Method of manufacturing electronic device, electronic apparatus, and mobile apparatus

A technology of electronic devices and manufacturing methods, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electric solid devices, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

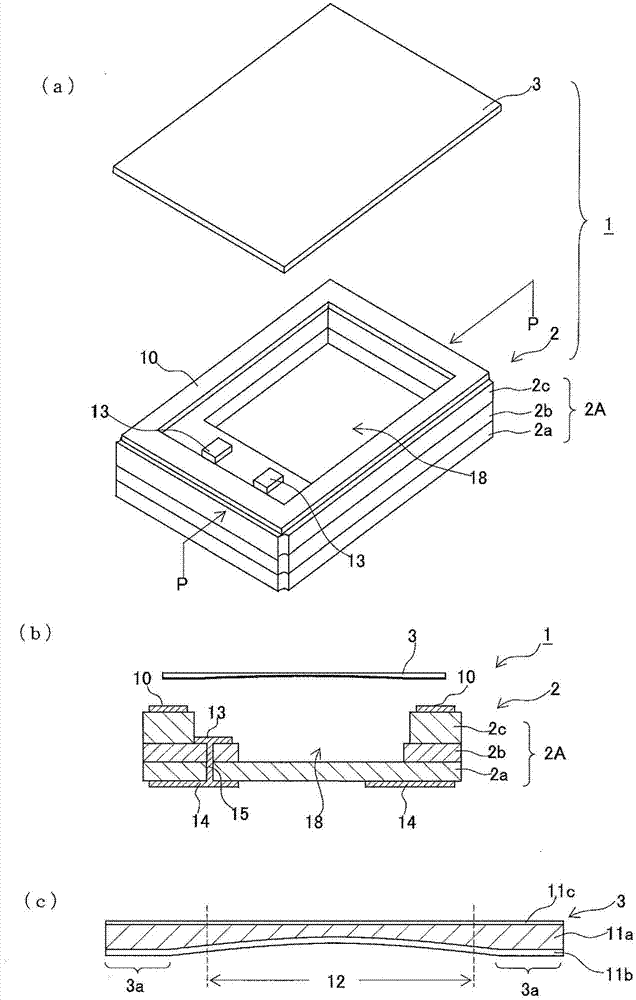

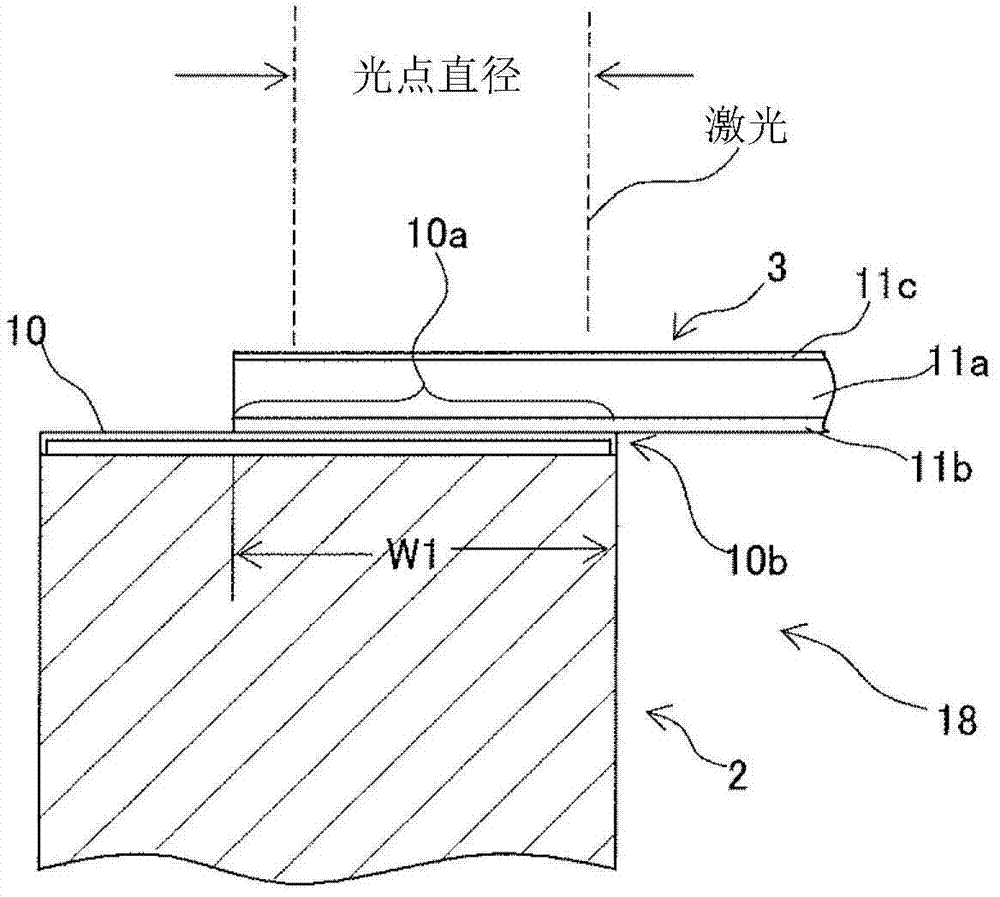

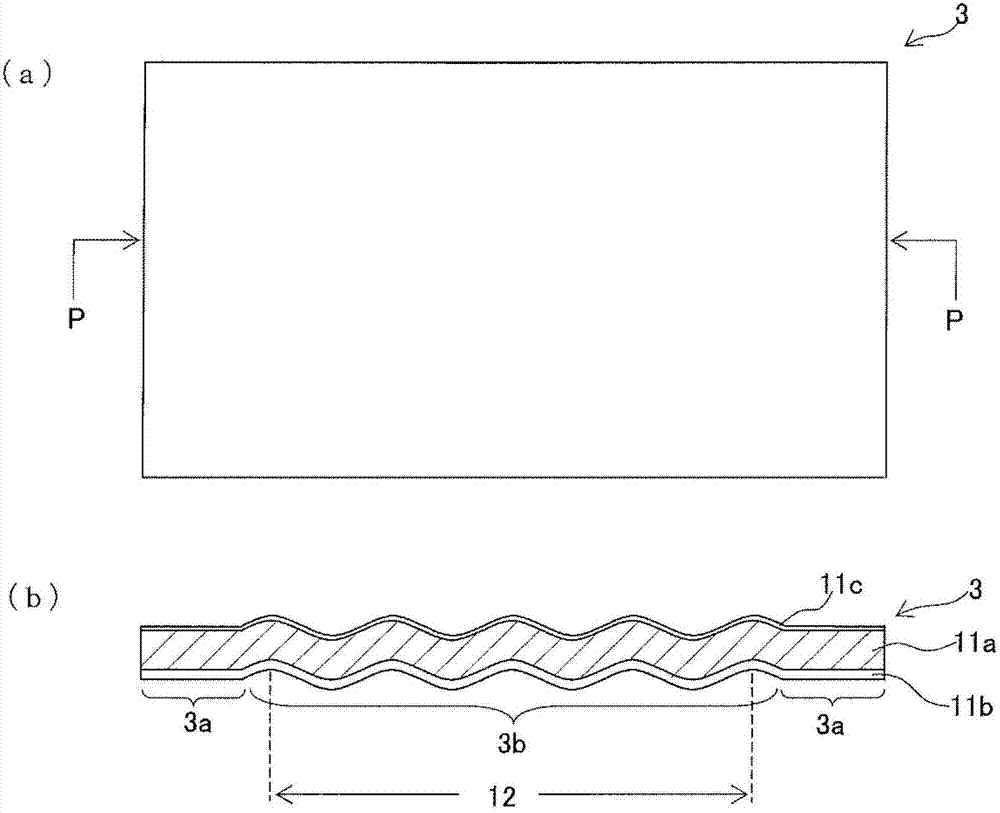

[0038] figure 1 (a) is an exploded perspective view of one embodiment of the electronic device container 1 of the present invention, (b) of the figure is a PP sectional view of (a), and (c) of the figure is an enlarged sectional view of the lid body 3 .

[0039] The container 1 for accommodating electronic components includes: a base substrate (container body) 2 made of ceramics having a concave portion on which the electronic component can be mounted; Cover 3.

[0040] The outline of the manufacturing method of the container 1 for electronic devices of this invention is as follows. That is, this manufacturing method is a method of manufacturing an electronic device container 1 provided with a base substrate 2 having an insulating substrate 2A made of ceramics and a metal lid 3, and the manufacturing method has the following steps: : Prepare the base subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com