Nitride LED epitaxy structure suitable for heavy current driving

An epitaxial structure and nitride technology, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as reducing the probability of the overlap of electron and hole wave functions, uneven distribution of carrier concentration and recombination, and adverse effects on quantum efficiency. , to weaken the adverse effects, improve the internal quantum efficiency of the LED, and reduce the intensity of the built-in polarization electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

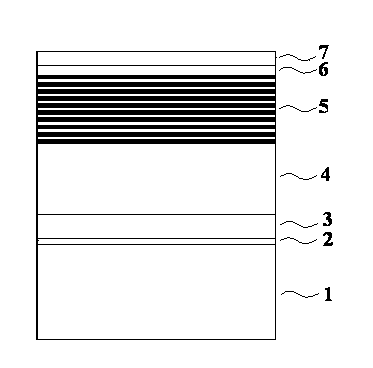

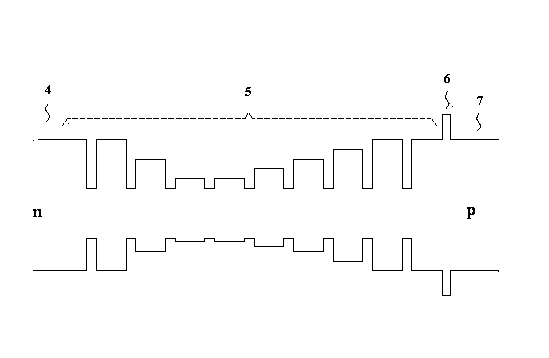

[0030] see figure 1 , the present invention is sapphire substrate 1, GaN low-temperature buffer layer 2, non-doped GaN layer 3, n-type GaN electron injection layer 4, composed of 10 In x Ga 1-x N (0≤x≤1) quantum barrier and 9 In 0.2 Ga 0.8 Active region layer 5 composed of N quantum wells, Al 0.13 Ga 0.87 N p-type electron blocking layer 6 and p-type GaN hole injection layer 7 . Among them, the film thickness of the GaN low-temperature buffer layer 2 is 25nm; the thickness of the non-doped GaN layer 3 is 2.5 μm; the thickness of the n-type GaN electron injection layer 4 is 2.5 μm, and a 5×10 19 / cm 3 concentration of Si for n-type doping. 10 In x Ga 1-xThe x values of N (0≤x≤1) quantum barriers are 0, 0, 0.06, 0.14, 0.14, 0.12, 0.06, 0.03, 0, 0 from bottom to top, that is, the forbidden band width of quantum barriers decreases first. Small and then increase the change trend, the film thickness of the quantum barrier remains unchanged at 10nm. The forbidden band w...

Embodiment 2

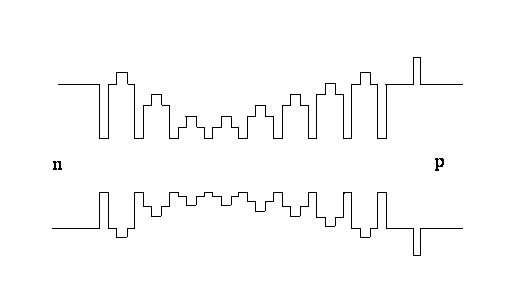

[0032] Except for the active region layer 5 , the LED epitaxial structure of Embodiment 2 of the present invention is completely the same as that of Embodiment 1. Such as image 3 , the active region 5 consists of 10 In x Ga 1-x N / Al y In z Ga 1-y-z N / In x Ga 1-x N (0≤x≤1; 0≤y, z≤1; y+z≤1) quantum barrier and 9 In 0.2 Ga 0.8 N quantum well composition. Among them, the single quantum barrier In x Ga 1-x N / Al y In z Ga 1-y-z N / In x Ga 1-x N consists of three layers of nitride In x Ga 1-x N. Al y In z Ga 1-y-z N, In x Ga 1-x N composition. In the same quantum barrier, the chemical composition of the first and third layers of nitride is the same, and the band gap of the second layer of nitride is larger than that of the other two layers. If the ordered real number pair (x, y, z) is used to represent the material composition of a single quantum barrier trilayer nitride, then, with the above 10 quantum barriers In x Ga 1-x N / Al y In z Ga 1-y-z N / In ...

Embodiment 3

[0034] Except for the active region 5, the epitaxial structure of the LED in the third embodiment of the present invention is completely the same as that in the first embodiment. see Figure 4 , the active region 5 consists of 8 In x Ga 1-x N (0≤x≤1) quantum barrier and 7 In 0.2 Ga 0.8 N quantum well composition. According to the bottom-up sequence of epitaxial growth, 8 In x Ga 1-x The maximum forbidden band width of N (0≤x≤1) quantum barriers shows a trend of decreasing first and then increasing. Among them, the material of the first and eighth quantum barriers is GaN; the forbidden band width of the second and third quantum barriers shows a uniformly decreasing change mode, and the value of x representing their chemical composition increases uniformly from 0 to 0.03, uniformly increased from 0.06 to 0.09; the forbidden band widths of the 4th, 5th, 6th, and 7th quantum barriers showed a uniform increase, and their x values were uniformly decreased from 0.15 to 0.12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com