DRAM (Dynamic Random Access Memory) structure with expansion groove and manufacturing method thereof

A trench, N-type technology, used in semiconductor/solid-state device manufacturing, transistors, electrical components, etc., can solve the problems of high etching process requirements, complex process, increased leakage, etc., to overcome low-leakage thin dielectric layers , the process is simple, the effect of large capacitor plate area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

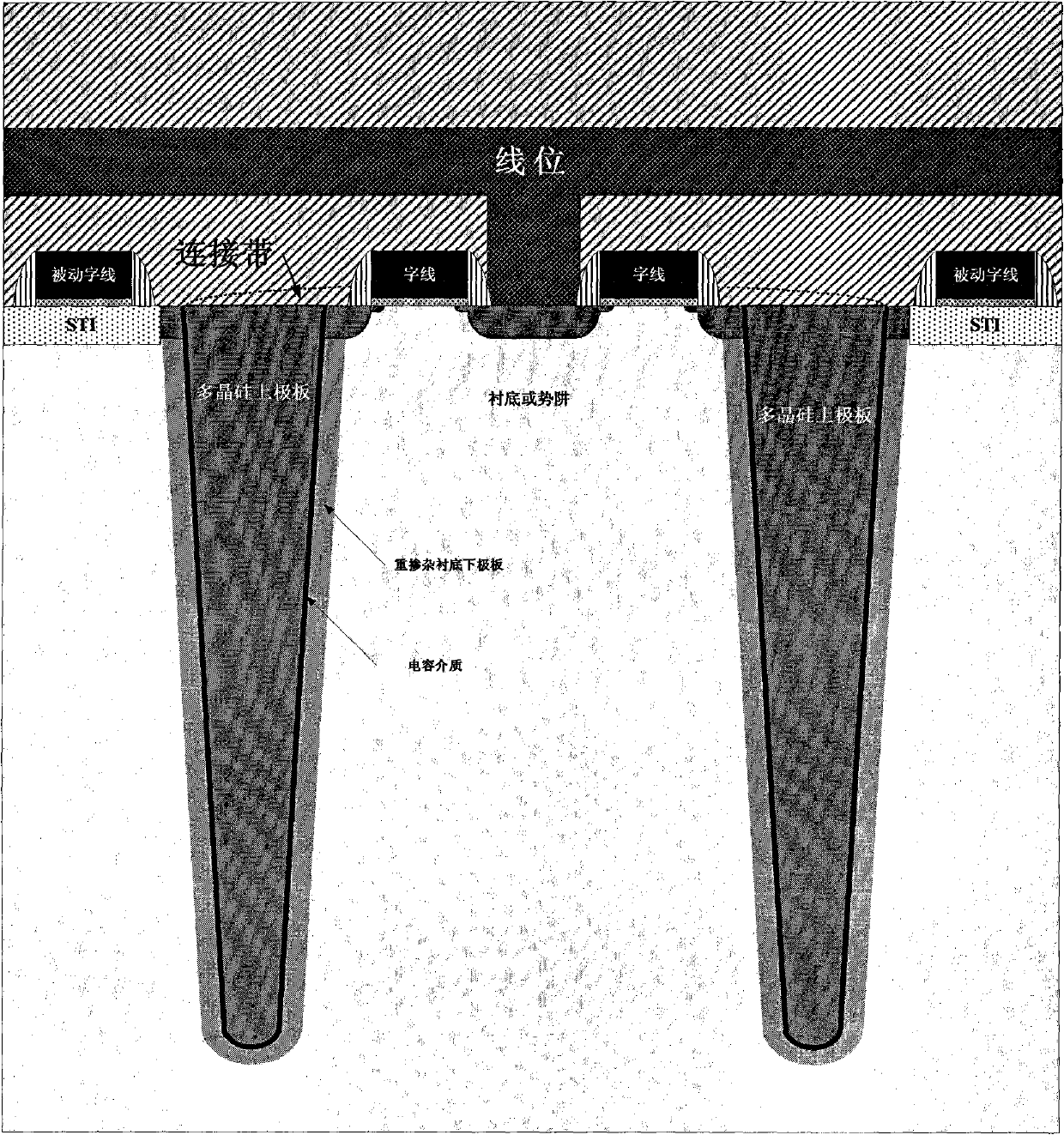

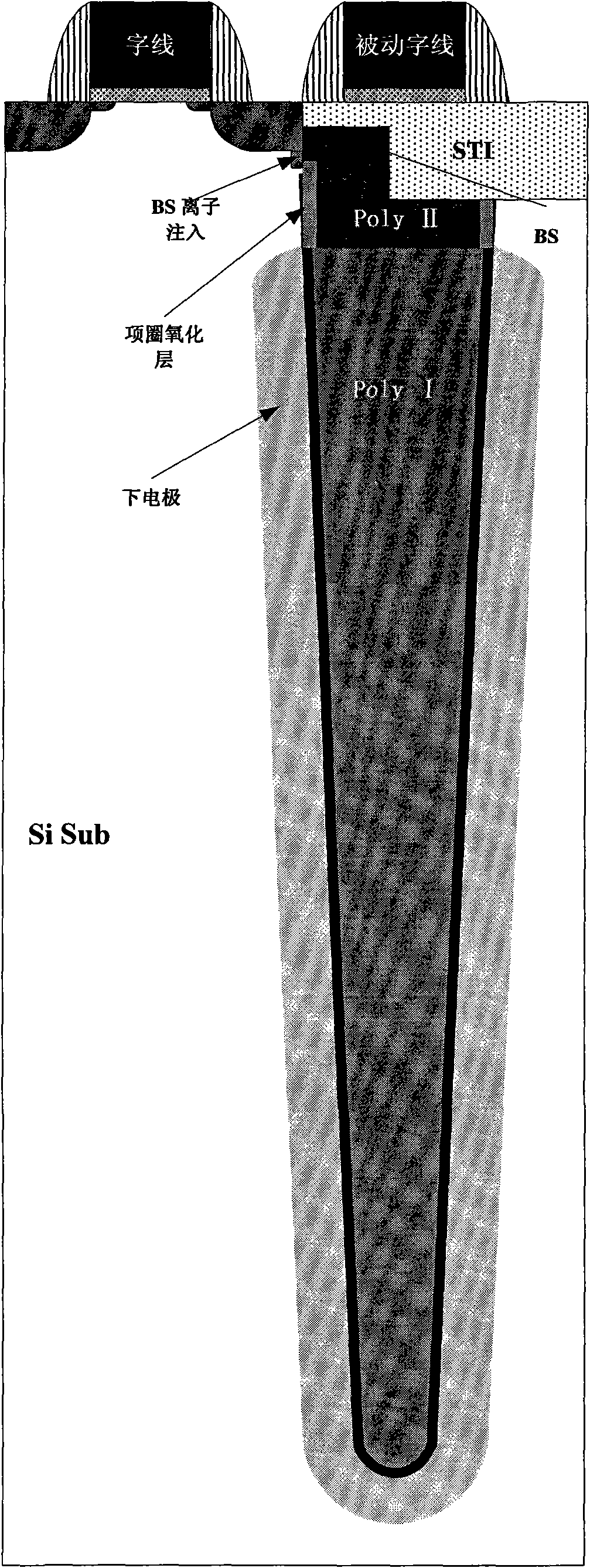

[0037] See first Figure 8 , this embodiment provides a DRAM structure with extended trenches based on the BEST process for fabricating buried connection straps, including an NMOS transistor 6 and a trench capacitor connected to its source.

[0038] Wherein, the trench capacitor includes:

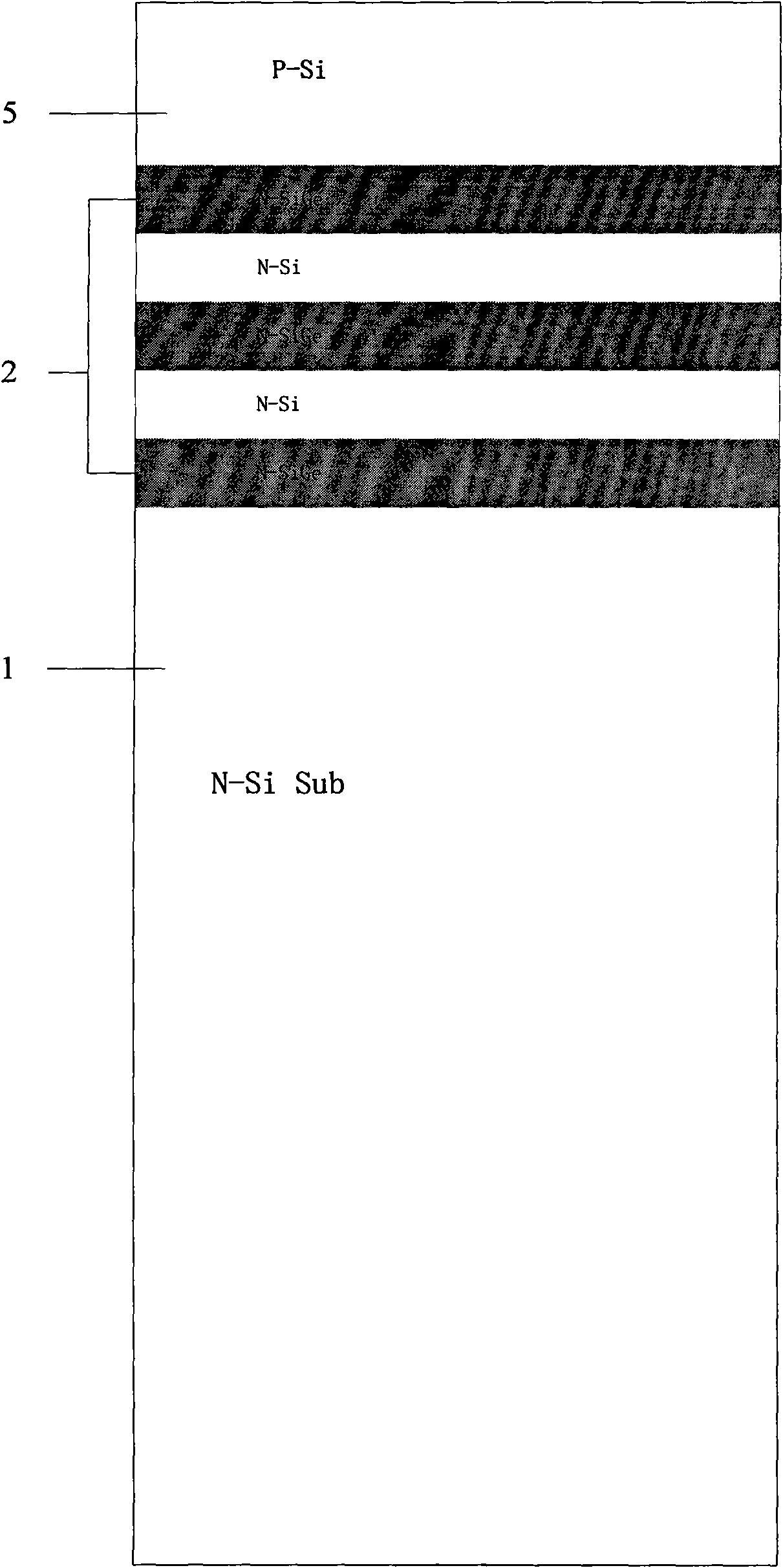

[0039] The semiconductor substrate can be a P-type substrate or an N-type substrate. The present embodiment takes the N-type Si substrate 1 as an example, so that it is the same N-type as the SiGe / Si epitaxial stack;

[0040] Alternately arranged N-type SiGe layers and N-type Si layers 2 are located on the N-type Si substrate 1 and can be multi-layered. In this embodiment, for example Figure 8As shown, on the N-type Si substrate 1, there are one layer of N-type SiGe layer, one layer of N-type Si layer, another layer of N-type SiGe layer, and another layer of N-type Si layer, which are arranged alternately upward;

[0041] The groove is located in the alternately arranged N-type SiGe laye...

Embodiment 2

[0057] See Figure 9 , which is different from Embodiment 1 in that: the uppermost layer of alternately grown multi-layer N-type SiGe layers and N-type Si layers is an N-type Si layer, and then a P-type Si layer is made on it.

[0058] In the present invention, the stacking order and number of alternate N-type SiGe layers and N-type Si layers are not limited.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com