LED chip structure of ITO structure and preparing method thereof

A technology of LED chip and multi-quantum well structure, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of P-GaN lateral expansion difficulty, large effective light emitting area of the chip, etc. Optical, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

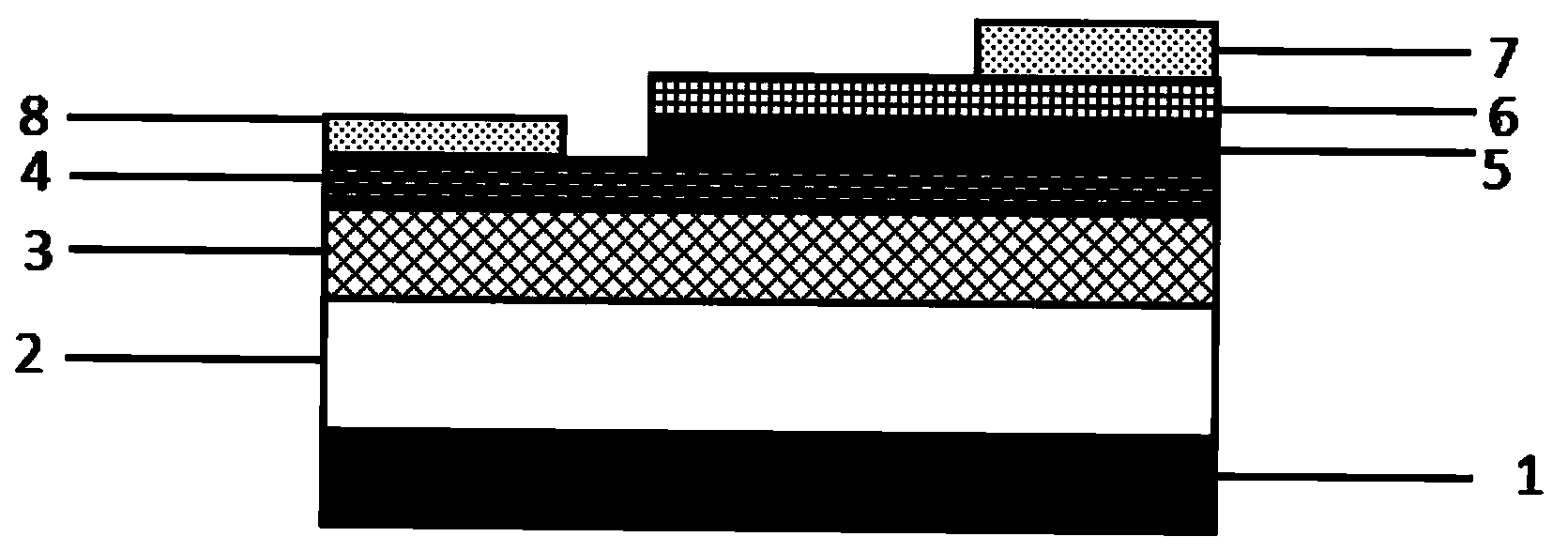

[0031] See attached figure 1 Shown, a kind of ITO structure LED chip structure and preparation method thereof, comprises the following steps:

[0032] 1) Using MOCVD or MBE to grow a nucleation layer 2 on the substrate 1, the growth temperature is 520-570°C, and the thickness is 10-30nm;

[0033] 2) growing a U-GaN layer 3 on the nucleation layer 2 at a growth temperature of 1080° C. and a thickness of 2-4 μm, which is an unintentional undoped layer;

[0034] 3) growing an N-GaN layer 4 on the U-GaN layer 3 at a growth temperature of 1080° C., a thickness of 0.2-1 μm, and Si doping at a concentration of 5E17 to 3E18;

[0035] 4) On the N-GaN layer 4, grow the InGaN / GaN multi-quantum well layer 5 for about 5-10 cycles, wherein the growth temperature is 650-850°C for the InGaN layer, 700-900°C for the GaN layer, and the In composition is 10%, and finally The growth cut-off layer is a GaN layer;

[0036] 5) pickling the surface of the epitaxial wafer;

[0037] 6) Carrying out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com