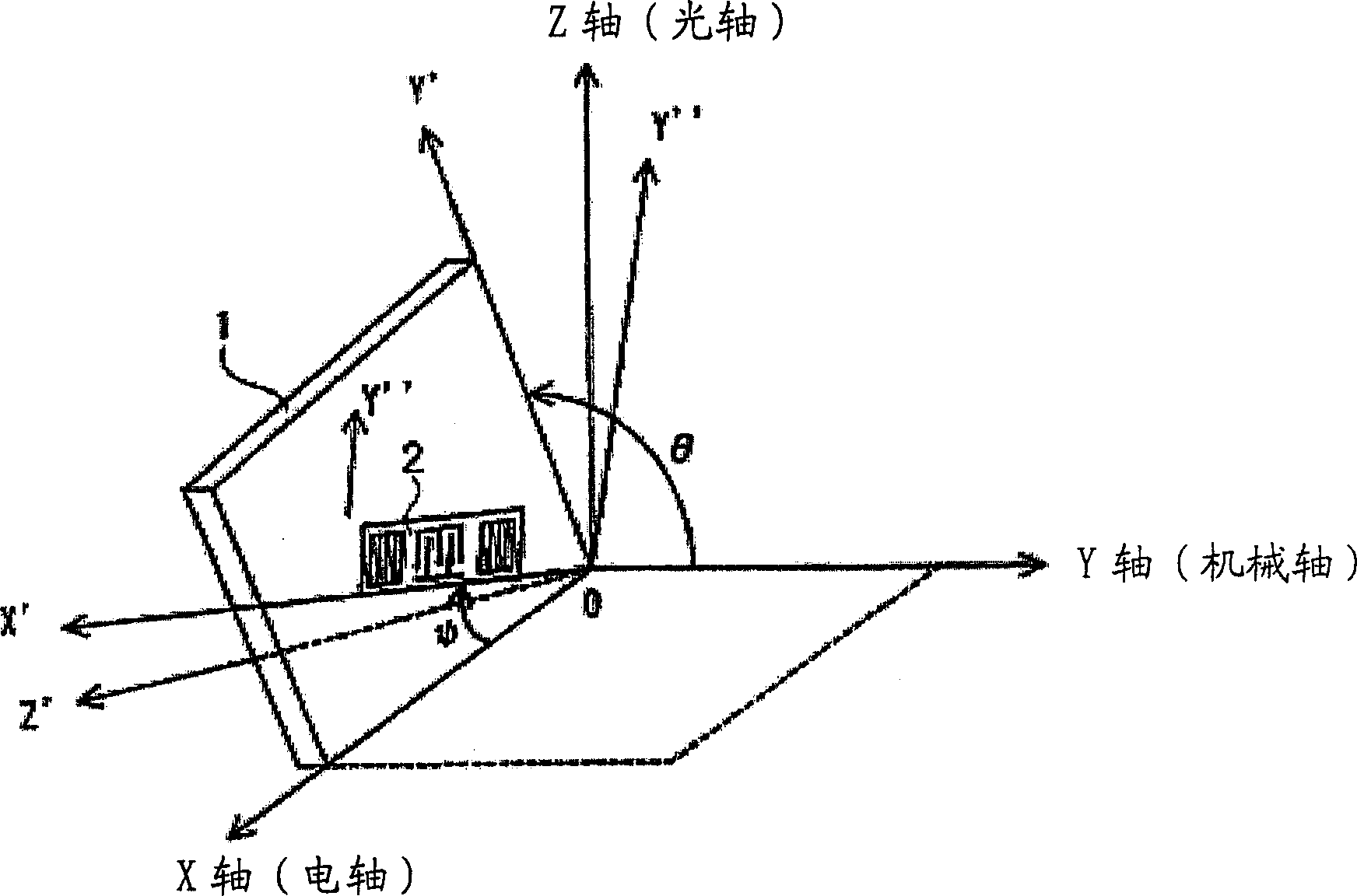

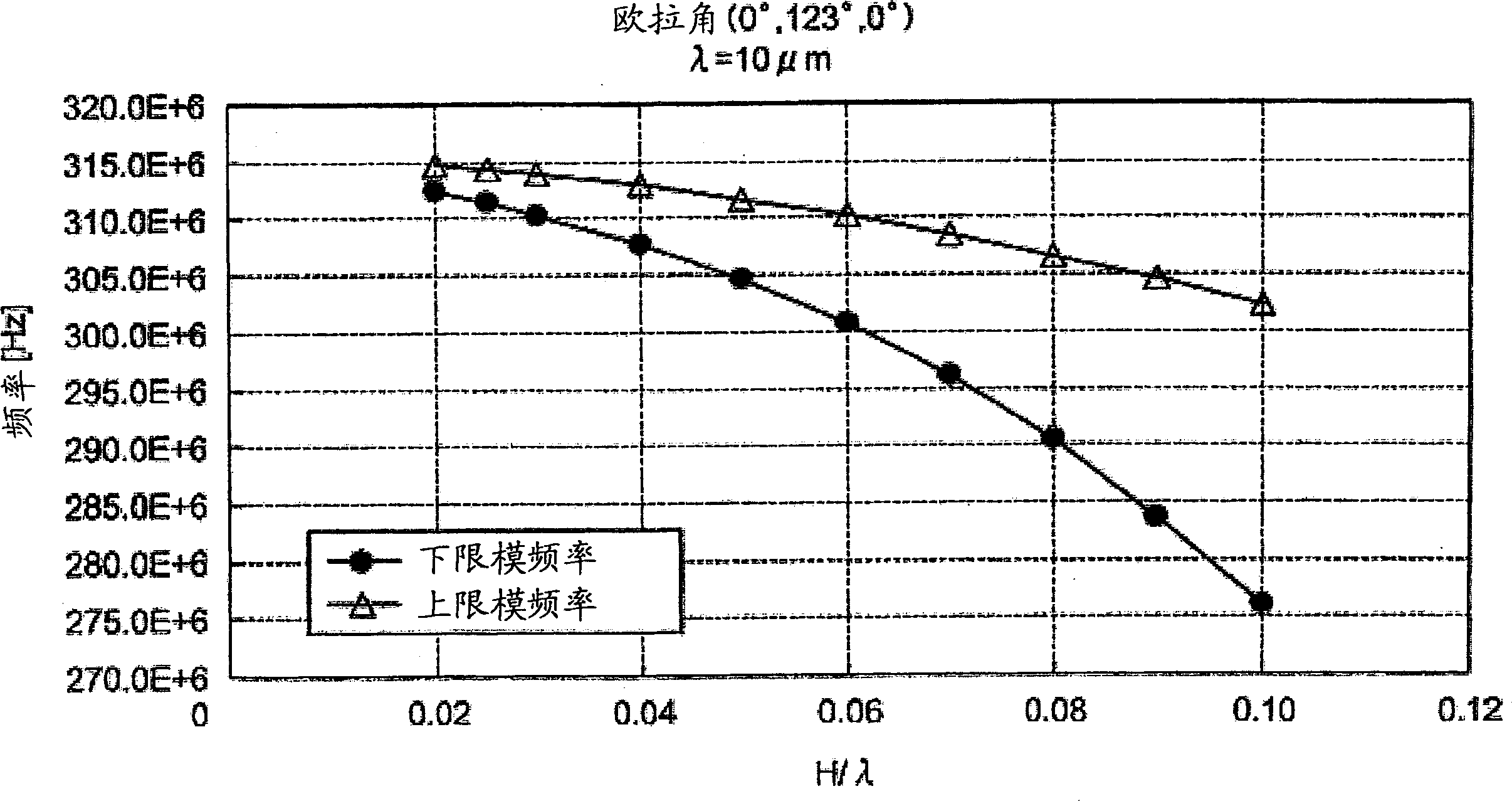

A surface acoustic wave device is provided. The surface acoustic wave device includes a piezoelectric substrate and an IDT which is disposed on the piezoelectric substrate and made of Al or an alloy containing Al as a main component and using an SH wave as an excitation wave, wherein the piezoelectric substrate is a rotated Y-cut quartz plate having a cut angle θ set to a range of −64.0°<θ<−49.3° rotated counterclockwise from a Z crystalline axis and a propagation direction of a surface acoustic wave set to a direction of 90°±5° with respect to an X crystalline axis, wherein, when a wavelength of an excited surface acoustic wave is denoted by λ, an electrode film thickness H / λ normalized with wavelength of the IDT is set to a range of 0.04<H / λ<0.12, and wherein, when a line occupancy rate mr of electrode fingers constituting the IDT is defined to be electrode finger width / (electrode finger width+electrode finger spacing), the line occupancy rate mr is set to a range of 0.53≦mr≦0.65.

Owner:SEIKO EPSON CORP

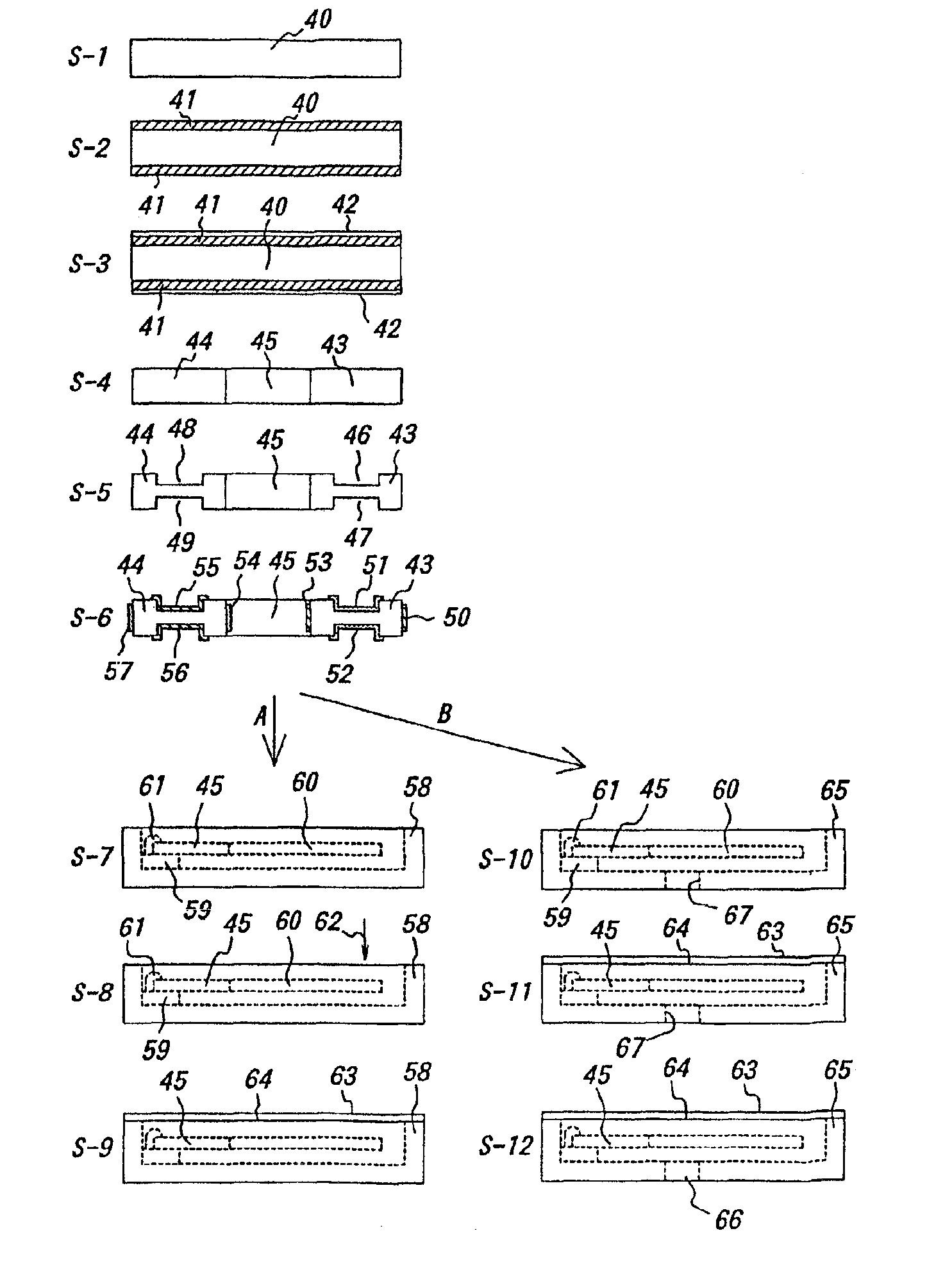

Method for manufacturing a quartz crystal unit

InactiveUS6898832B2Improve accuracyLow pricePrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyResonatorTuning fork

In a method for manufacturing a quartz crystal unit, a quartz crystal tuning fork resonator is formed by etching a quartz crystal wafer to form a quartz crystal tuning fork base, quartz crystal tuning fork tines connected to the quartz crystal tuning fork base, and a groove having stepped portions in at least one of opposite main surfaces of each of the quartz crystal tuning fork tines. A first electrode is disposed on at least one of the stepped portions of each of the grooves and a second electrode is disposed on each of side surfaces of each of the quartz crystal tuning fork tines. A frequency of oscillation of the quartz crystal tuning fork resonator is adjusted at least twice and in different steps. The quartz crystal tuning fork resonator is then mounted in a case and an open end of the case is covered with a lid.

Owner:PIEDEK TECHN LAB

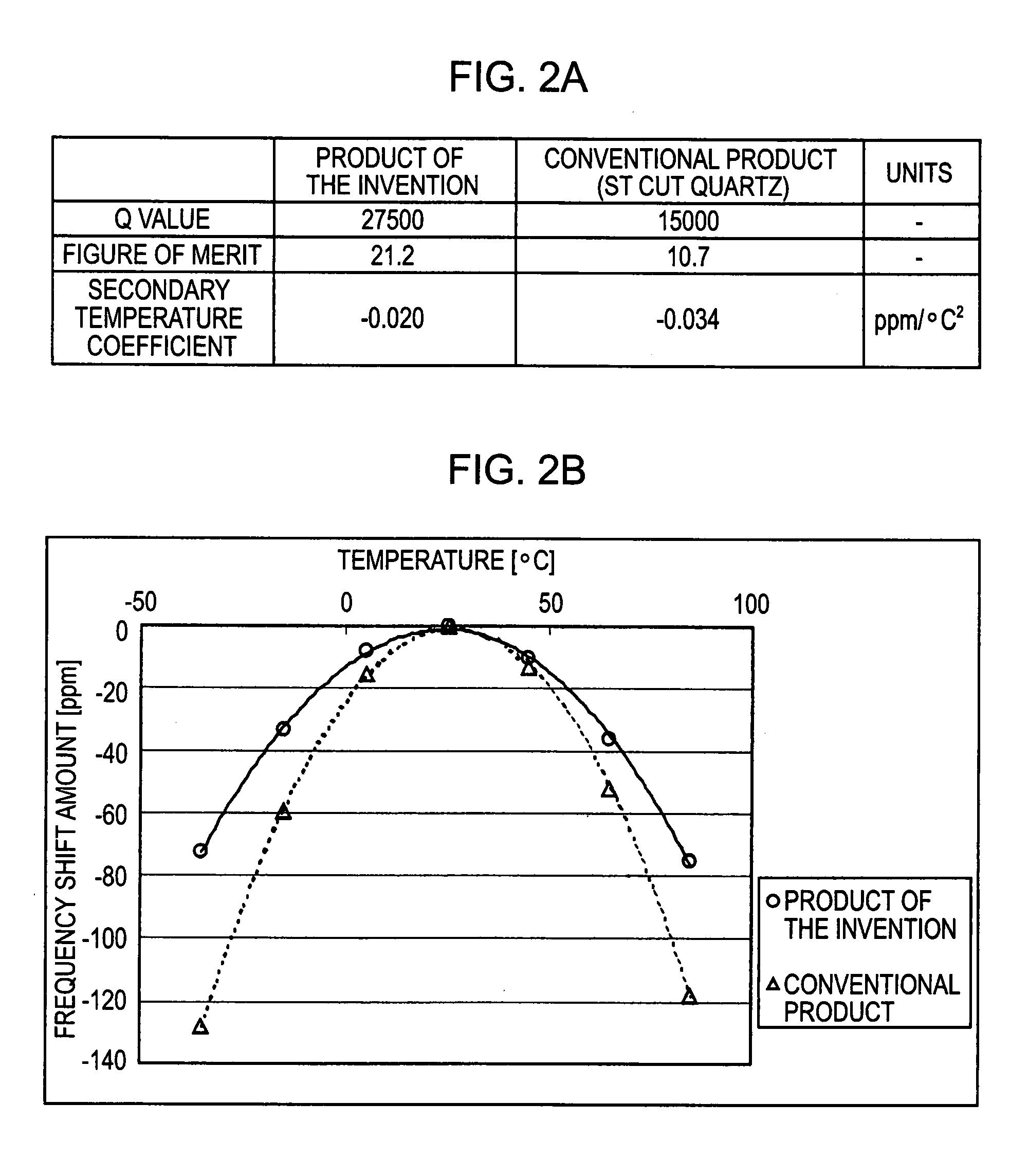

Surface acoustic wave device

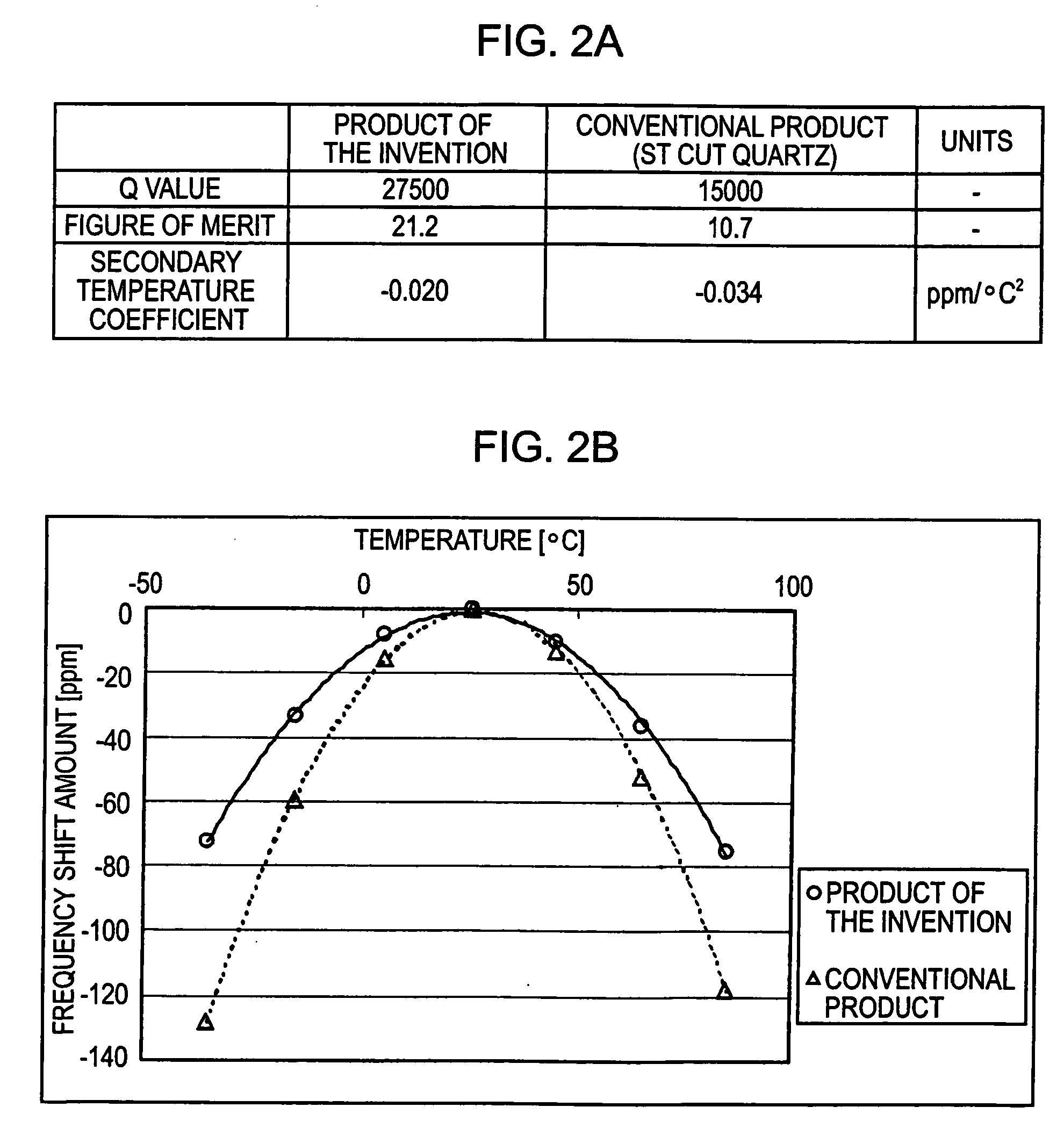

InactiveUS20080084134A1Small sizeHigh Q-valueImpedence networksPiezoelectric/electrostriction/magnetostriction machinesOccupancy rateAcoustic wave

A surface acoustic wave device is provided. The surface acoustic wave device includes a piezoelectric substrate and an IDT which is disposed on the piezoelectric substrate and made of Al or an alloy containing Al as a main component and using an SH wave as an excitation wave, wherein the piezoelectric substrate is a rotated Y-cut quartz plate having a cut angle θ set to a range of −64.0<θ<−49.3° rotated counterclockwise from a Z crystalline axis and a propagation direction of a surface acoustic wave set to a direction of 90°±5° with respect to an X crystalline axis, wherein, when a wavelength of an excited surface acoustic wave is denoted by λ, an electrode film thickness H / λ normalized with wavelength of the IDT is set to a range of 0.04<H / λ<0.12, and wherein, when a line occupancy rate mr of electrode fingers constituting the IDT is defined to be electrode finger width / (electrode finger width+electrode finger spacing), the line occupancy rate mr is set to a range of 0.53≦mr≦0.65.

Owner:TOYO TSUSHINKI

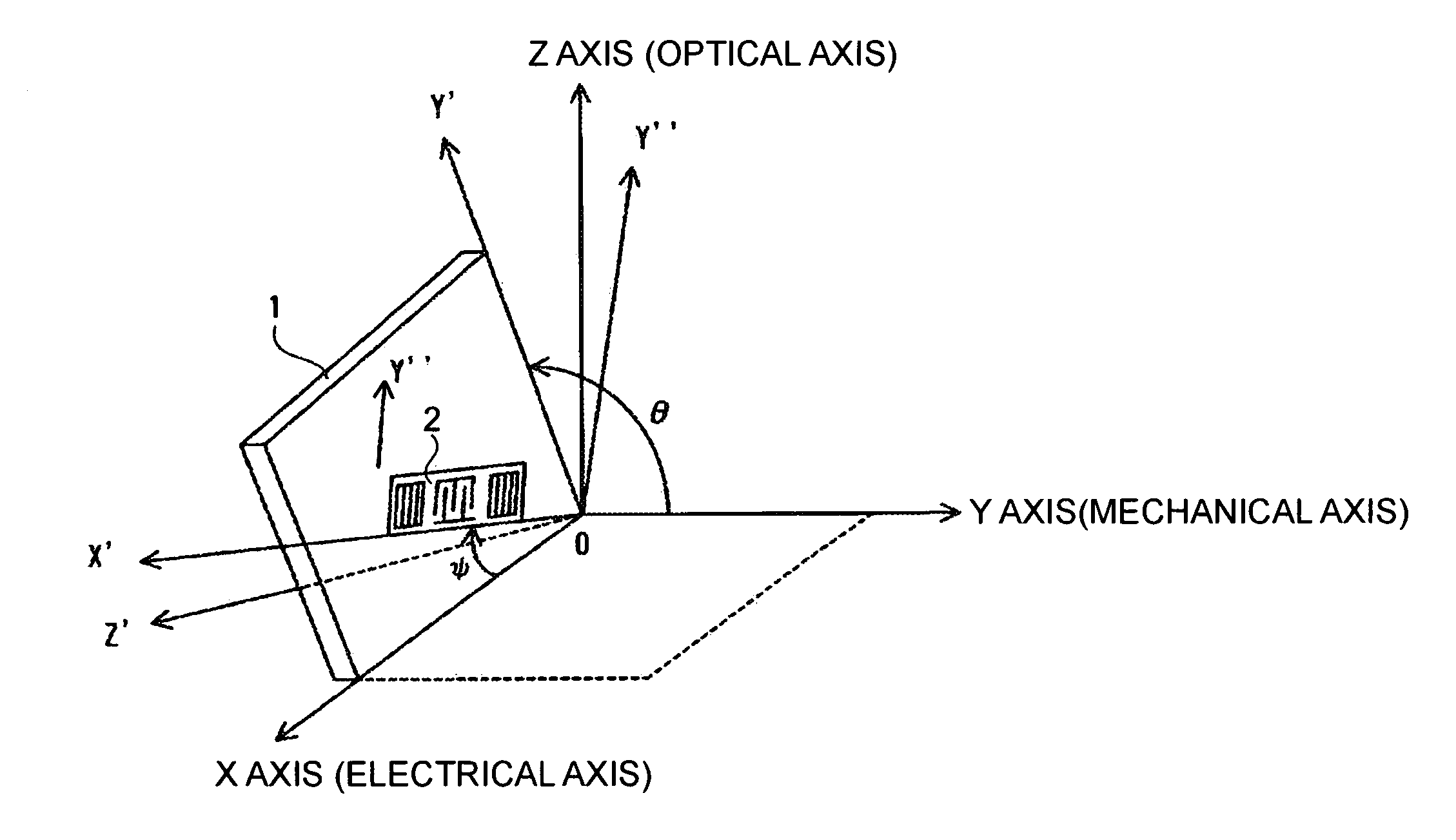

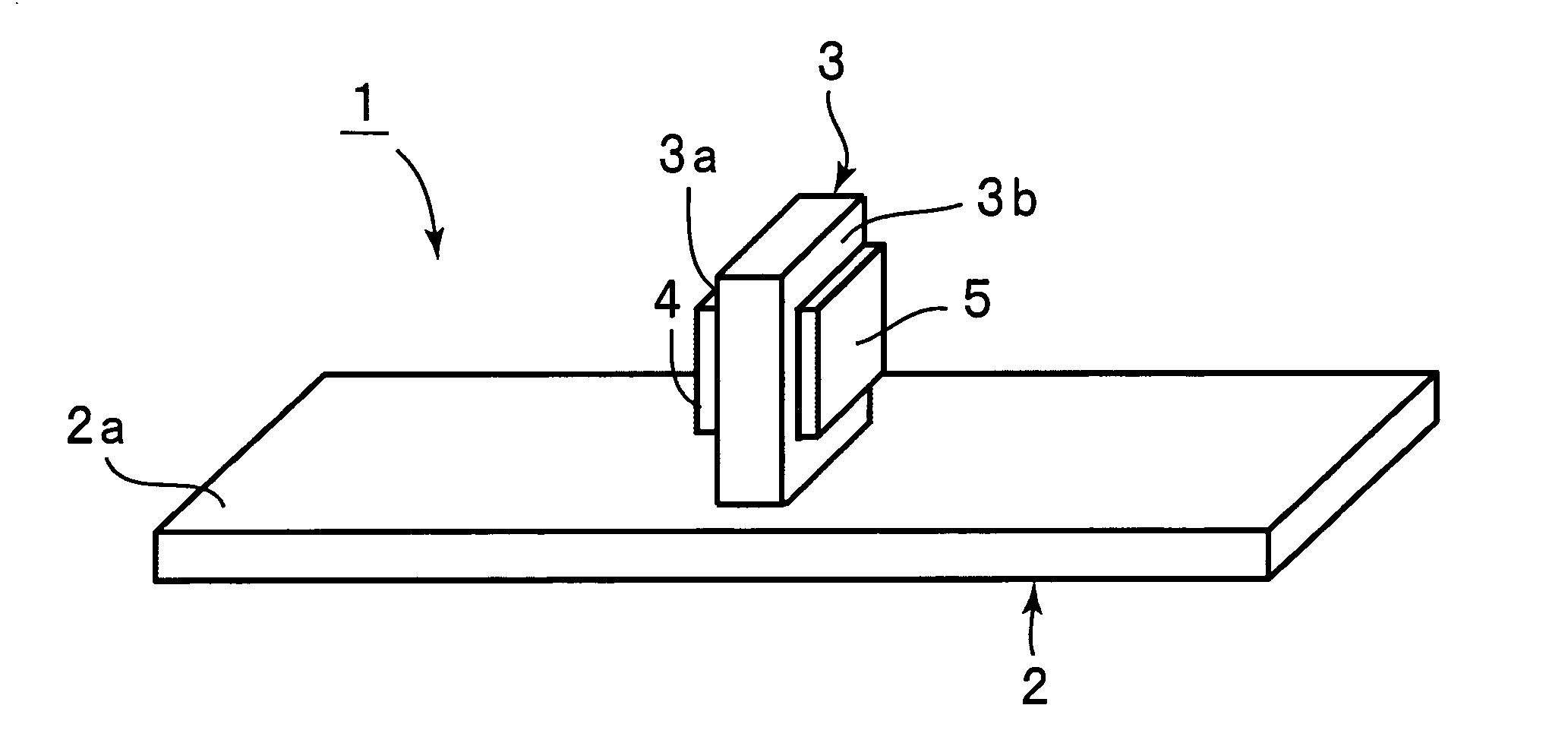

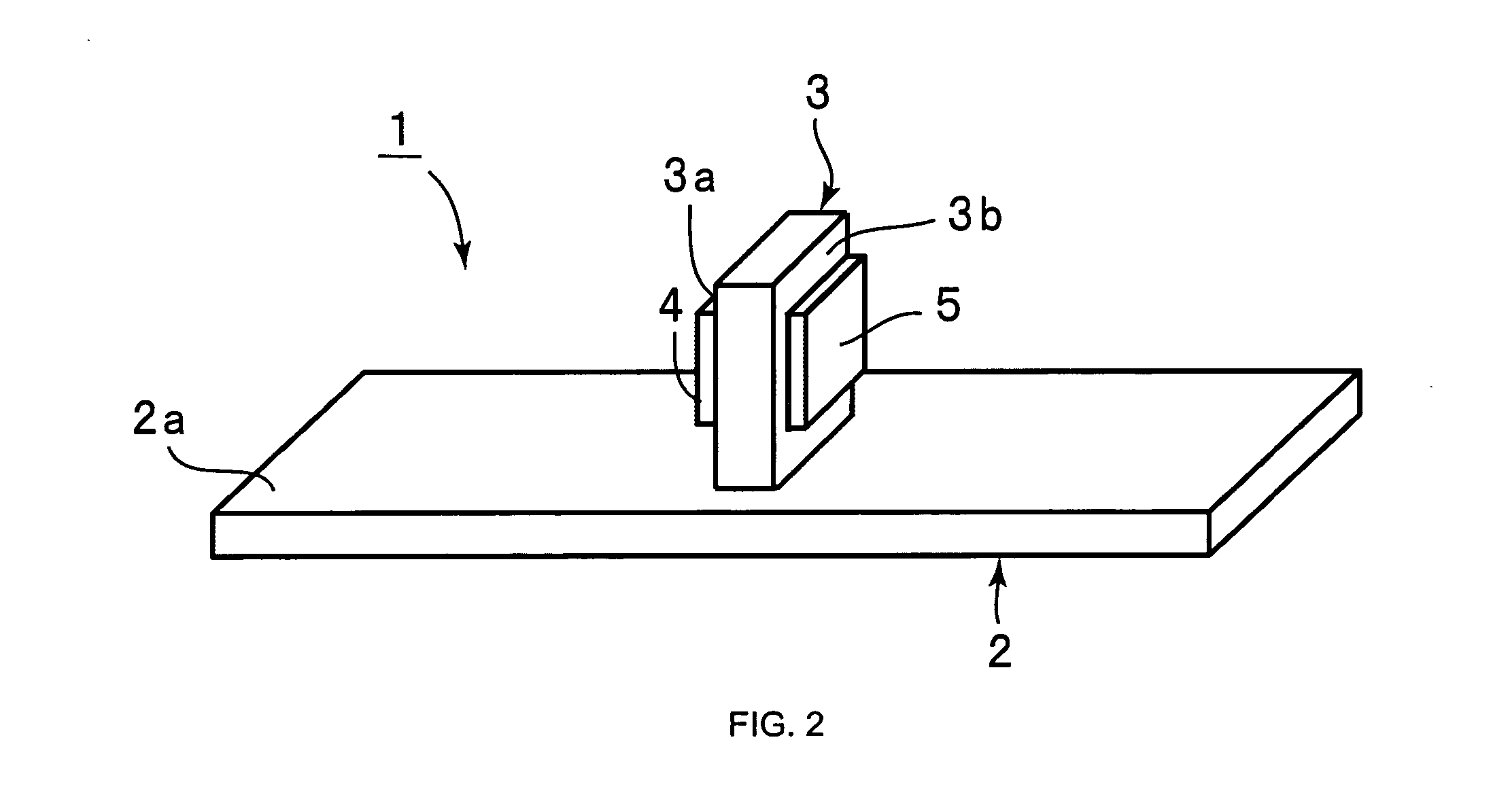

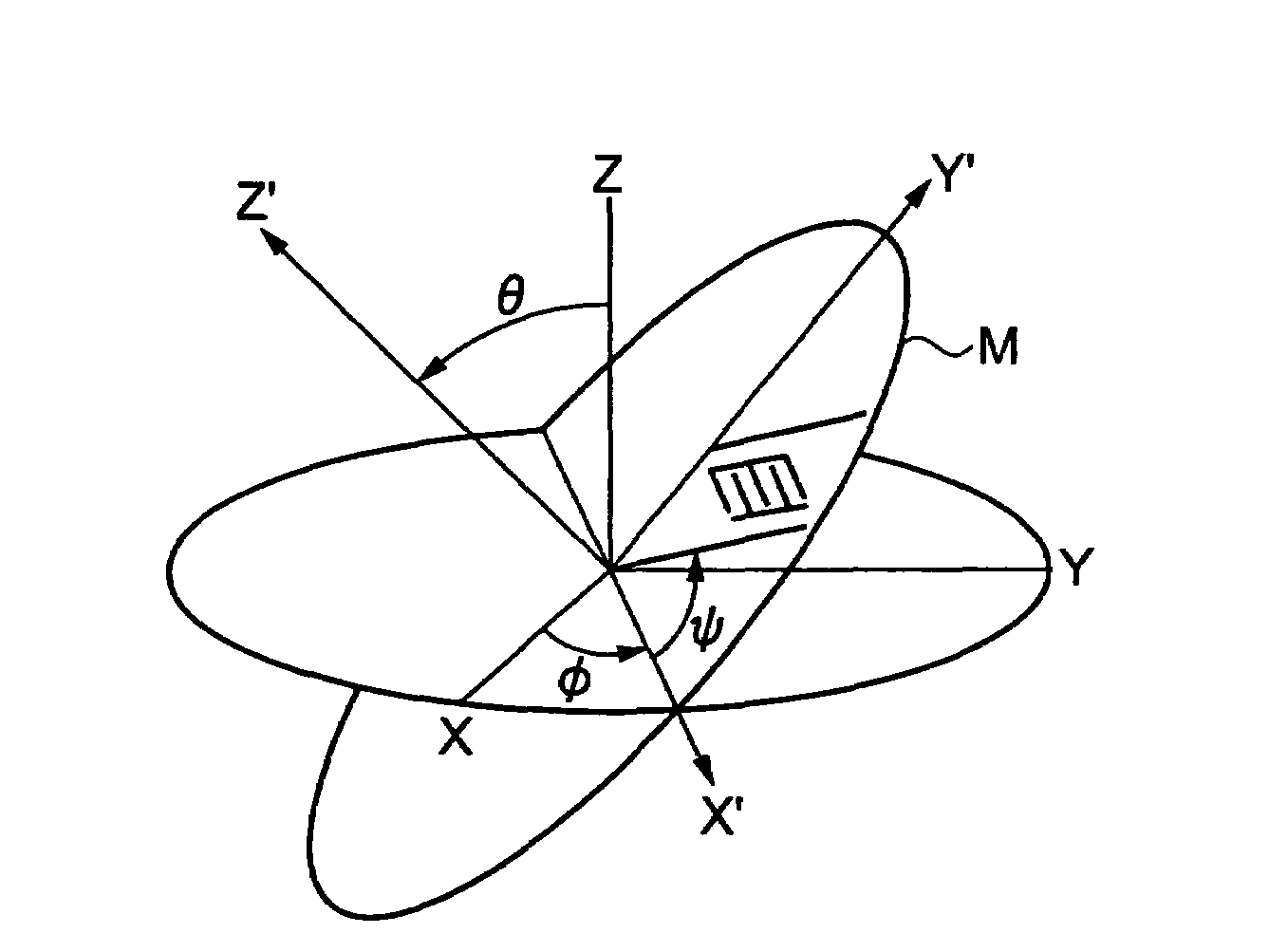

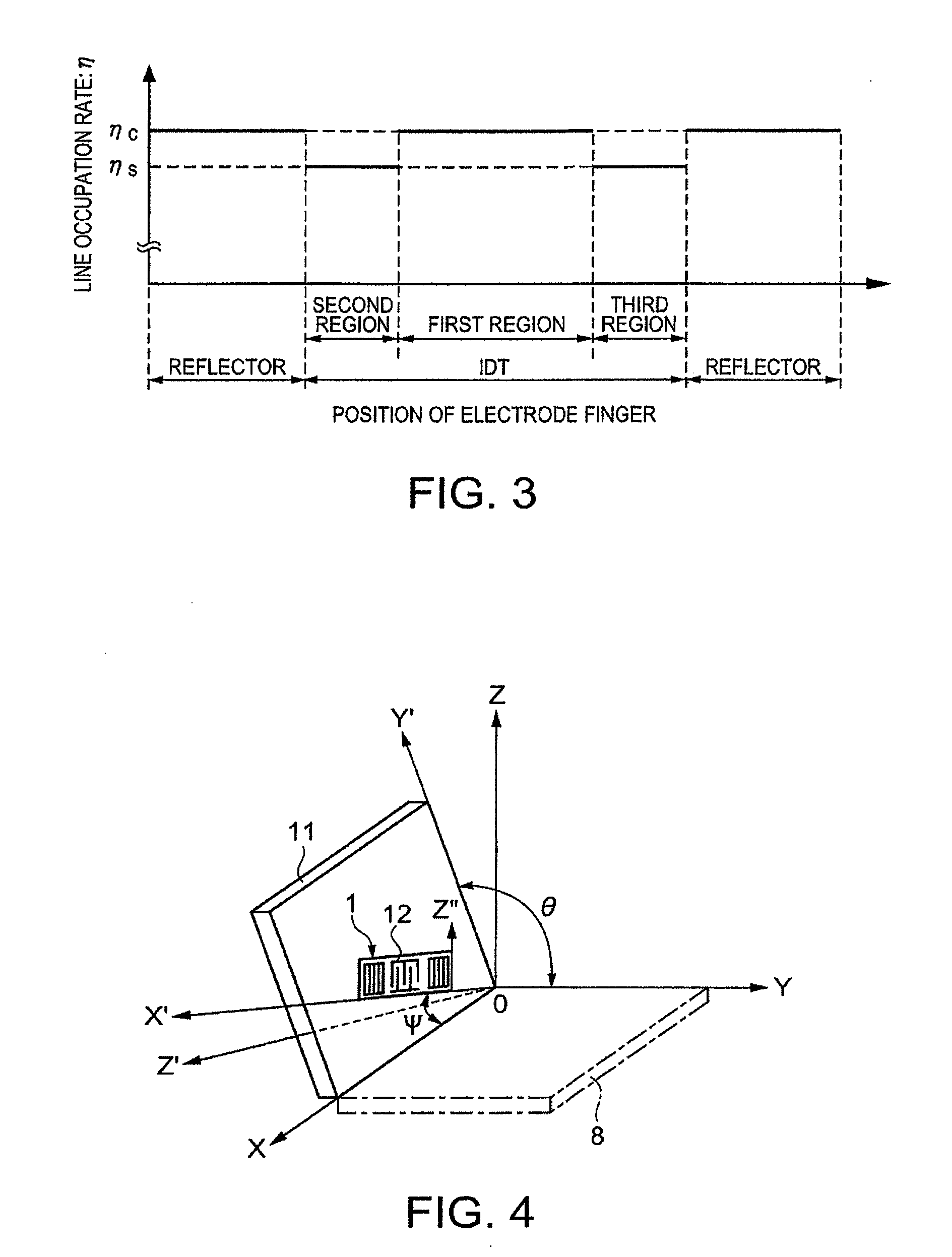

Surface acoustic wave device and electronic apparatus

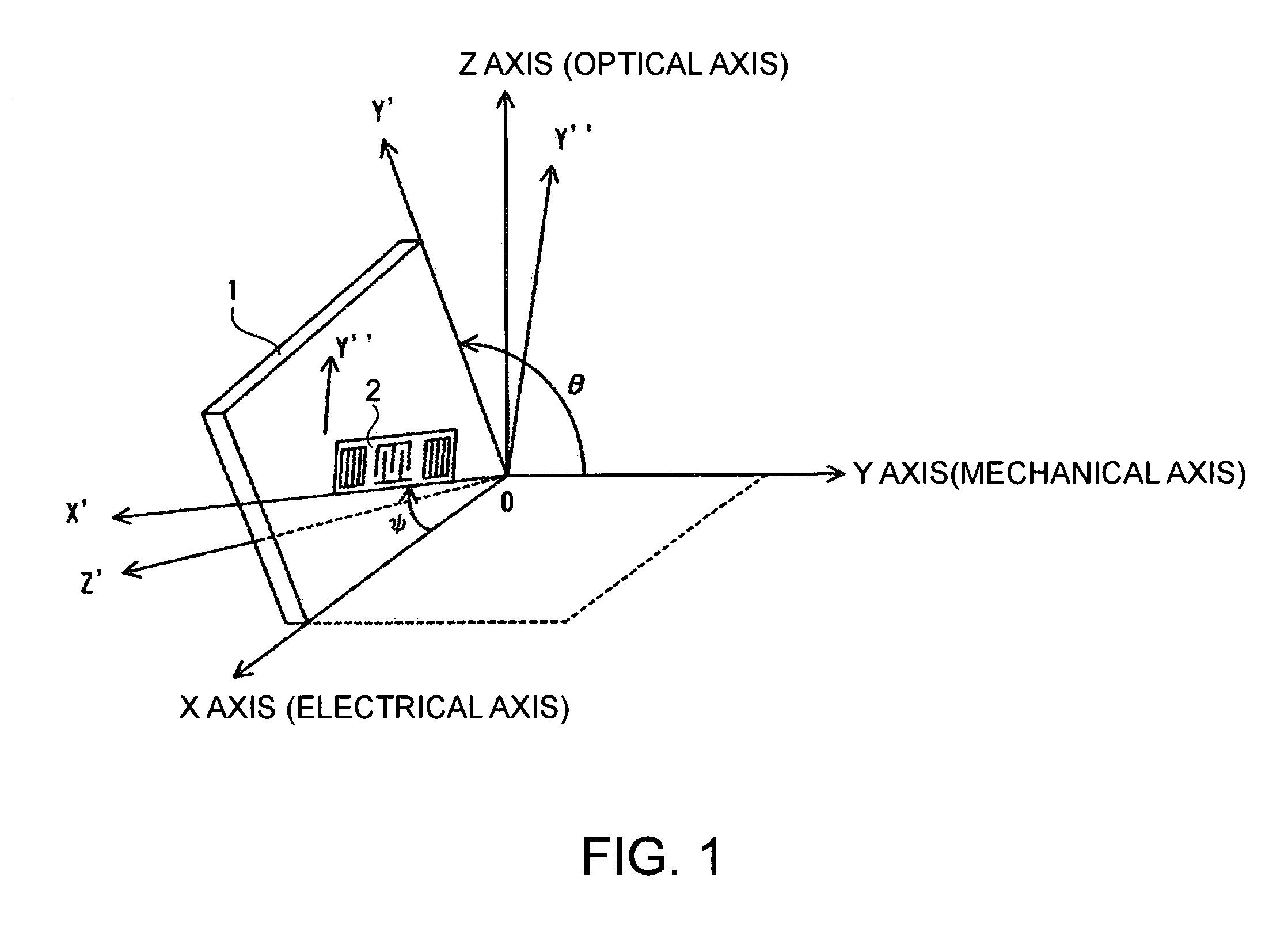

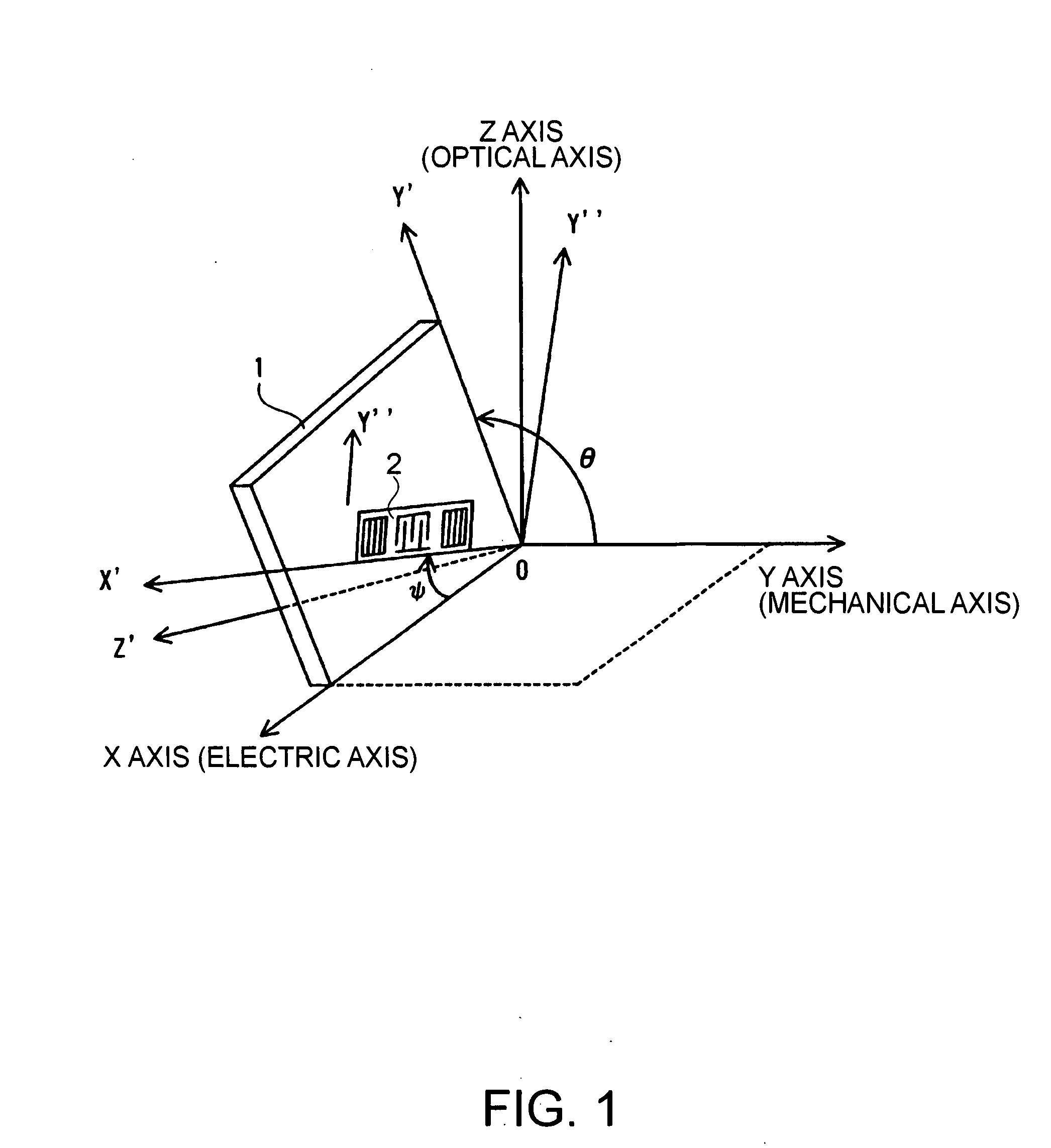

InactiveUS20060108894A1Good frequency temperature characteristicEasily applyImpedence networksPiezoelectric/electrostriction/magnetostriction machinesInterdigital transducerStopband

A surface acoustic wave device including at least an interdigital transducer electrode that excites a Rayleigh surface acoustic wave on a surface of a crystal substrate and giving excitation in an upper limit mode of a stopband of the surface acoustic wave, wherein Euler angle representation (ψ, θ, Ψ) showing a cut angle and surface acoustic wave propagation direction of the crystal substrate is set as (0°, 0°≦θ≦180°, 0°<|Ψ|<90°).

Owner:SEIKO EPSON CORP

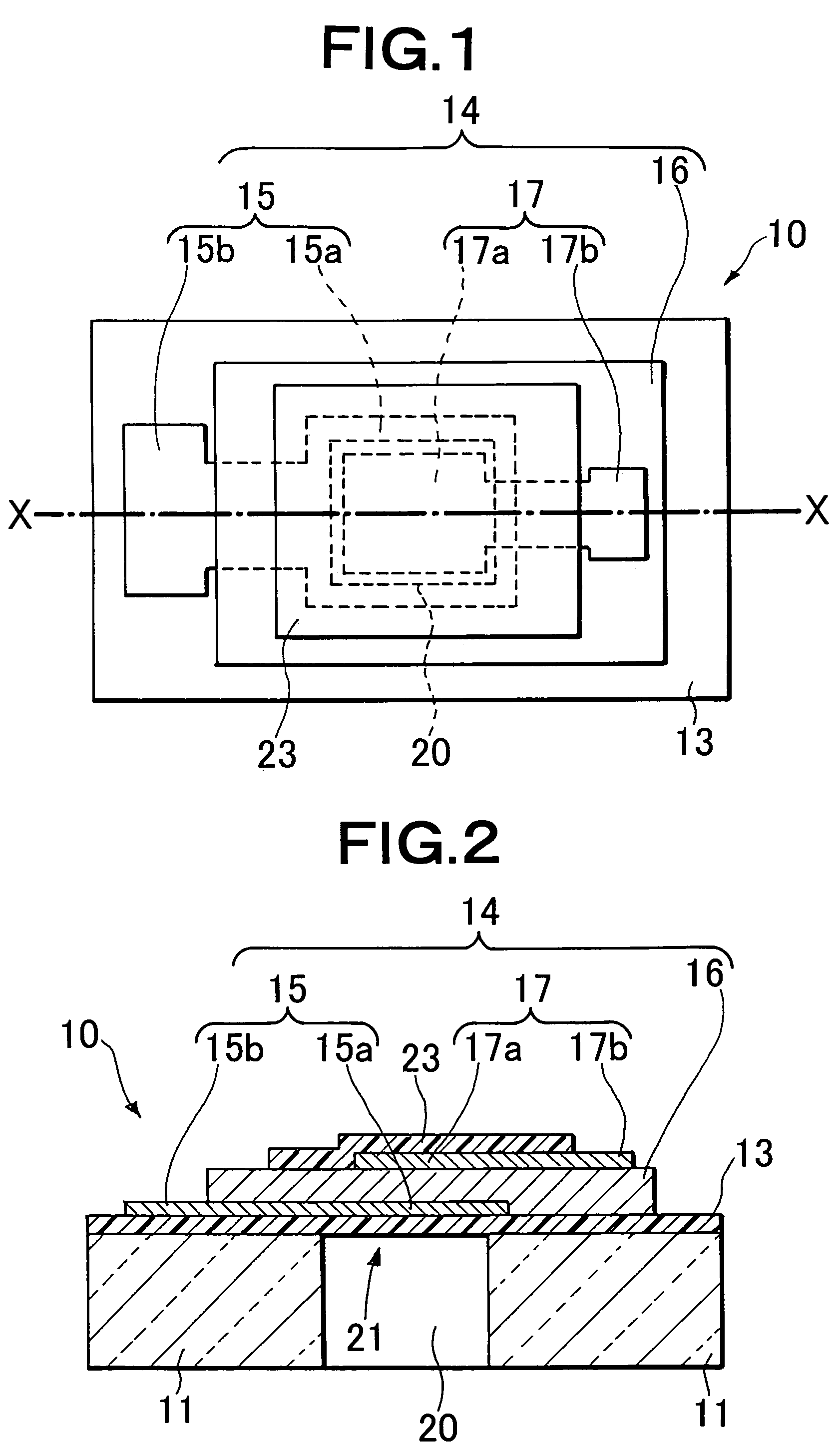

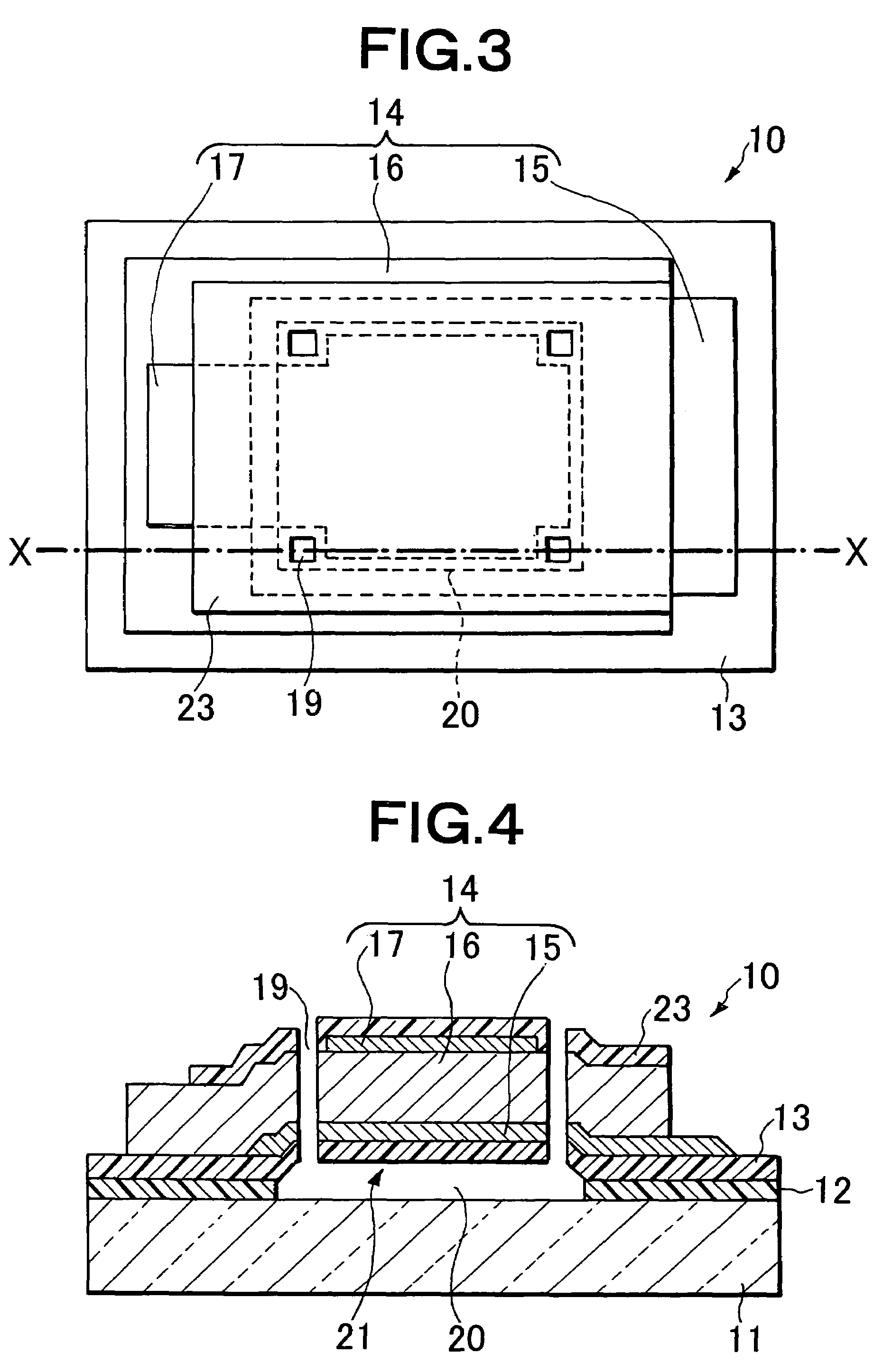

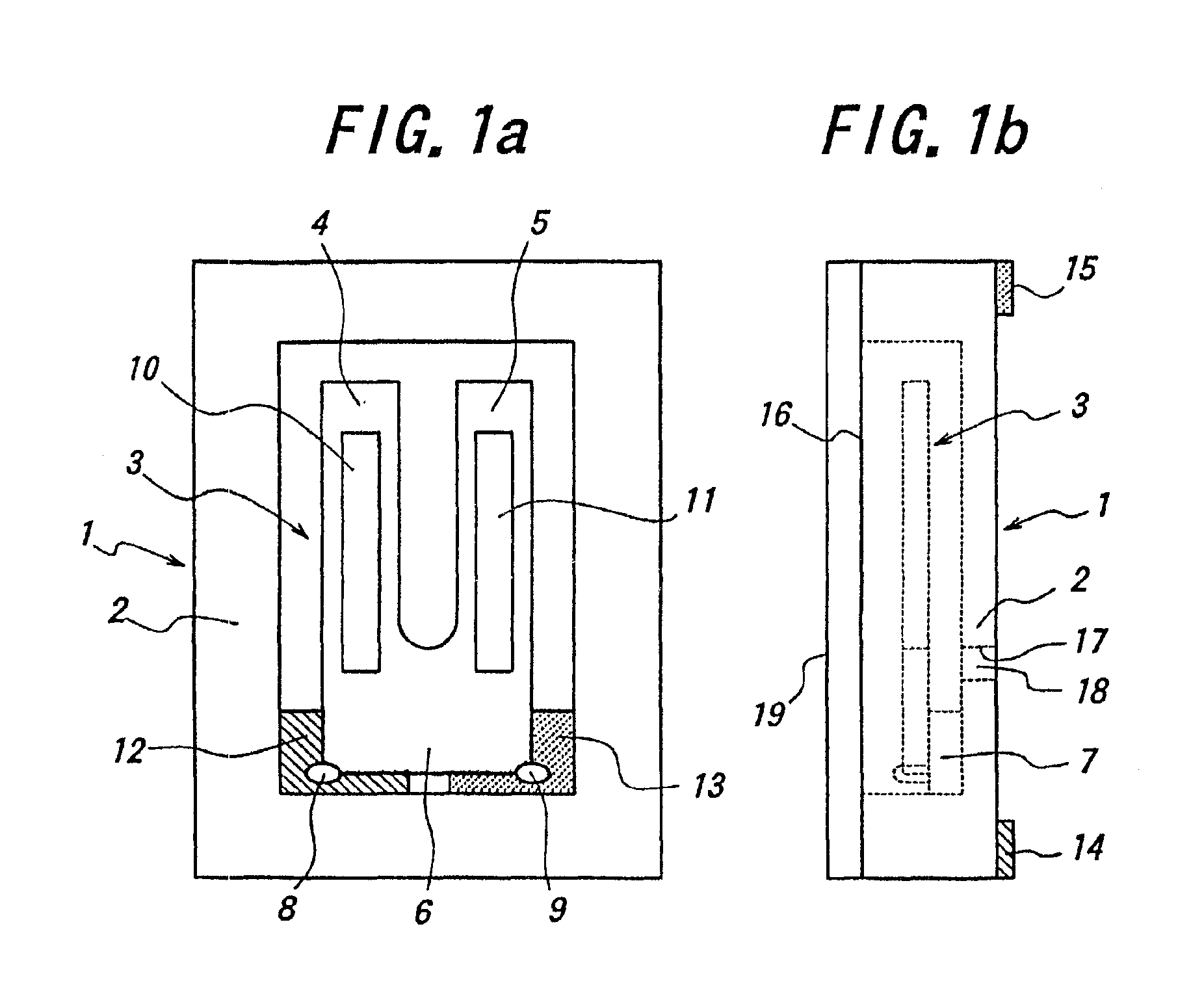

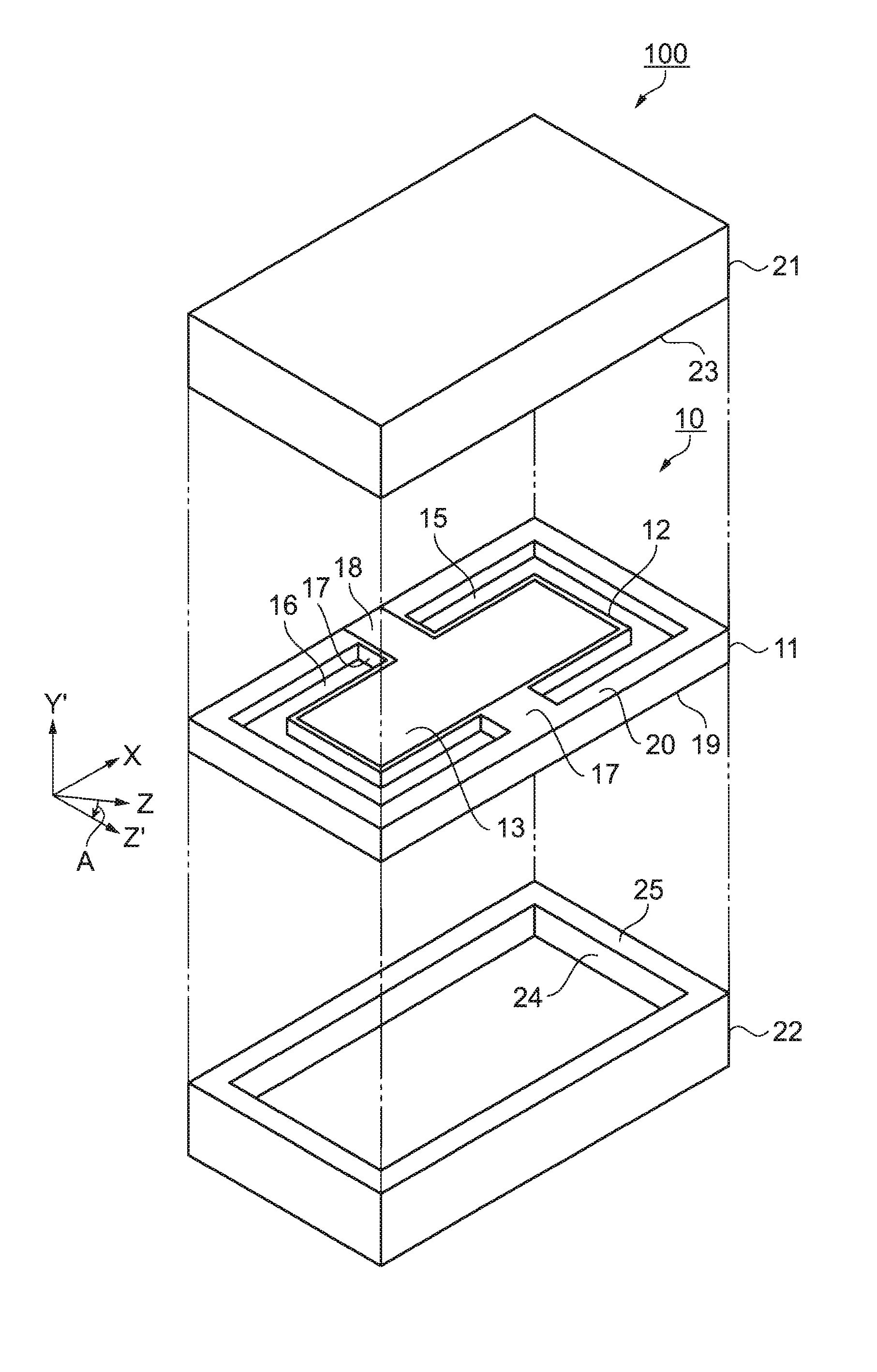

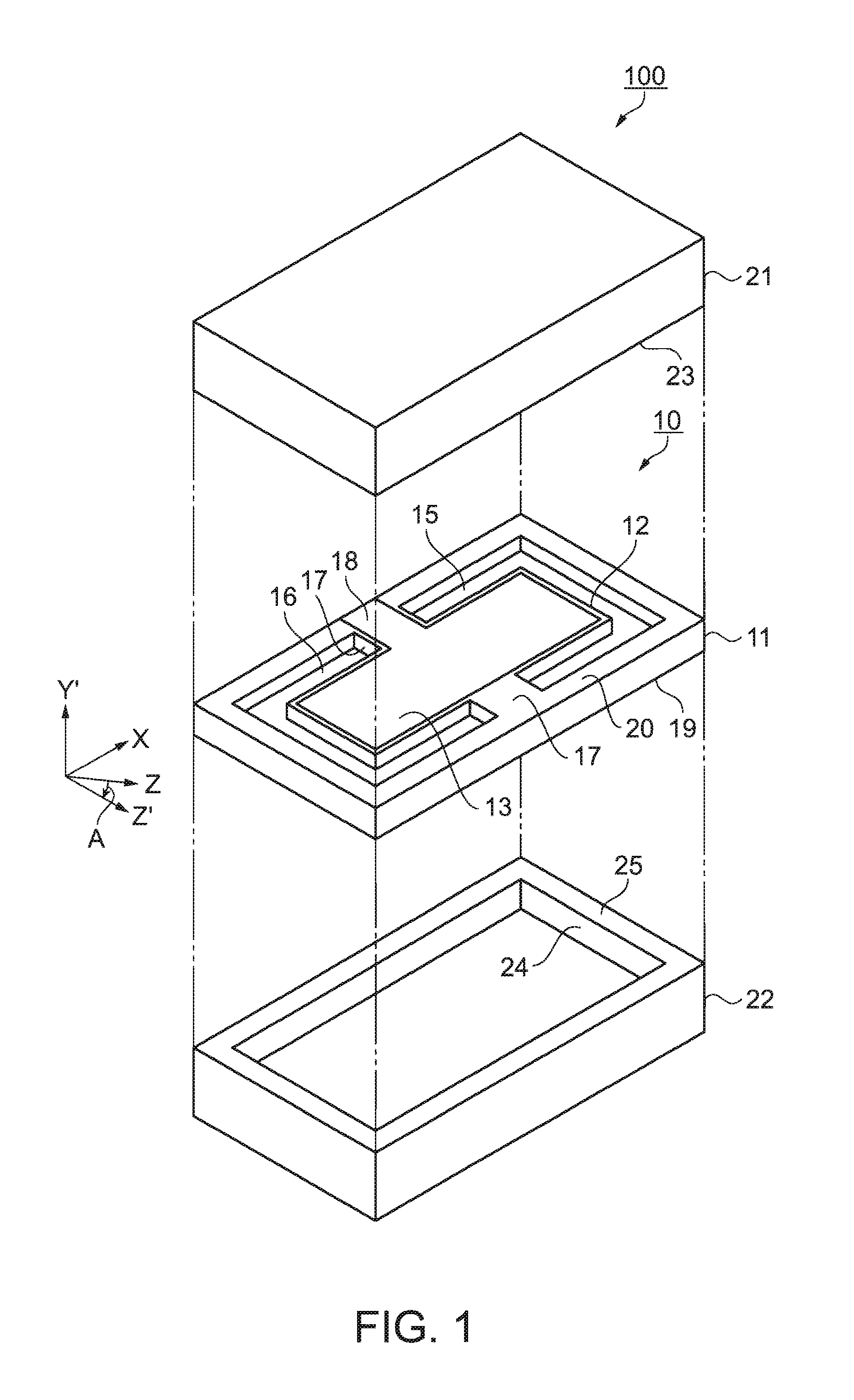

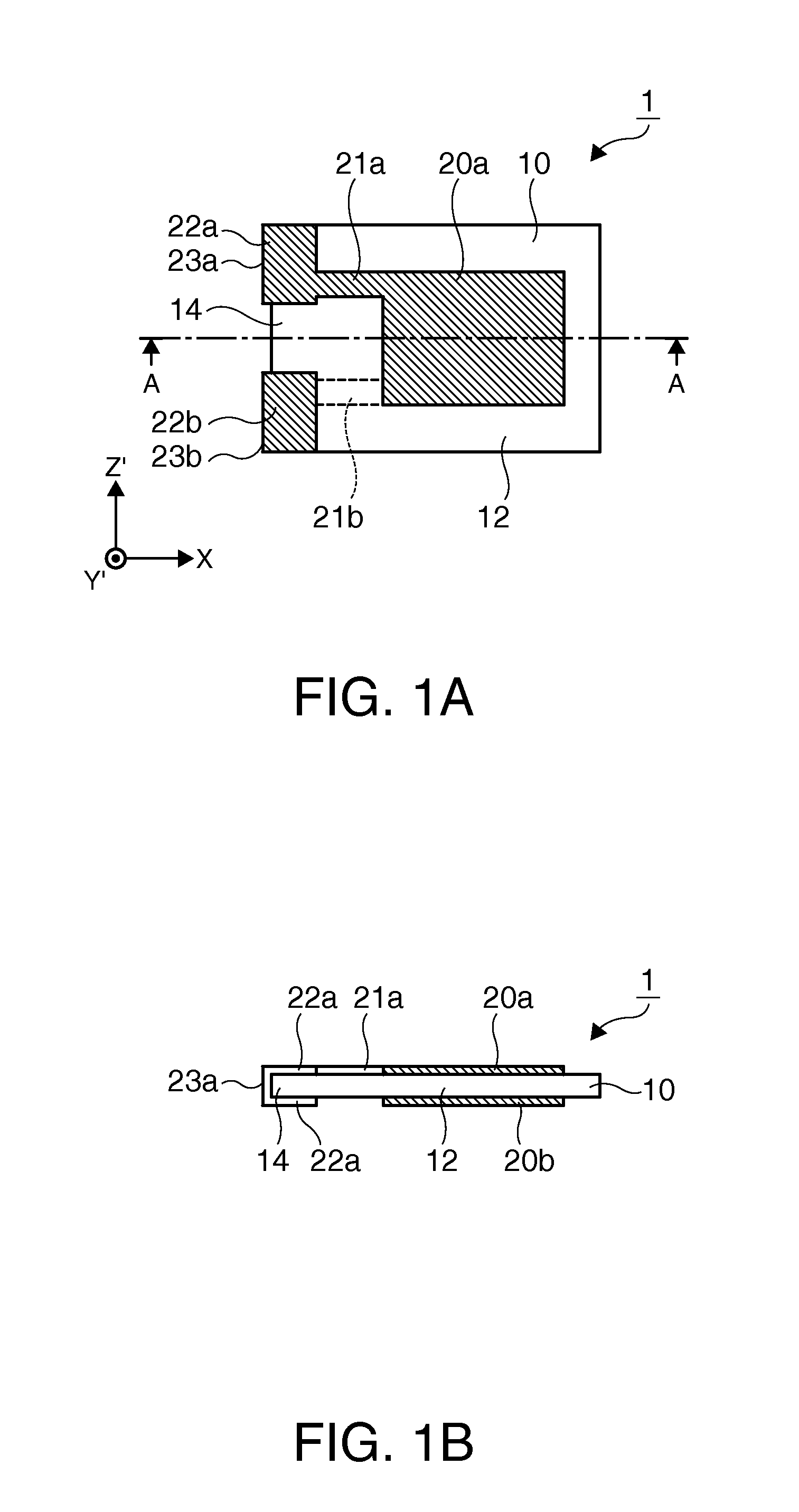

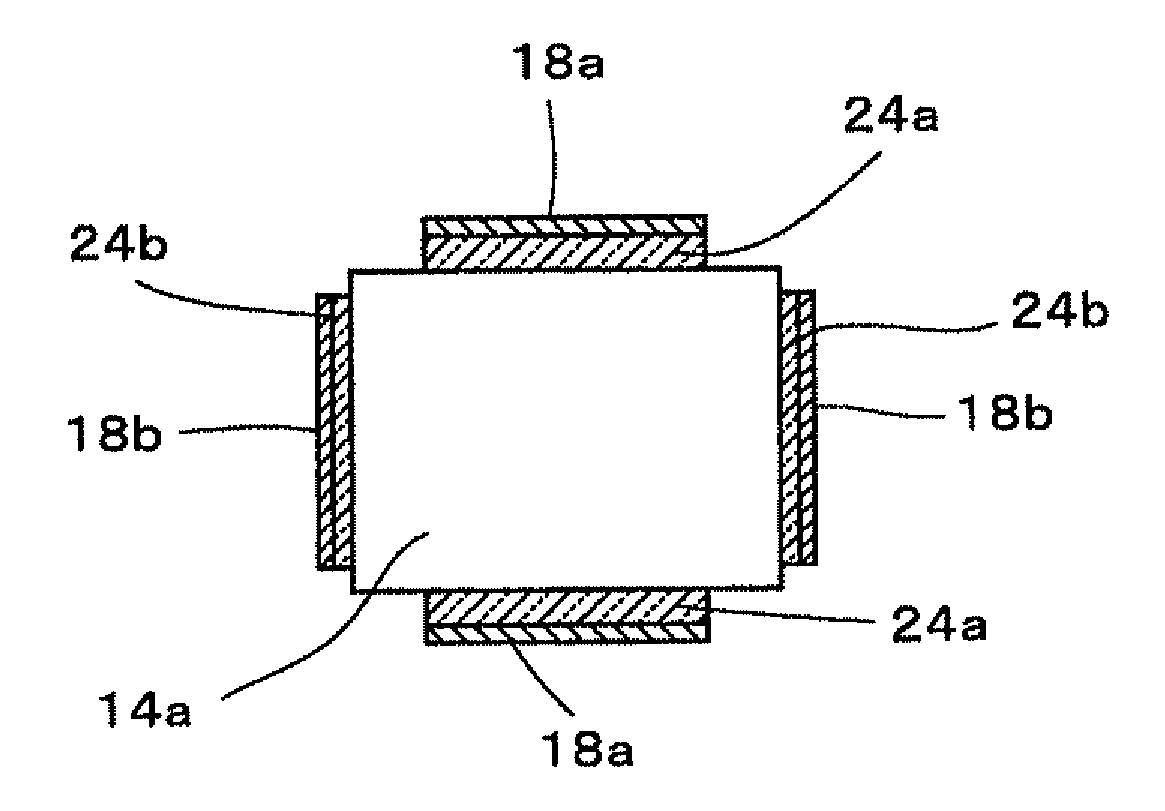

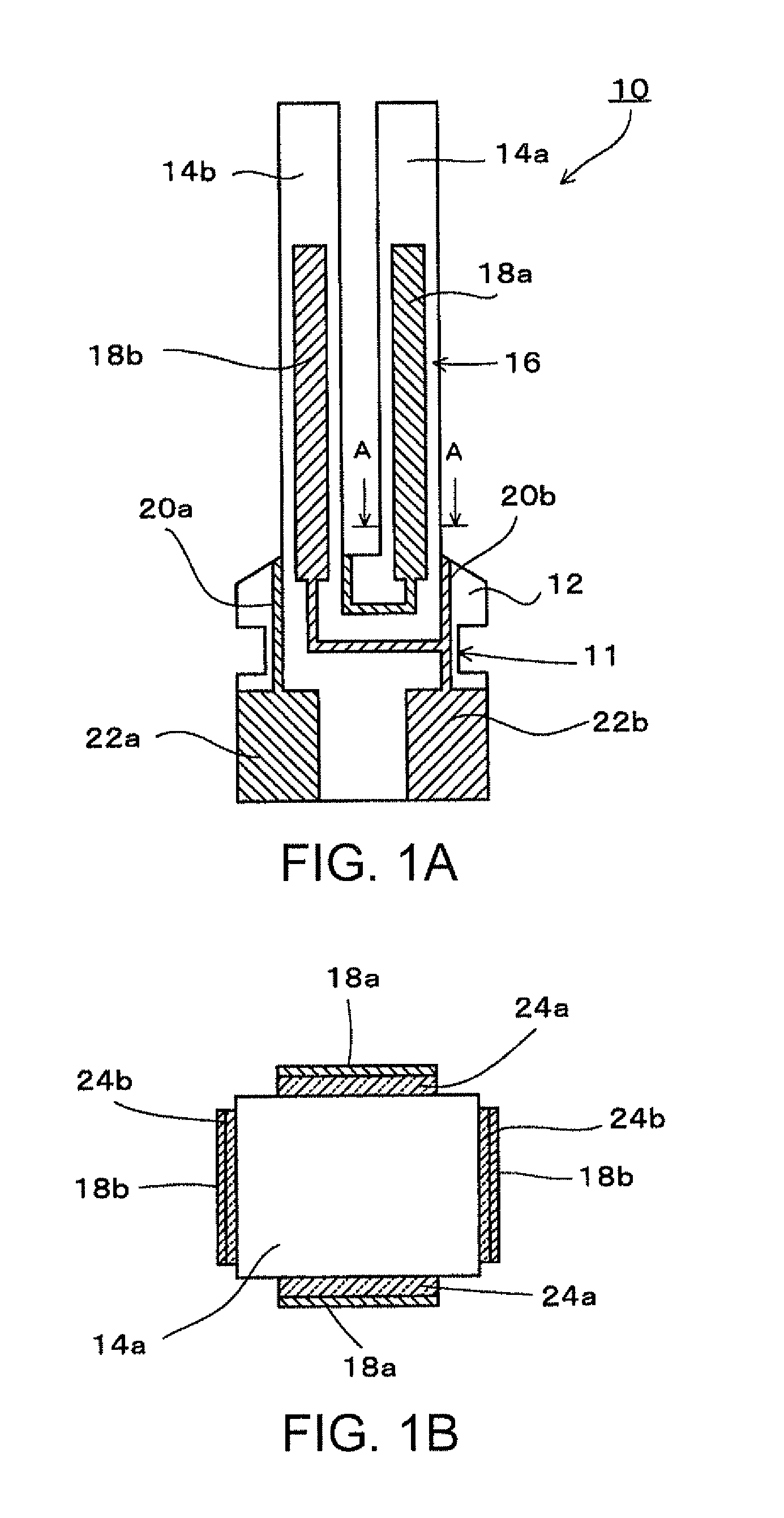

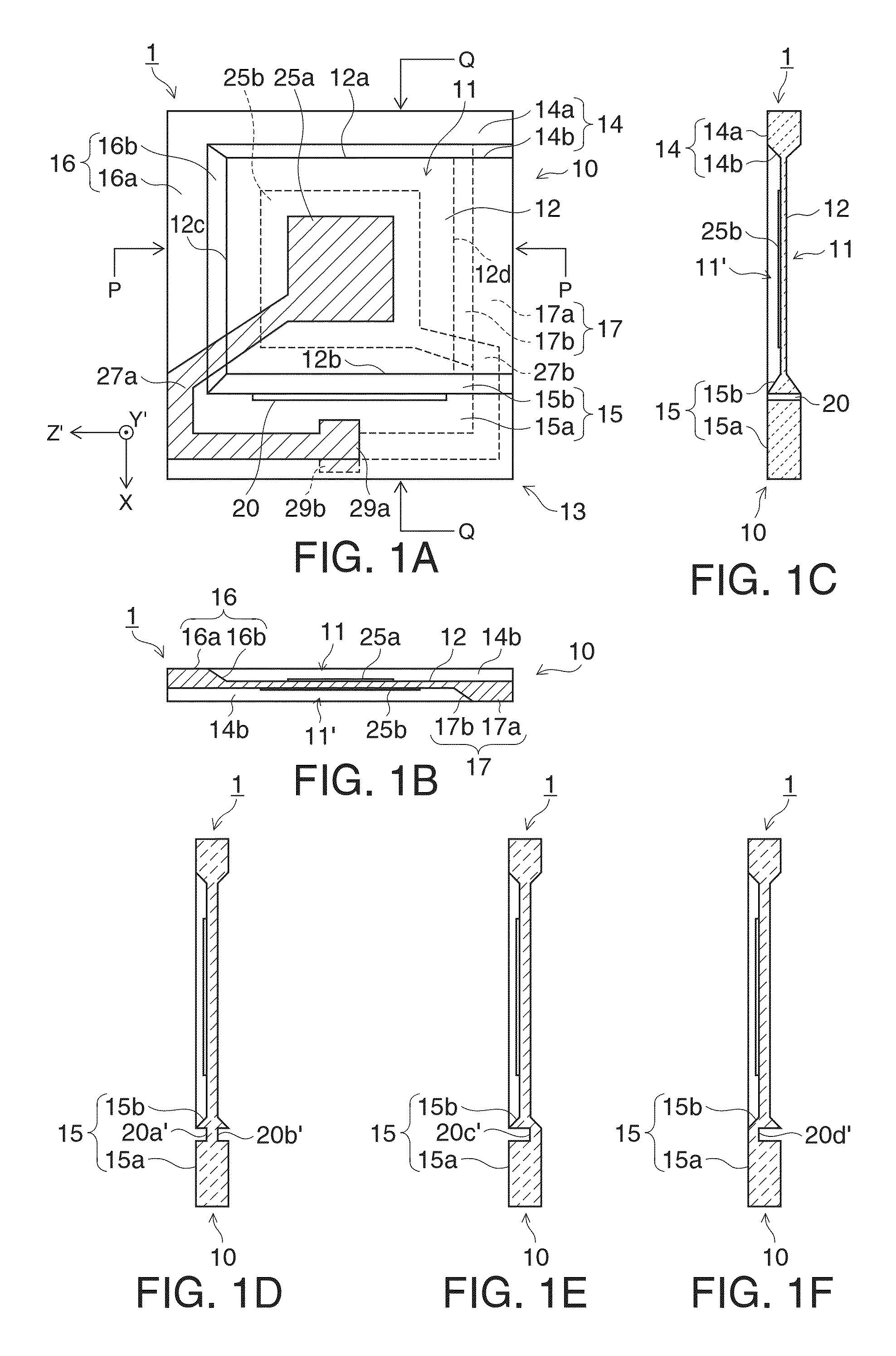

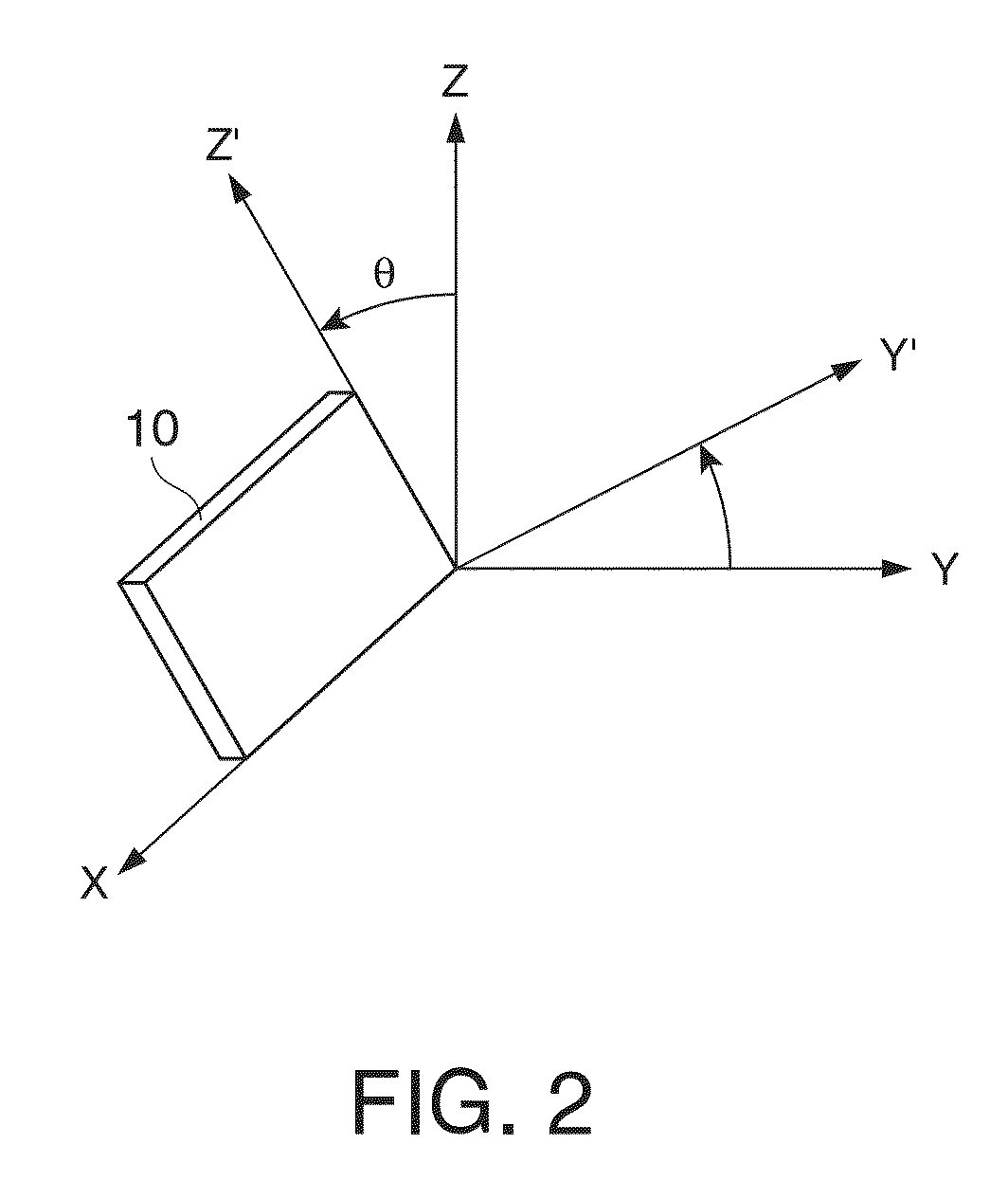

Quartz crystal resonator

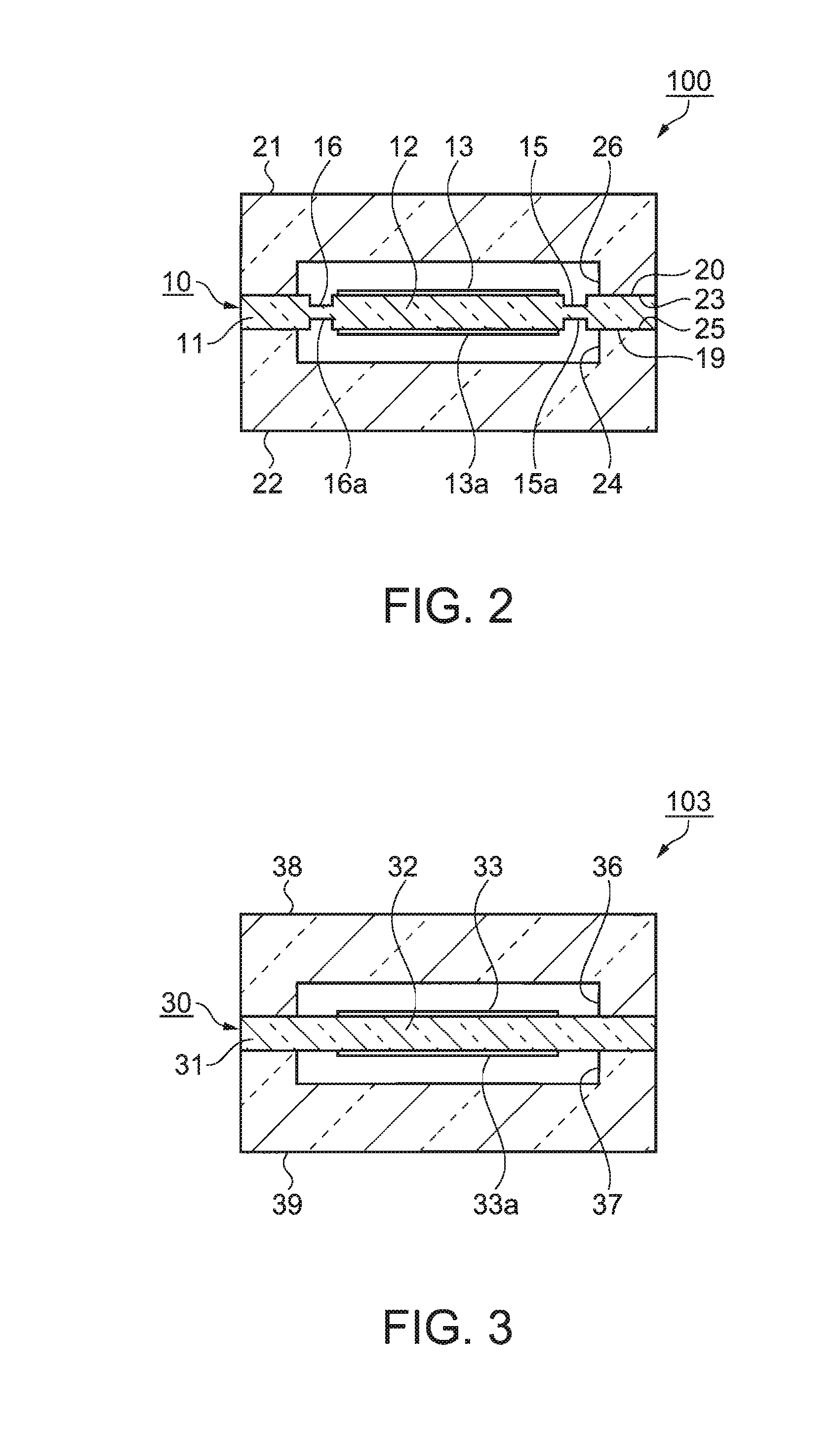

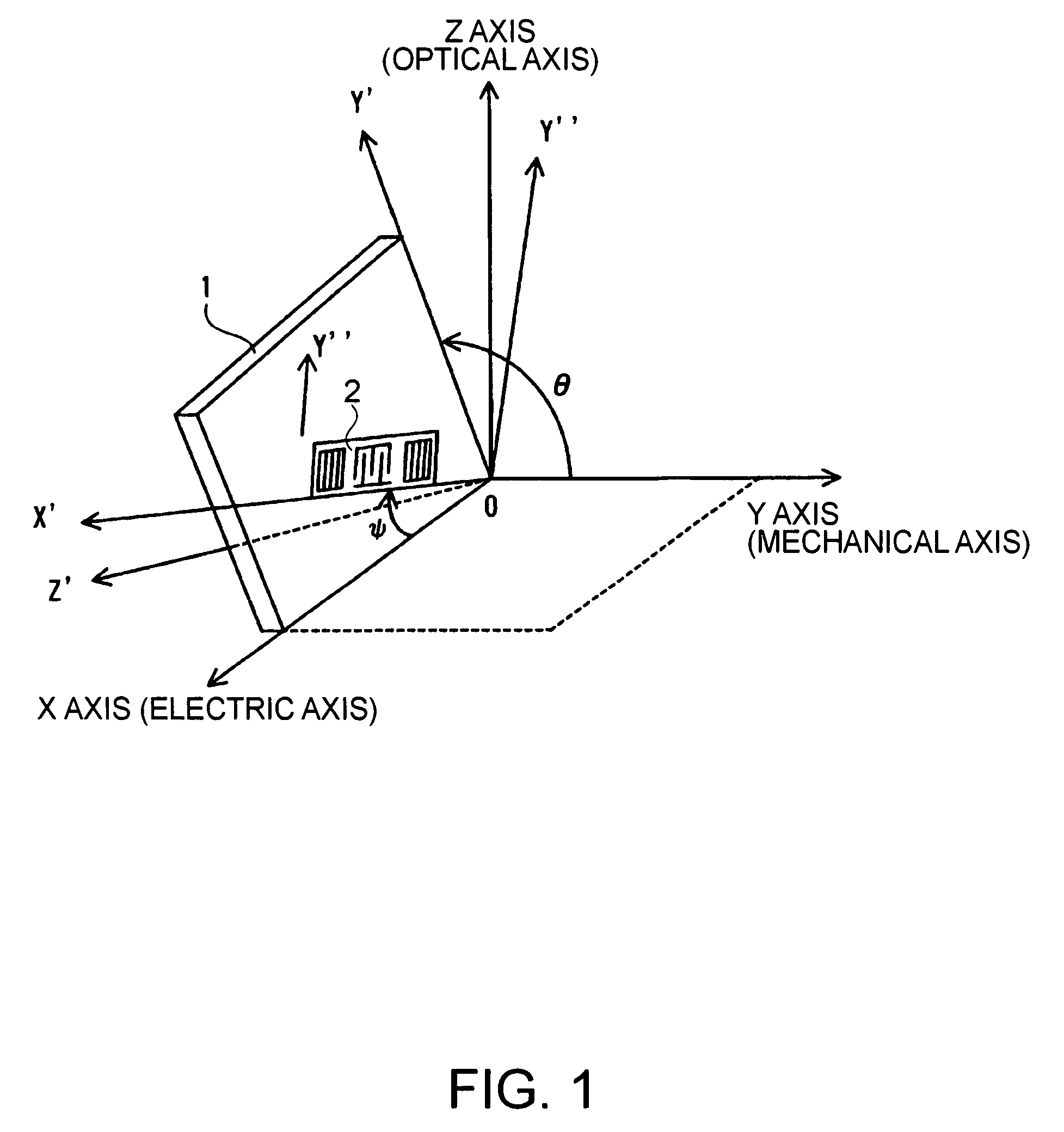

InactiveUS20080079334A1Reduce deteriorationExcellent frequency temperature characteristicsPiezoelectric/electrostriction/magnetostriction machinesImpedence networksQuartz crystal resonatorResonance

A quartz crystal resonator includes a quartz crystal resonator element having a main surface including an X axis (electrical axis) and a Z' axis of an inclination rotated at an angle (y) equal to or greater than 36.4 degrees and equal to or smaller than, 40.5 degrees from a Z axis (optical axis) around the X axis, a main vibrating portion vibrating at a predetermined resonance frequency (f) and a supporting portion integrally formed with the main vibrating portion in such a manner as to be formed peripherally to surround the main vibrating portion, and two covers having a thermal expansion coefficient equal to or greater than 6x10-6 per degrees centigrade and equal to or smaller than 10x10-6 per degrees centigrade and bonded to the supporting portion so as to sandwich the quartz crystal resonator element therebetween.

Owner:SEIKO EPSON CORP +1

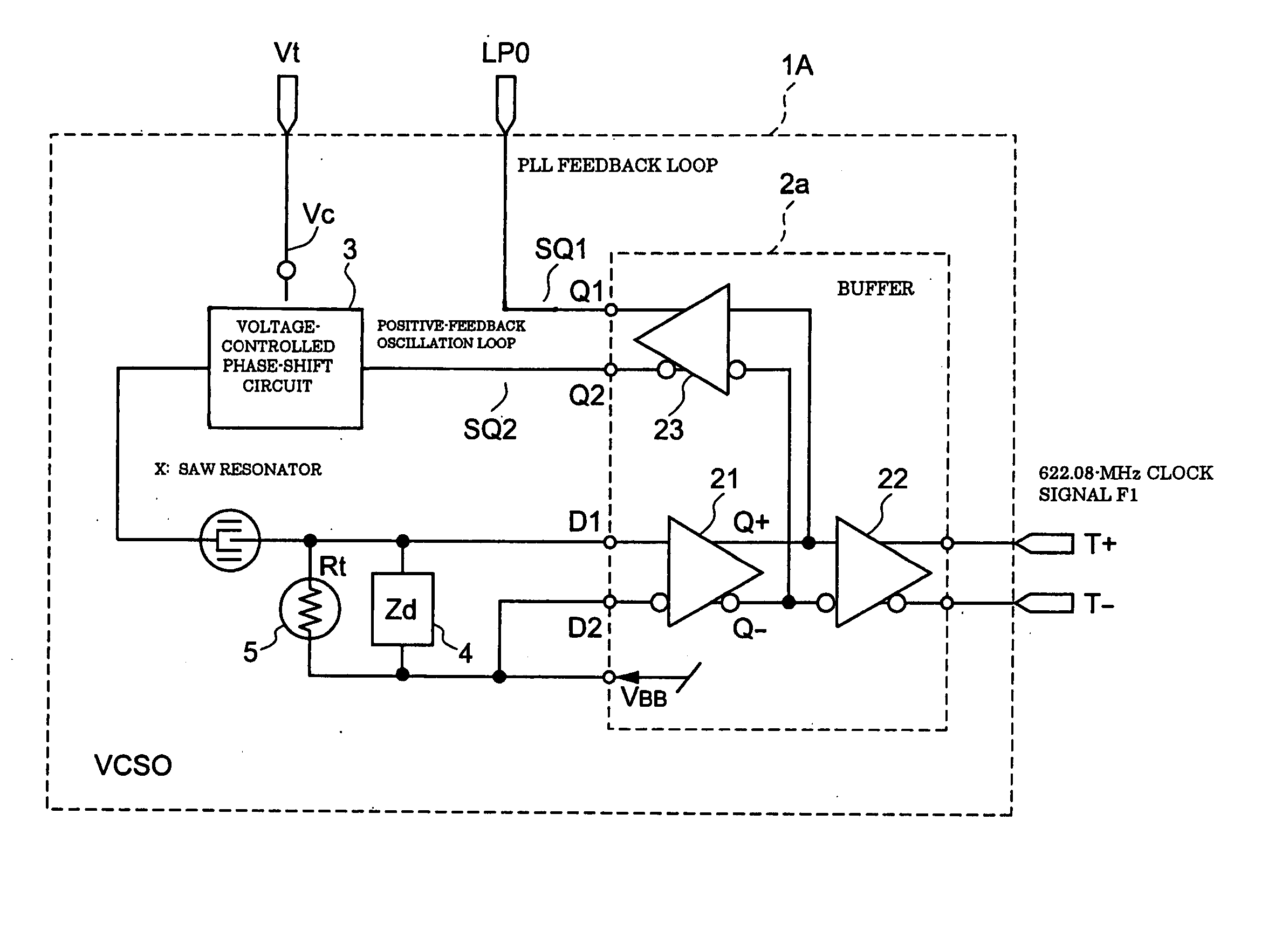

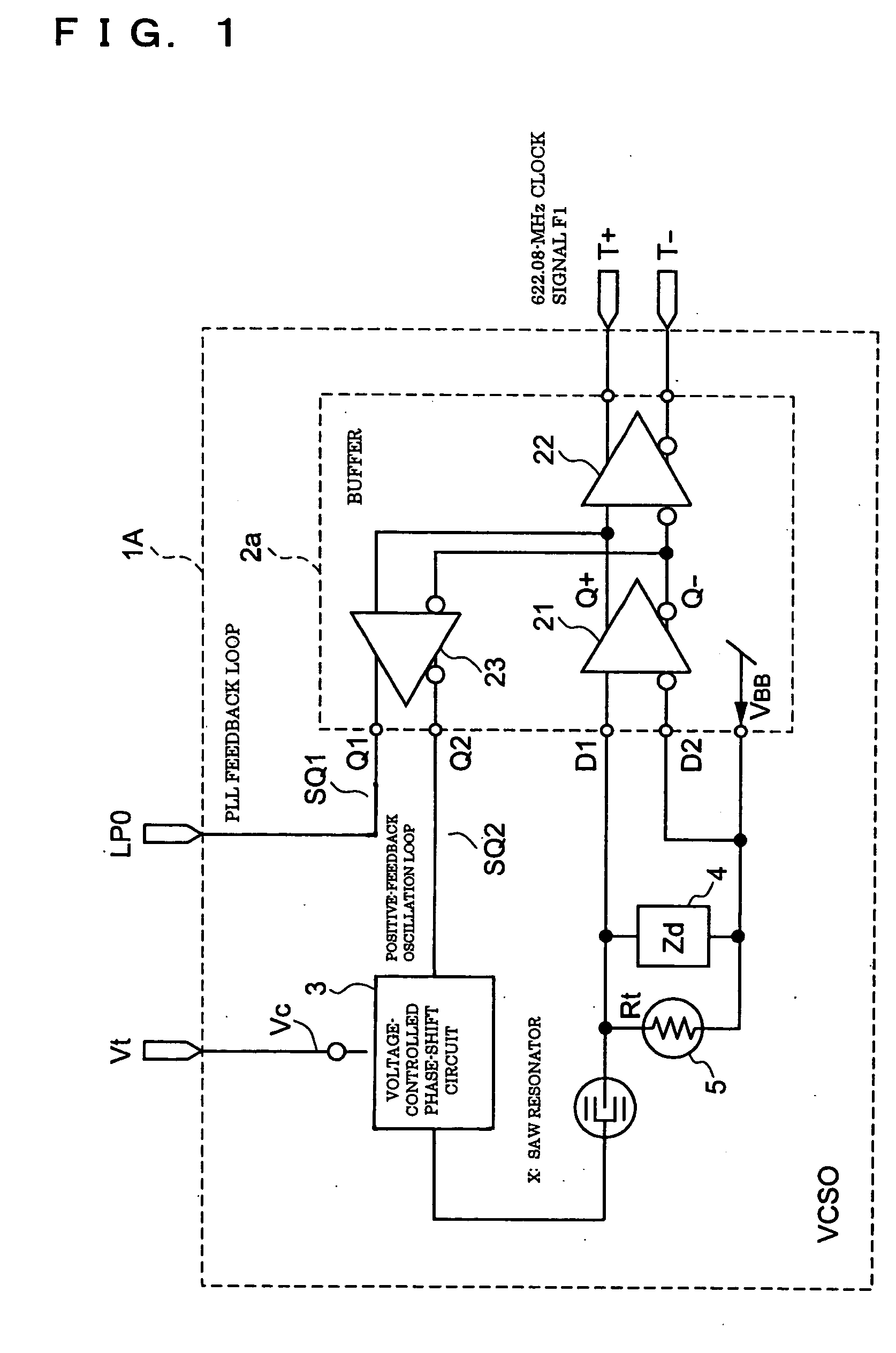

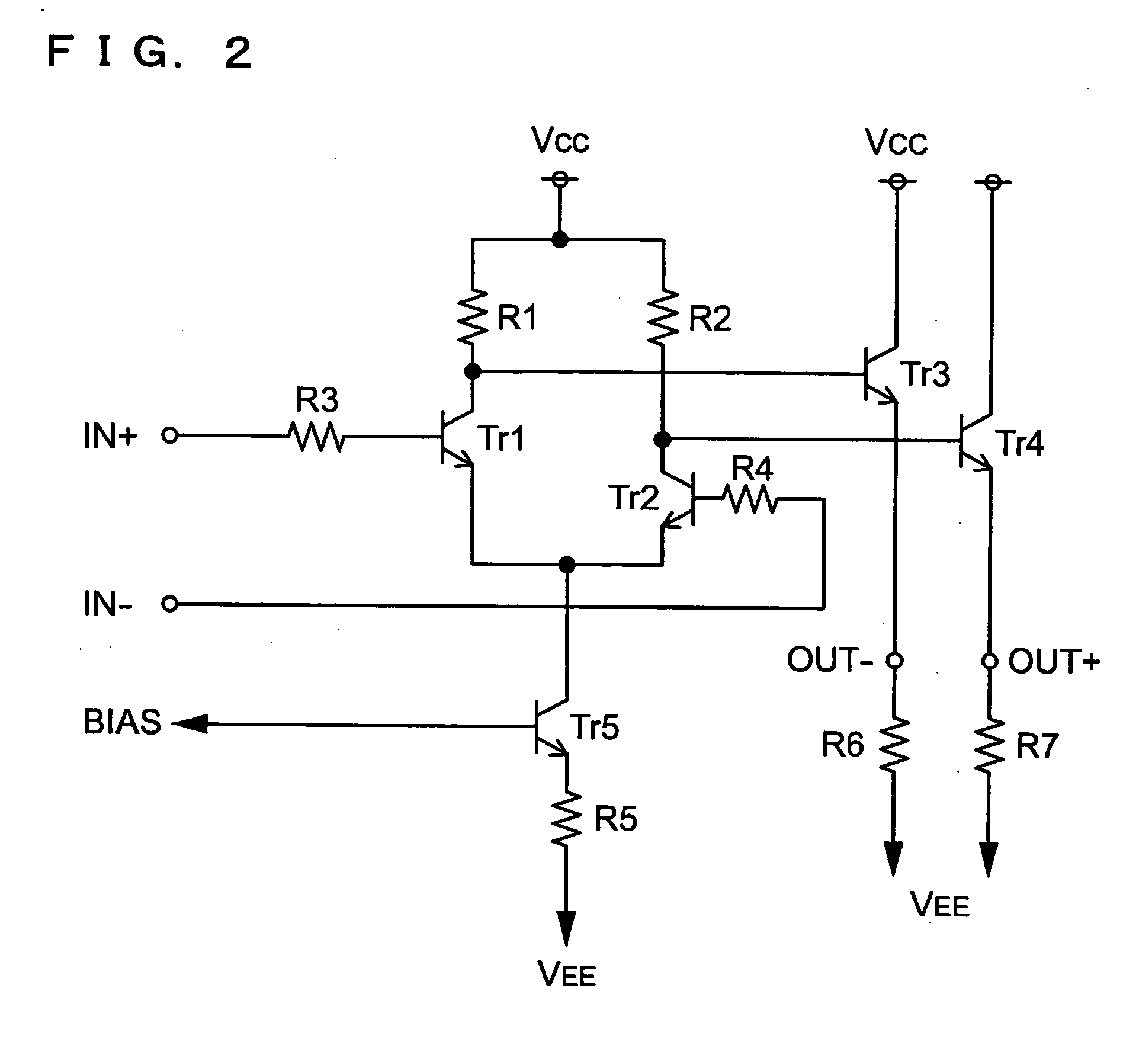

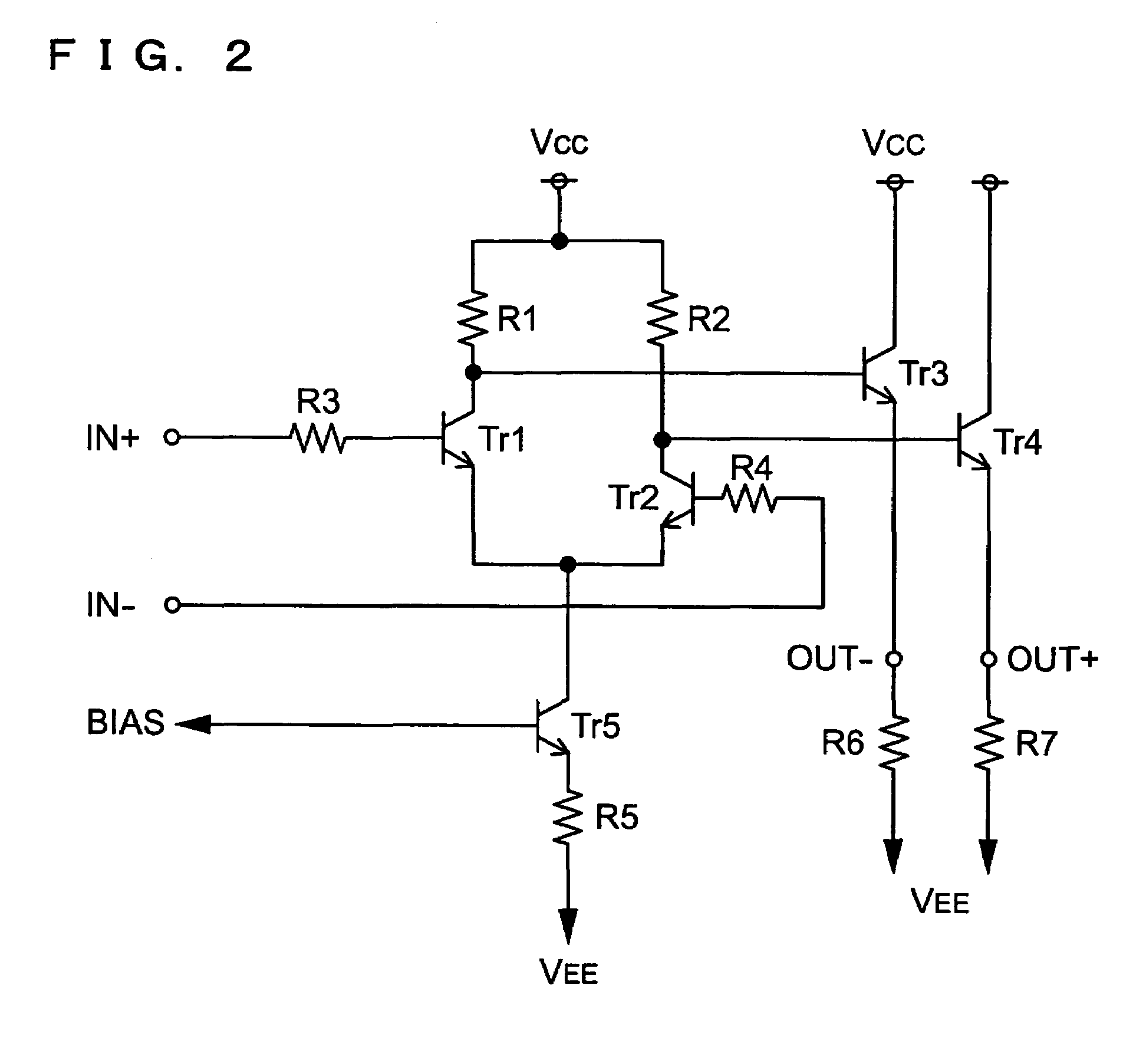

Voltage-controlled oscillator, clock converter, and electronic device

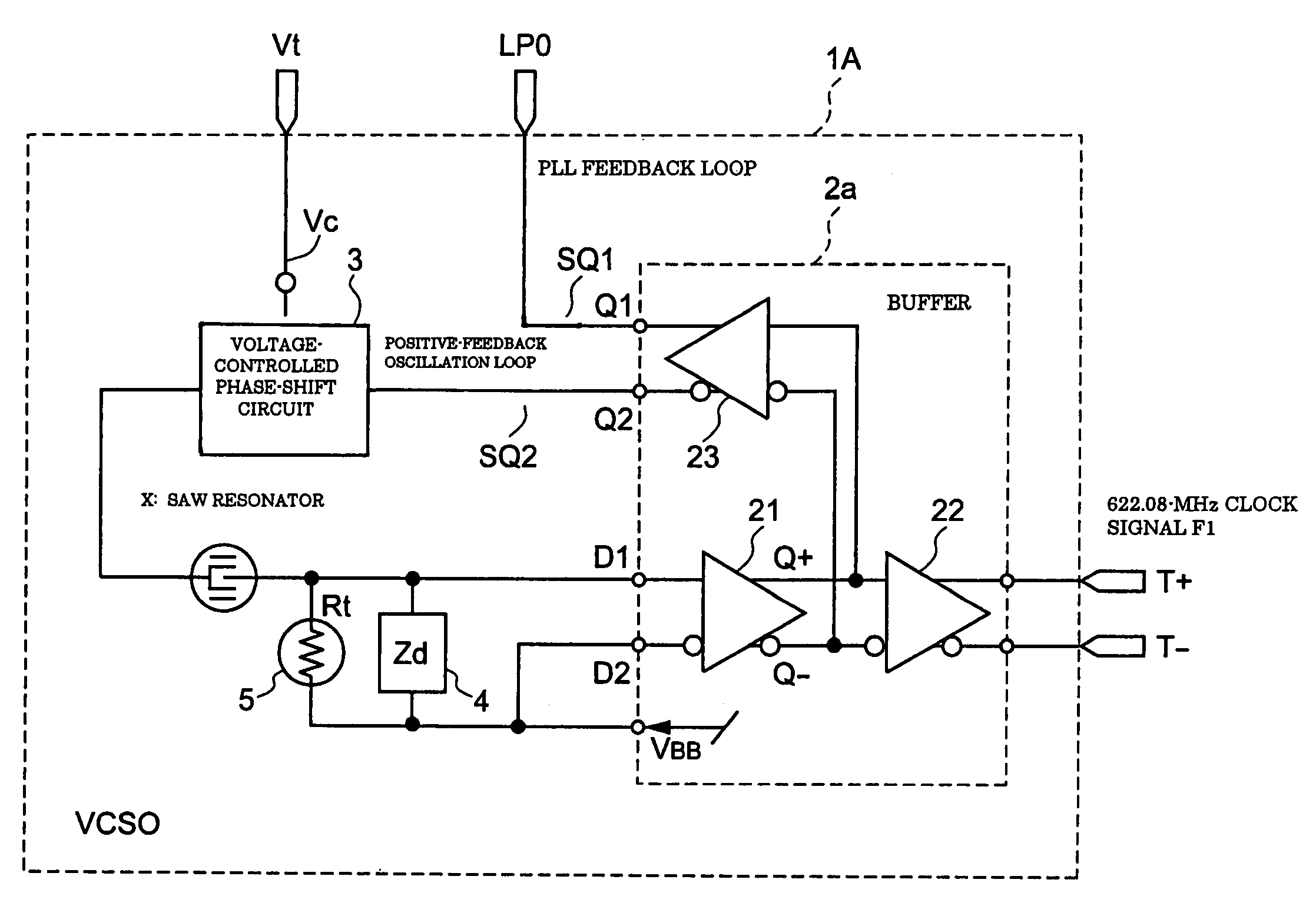

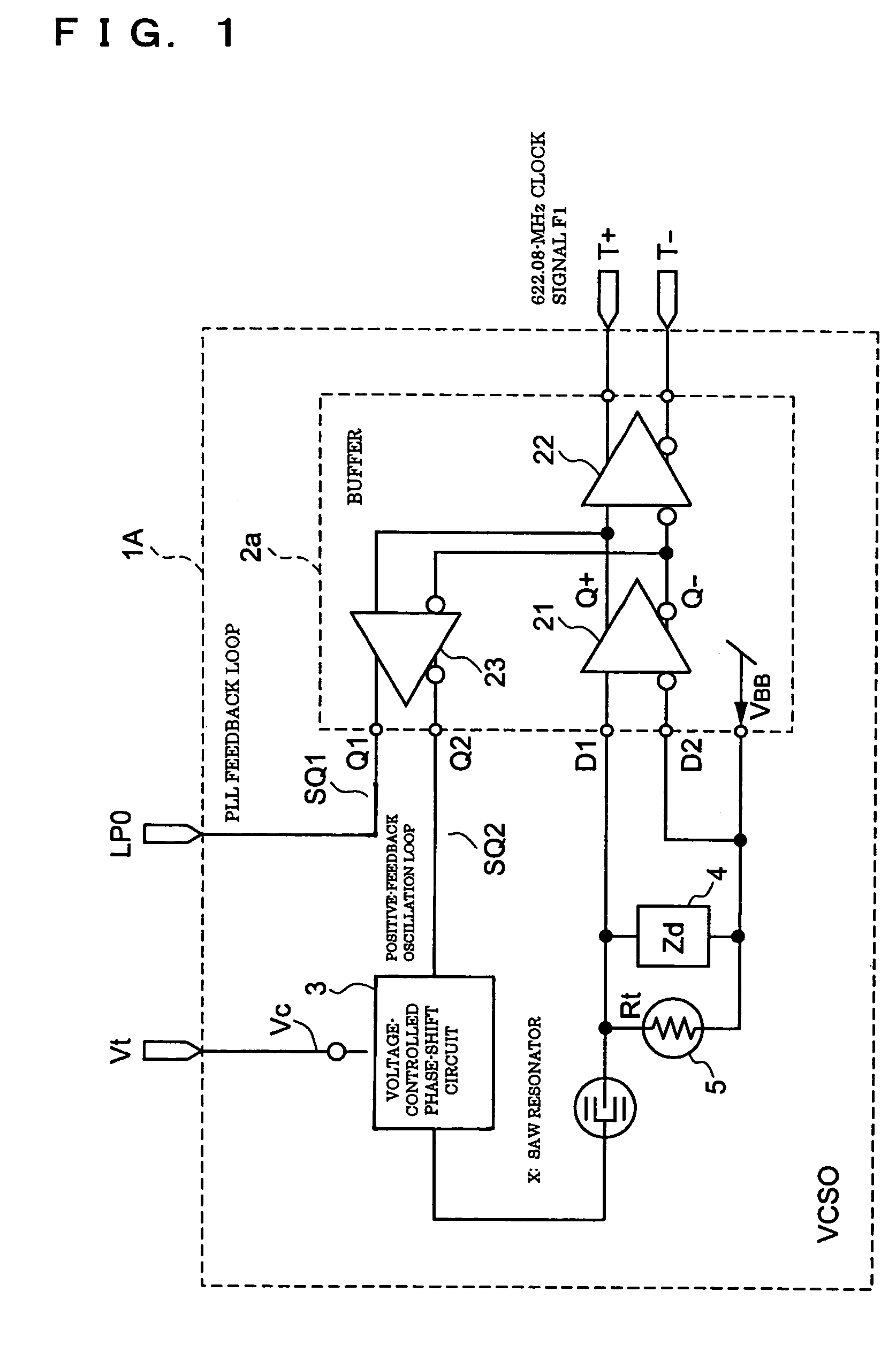

InactiveUS20050122179A1Data transmission is stableStable receptionRadiation pyrometryImpedence networksPropagation delayPhase shifted

A voltage-controlled oscillator includes a voltage-controlled phase-shift circuit, outputting a signal with the shift deviated from an input signal by a specified amount with an external control voltage Vt, a SAW resonator, a buffer, inputting a resonance signal having a specified resonance frequency from the SAW resonator, outputting a clock signal with a desired frequency, and outputting a positive-feedback-oscillation-loop output signal, wherein the voltage-controlled phase-shift circuit, the SAW resonator, and the buffer construct a positive-feedback oscillation loop, in which the frequency temperature characteristic of the SAW resonator is rotated by a specified amount using the temperature characteristic of the propagation delay time of the buffer to correct the frequency temperature characteristic of the SAW resonator.

Owner:SEIKO EPSON CORP

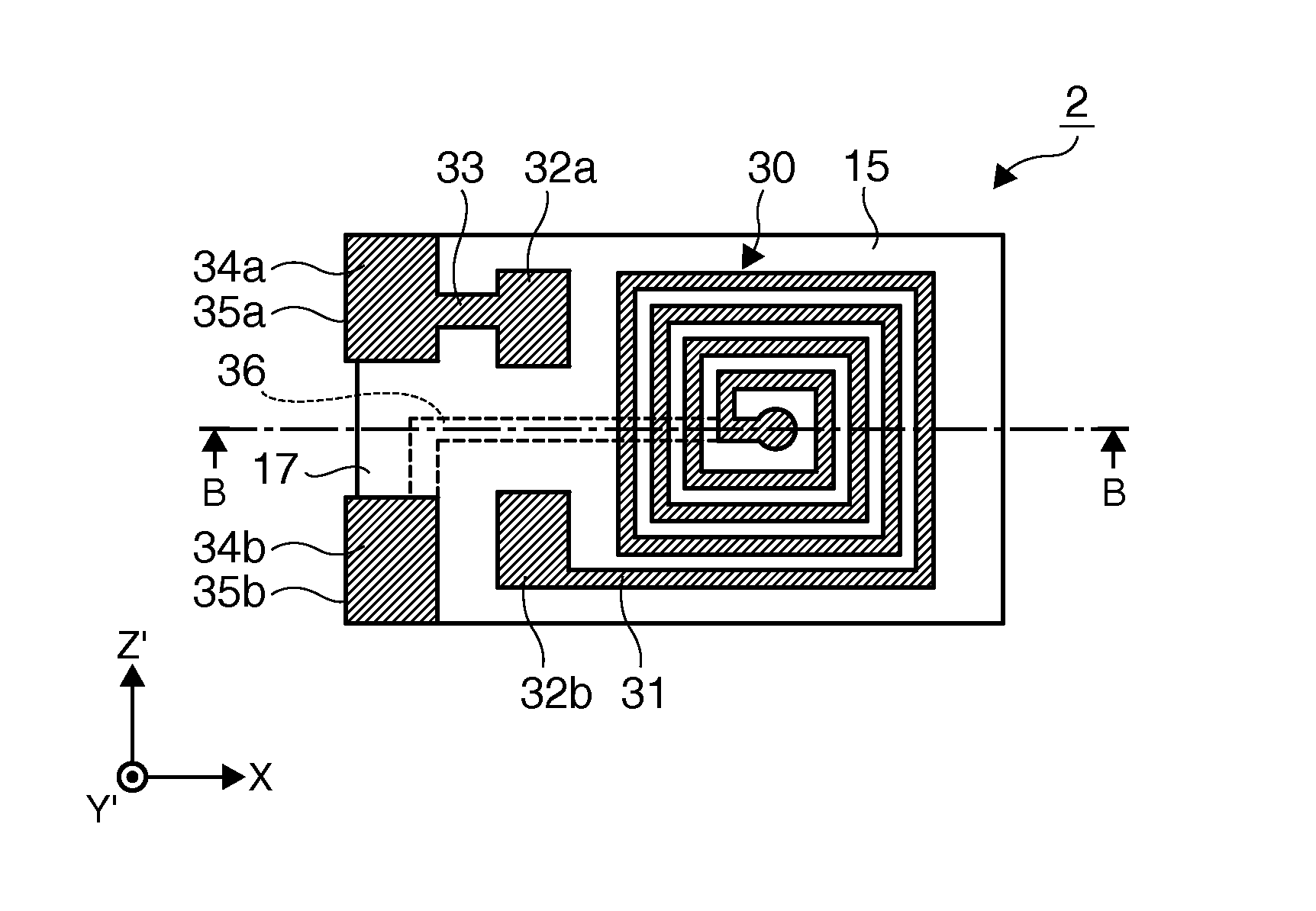

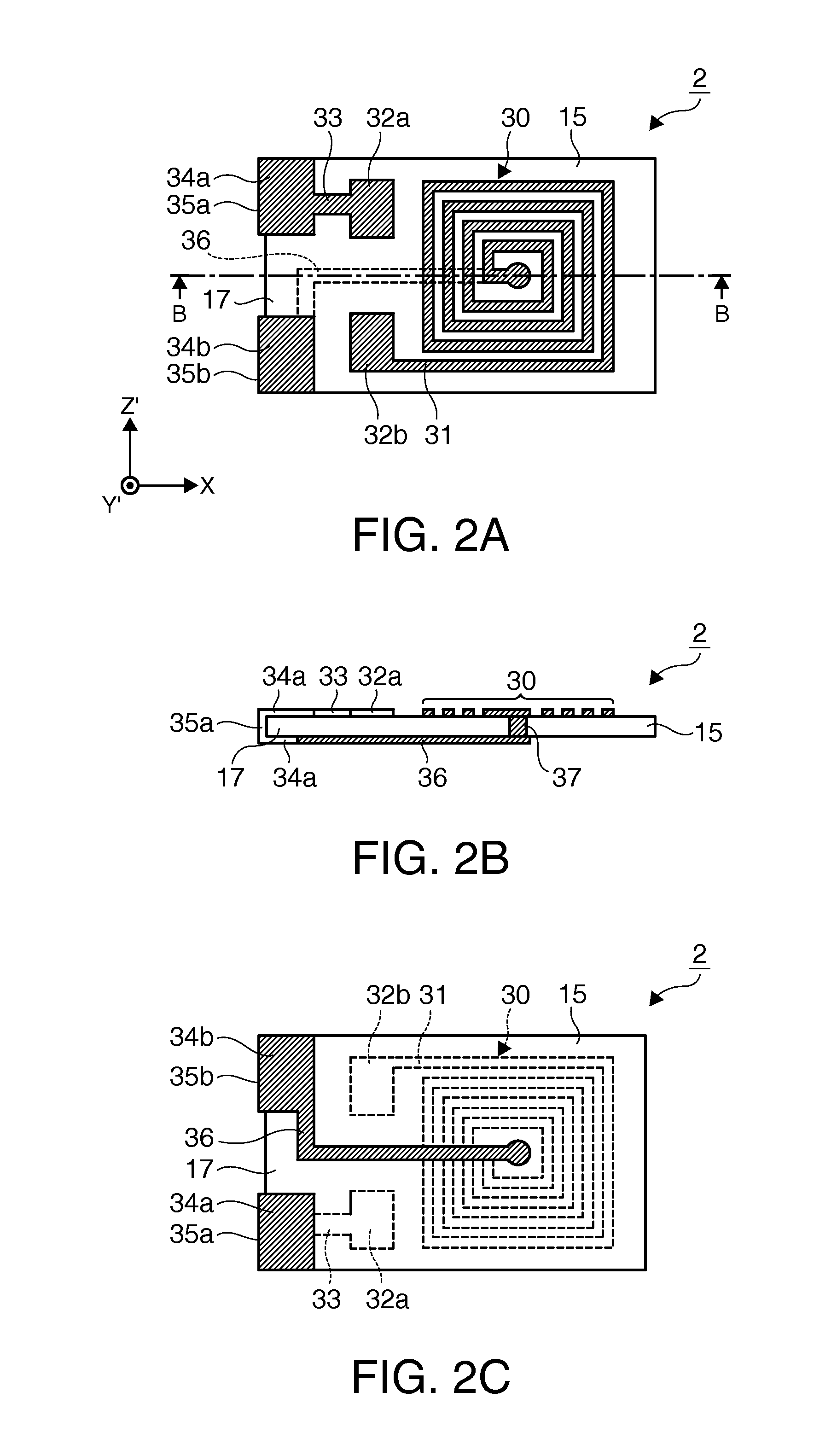

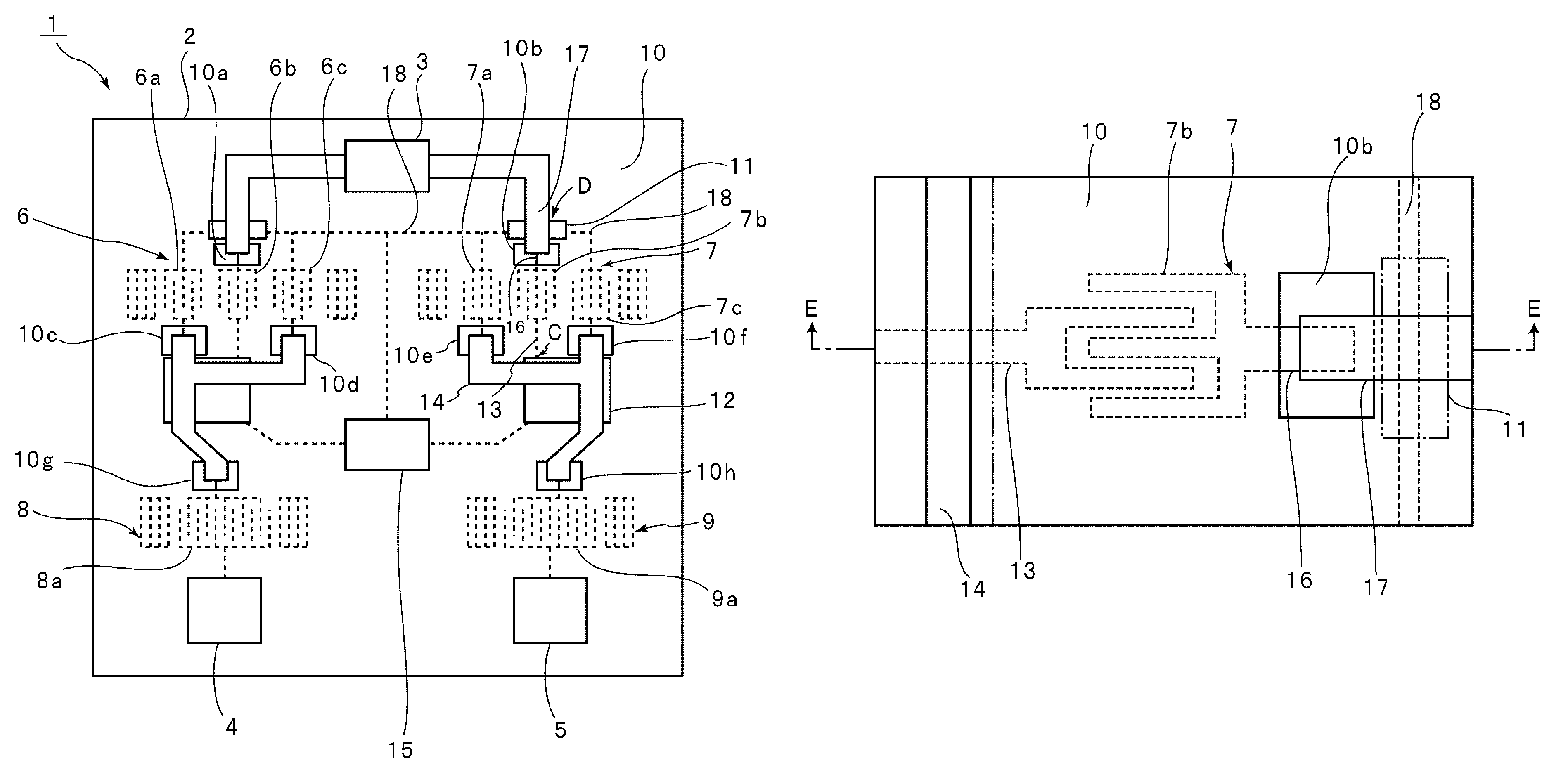

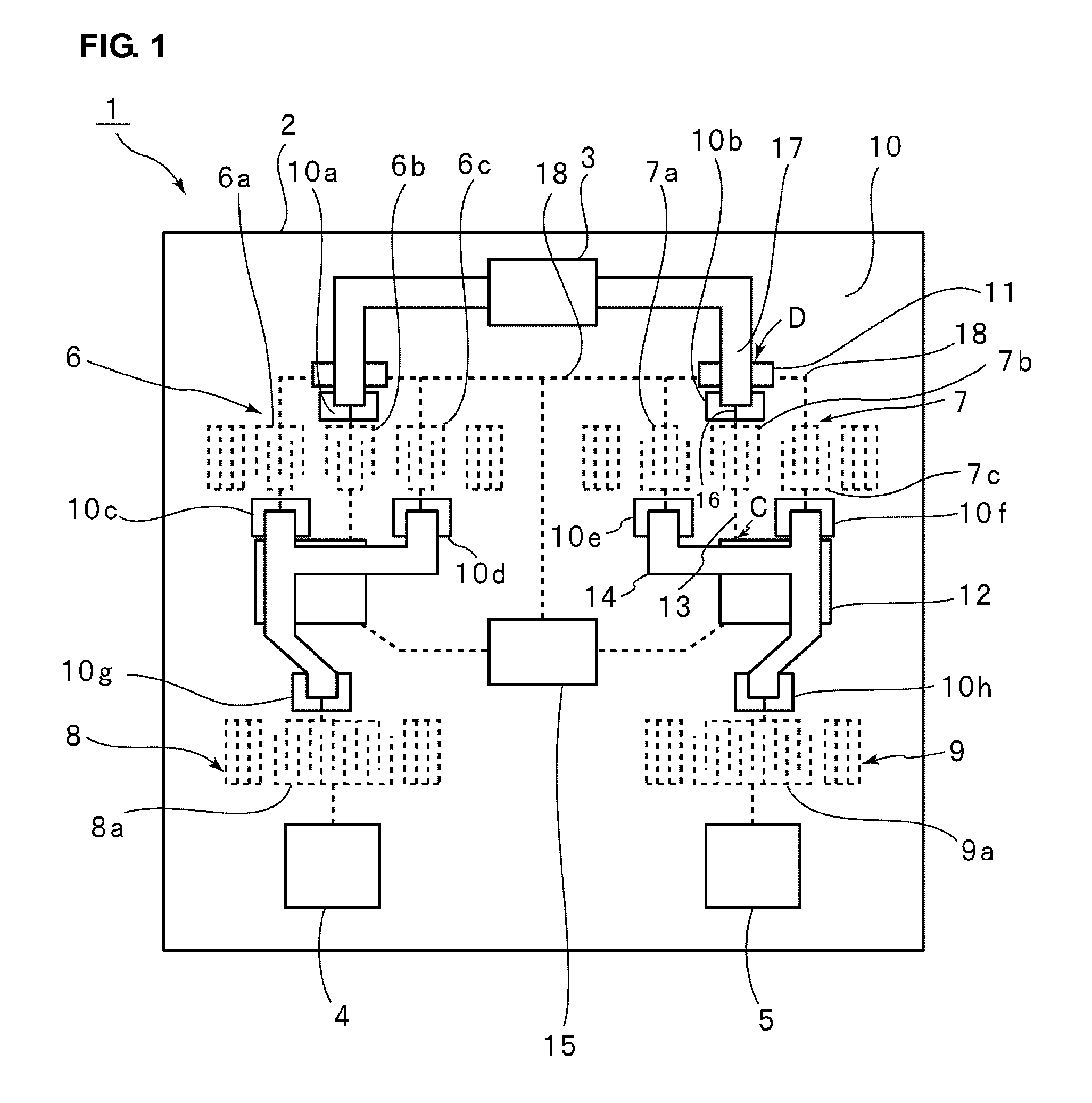

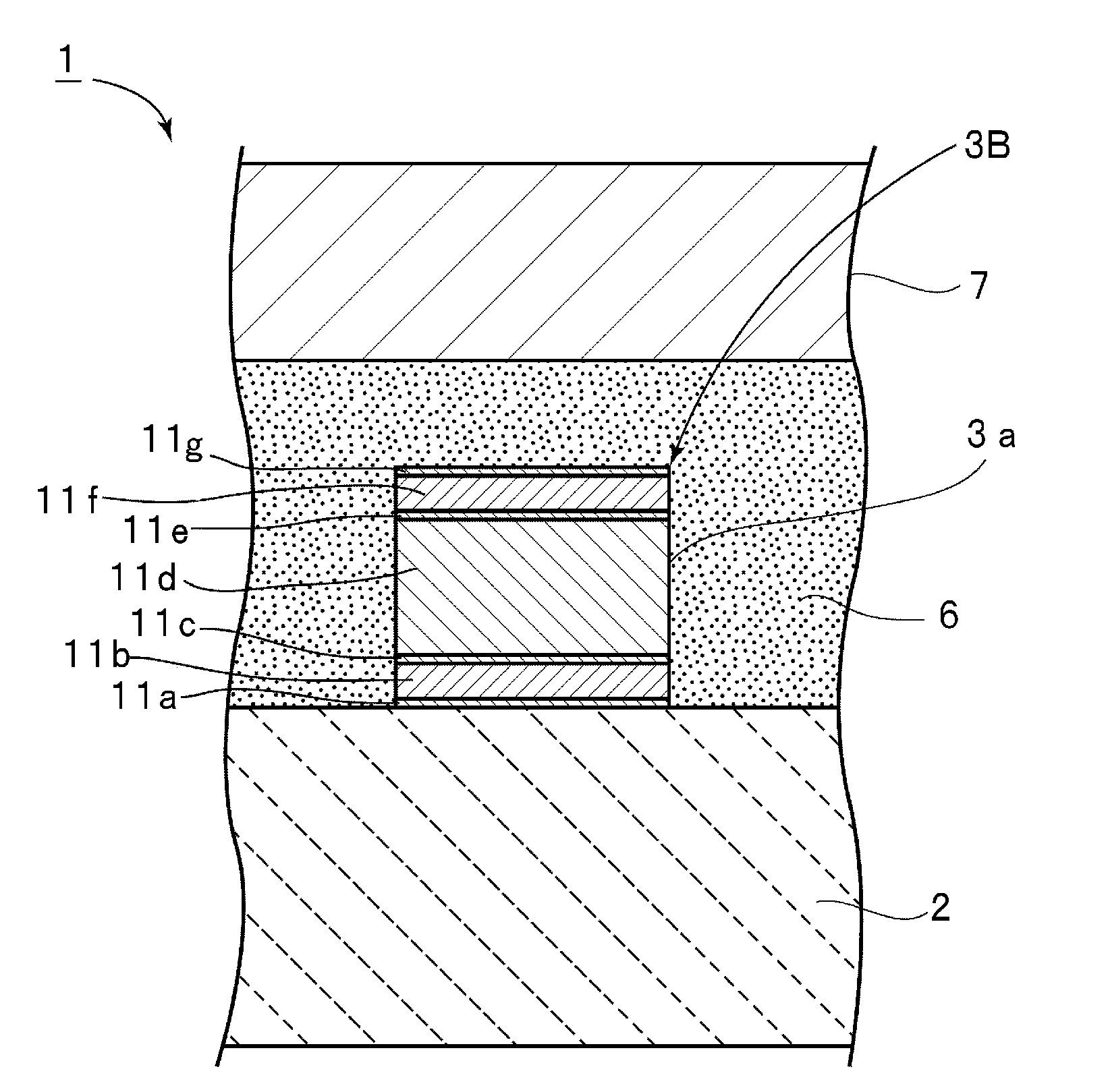

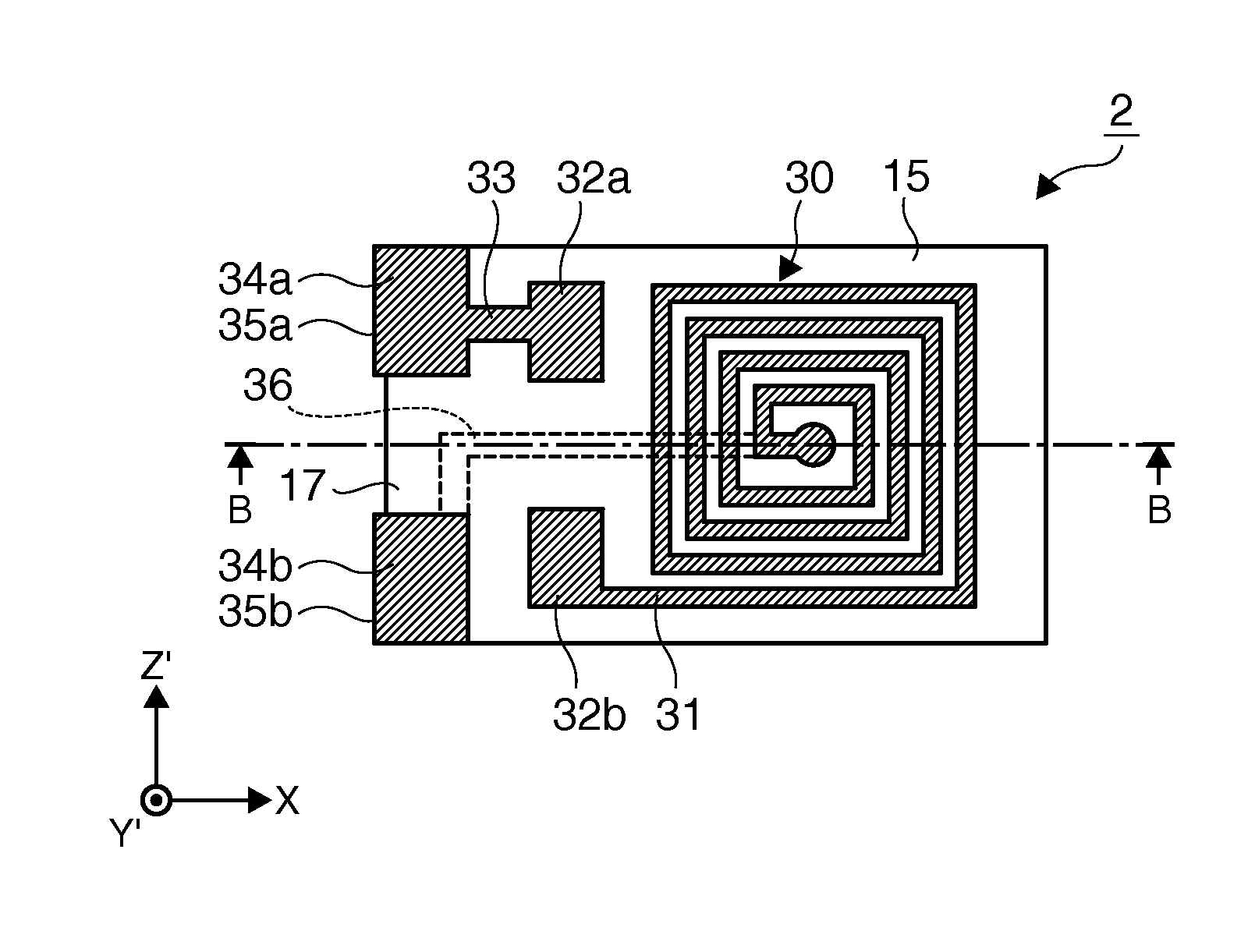

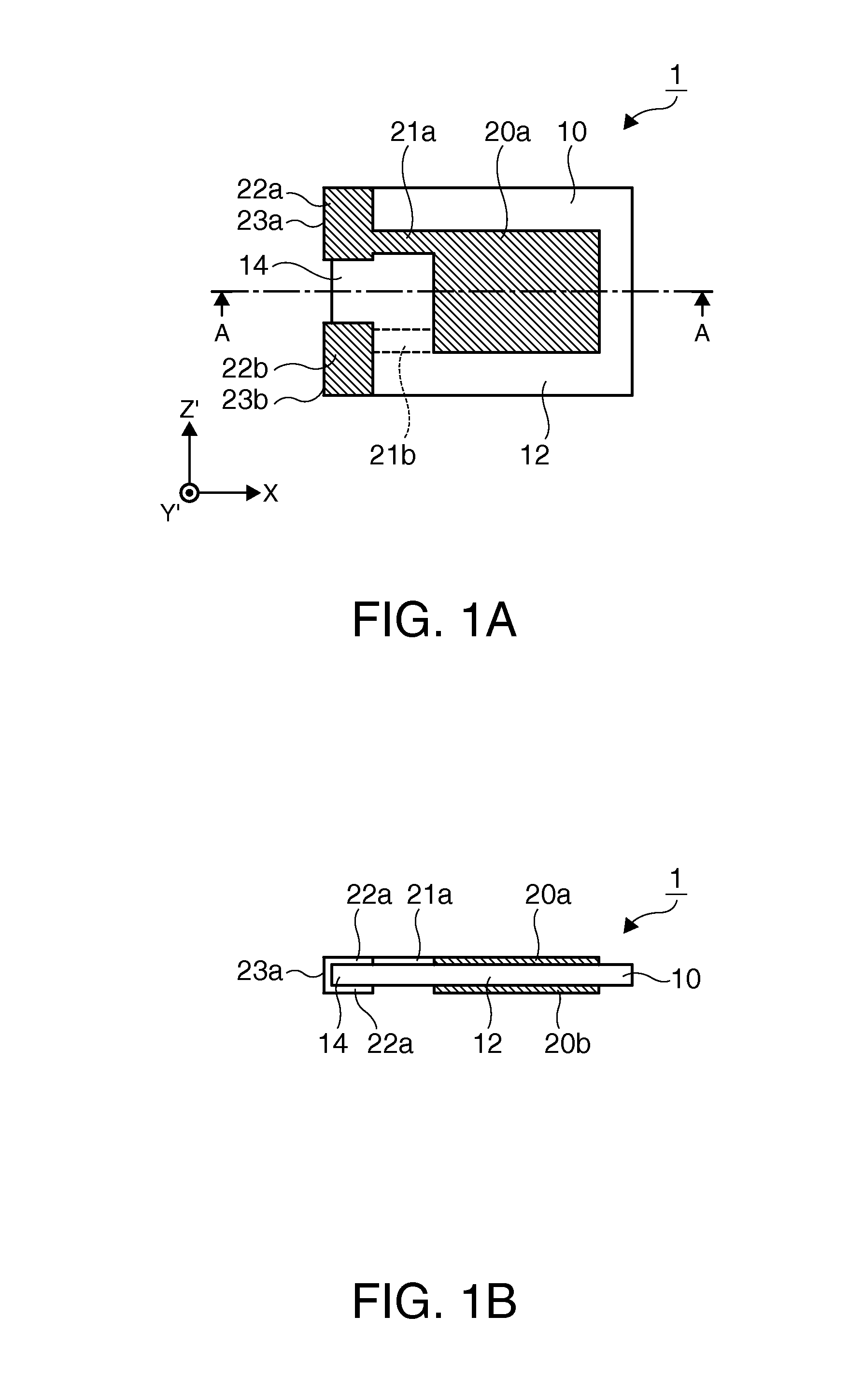

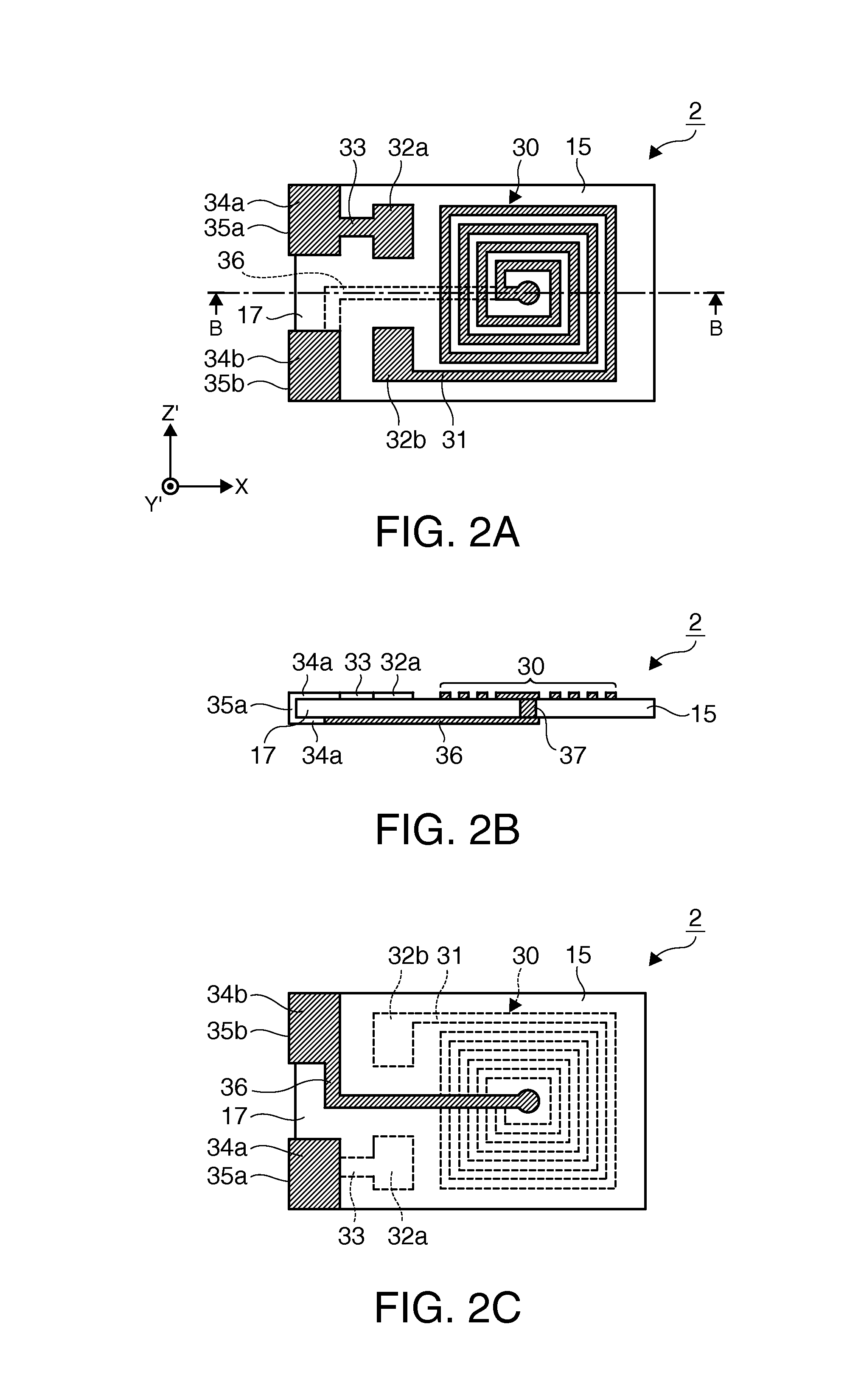

Resonating element, resonator, electronic device, electronic apparatus, and moving body

InactiveUS20130335157A1Excellent frequency temperature characteristicsRelieve pressureImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectricityElectron

A resonating element includes a resonator element that includes a vibrating portion and an excitation electrode provided on both main surfaces of the vibrating portion, an intermediate substrate in which the resonator element is mounted so as to be spaced from the excitation electrode, and a spiral electrode pattern that is provided on at least one main surface of the intermediate substrate, in which the electrode pattern is electrically connected to the excitation electrode.

Owner:SEIKO EPSON CORP

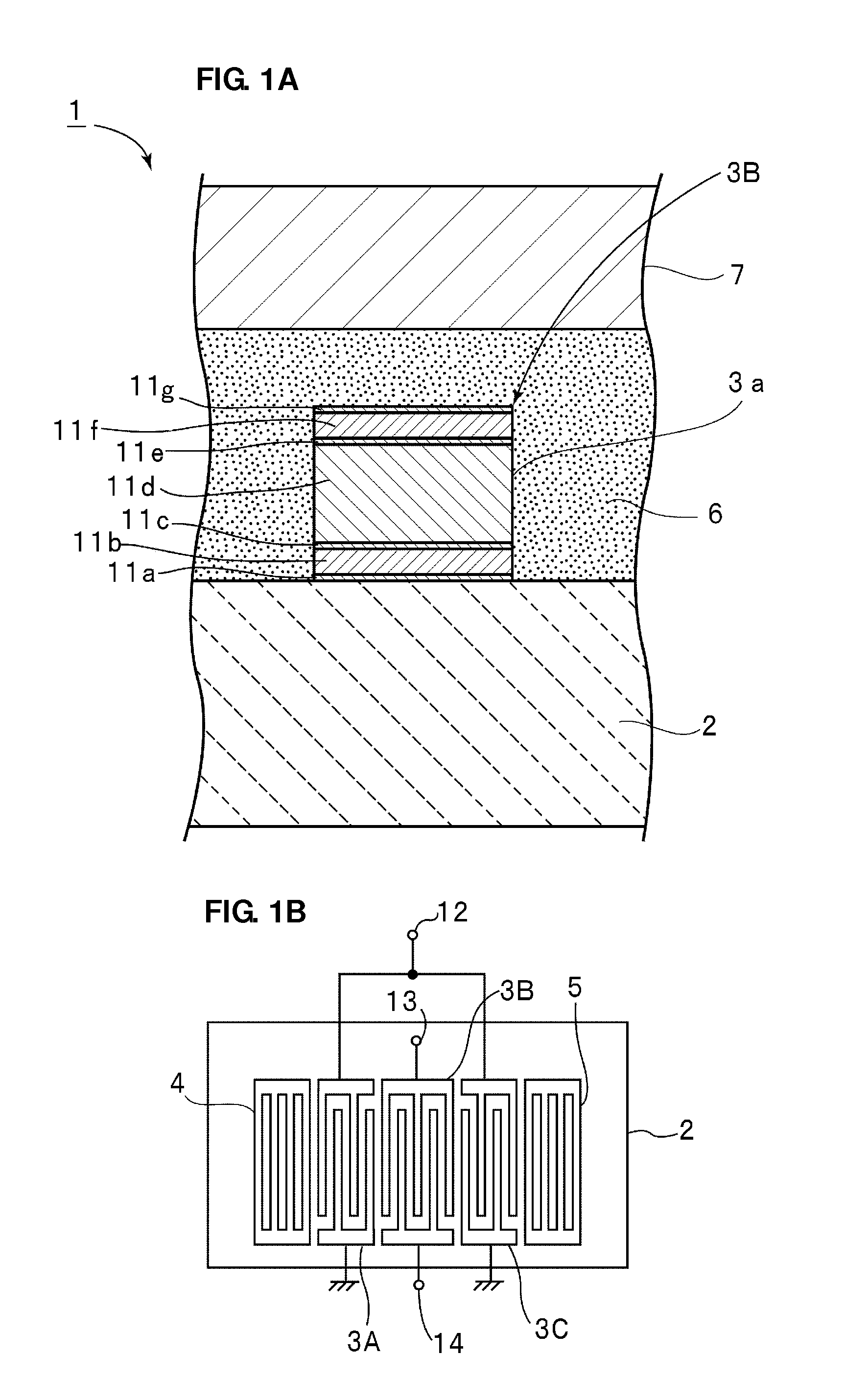

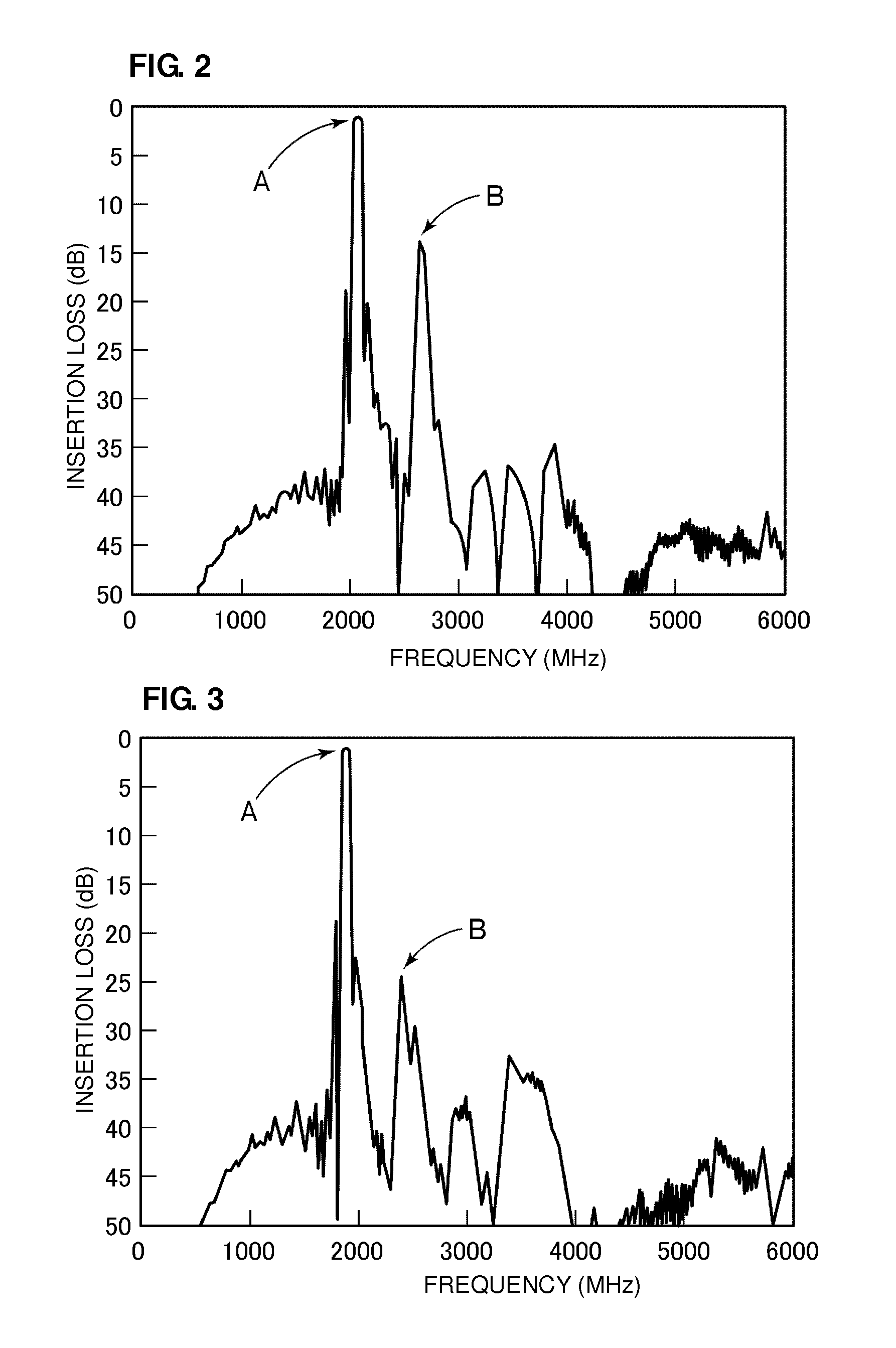

Surface acoustic wave device and electronic apparatus

InactiveUS7696675B2Excellent frequency temperature characteristicsHigh frequencyImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveSurface acoustic wave

A surface acoustic wave device includes: a quartz substrate; and at least a single-type IDT electrode provided on a surface of the quartz substrate for exciting a Rayleigh surface acoustic wave in the upper limit mode of the surface acoustic wave stop band with the following relationships satisfied;φ=0°, 110°≦θ≦140°, and 38°≦|ψ|≦44°, when the quartz substrate cut angles and the surface acoustic wave propagation direction are represented by Euler angles (φ, θ, ψ), and wherein the electrode thickness relative to wavelength set such thatH / λ≧0.1796η3−0.4303η2+0.2071η+0.0682, with the thickness of the IDT electrode defined as H, the width of an electrode IDT finger defined as d, the pitch between the electrode fingers of the IDT electrode as P, the wavelength of the surface acoustic wave as λ, and where η=d / P.

Owner:COLUMBIA PEAK VENTURES LLC

Voltage-controlled oscillator, clock converter, and electronic device

InactiveUS7012476B2Excellent frequency temperature characteristicsStable receptionRadiation pyrometryPulse automatic controlVoltage controlVoltage-controlled oscillator

A voltage-controlled oscillator includes a voltage-controlled phase-shift circuit, outputting a signal with the shift deviated from an input signal by a specified amount with an external control voltage Vt, a SAW resonator, a buffer, inputting a resonance signal having a specified resonance frequency from the SAW resonator, outputting a clock signal with a desired frequency, and outputting a positive-feedback-oscillation-loop output signal, wherein the voltage-controlled phase-shift circuit, the SAW resonator, and the buffer construct a positive-feedback oscillation loop, in which the frequency temperature characteristic of the SAW resonator is rotated by a specified amount using the temperature characteristic of the propagation delay time of the buffer to correct the frequency temperature characteristic of the SAW resonator.

Owner:SEIKO EPSON CORP

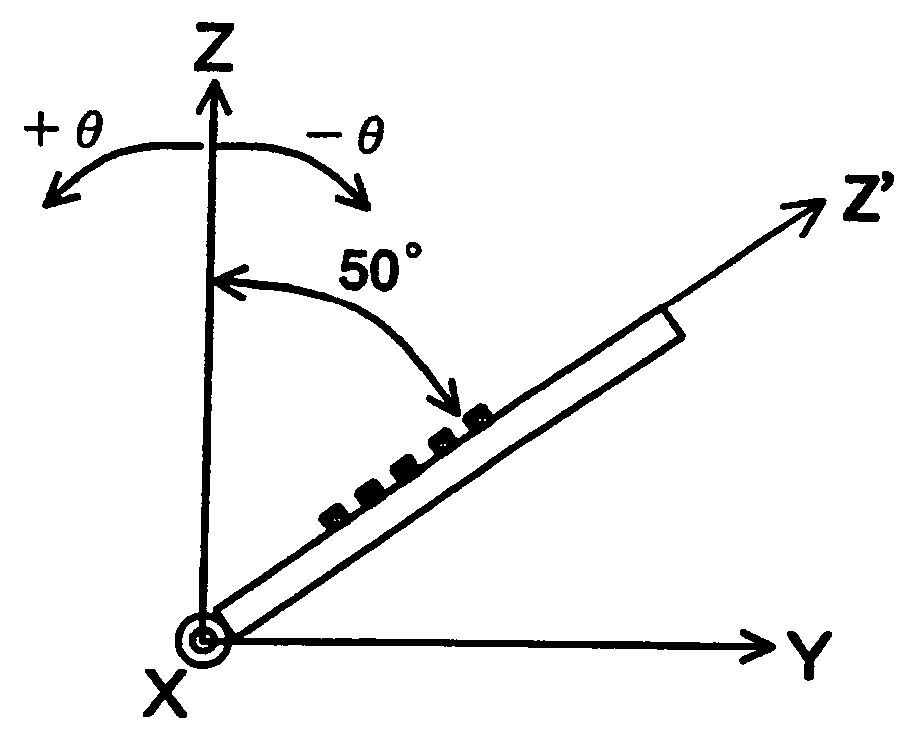

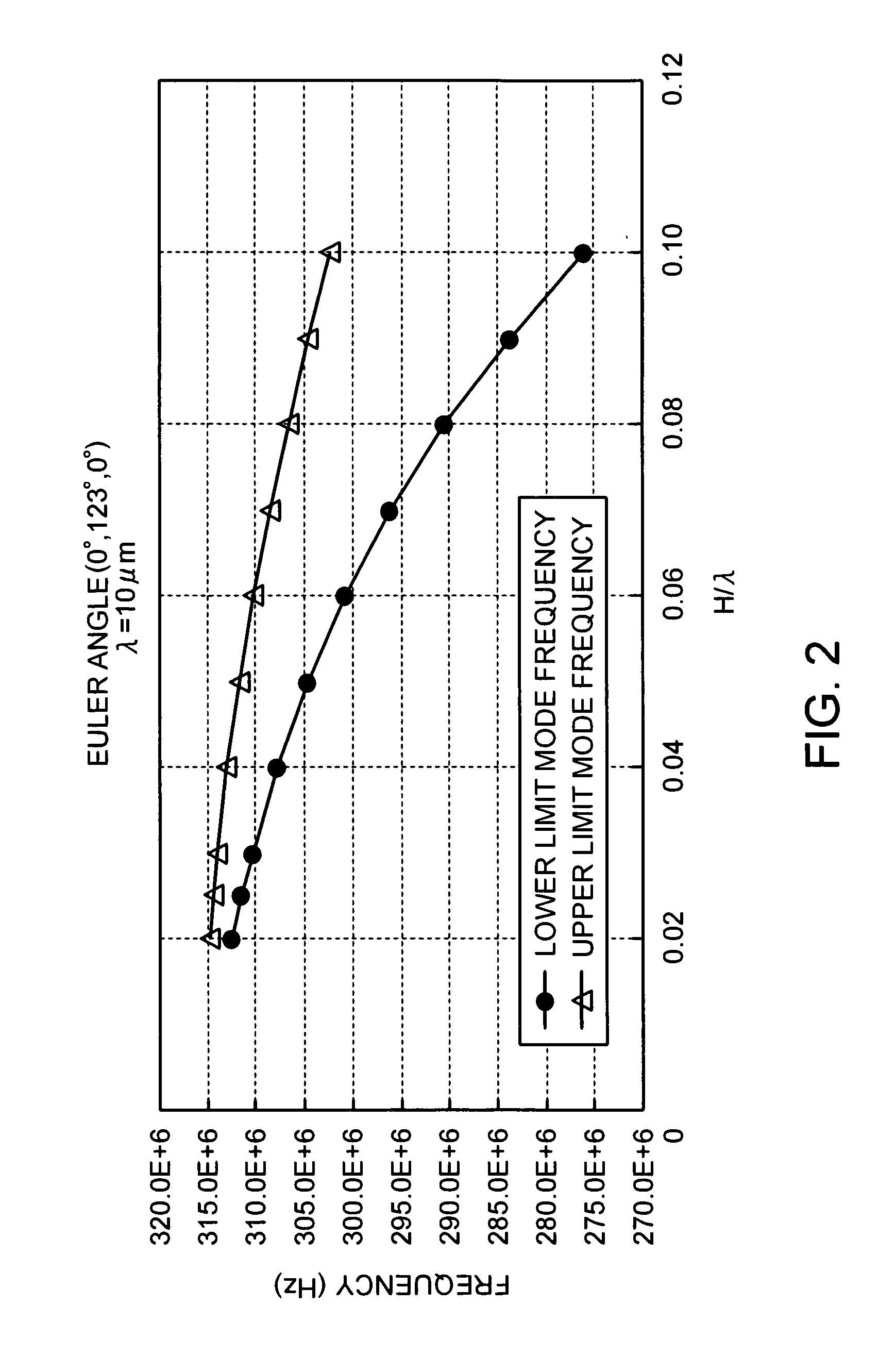

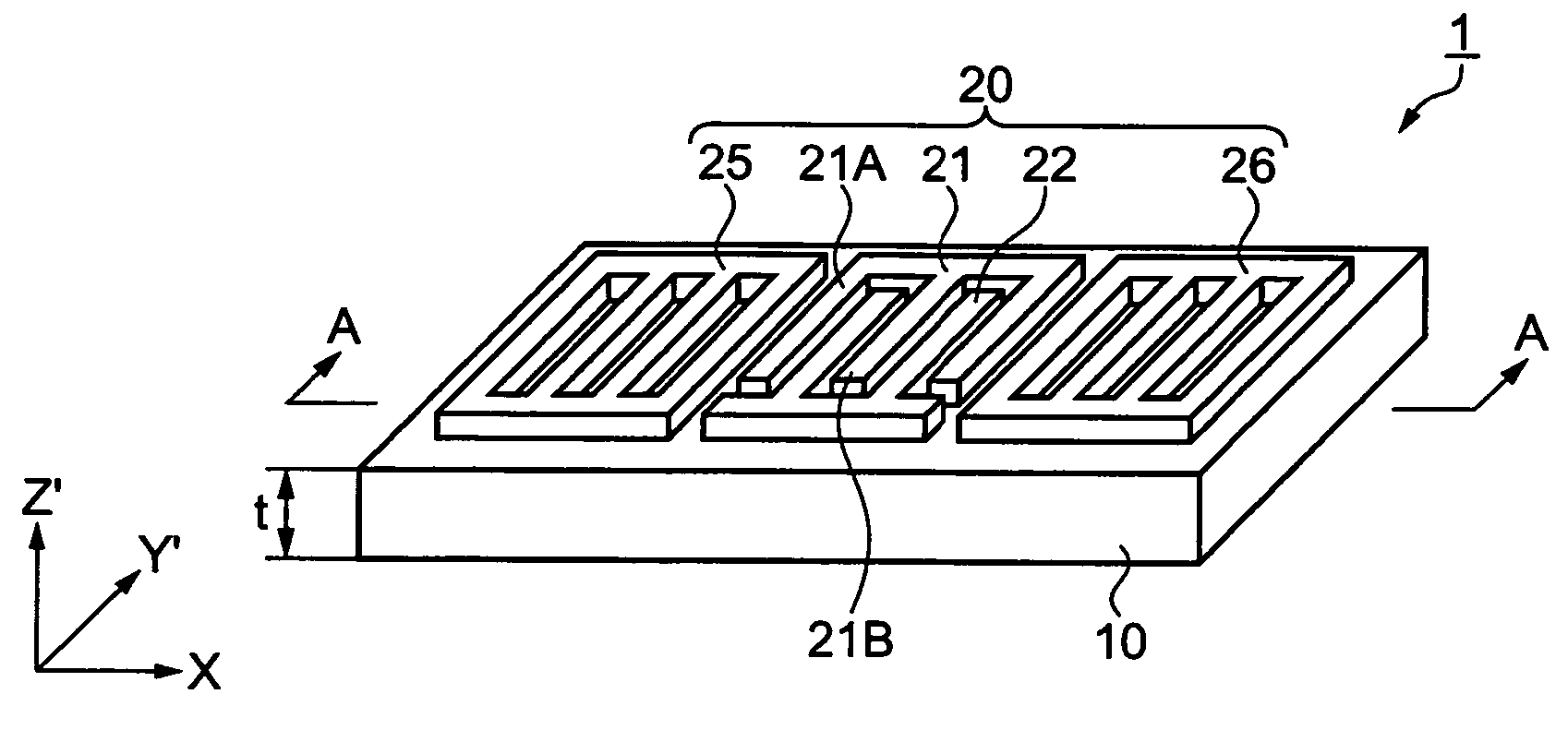

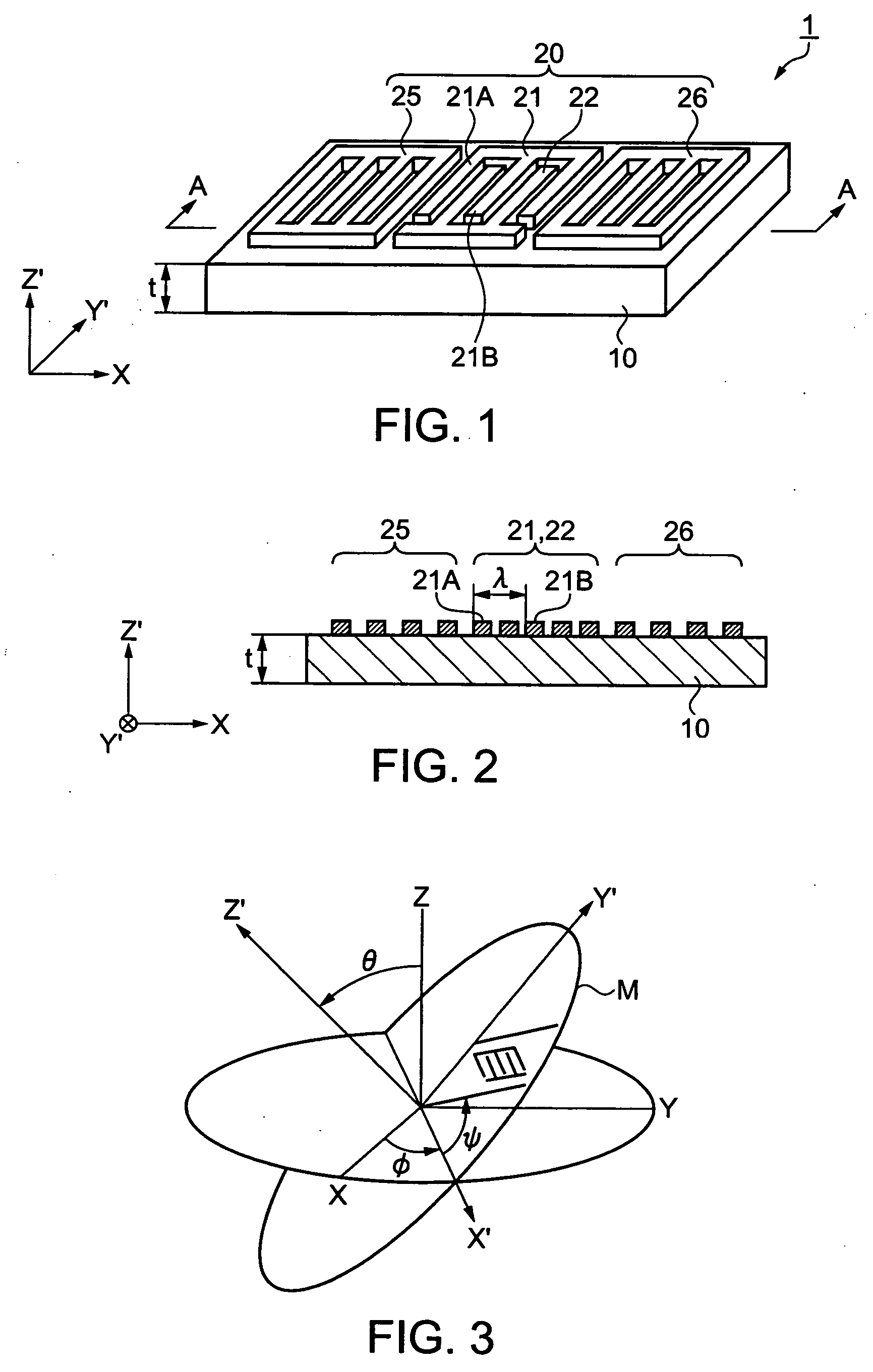

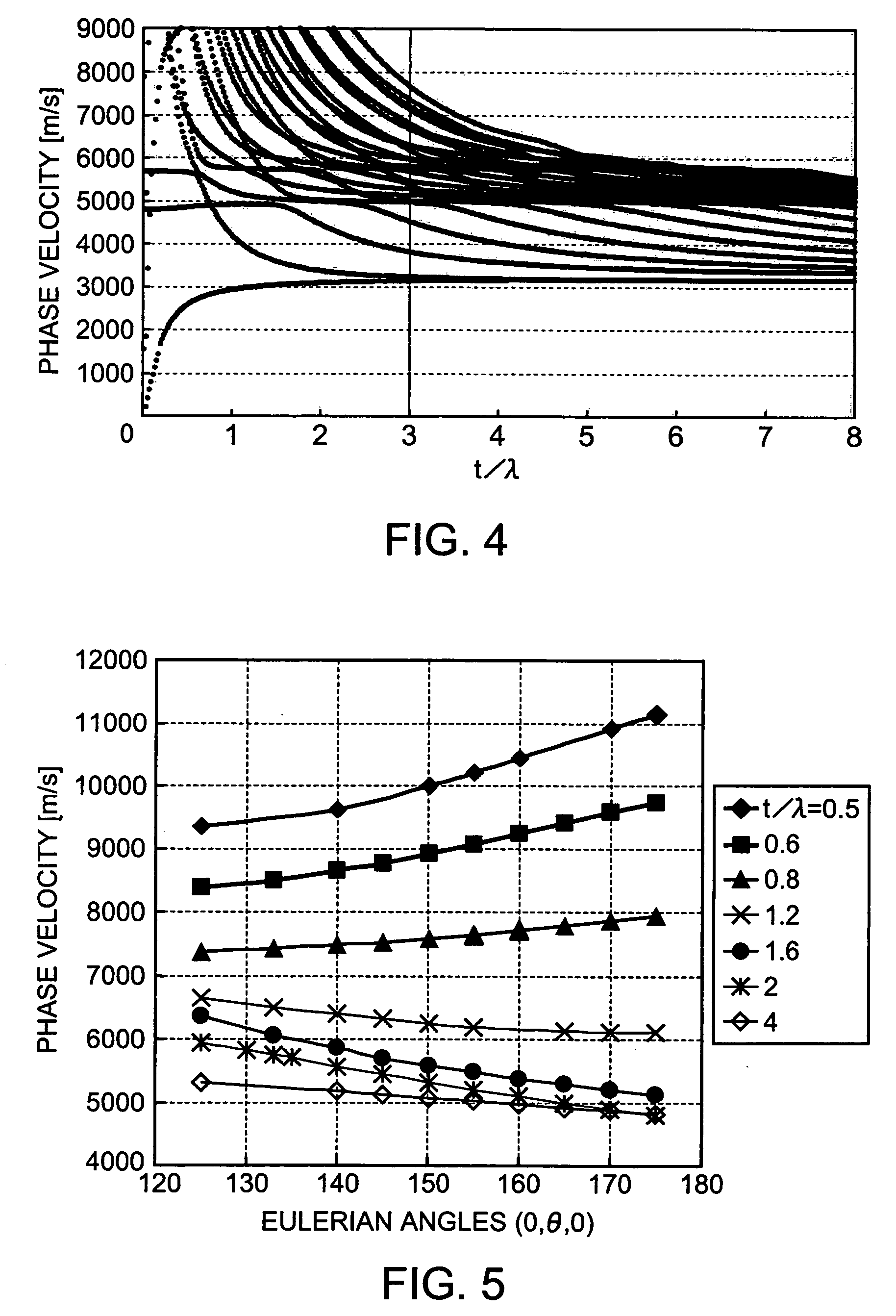

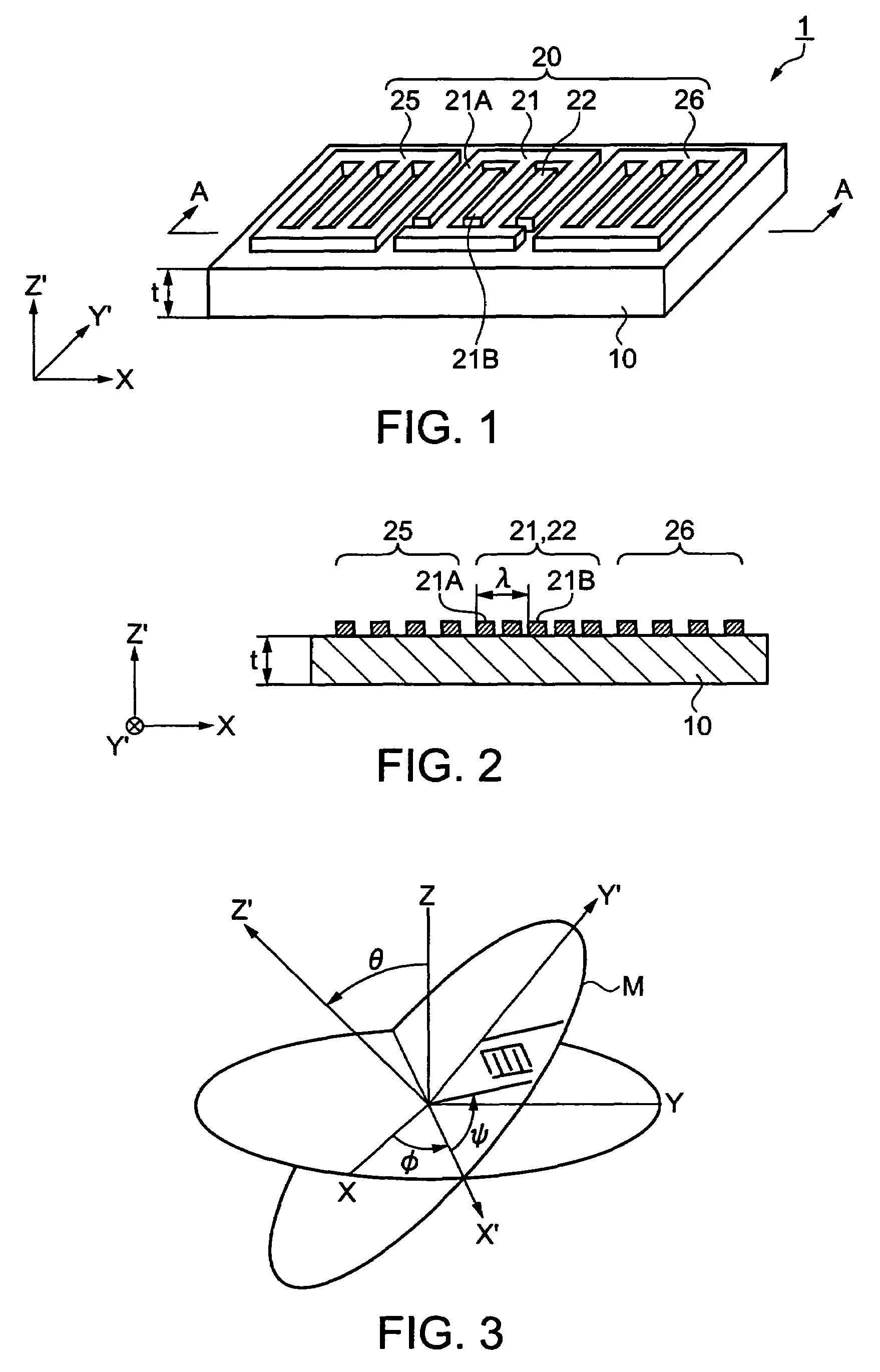

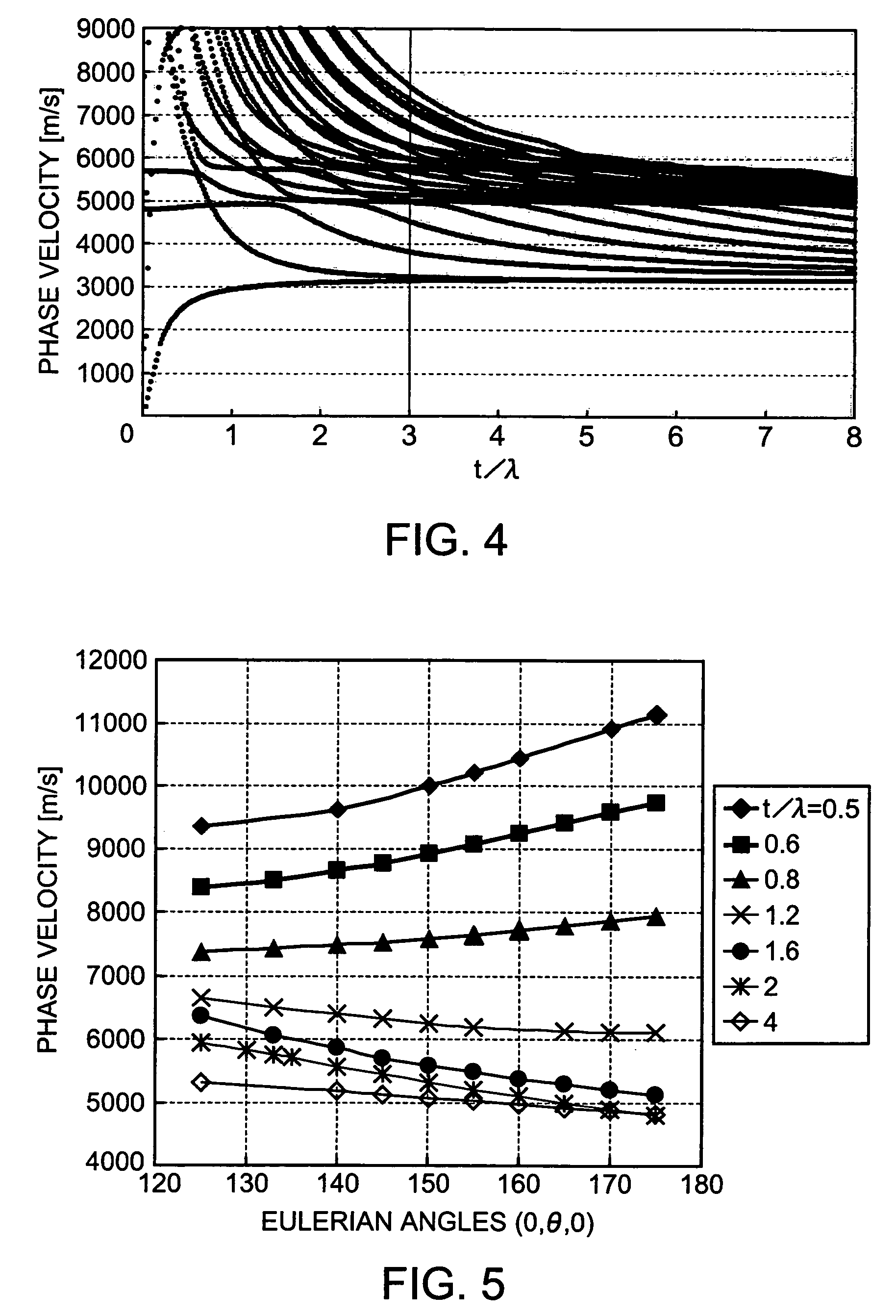

Lamb-wave high-frequency resonator

InactiveUS20060152107A1High-frequency waveExcellent frequency temperature characteristicsImpedence networksPiezoelectric/electrostriction/magnetostriction machinesQuartz substrateResonator

A Lamb-wave high-frequency resonator includes a comb-shaped IDT electrode for exciting a Lamb wave on one main surface of a quartz substrate. The IDT electrode is formed such that the cut angle of the quartz substrate and the direction of propagation of the Lamb wave are expressed in Euler angles (0, θ, 0).

Owner:SEIKO EPSON CORP

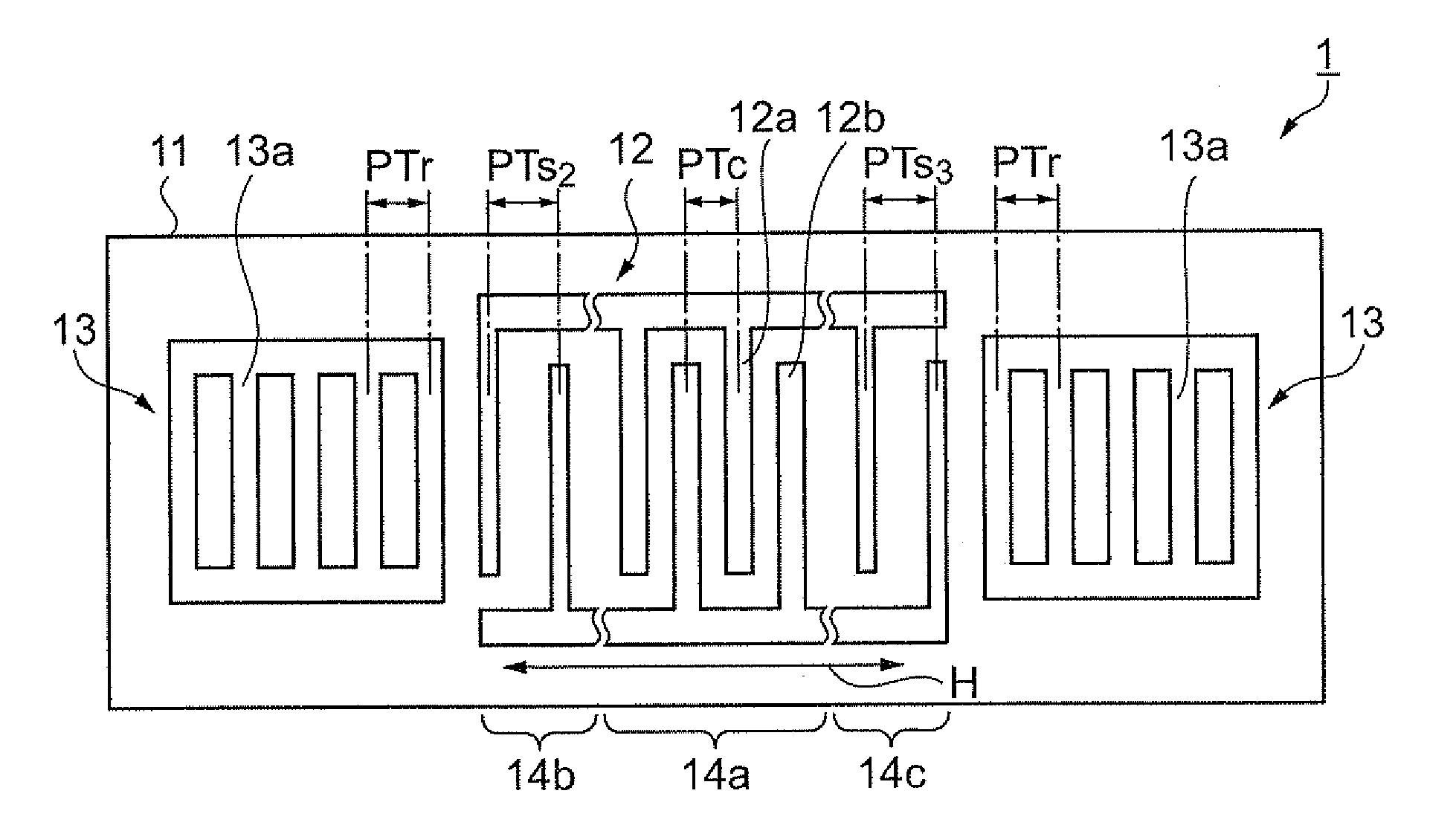

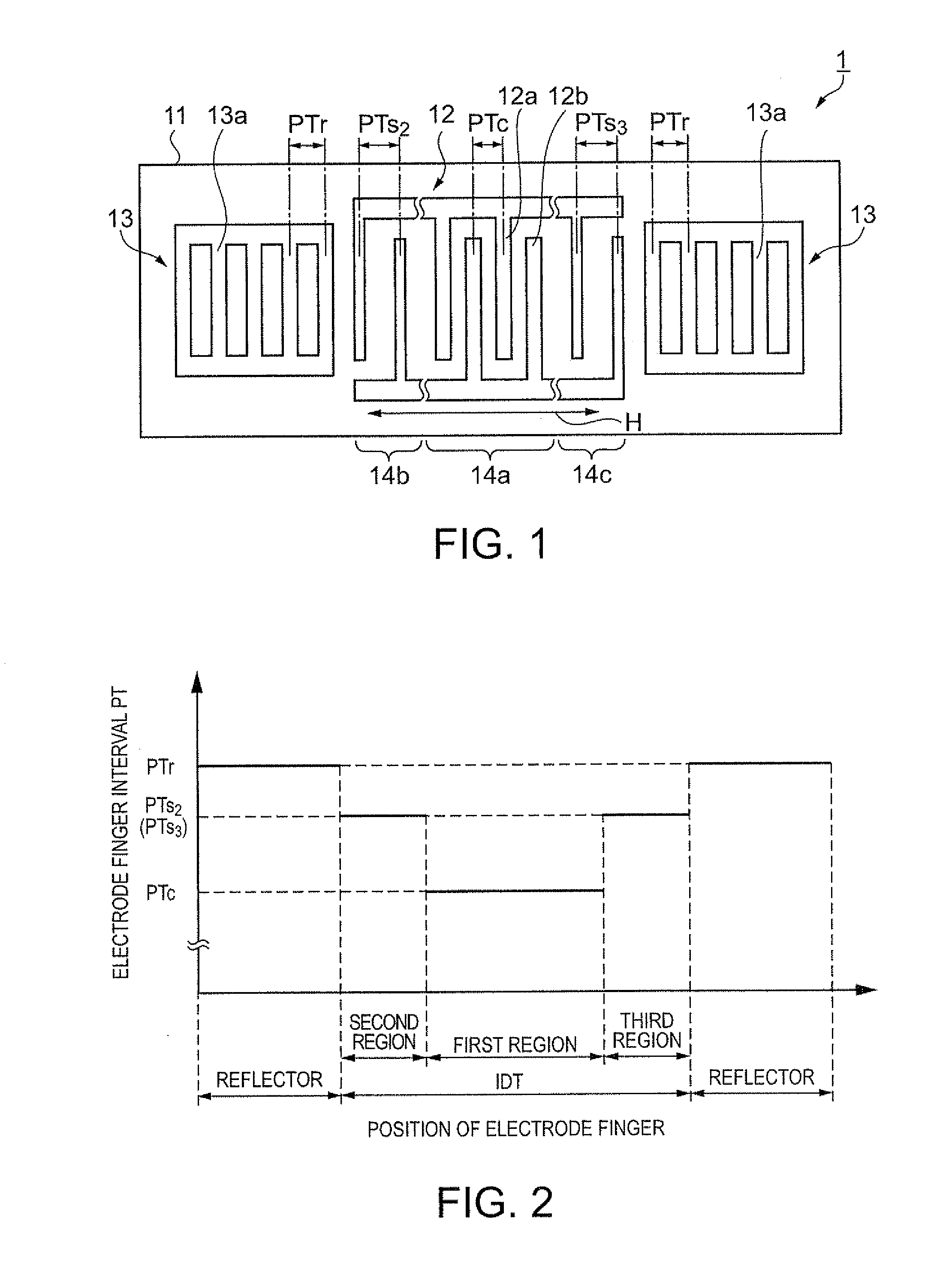

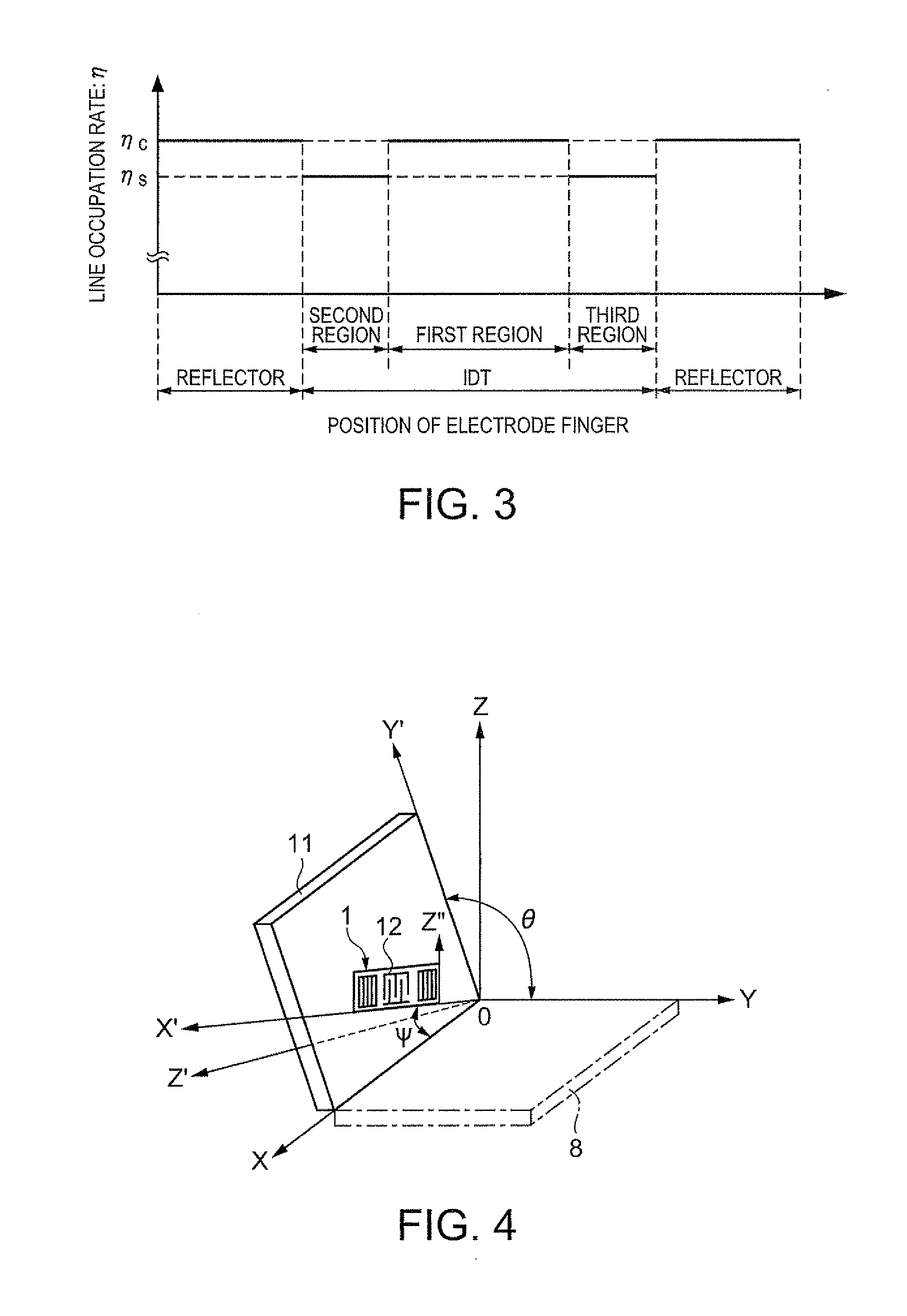

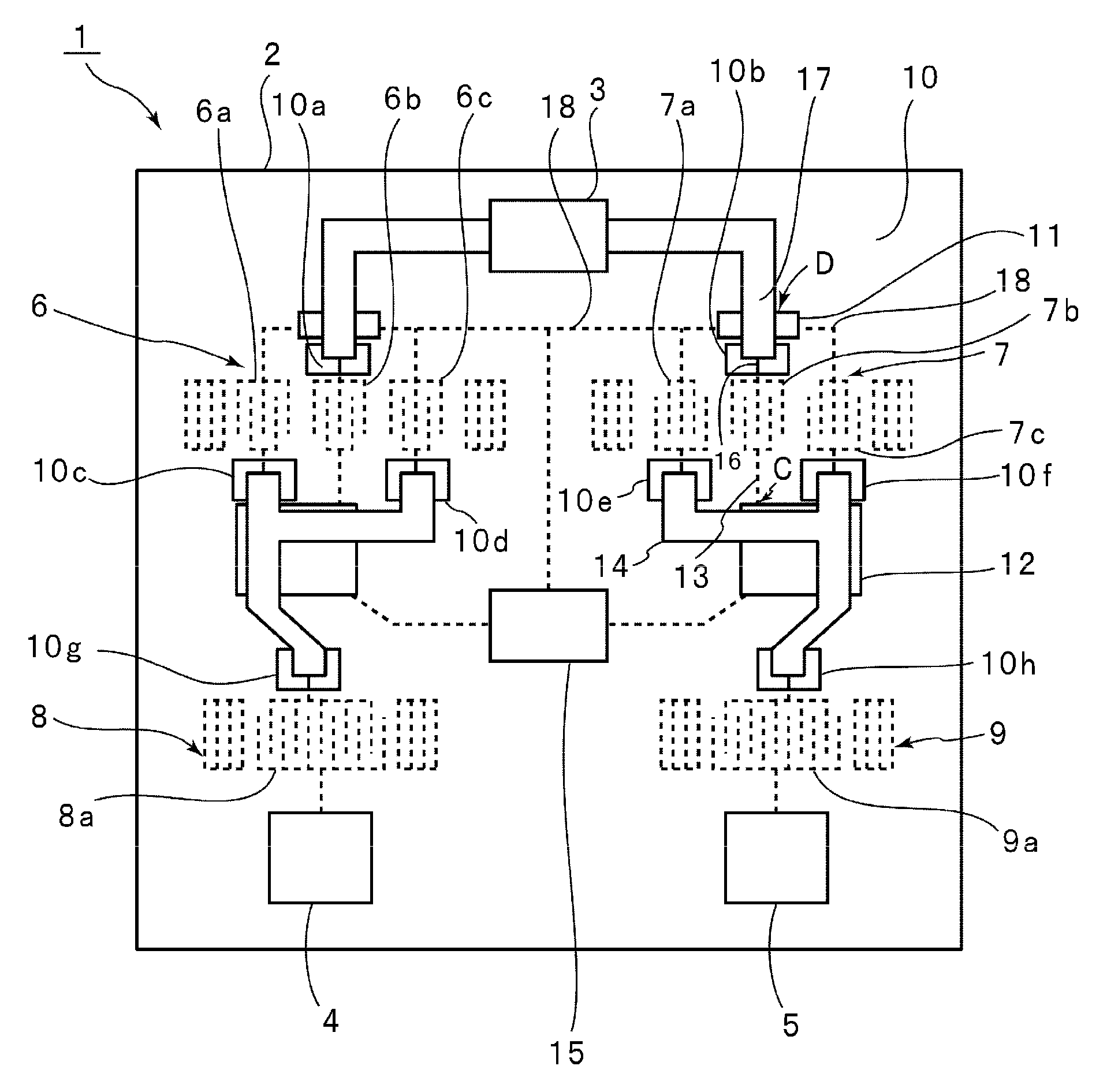

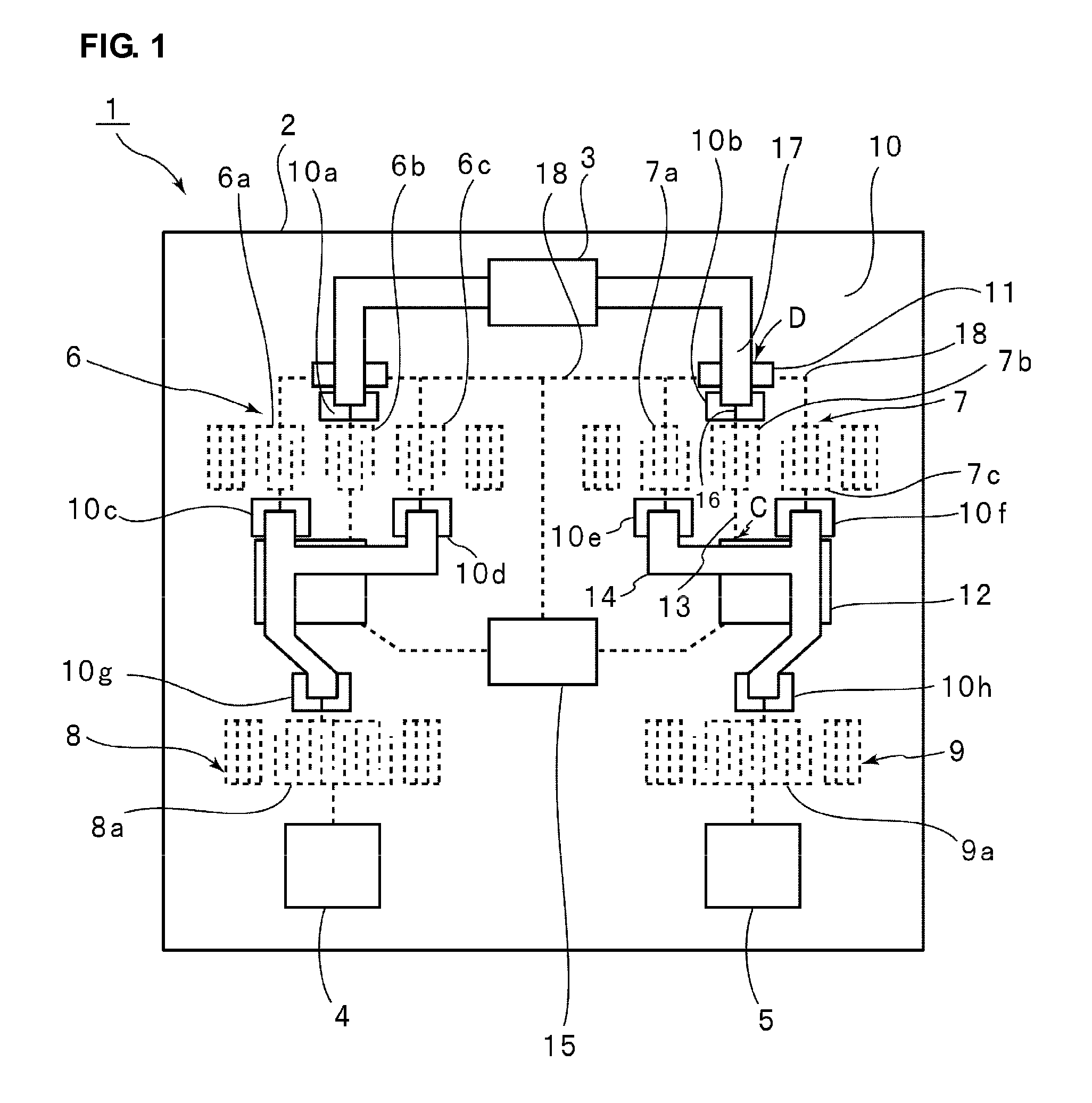

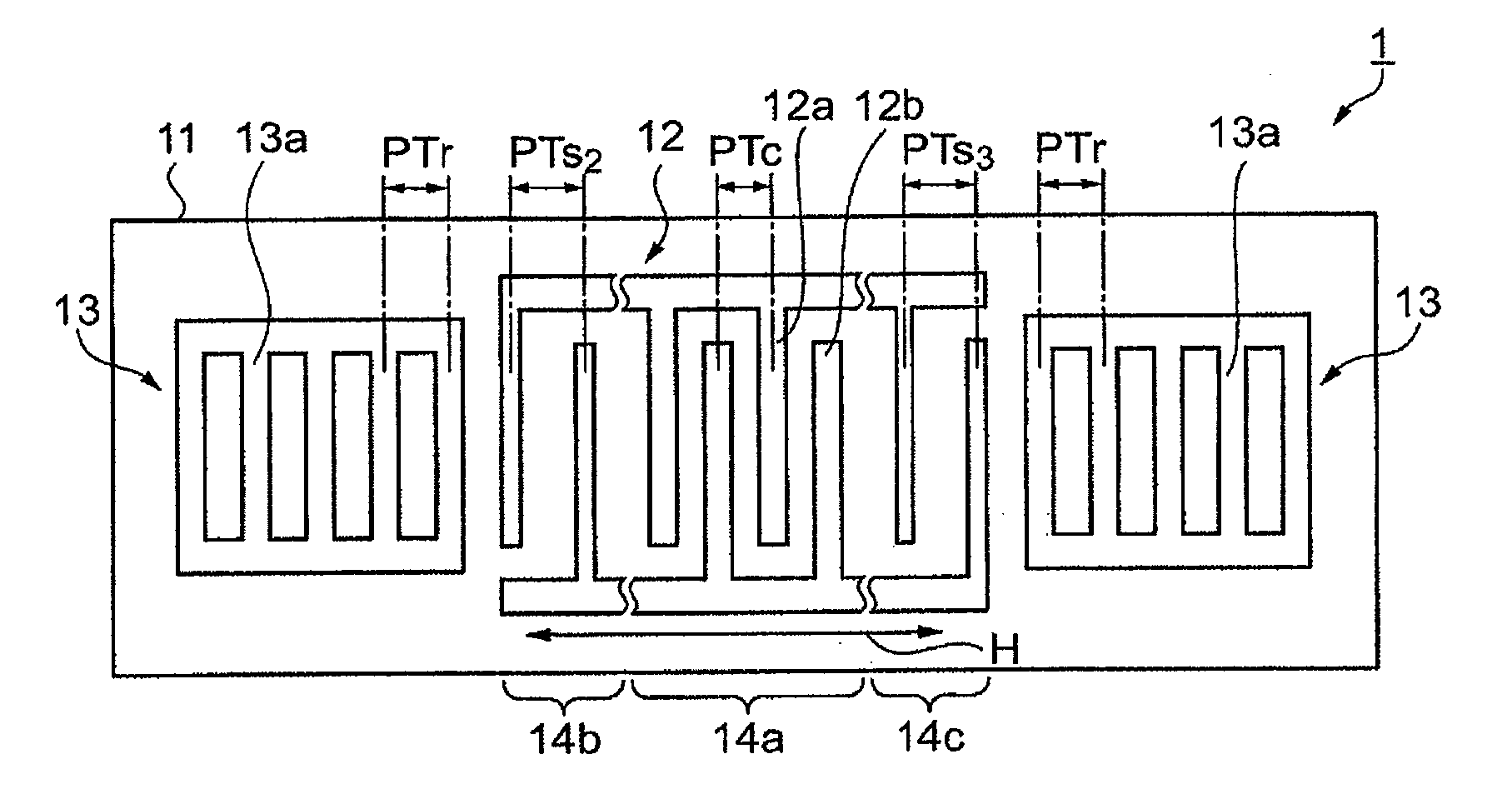

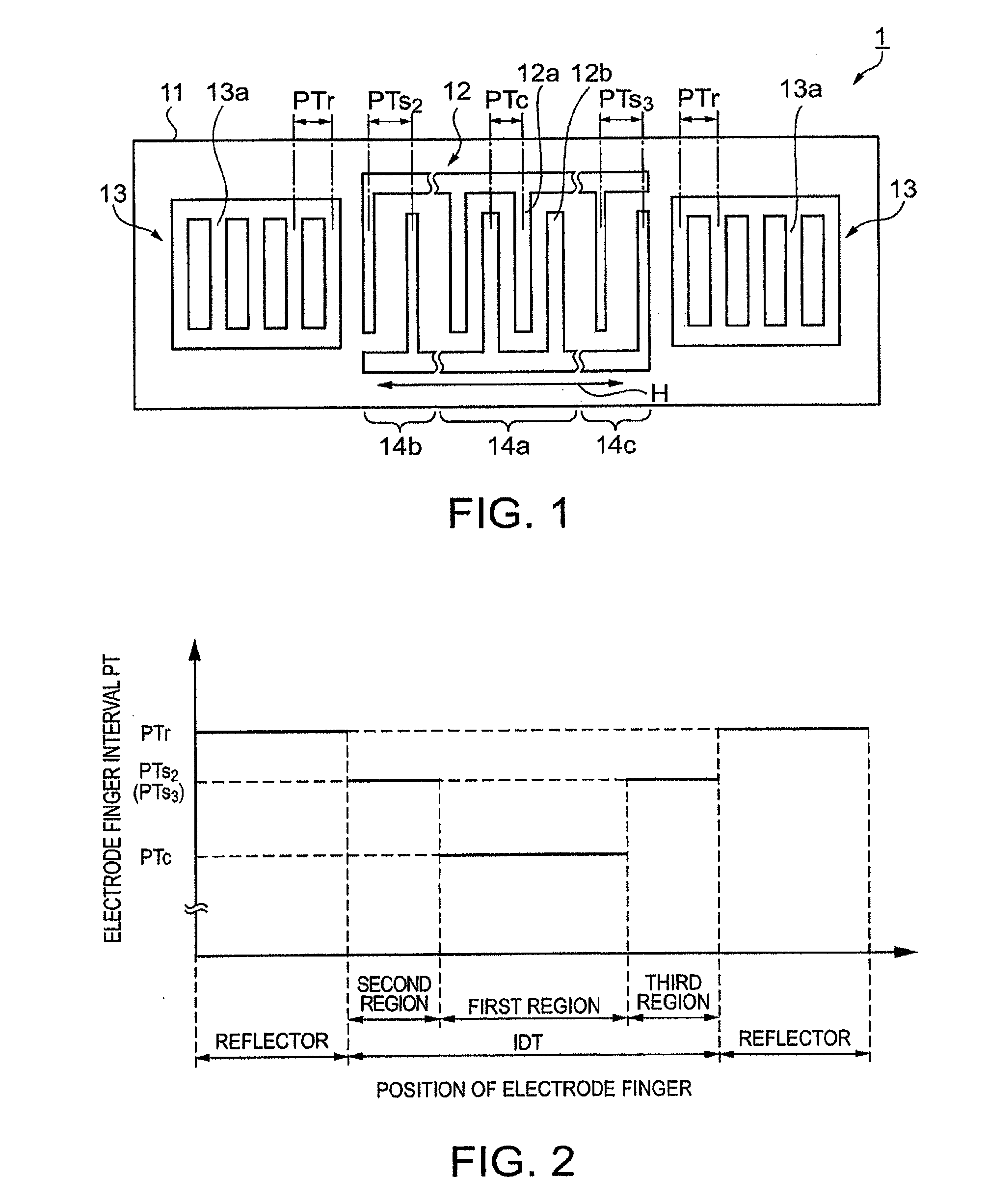

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module device

ActiveUS20100102669A1Reduce power consumptionGrowth inhibitionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectromechanical coupling coefficientSurface acoustic wave oscillators

A surface acoustic wave resonator includes a piezoelectric substrate and an interdigital transducer (IDT) that includes electrode fingers exciting a surface acoustic wave on the piezoelectric substrate, a first region at a center of the IDT, and a second region and a third region at opposite sides of the IDT. In the IDT, a line occupation rate at which an electromechanical coupling coefficient becomes a maximum is different from the line occupation rate at which reflection of the surface acoustic wave becomes a maximum.

Owner:SEIKO EPSON CORP

Surface acoustic wave device and electronic apparatus

InactiveUS20100001617A9Excellent frequency temperature characteristicsHigh frequencyPiezoelectric/electrostriction/magnetostriction machinesImpedence networksAcoustic waveSurface acoustic wave

A surface acoustic wave device includes: a quartz substrate; and at least a single-type IDT electrode provided on a surface of the quartz substrate for exciting a Rayleigh surface acoustic wave in the upper limit mode of the surface acoustic wave stop band with the following relationships satisfied;φ=0, 110°≦θ≦140°, and 38°≦|ψ|≦44°, when the quartz substrate cut angles and the surface acoustic wave propagation direction are represented by Euler angles (φ, θ, ψ), and wherein the electrode thickness relative to wavelength set such thatH / λ≧0.1796η3−0.4303η2+0.2071η+0.0682, with the thickness of the IDT electrode defined as H, the width of an electrode IDT finger defined as d, the pitch between the electrode fingers of the IDT electrode as P, the wavelength of the surface acoustic wave as λ, and where η=d / P.

Owner:COLUMBIA PEAK VENTURES LLC

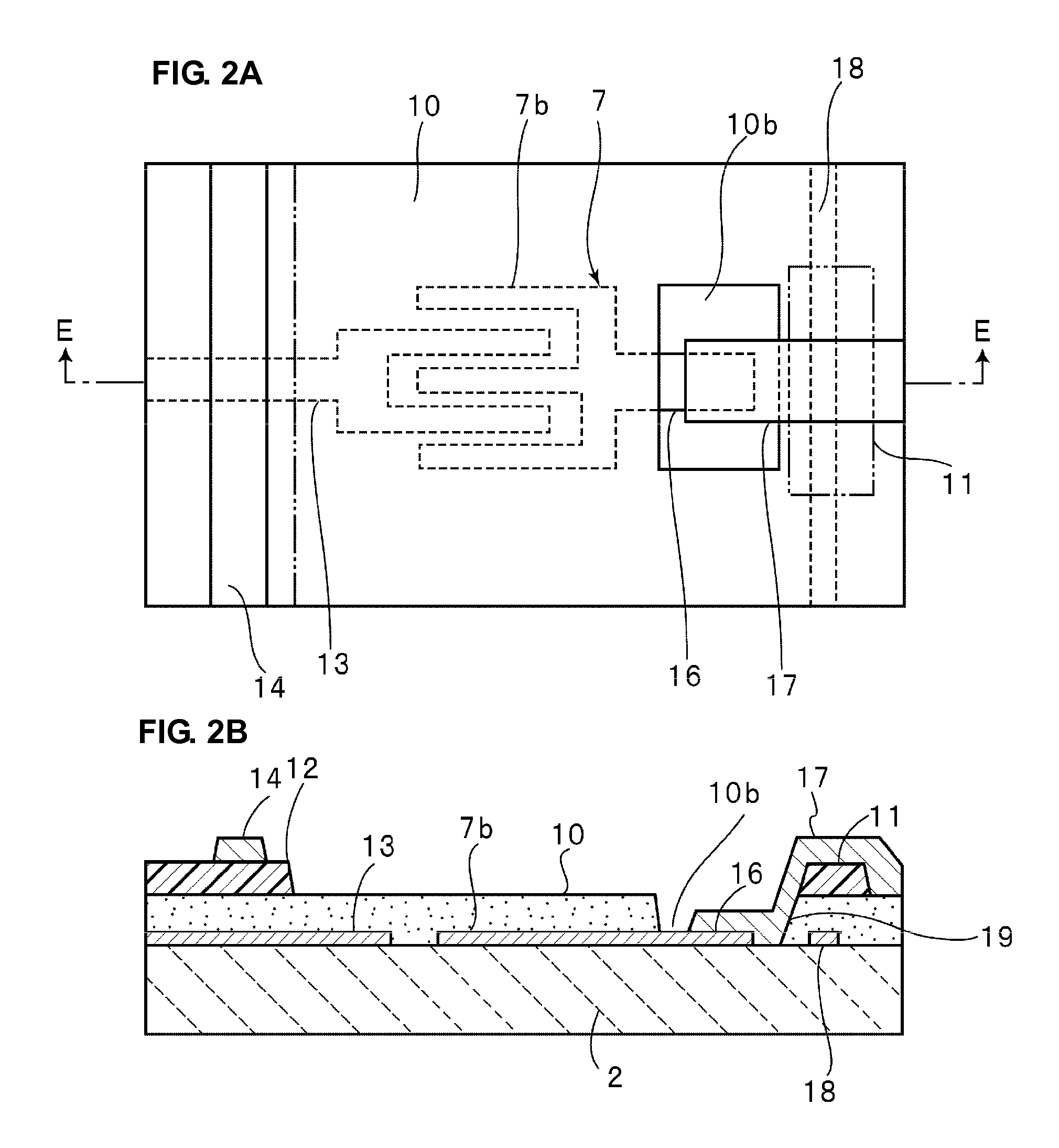

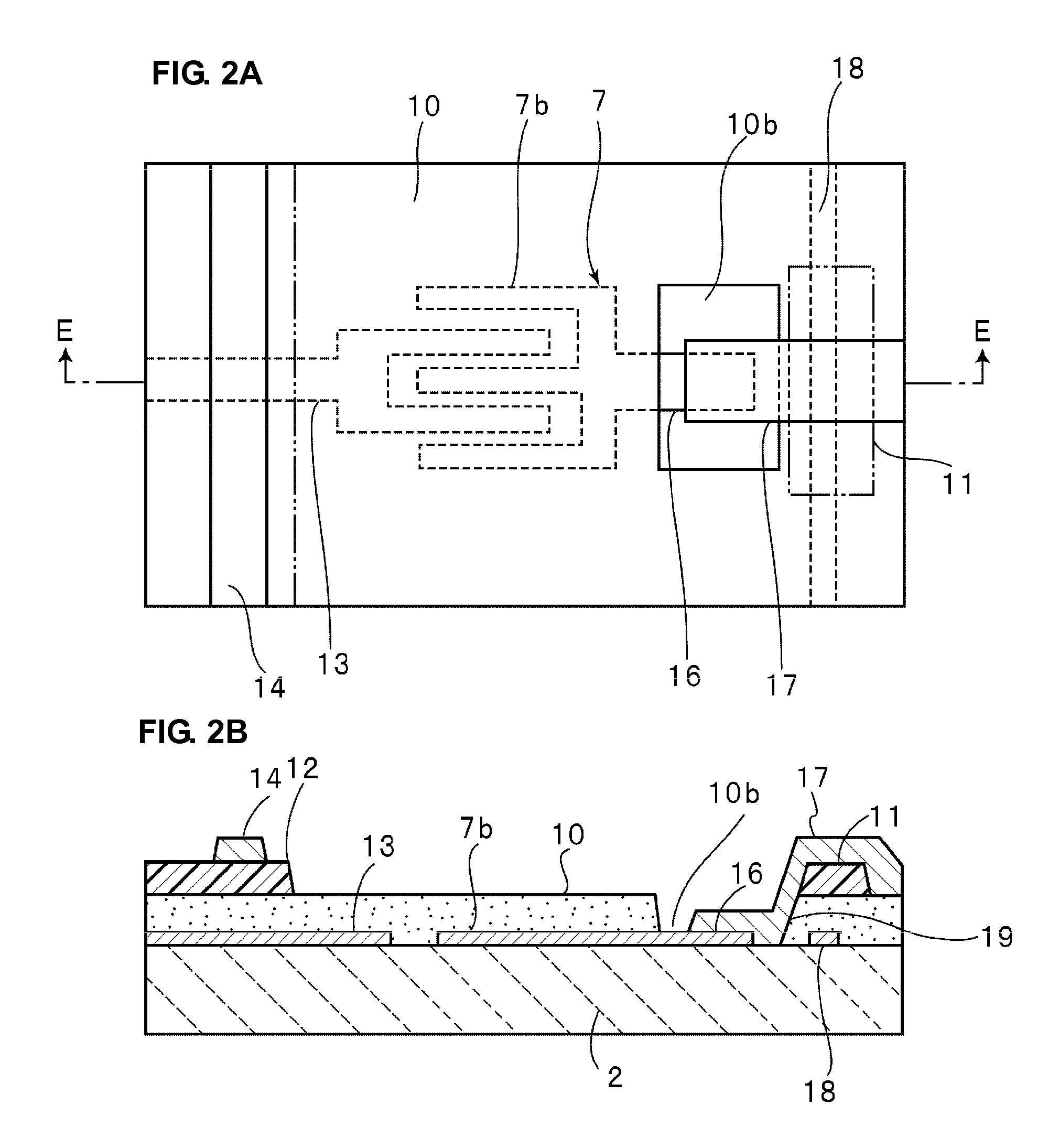

Method for manufacturing surface acoustic wave device and surface acoustic wave device

ActiveUS7479852B2Excellent frequency temperature characteristicsSimple processPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveEngineering

A method for manufacturing a surface acoustic wave device includes the steps of forming an IDT electrode, a first wiring pattern, and a third wiring pattern on a piezoelectric substrate, forming an insulating film covering the IDT electrode and the wiring patterns, forming a photosensitive resin film, obtaining the photosensitive resin film, and forming a second wiring pattern on an insulating layer composed of the insulating film and the photosensitive resin film laminated on the insulating film so that the second wiring pattern three-dimensionally crosses the first wiring pattern.

Owner:MURATA MFG CO LTD

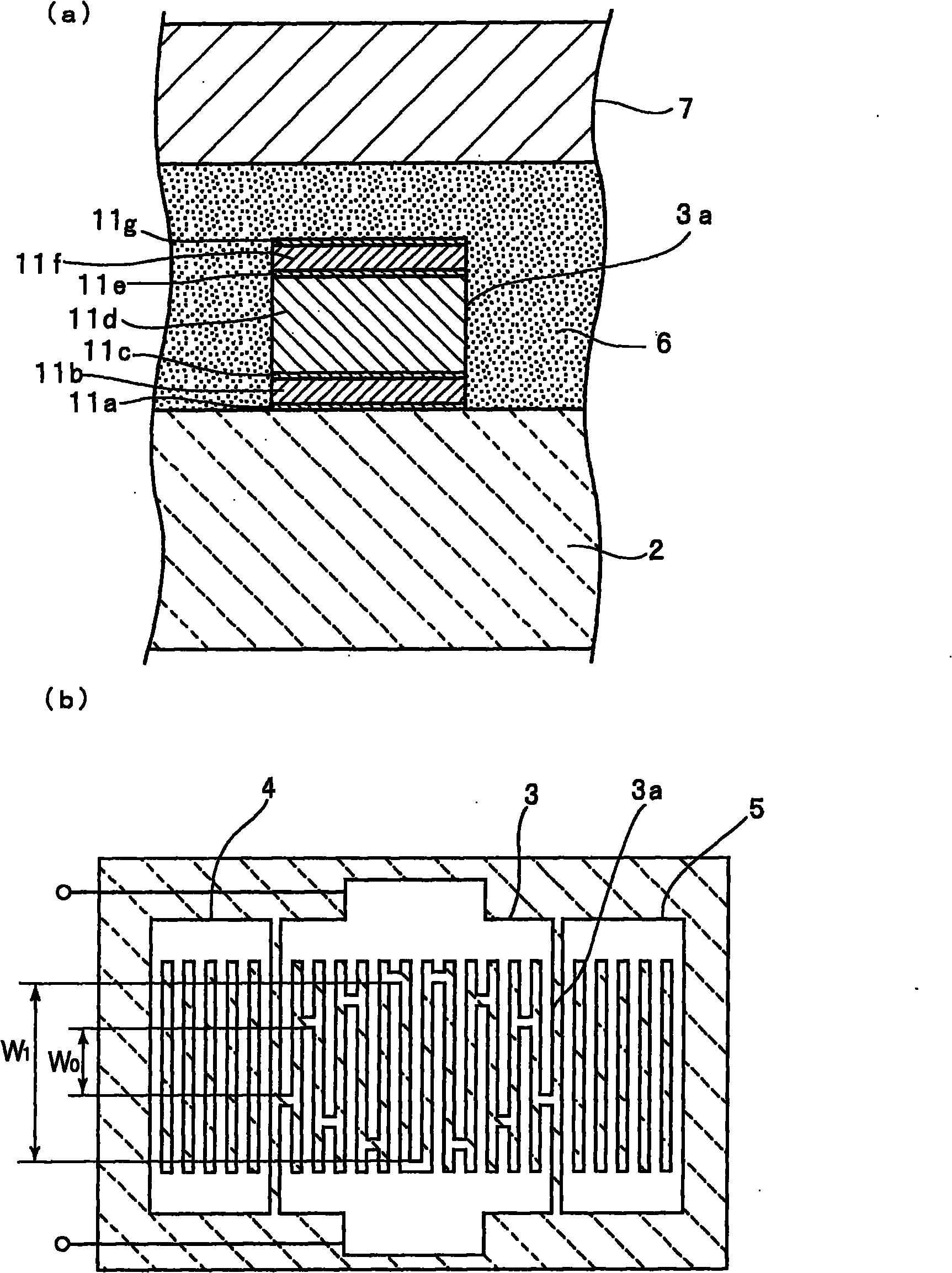

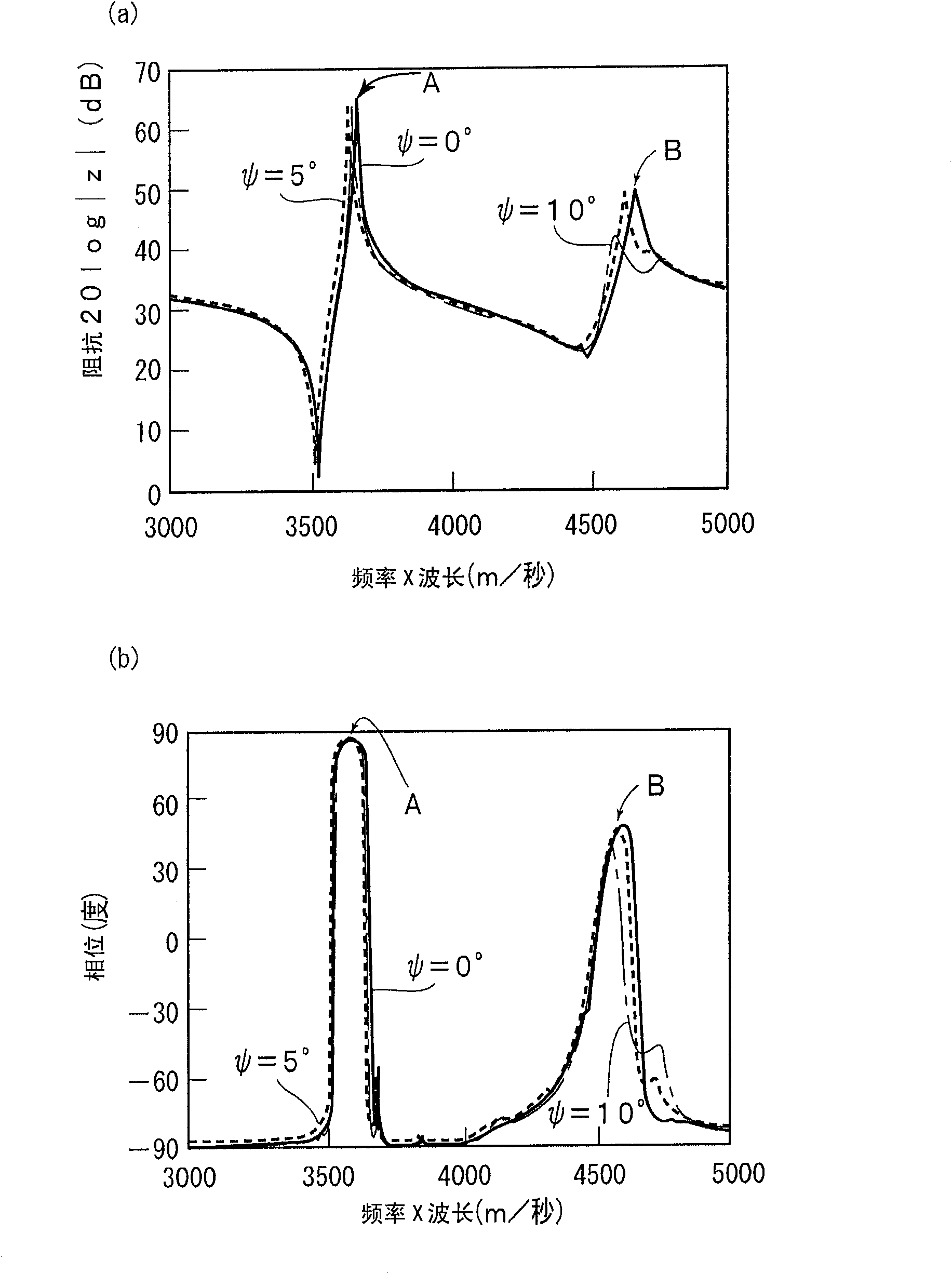

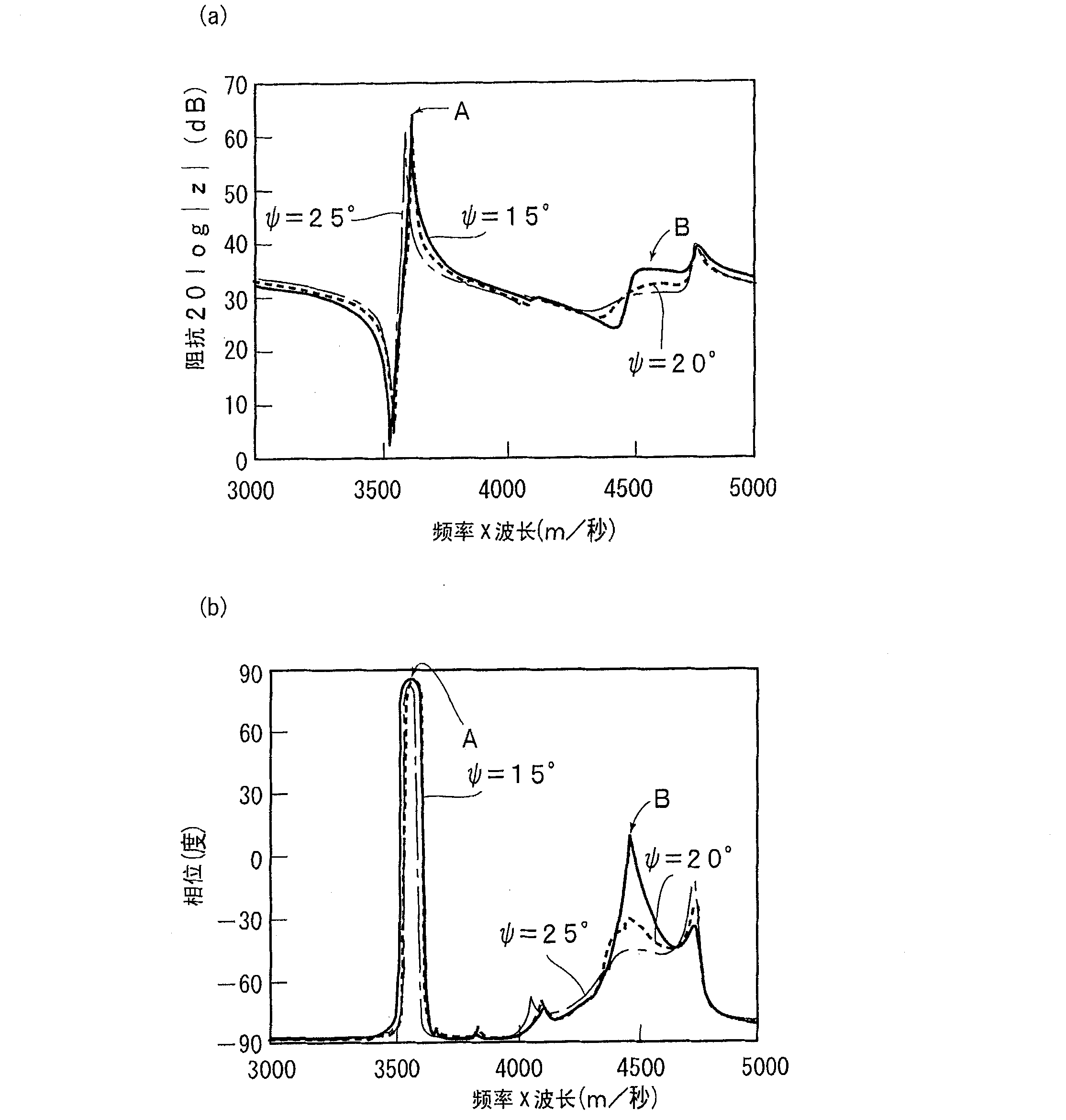

Acoustic wave device

InactiveCN101789769ASuppress spursReduce the absolute valueImpedence networksAcoustic waveHigher order mode

An acoustic wave device having an improved frequency-temperature characteristic and in which a spurious response of the higher order mode is suppressed includes a piezoelectric substrate (2) made of LiNbO3, a SiO2 layer (6) laminated on the piezoelectric substrate (2), and an IDT electrode (3) disposed in an interface of the piezoelectric substrate (2) and the SiO2 layer (6), wherein [phi] and [theta] of Euler angles expressed by ([phi], [theta], [psi]) of LiNbO3 substrate satisfy [phi]=0 DEG and 80 DEG <=[theta]<=130 DEG , respectively. The acoustic wave device using an acoustic wave primarily having an SH wave, wherein [psi] is set to satisfy 5 DEG <=[psi]<=30 DEG .

Owner:MURATA MFG CO LTD

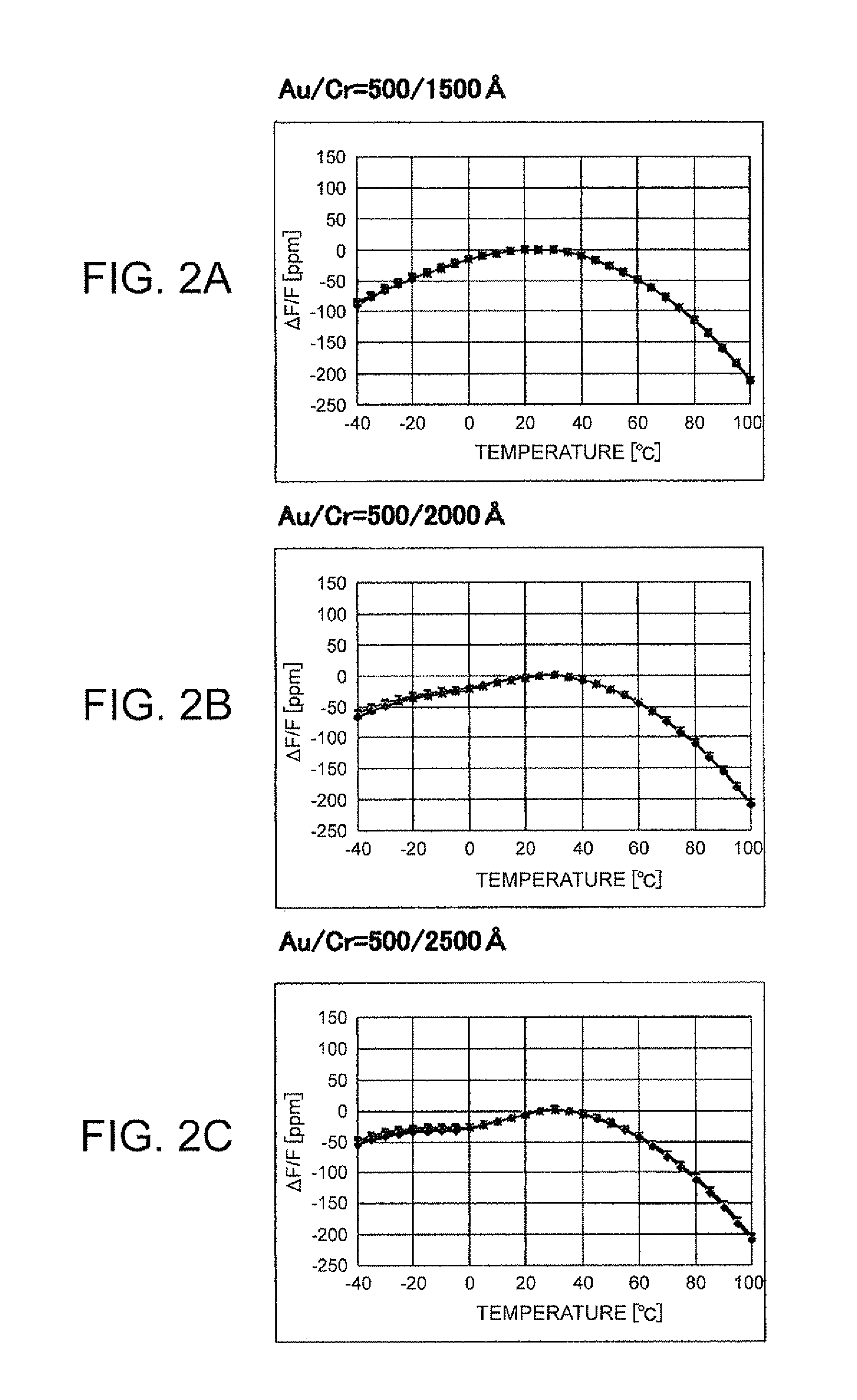

Piezoelectric resonator, method for manufacturing the same, piezoelectric filter, and duplexer

ActiveUS20060066175A1Excellent frequency temperature characteristicsImprove environmental resistancePiezoelectric/electrostrictive device manufacture/assemblyImpedence networksSubstrate surfaceDuplexer

A piezoelectric resonator suitable for use in a high frequency band is provided, in which variation in the piezoelectric material is reduced, variation in performance is reduced, and production can be performed without the need for a polarization treatment step. In the piezoelectric resonator, a piezoelectric material made of a wurtzite structure compound crystal is disposed, the crystal epitaxially grown in such a way that a (1,1,−2,0) crystal face becomes parallel to a surface of the R-plane sapphire substrate having a (0,1,−1,2) crystal face parallel to the substrate surface, and a pair of excitation electrodes are disposed on a pair of principal surfaces opposite to each other in the thickness direction of the piezoelectric material in such a way that the pair of excitation electrodes sandwich the C plane which is a (0,0,0,1) crystal face perpendicular to the (1,1,−2,0) crystal face of the tabular piezoelectric material.

Owner:MURATA MFG CO LTD

Lamb-wave high-frequency resonator

InactiveUS7327070B2High-frequency waveExcellent frequency temperature characteristicsImpedence networksPiezoelectric/electrostriction/magnetostriction machinesQuartz substrateResonator

A Lamb-wave high-frequency resonator includes a comb-shaped IDT electrode for exciting a Lamb wave on one main surface of a quartz substrate. The IDT electrode is formed such that the cut angle of the quartz substrate and the direction of propagation of the Lamb wave are expressed in Euler angles (0, θ, 0).

Owner:SEIKO EPSON CORP

IDT/h-BN/c-BN/diamond multi-layer film structure surface acoustic wave device and its manufacture method

InactiveCN101060318ASmall difference in phase velocity VSmall velocity dispersionImpedence networksTemperature coefficientFilm structure

The disclosed IDT / h-BN / c-BN / diamond multilayer membrane structure SAW device comprises: from bottom to top, a nano-diamond membrane base prepared on mirror silicon, a nano c-BN membrane intermediate layer, a high-C-axis preferred orientated nano h-BN membrane, and an IDT. This invention can be used on condition of 2. 5GHz, high electromechanical coupling factor, smaller loss at 8w propagation, and low frequency temperature coefficient.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for manufacturing surface acoustic wave device and surface acoustic wave device

ActiveUS20080204167A1Excellent frequency temperature characteristicsSimple processPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveEngineering

A method for manufacturing a surface acoustic wave device includes the steps of forming an IDT electrode, a first wiring pattern, and a third wiring pattern on a piezoelectric substrate, forming an insulating film covering the IDT electrode and the wiring patterns, forming a photosensitive resin film, obtaining the photosensitive resin film, and forming a second wiring pattern on an insulating layer composed of the insulating film and the photosensitive resin film laminated on the insulating film so that the second wiring pattern three-dimensionally crosses the first wiring pattern.

Owner:MURATA MFG CO LTD

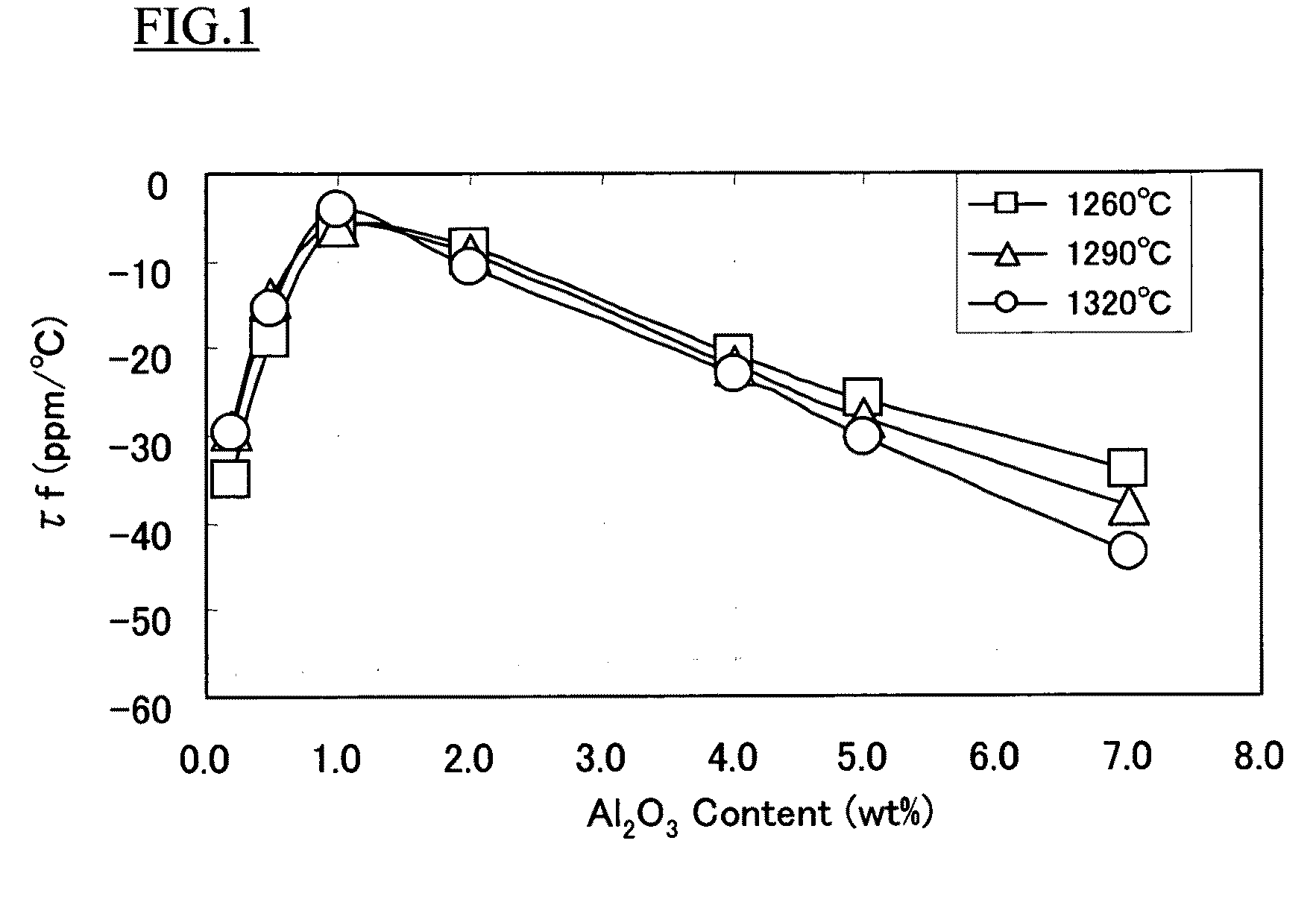

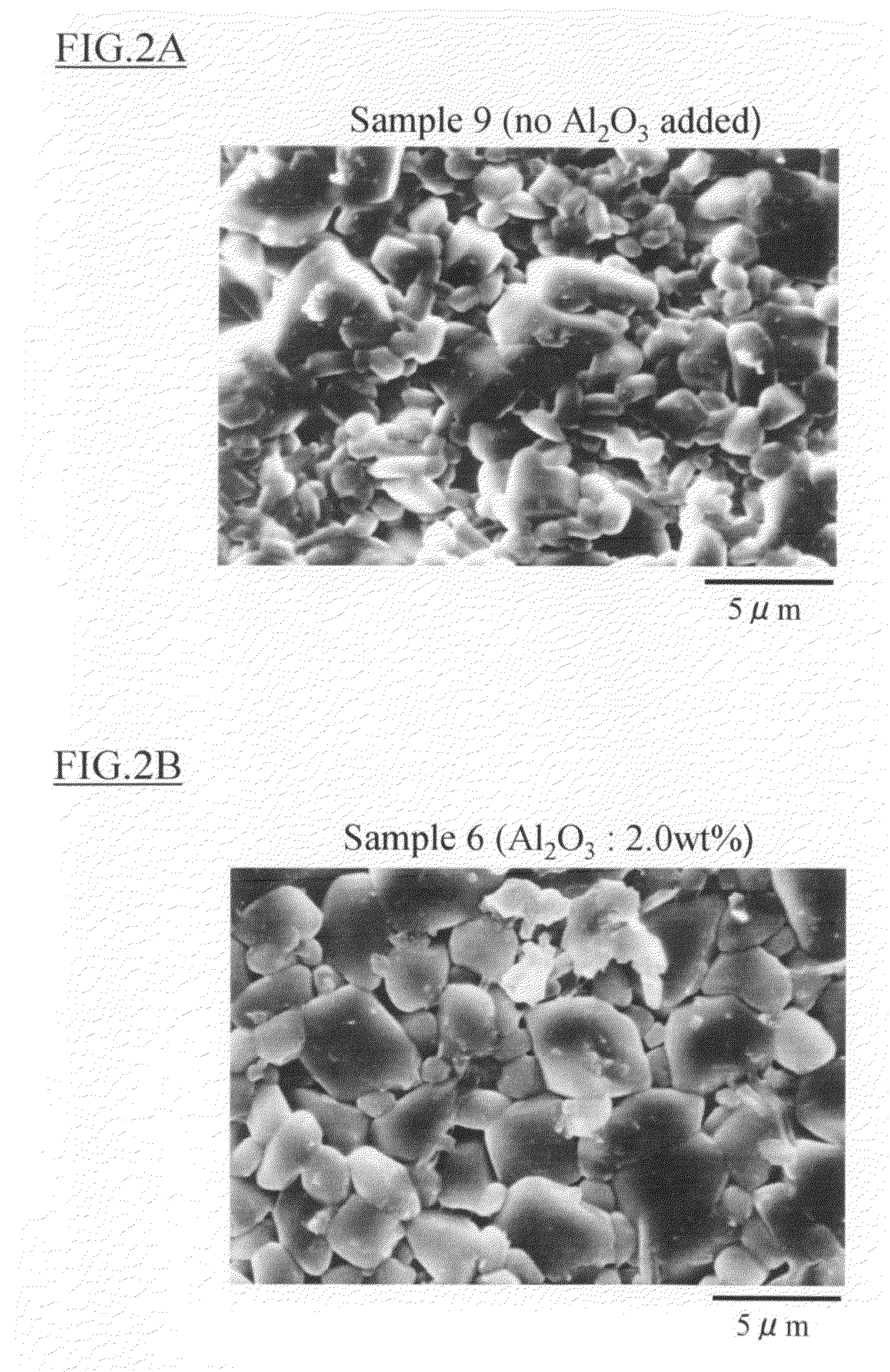

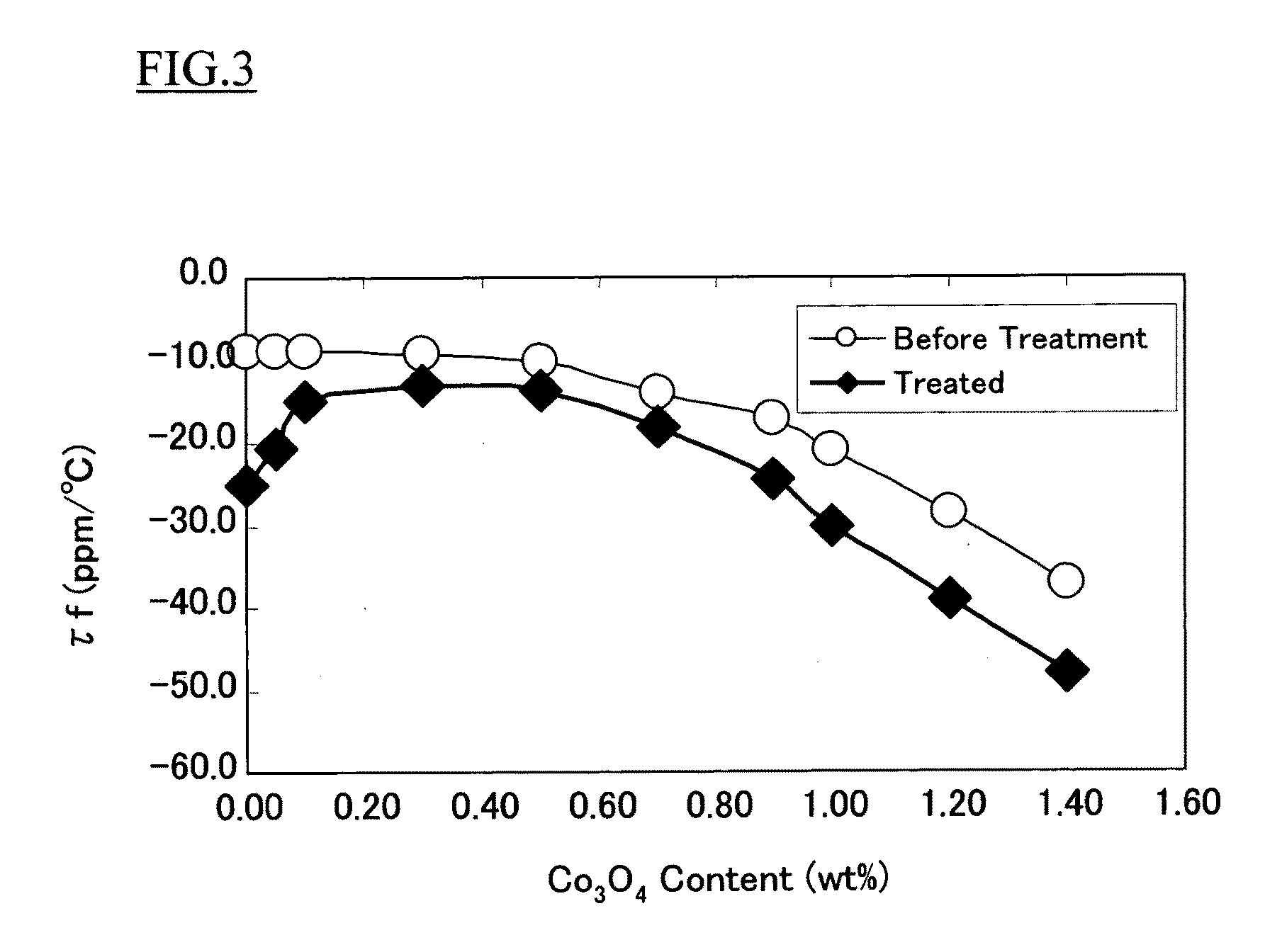

Dielectric ceramic composition

ActiveUS20090088314A1Low dielectric constantExcellent frequency temperature characteristicsDielectric ceramicsPermittivity

A dielectric ceramic composition comprising forsterite in an amount of 93.0 to 99.0 mol % when calculating in terms of 2MgO—SiO2 and calcium titanate in an amount of 1.0 to 7.0 mol % when calculating in terms of CaTiO3 as main components, and as a subcomponent, aluminum oxide in an amount of 0.2 to 5 mass % when calculating in terms of Al2O3 per 100 mass % of said main components. According to the present invention, a dielectric ceramic composition, capable of having both low permittivity and good frequency-temperature characteristic as well as ensuring high Qf value and further having sufficient mechanical strength, and suitable to use in an antenna, a filter and the like used in the high-frequency region, can be provided. Also, the present invention allows providing a dielectric ceramic composition further having resistance to reduction in addition to all of the above properties.

Owner:TDK CORPARATION

Vibrating element and vibrator

InactiveUS8134283B2Excellent frequency temperature characteristicsValue can be obtainedPiezoelectric/electrostriction/magnetostriction machinesImpedence networksYoung's modulusThermal expansion

A vibrating element includes: a vibrating body having frequency temperature dependency; and a temperature characteristic correcting part provided on a surface of the vibrating body. The temperature characteristic correcting part has a temperature characteristic of at least one of a Young's modulus and a thermal expansion coefficient and is expressed by a temperature characteristic curve which has at least one of an inflection point and an extremal value. In the vibrating element, a temperature of at least one of the inflection point and the extremal value is within an operating temperature range of the vibrating body.

Owner:SEIKO EPSON CORP

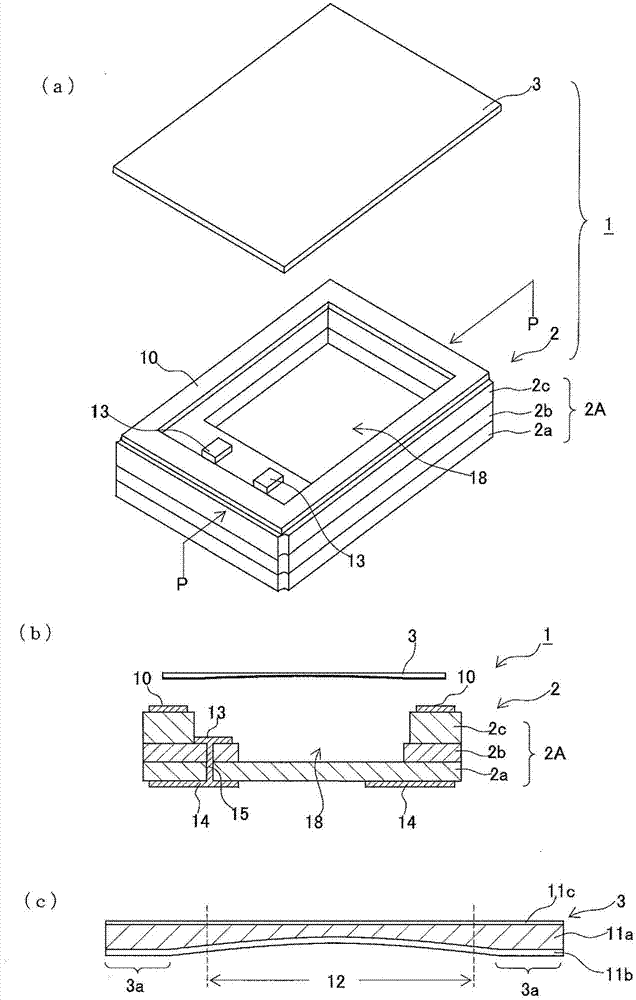

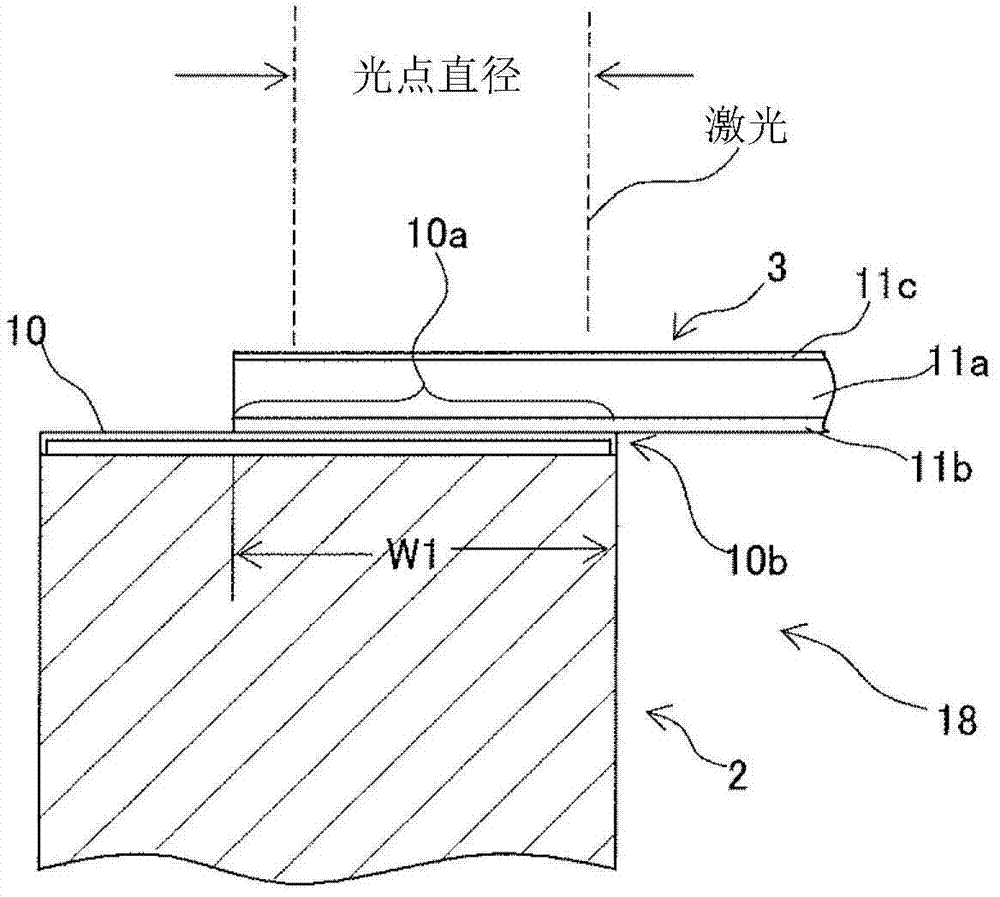

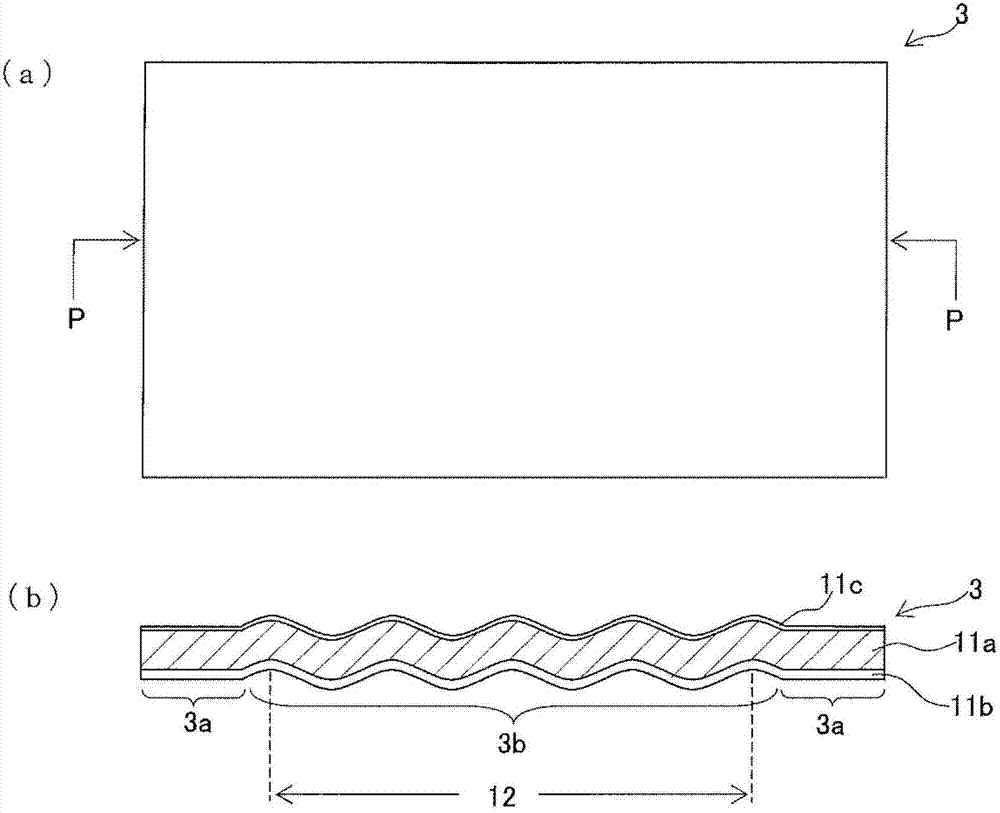

Method of manufacturing electronic device, electronic apparatus, and mobile apparatus

InactiveCN103681519AImprove air tightnessGood frequency accuracyPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksEngineeringElectric devices

The invention provides a method of manufacturing an electronic device, an electronic apparatus, and a mobile apparatus. No cracks can be generated on the ceramic material of a base substrate when a lid is joined to the sealing part of the base substrate. The method of manufacturing the electronic device including an electronic element, a base substrate, and a lid member, includes joining the lid member to the sealing part by application of an energy beam so that a plate thickness of the lid member may be larger in a part joined to the sealing part than in a part located inside of the part in a plan view along the thickness direction.

Owner:SEIKO EPSON CORP

Surface acoustic wave device and electronic apparatus

InactiveCN1780143AExcellent frequency temperature characteristicsEasy to high frequencyImpedence networksSurface acoustic wave sensorQuartz

Surface acoustic wave devices and electronic equipment. An object of the present invention is to provide a surface acoustic wave device that uses the upper limit mode of the stop band as the oscillation frequency of the surface acoustic wave device, has excellent frequency-temperature characteristics, and is easy to increase in frequency. As a solution, in a surface acoustic wave device (2) having at least an IDT electrode for exciting a Rayleigh-type surface acoustic wave on the surface of a quartz substrate (1), when expressed in terms of Euler angles (φ, θ, ψ) When representing the cutting angle of the quartz substrate (1) and the propagation direction of the surface acoustic wave, it is set to φ=0°, 0°≤θ≤180°, and 0°<|ψ|<90°.

Owner:SEIKO EPSON CORP

Elastic wave device using SH waves as the principal component

ActiveUS8143762B2Excellent frequency temperature characteristicsReduce componentsImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAlloyAcoustics

An elastic wave device that achieves an improved frequency-temperature characteristic and a sufficiently reduced spurious component includes a piezoelectric body including a LiNbO3 substrate, a first dielectric layer including a SiO2 layer, a second dielectric layer, and IDT electrodes disposed at an interface between the piezoelectric body and the first dielectric layer. Each of the IDT electrodes includes a multilayer structure in which a first electrode film including at least one layer including Pt or a Pt-based alloy and a second electrode film including Al or an Al-based alloy are provided. φ and θ of Euler angles (φ, θ, ψ) of the LiNbO3 substrate are in the range of φ=0±about 2° and the range of about 80°≦θ≦about 130°, respectively. ψ is in the range of about 5°≦ψ≦about 30°. The normalized thickness h / λ and ψ satisfy the following expression: h / λ×100≦about 0.0019×ψ2+about 0.0115×ψ+3.0.

Owner:MURATA MFG CO LTD

Resonating element, resonator, electronic device, electronic apparatus, and moving body

InactiveUS8928419B2Relieve pressureStable characteristicsPiezoelectric/electrostriction/magnetostriction machinesImpedence networksElectronResonator

A resonating element includes a resonator element that includes a vibrating portion and an excitation electrode provided on both main surfaces of the vibrating portion, an intermediate substrate in which the resonator element is mounted so as to be spaced from the excitation electrode, and a spiral electrode pattern that is provided on at least one main surface of the intermediate substrate, in which the electrode pattern is electrically connected to the excitation electrode.

Owner:SEIKO EPSON CORP

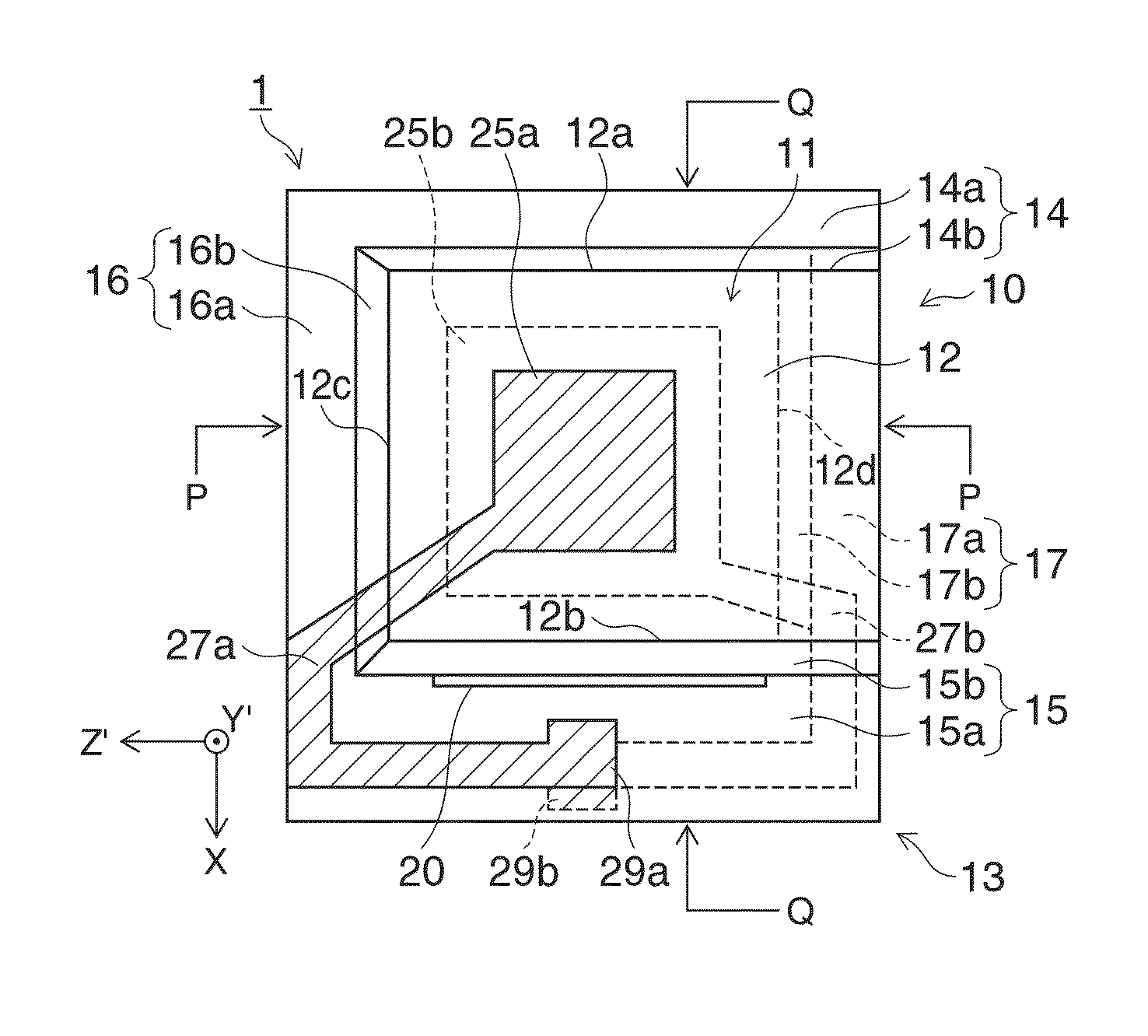

Resonating element, resonator, electronic device, electronic apparatus, moving vehicle, and method of manufacturing resonating element

ActiveUS8791766B2The process steps are simpleResist impactImpedence networksPiezoelectric/electrostriction/magnetostriction machinesMobile vehicleThick wall

A piezoelectric resonating element includes a piezoelectric substrate having a rectangular vibrating portion and a thick-walled portion, excitation electrodes and, and lead electrodes. The thick-walled portion includes a fourth thick-walled portion, a third thick-walled portion, a first thick-walled portion, and a second thick-walled portion. The third thick-walled portion includes a third slope portion and a third thick-walled body, and at least one slit is formed in the third thick-walled portion.

Owner:SEIKO EPSON CORP

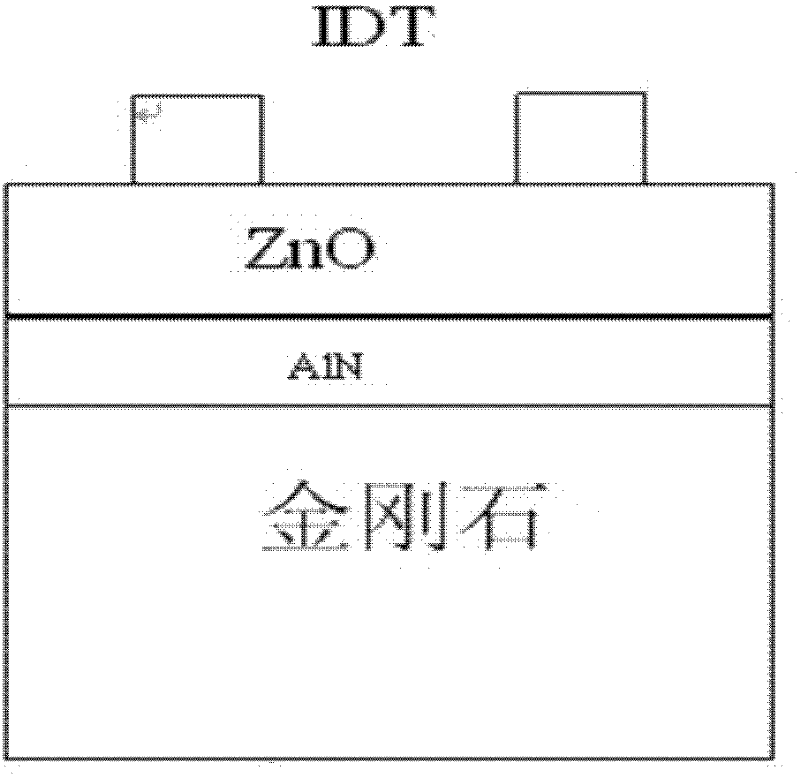

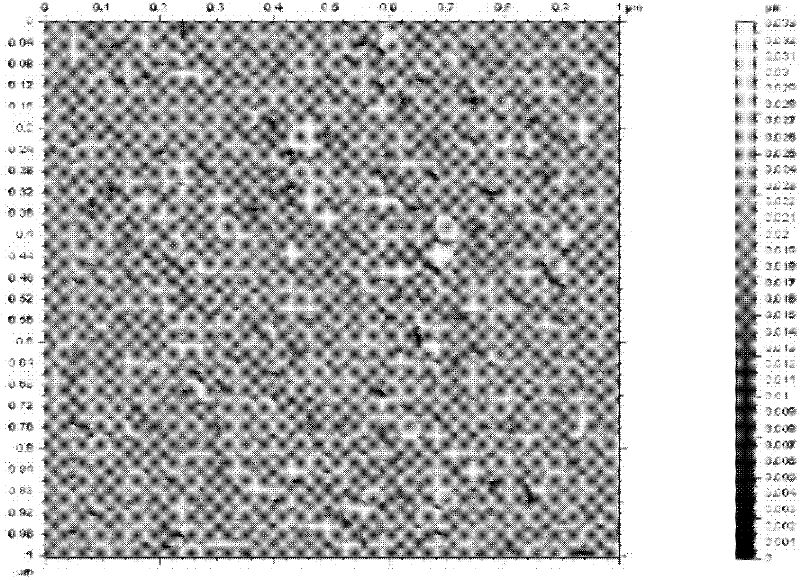

High frequency surface acoustic wave device with AlN (aluminum nitride) film as interlayer and preparation method thereof

InactiveCN102412803ASmall velocity dispersionHigh electromechanical coupling coefficientImpedence networksVacuum evaporation coatingFrequency dispersionChemical vapor deposition

The invention provides a high frequency surface acoustic wave device with an AlN (aluminum nitride) film as an interlayer. The device is characterized in that an a-axis preferred orientation AlN film is taken as a CVD (chemical vapor deposition) diamond substrate and a c-axis preferred orientation ZnO film is taken as an interlayer, the substrate and the interlayer are formed into an IDT(interdigital transducer) / ZnO / a-axis preferred orientation AlN / diamond multi-layered membrane structure and the structure is stacked with the IDT in sequence to form the high frequency surface acoustic wave device; the preparation method comprises the following steps of preparing an a-axis preferred oritention AlN film interlayer, and preparing a c-axis preferred oritentation ZnO film on the a-axis preferred orientation AlN film interlayer. The device and the preparation method provided by the invention have the following advantages that the sound velocity frequency dispersion caused by a large sound velocity gap between nanodiamond and ZnO can be solved, the application demand of the surface acoustic wave with high frequency above 4.8 GHz can be met, and moreover, the process is simple and easy to implement, and is beneficial for large-scale population and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

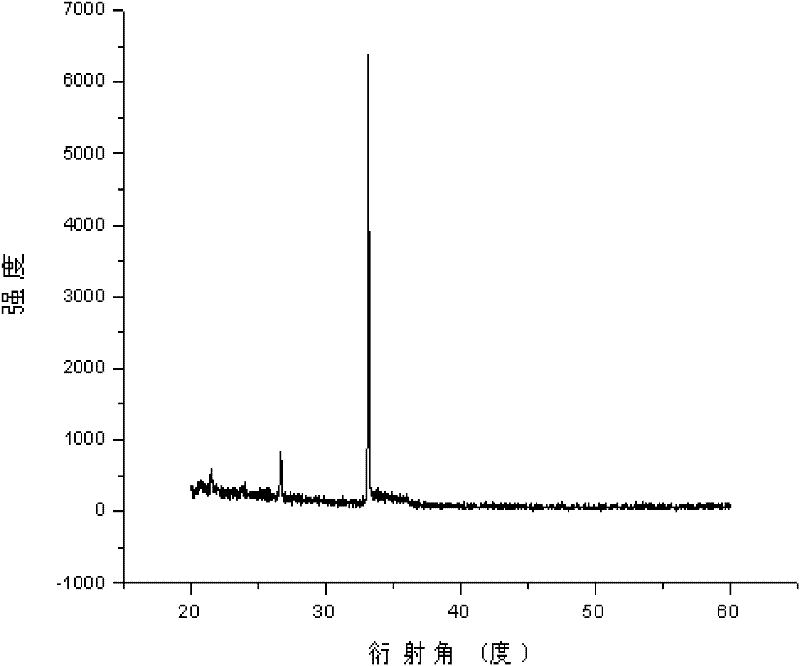

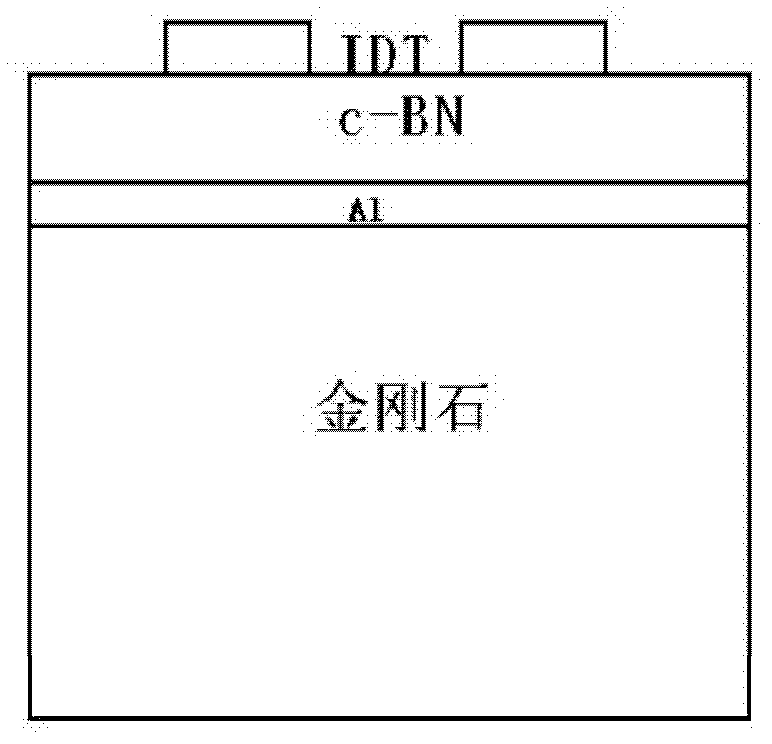

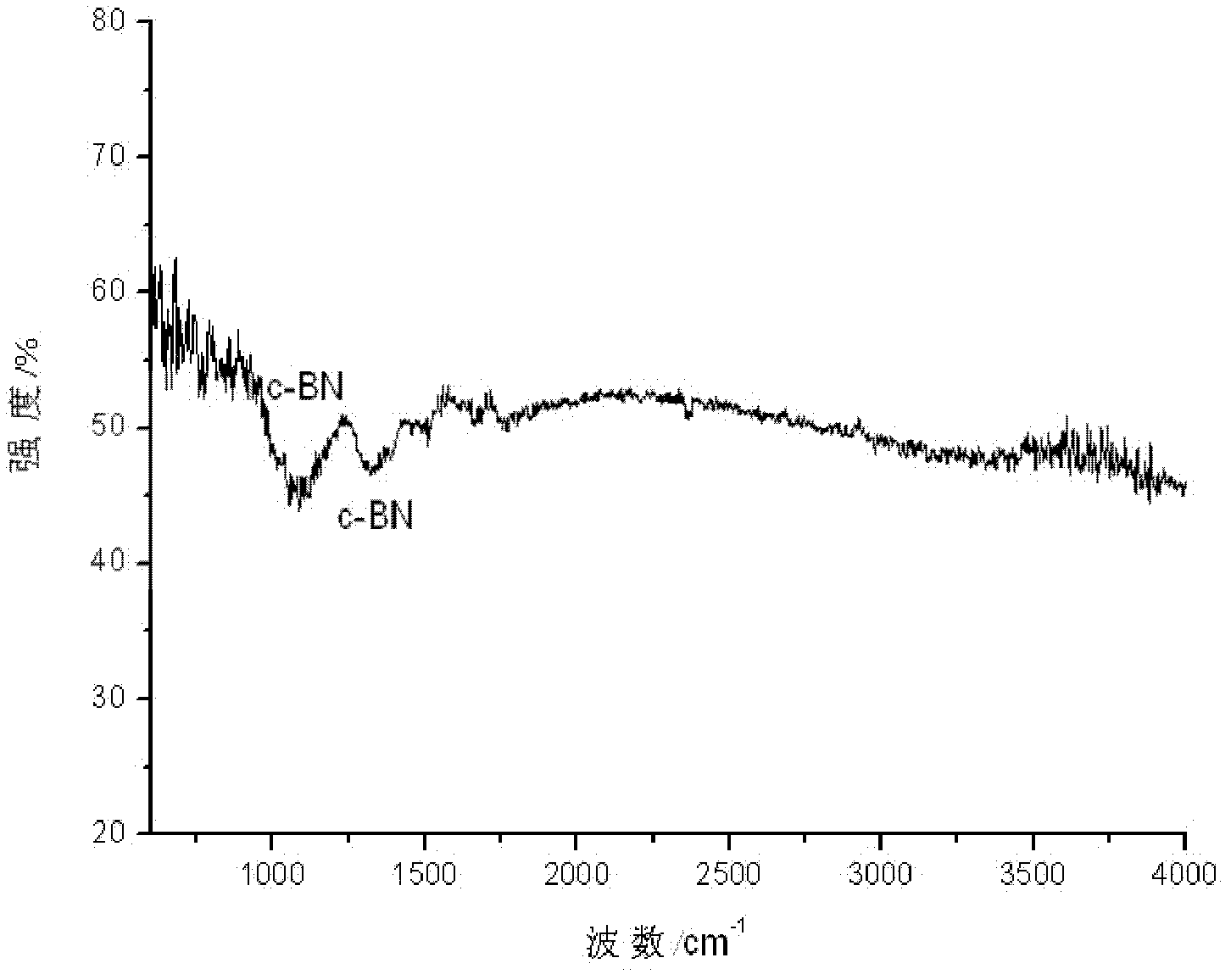

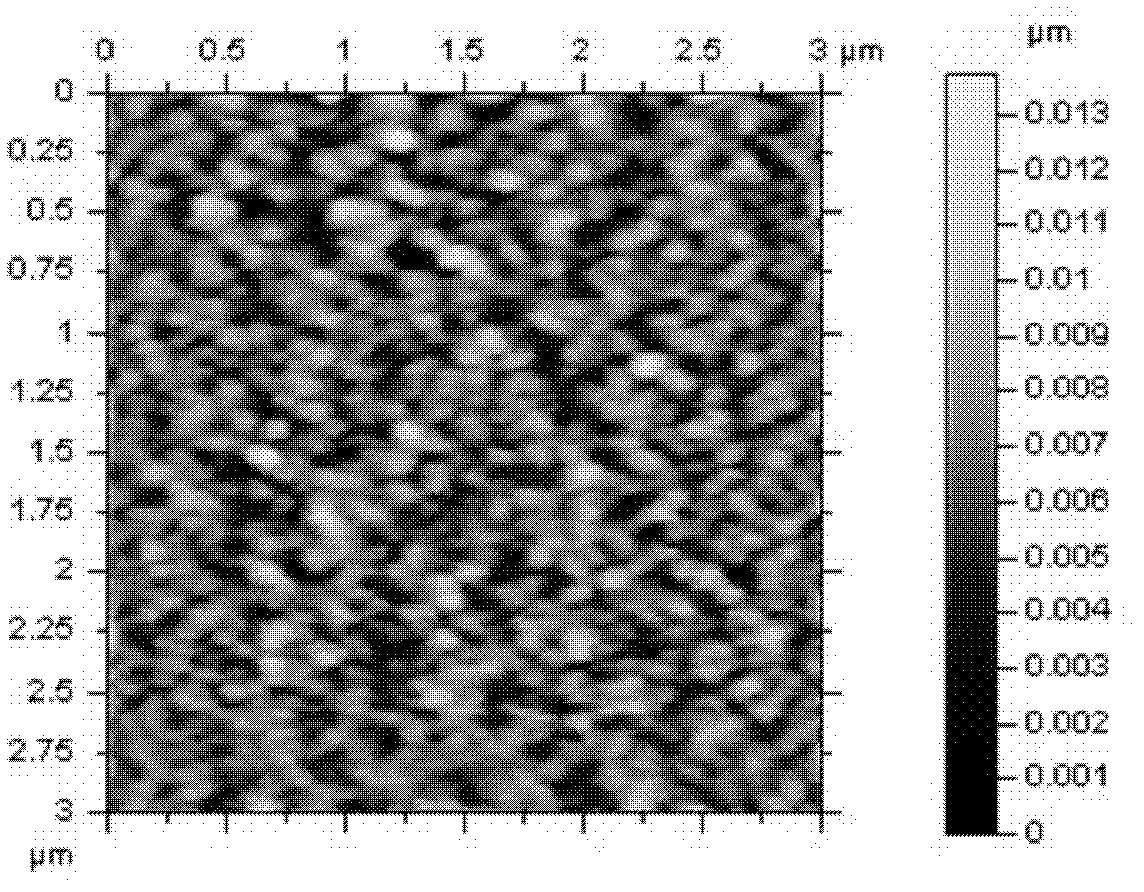

Cubic boron nitride piezoelectric film surface acoustic wave device and preparation method thereof

InactiveCN102437831AHigh frequencySmall velocity dispersionImpedence networksElectromechanical coupling coefficientRadio frequency magnetron sputtering

The invention provides a cubic boron nitride piezoelectric film surface acoustic wave (SAW) device which is an IDT / c-BN / Al / diamond multilayer film structure and is composed of a diamond substrate, an interface layer nano-aluminum film and a layer of nano-cubic boron nitride (c-BN) piezoelectric film formed on a surface of the nano-aluminum film. A preparation method of the device comprises the following steps: (1) employing a direct current magnetron sputtering method to deposit the nano-aluminum film on a nano-CVD diamond substrate surface; (2) employing a radio frequency magnetron sputtering method to deposit the nano-cubic boron nitride (c-BN) piezoelectric film on a surface of the nano-aluminum film; (3) preparing an interdigital transducer (IDT) on a surface of the nano-cubic boron nitride (c-BN) piezoelectric film. The surface acoustic wave device can satisfy application requirements of various fields like the surface acoustic wave (SAW) device with high frequency (4.8 GHz or more), a high electromechanical coupling coefficient, large power (more than 8 w), low propagation loss and a low frequency temperature coefficient, preparation technology is simple, application is easy, and popularization is facilitated.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Surface acoustic wave resonator, surface acoustic wave oscillator, and surface acoustic wave module device

InactiveUS20120105165A1Growth inhibitionExcellent CIImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectromechanical coupling coefficientSurface acoustic wave oscillators

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com