Electrochemical method for preparing fluorine-containing hydroxyapatite/zirconia transition coating on surface of medical titanium

A fluorine-containing hydroxyapatite, electrochemical technology, applied in medical science, pharmaceutical formulations, dental preparations, etc., can solve the problems of shortening the service life of materials, shedding, and low bonding strength, and achieve increased strength and high utilization of raw materials , The effect of uniform and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

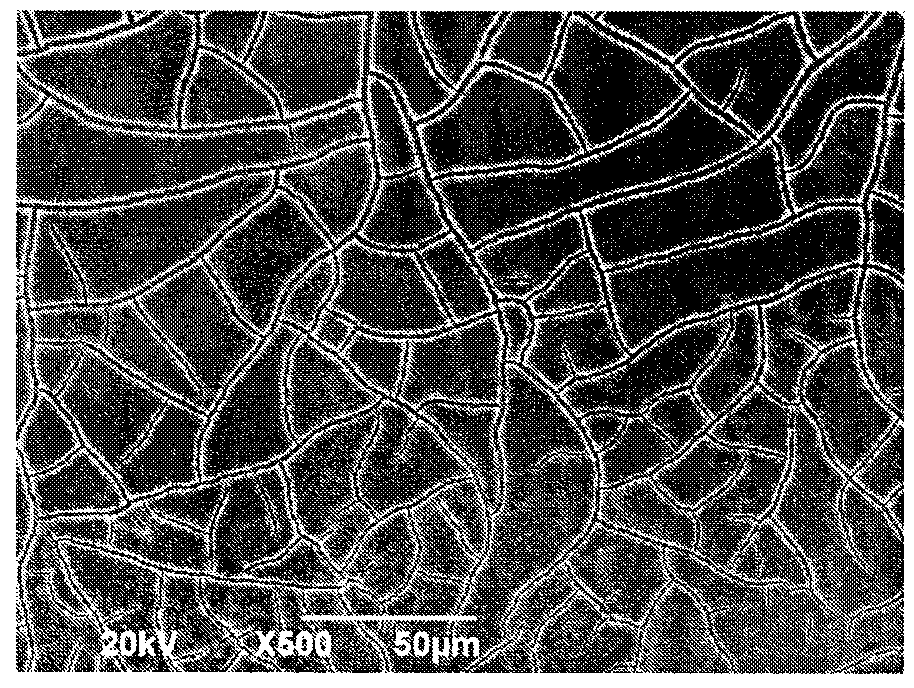

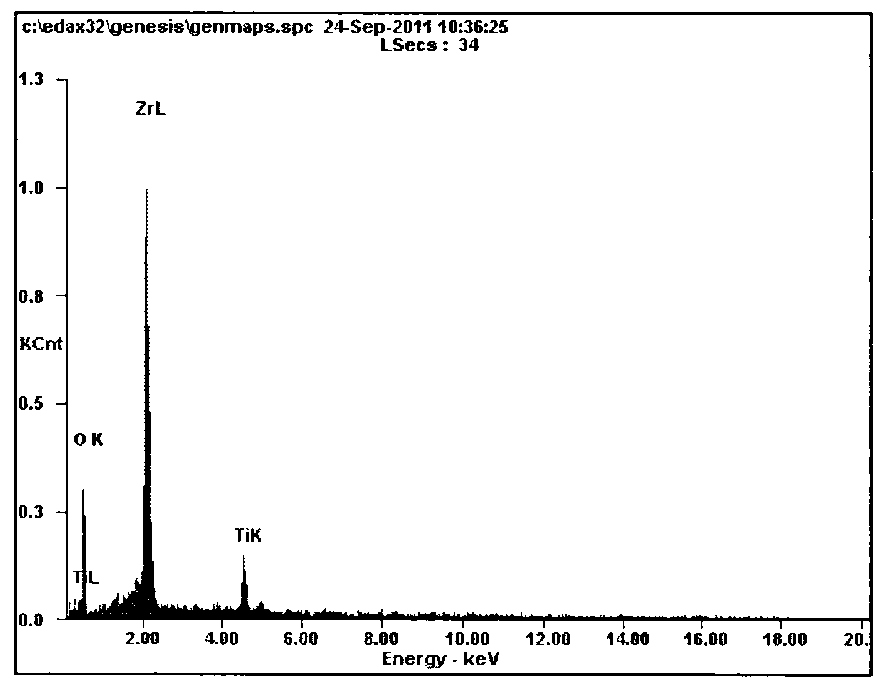

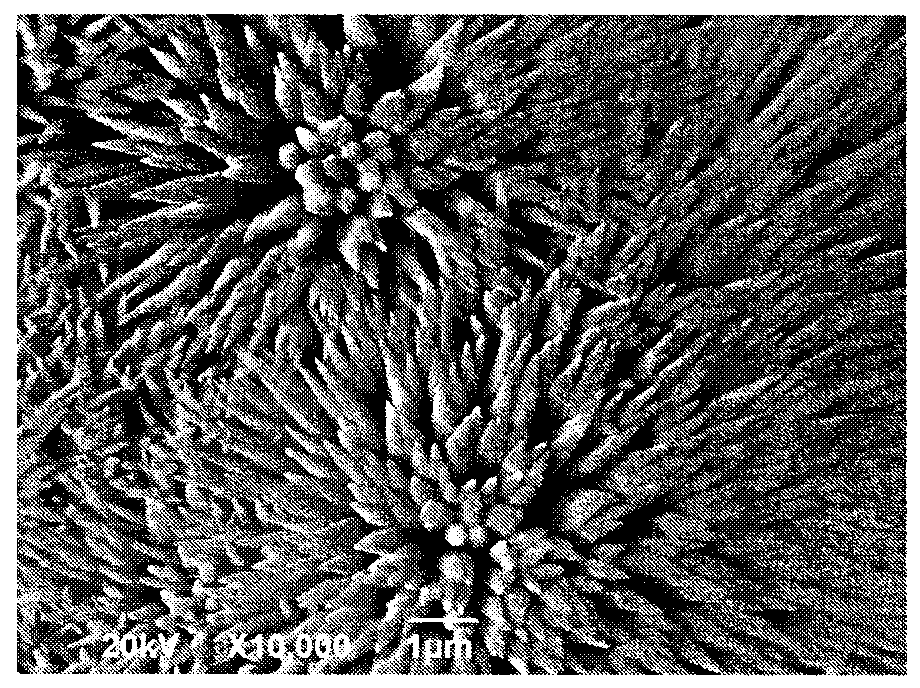

[0024] (1) Wire-cut medical pure titanium into 10×10×1mm titanium sheets; grind the titanium sheets with sandpaper until the surface is smooth without machining traces; respectively use absolute ethanol, acetone, and deionized water with ultrasonic waves Cleaning time is 10min; then use HF:HNO 3 :H 2 O=1:1:10 acid solution for acid etching for 20s. Finally, put the sample into the sample bag and wait for the test.

[0025] (2) The Ti sheet was used as the cathode working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and the distance between the electrodes was 2 cm.

[0026] (3) Weigh 0.5781 g of anhydrous zirconium oxynitrate, dissolve it with 100 ml of hot dilute nitric acid, set the volume to 200 ml after cooling, adjust the pH of the solution to 2.2 with ammonia water, and finally obtain a uniform electrolyte. Put the electrolyte solution into a 250ml glass beaker for electroc...

Embodiment 2

[0032] (1) Wire-cut medical pure titanium into 10×10×1mm titanium sheets; grind the titanium sheets with sandpaper until the surface is smooth without machining traces; respectively use absolute ethanol, acetone, and deionized water with ultrasonic waves Cleaning time is 10min; then use HF:HNO 3 :H 2 O=1:1:10 acid solution for acid etching for 20s. Finally, put the sample into the sample bag and wait for the test.

[0033] (2) The Ti sheet was used as the cathode working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and the distance between the electrodes was 2 cm.

[0034] (3) Weigh 0.5781 g of anhydrous zirconium oxynitrate, dissolve it with 100 ml of hot dilute nitric acid, set the volume to 200 ml after cooling, adjust the pH of the solution to 2.2 with ammonia water, and finally obtain a uniform electrolyte. Put the electrolyte solution into a 250ml glass beaker for electroc...

Embodiment 3

[0038] (1) Wire-cut medical pure titanium into 10×10×1mm titanium sheets; grind the titanium sheets with sandpaper until the surface is smooth without machining traces; respectively use absolute ethanol, acetone, and deionized water with ultrasonic waves Cleaning time is 10min; then use HF:HNO 3 :H 2 O=1:1:10 acid solution for acid etching for 20s. Finally, put the sample into the sample bag and wait for the test.

[0039] (2) The Ti sheet was used as the cathode working electrode, the platinum electrode was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode, and the distance between the electrodes was 2 cm.

[0040] (3) Weigh 0.5781 g of anhydrous zirconium oxynitrate, dissolve it with 100 ml of hot dilute nitric acid, set the volume to 200 ml after cooling, adjust the pH of the solution to 2.2 with ammonia water, and finally obtain a uniform electrolyte. Put the electrolyte solution into a 250ml glass beaker for electroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com