Light emitting diode epitaxial wafer and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve the problems of low luminous efficiency and uneven wavelength uniformity of light-emitting diodes, and achieve improved lattice quality, uniform distribution, and tight fit. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

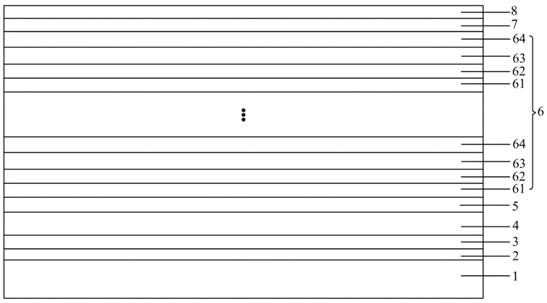

[0041] see figure 1 , is a schematic structural diagram of a light-emitting diode epitaxial wafer provided by the first embodiment of the present invention. For the convenience of description, only the part related to the embodiment of the present invention is shown. The light-emitting diode epitaxial wafer provided by the embodiment of the present invention includes:

[0042] A substrate 1, and a buffer layer 2, an undoped u-GaN layer 3, an N-type GaN layer 4, a stress release layer 5, a multiple quantum well layer 6, an electron blocking layer 7, and a P type GaN layer 8;

[0043] The multiple quantum well layer 6 includes a front insertion layer 61, a quantum well layer 62, a rear insertion layer 63 and a quantum barrier layer 64 that are periodically and repeatedly stacked;

[0044] The front insertion layer 61 includes laminated In x N 1-x Layer and In y Ga 1-y N layer, In x N 1-x Layer and In y Ga 1-y The surface contacted by the N layer is also subjected to H ...

Embodiment 2

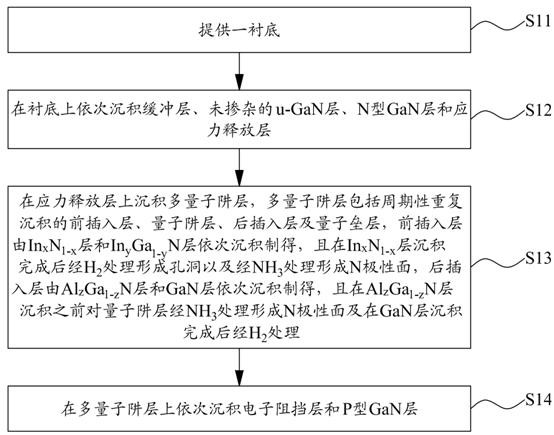

[0065] see figure 2 , shows a method for fabricating a light-emitting diode epitaxial wafer in the second embodiment of the present invention, and the method specifically includes steps S11 to S14 .

[0066] Step S11, providing a substrate.

[0067] Wherein, in the embodiments of the present invention, the selected substrates include but are not limited to sapphire substrates, silicon substrates, silicon carbide substrates, aluminum nitride substrates, gallium nitride substrates, and substrates such as silicon dioxide and sapphire. The composite substrate composed of, specifically, in this embodiment, sapphire is used as the epitaxial layer growth substrate, which can make a periodically changing structure on the substrate to form a patterned substrate, or SiO can be used 2 -Al 2 O 3 and other composite patterned substrates. Specifically, in the embodiment of the present invention, a sapphire patterned substrate is used as the epitaxial layer growth substrate.

[0068] F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com