Surface acoustic wave device

a surface acoustic wave and waveguide technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive/magnetostriction machines, oscillator generators, etc., can solve the problem of low reflection efficiency of the grating reflector for the saw, difficult to implement a saw device having a small size and high q value, and excellent frequency temperature characteristics. , the effect of high q valu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

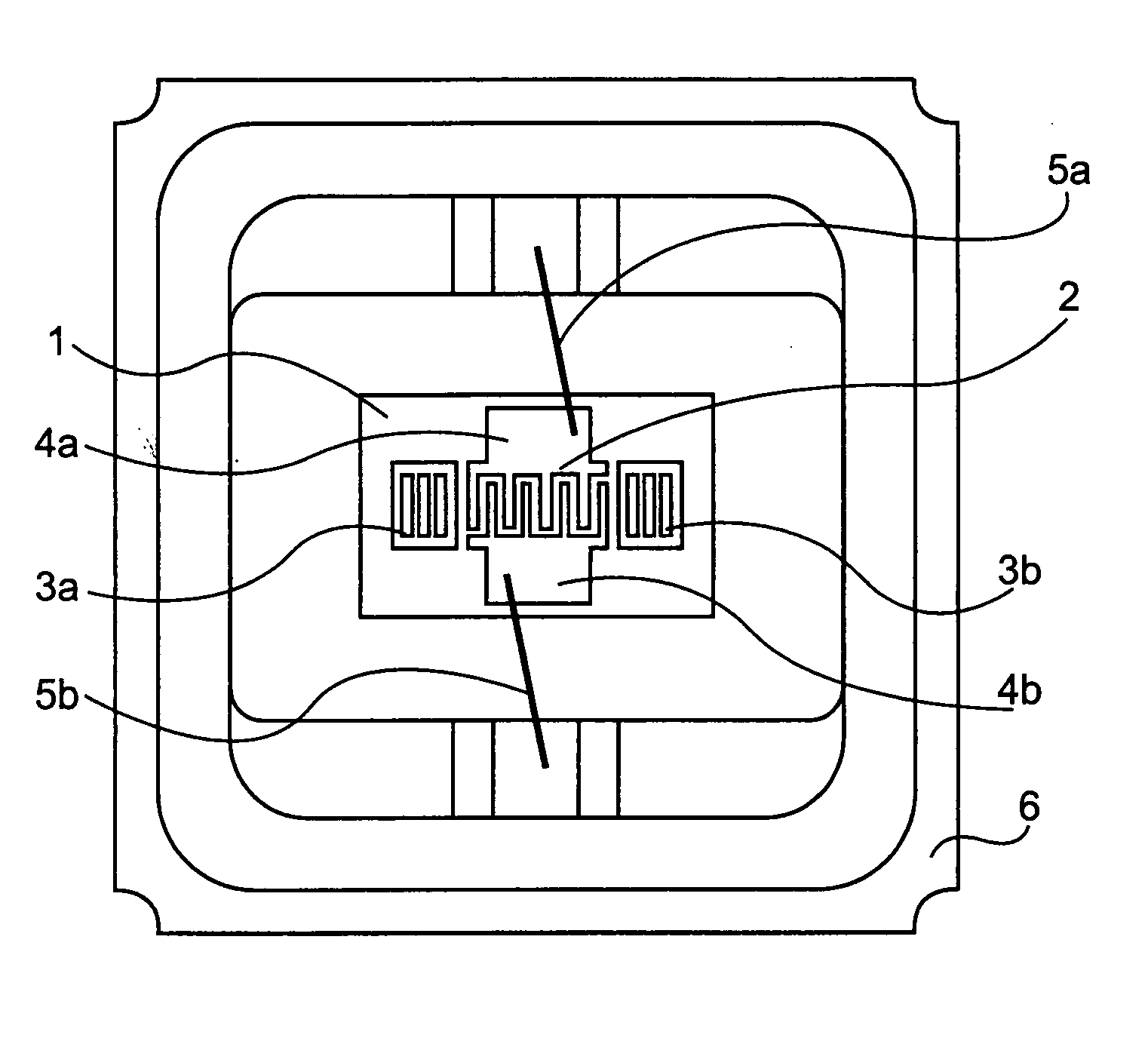

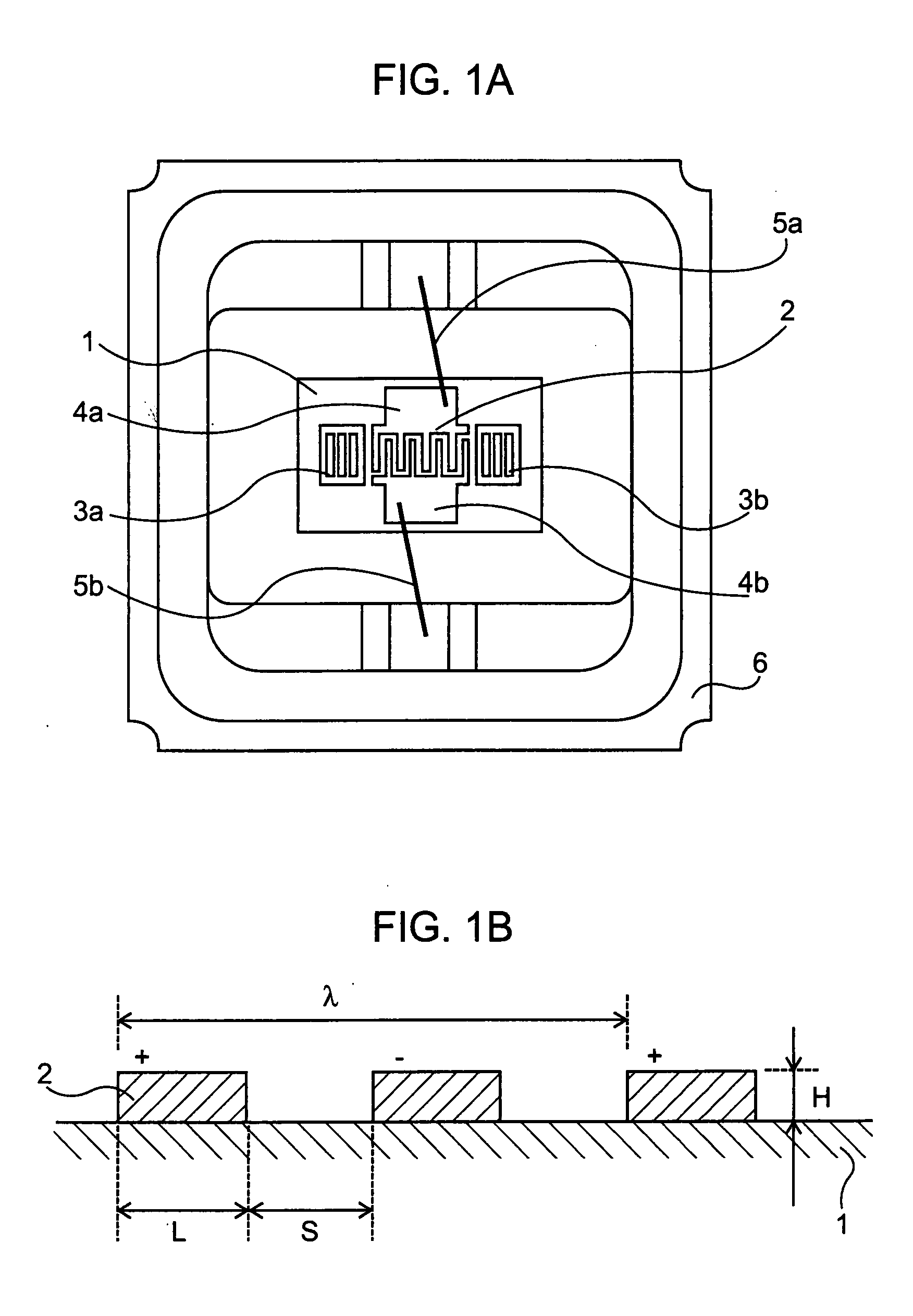

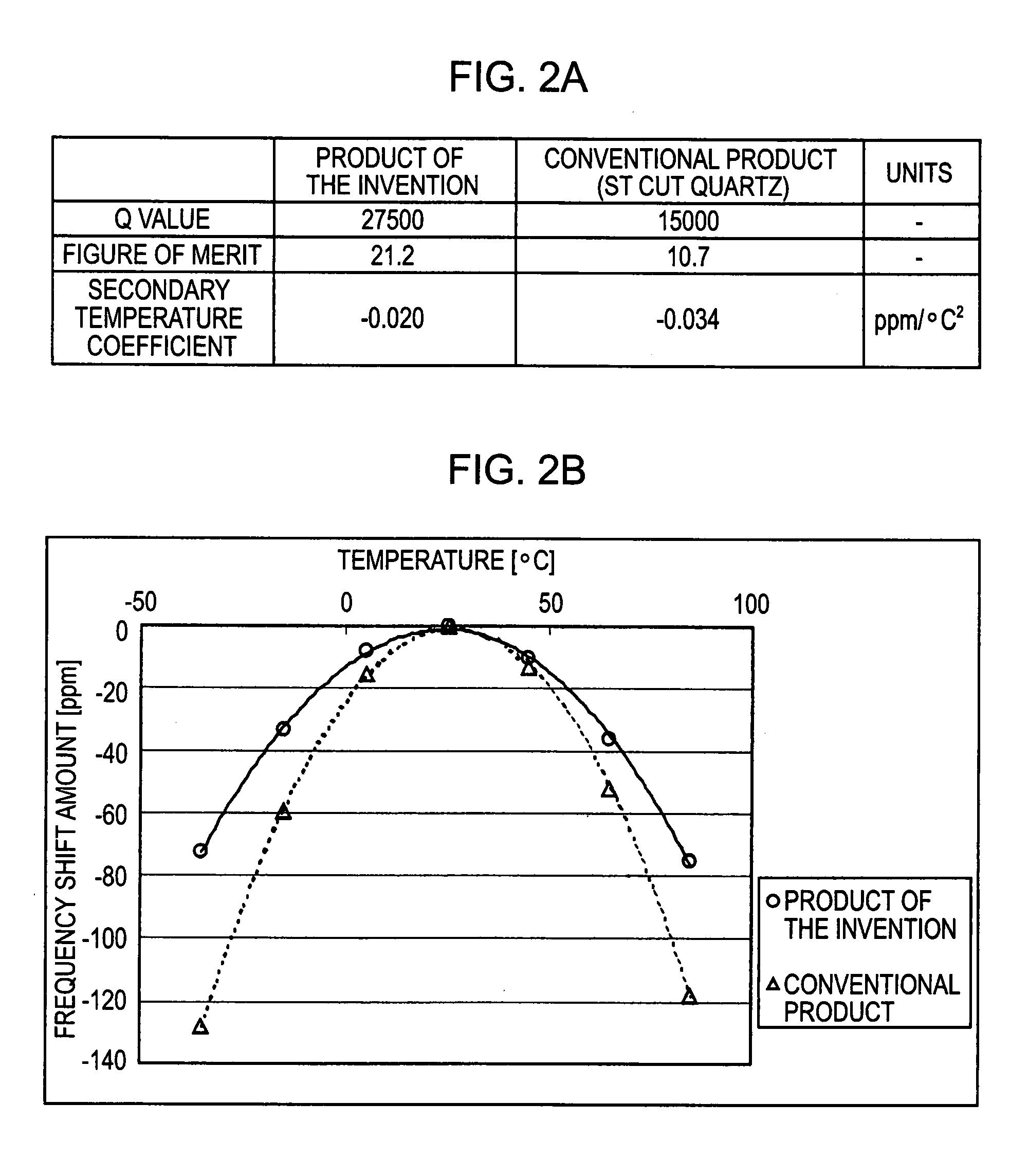

[0052] Hereinafter, the present invention will be described with reference to the accompanying drawings. FIG. 1A is a plan view showing an SAW resonator according to the invention. An IDT 2 constructed by alternately inserting positive electrode fingers and negative electrode fingers and grating reflectors 3a and 3b which reflect SAW at sides of the IDT 2 are disposed on a piezoelectric substrate 1. Input / output pads 4a and 4b of the IDT 2 and input / output terminals of a package 6 are electrically connected with metal wires 5a and 5b, and an opening of the package 6 are hermetically sealed with a cap (lid). The piezoelectric substrate 1 is a rotated Y-cut quartz plate having a cut angle θ which is set to about an angle rotated by −50° counterclockwise from a Z crystalline axis and having an SAW propagation direction which is set to a direction of 90°±5° approximately perpendicular to an X crystalline axis. Here, the excited SAW is an SH wave. Materials for forming electrodes of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com