LED chip structure of graphene structure and manufacturing method thereof

A graphene and graphene layer technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large effective light emitting area of the chip and difficulty in lateral expansion of P-GaN, and achieve the relief of metal electrode blocking area and high light transmission. The effect of high conductivity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

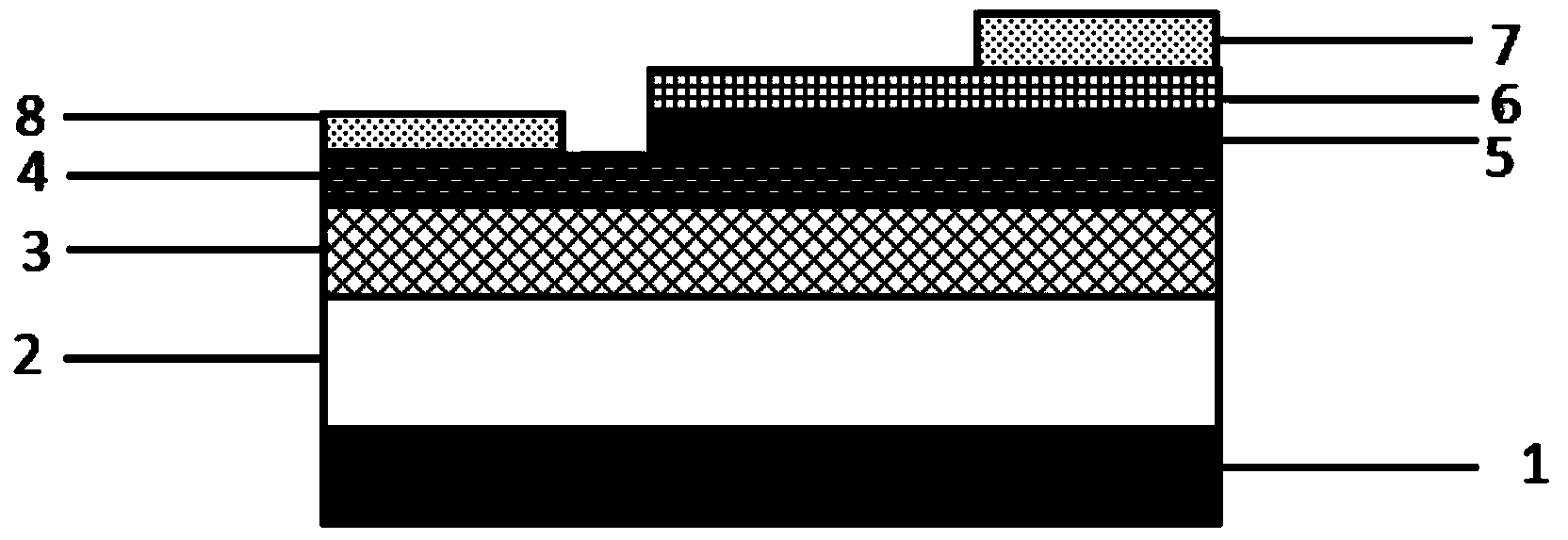

[0042] Embodiment one: see attached figure 1 Shown, a kind of graphene LED chip structure and preparation method thereof, comprises the following steps:

[0043] 1) Using MOCVD or MBE to grow a nucleation layer 2 on the substrate 1, the growth temperature is 520-570°C, and the thickness is 10-30nm;

[0044] 2) growing a U-GaN layer 3 on the nucleation layer 2 at a growth temperature of 1080° C. and a thickness of 2-4 μm without doping;

[0045] 3) growing an N-GaN layer 4 on the U-GaN layer 3 at a growth temperature of 1080° C., a thickness of 0.2-1 μm, and a Si doping concentration of 5E17˜3E18;

[0046]4) On the N-GaN layer 4, grow the InGaN / GaN multi-quantum well layer 5 for about 5-10 periods, wherein the growth temperature is 650-850° C. for the InGaN layer, with a thickness of 1-5 nm, and 700-900° C. for the GaN layer, with a thickness of 5-5 nm. 10nm, In composition is 10%, and the final growth cut-off layer is GaN layer;

[0047] 5) pickling the surface of the epita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com