GeSn quantum well infrared illuminator with strain source

A technology of infrared luminescence and quantum wells, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor material quality and thermal stability, difficulty in wide-range bandgap adjustment, etc., and achieve the effect of rapid and efficient radiation recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to understand the technical essence of the present invention more clearly, the structure and process realization of the present invention are described in detail below in conjunction with the accompanying drawings and embodiments:

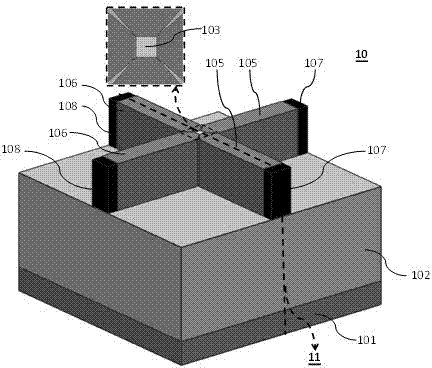

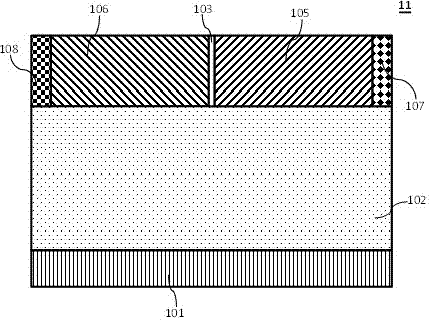

[0020] see figure 1 and figure 2 The shown GeSn quantum well infrared emitter with a strain source, which includes:

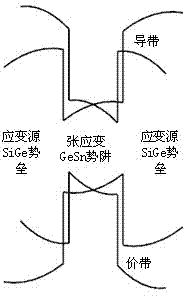

[0021] The active region 103 and the relaxed layer 102 , the active region 103 is located on the relaxed layer 102 . They use single crystal GeSn material, the general formula of the material is Ge 1-x sn x (0≤ x ≤0.25), if Ge can be used 0.93 sn 0.07 .

[0022] no + Type strainer 105 with p + Type strain source 106, distributed in pairs around the active region, using single crystal SiGe material, the general formula of the material is Si 1-x Ge x (0≤ x ≤0.4), if Si can be used 0.7 Ge 0.3 .

[0023] The two first electrodes 107 are connected to the strain source 105 .

[0024] The two second electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com