Tray with air bridge structure and epitaxial growth method

An air bridge and tray technology, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor uniformity of homogeneous epitaxial wafers, and the back of the semiconductor substrate is easy to be baked black, etc., to achieve good temperature consistency, Wavelength uniformity is improved and the effect of enlarging the flow space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

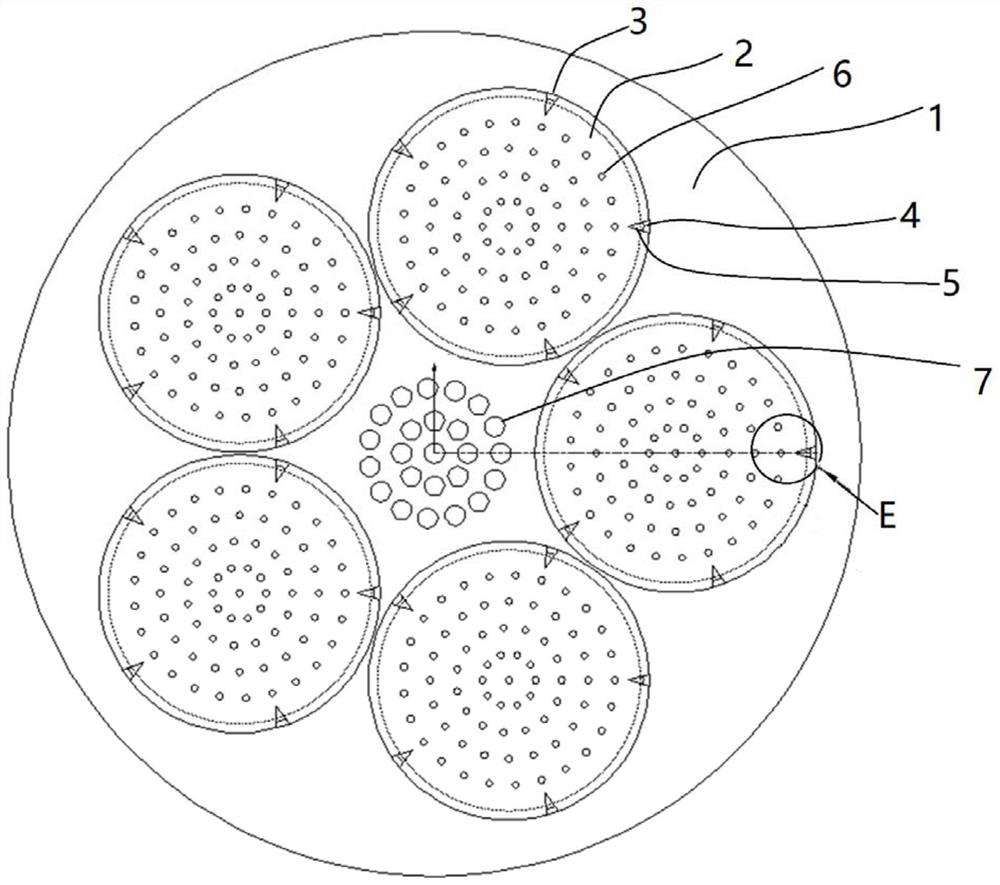

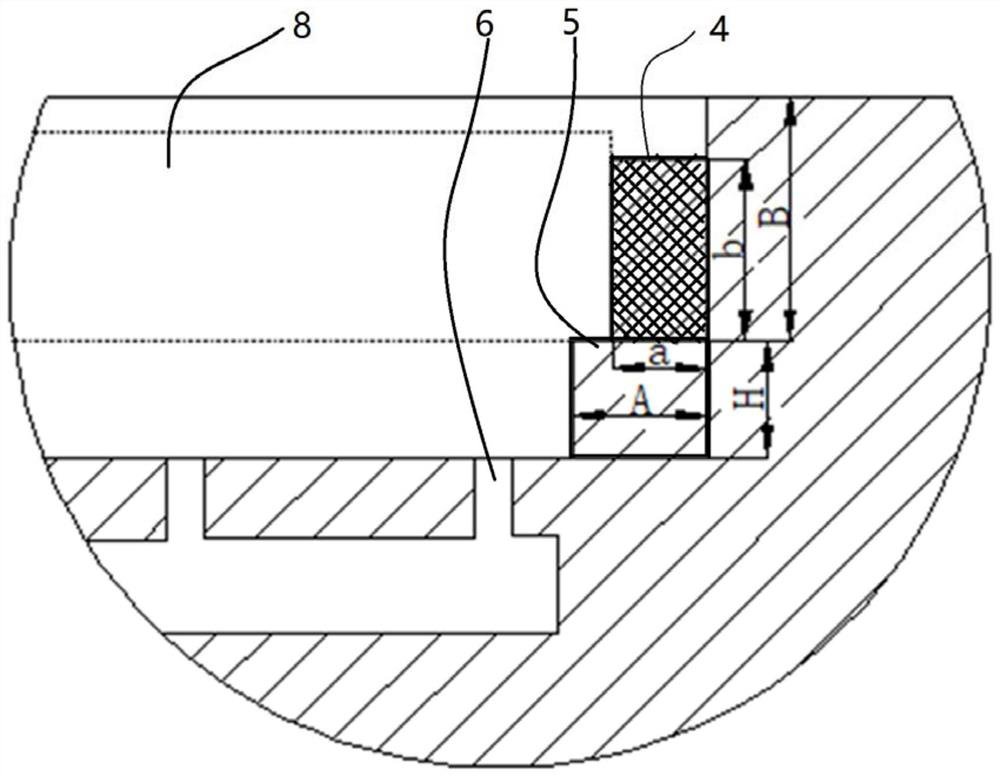

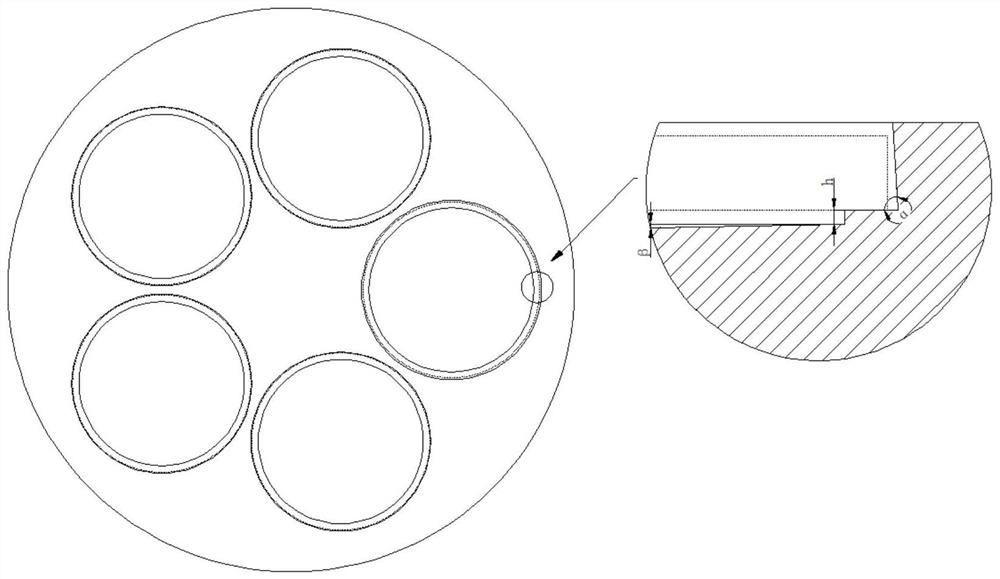

[0023] figure 1 It is a schematic diagram of the pallet structure of the present invention; figure 2 for figure 1 The partially enlarged schematic diagram of the cross-section of the compound step at the mark letter E in , a tray with an air bridge structure, including a tray main body 1, the end surface of the tray main body is provided with a groove 2 for placing a substrate 8; the bottom of the groove is provided with multiple A spray hole 6; a plurality of grooves are arranged on the main body of the tray, and a plurality of composite steps 3 are arranged in each groove; a through hole 7 is arranged in the central area of the tray, and communicates with the spray hole at the bottom of the groove.

[0024] Preferably: the composite step is composed of the first step 4 and the second step 5; the first step is close to the inner wall of the groove, and the first step is used to form an air bridge with the inner wall; wherein the first step is close to the groove On the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com