Method for reducing warping stress of LED epitaxy

A warpage stress and epitaxy technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the warpage stress of LED epitaxy, aggravating the degree of epitaxy warping of epitaxial wafers, and lattice mismatch, so as to improve the wavelength Yield rate, improvement of wavelength uniformity, and effect of warpage improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Such as Figure 1 to Figure 3 As shown, the present invention provides a method for reducing the epitaxial warpage stress of an LED. The method at least includes the following steps:

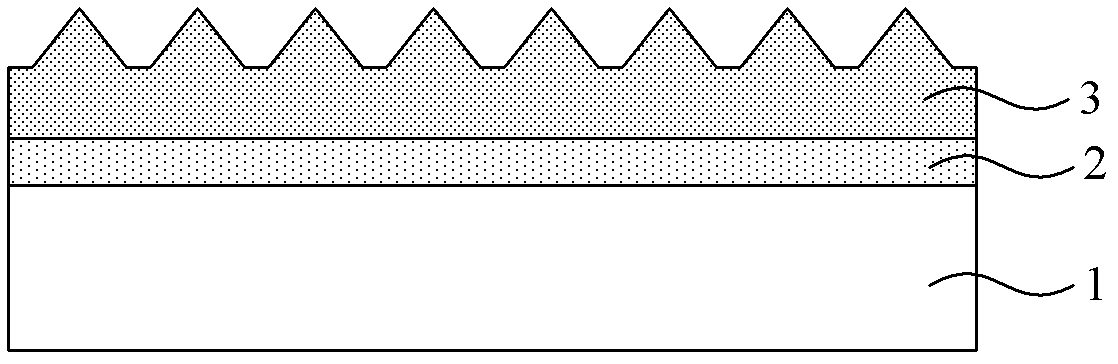

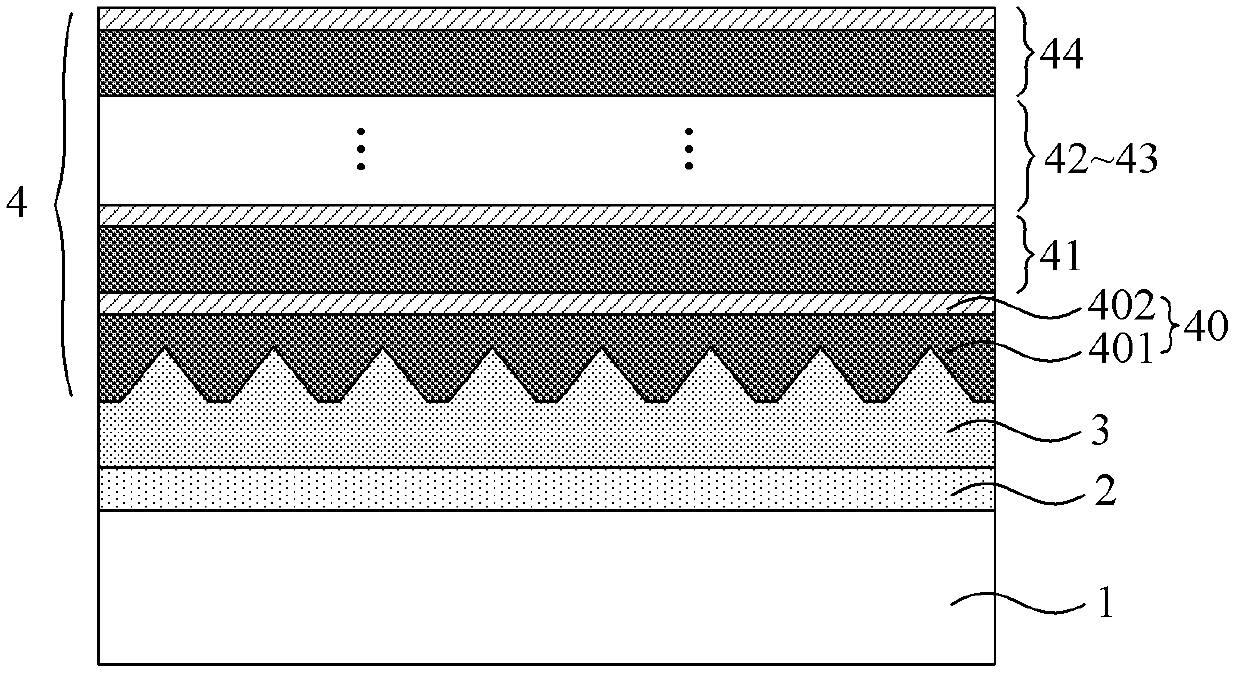

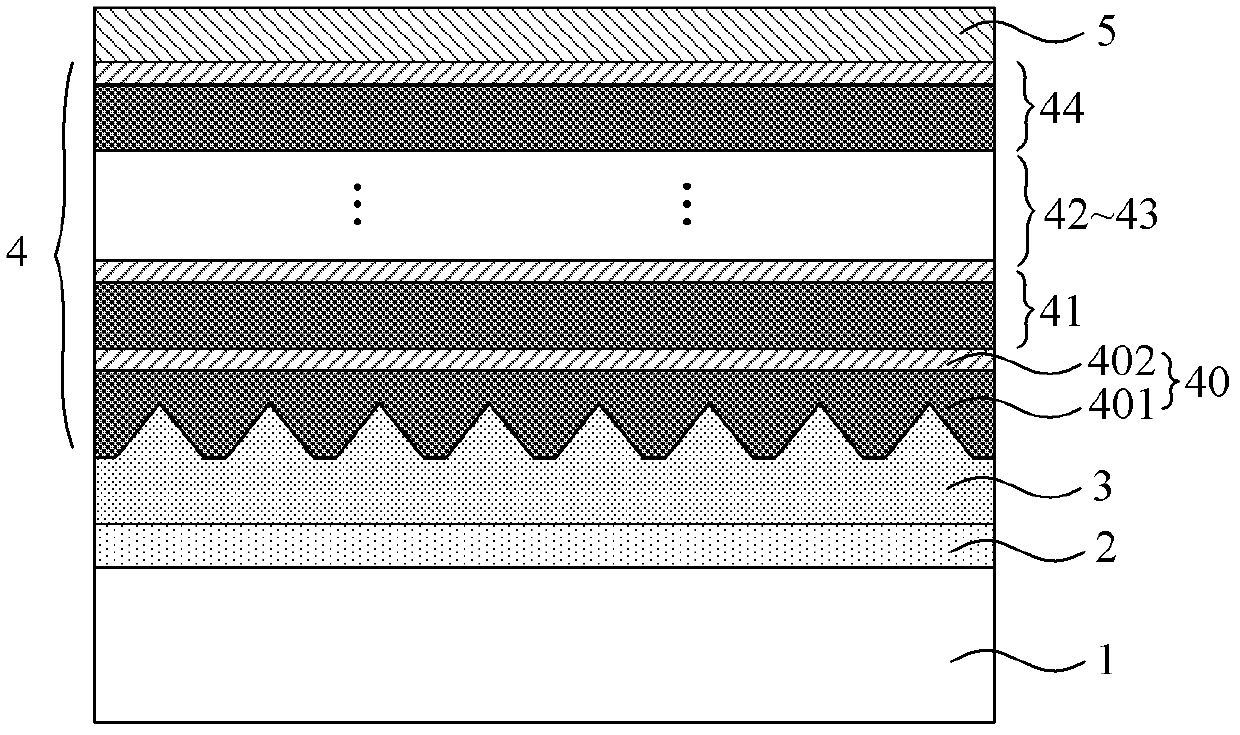

[0036] Such as figure 1 As shown, first perform step 1) to provide a sapphire substrate 1. The substrate is a patterned sapphire substrate (PSS), the substrate pattern is a triangularly arranged cone-shaped high-pack structure, and the bottom of the cone-shaped high-pack The diameter is 2.4μm, the height of the cone is 1.5μm, and the interval between adjacent cones is 0.6μm (duty cycle is 0.8). The metal organic chemical vapor deposition (MOCVD) method is used, when the temperature is 500~600℃ and the pressure When it is 400-600 Torr, epitaxially (two-dimensional growth, layer-by-layer growth, Frank-van der Merwe growth mode) a GaN buffer layer 2 on the sapphire substrate 1, and then when the temperature is 900-1000°C and the pressure is 400 At ~600 Torr, a three-dimensional growth (island g...

Embodiment 2

[0045] The second embodiment adopts basically the same technical solution as the first embodiment, but the difference is: ① When the two superlattices are prepared, although the double-layer film of the superlattice all contains a GaN layer and Al 1-x Ga x N layer, but the GaN layer and the Al 1-x Ga x The upper and lower positions of the N layer are different. In the first embodiment, the double-layer film is the GaN / Al 1-x Ga x N double-layer film, namely each GaN / Al 1-x Ga x Al in N bilayer film 1-x Ga x The N layer is located on the GaN layer, and in the second embodiment, the double-layer film is Al 1-x Ga x N / GaN double-layer film, namely each Al 1-x Ga x The GaN layer in the N / GaN bilayer film is located in Al 1-x Ga x Above the N layer; ②The number of periodic epitaxy of the double-layer film in the superlattice prepared by the two is different. In the first embodiment, the periodic epitaxy of the GaN / Al 1-x Ga x N double-layer film 5 times, and in the second embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com