Shaft-mounted brake disc module for high-speed train

A technology for high-speed trains and brake discs, applied in the direction of brake discs, brake parts, brake types, etc., can solve the problems of heat dissipation efficiency to be improved, achieve good braking effect and solve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

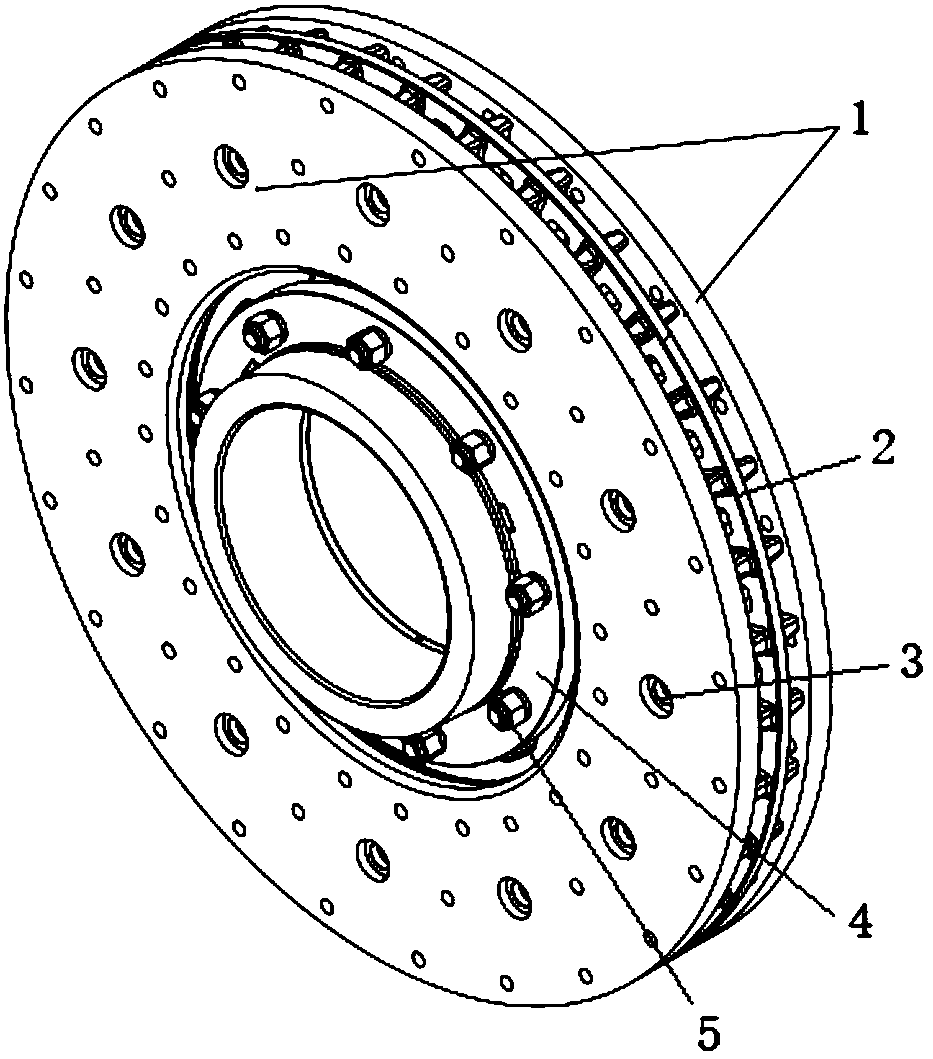

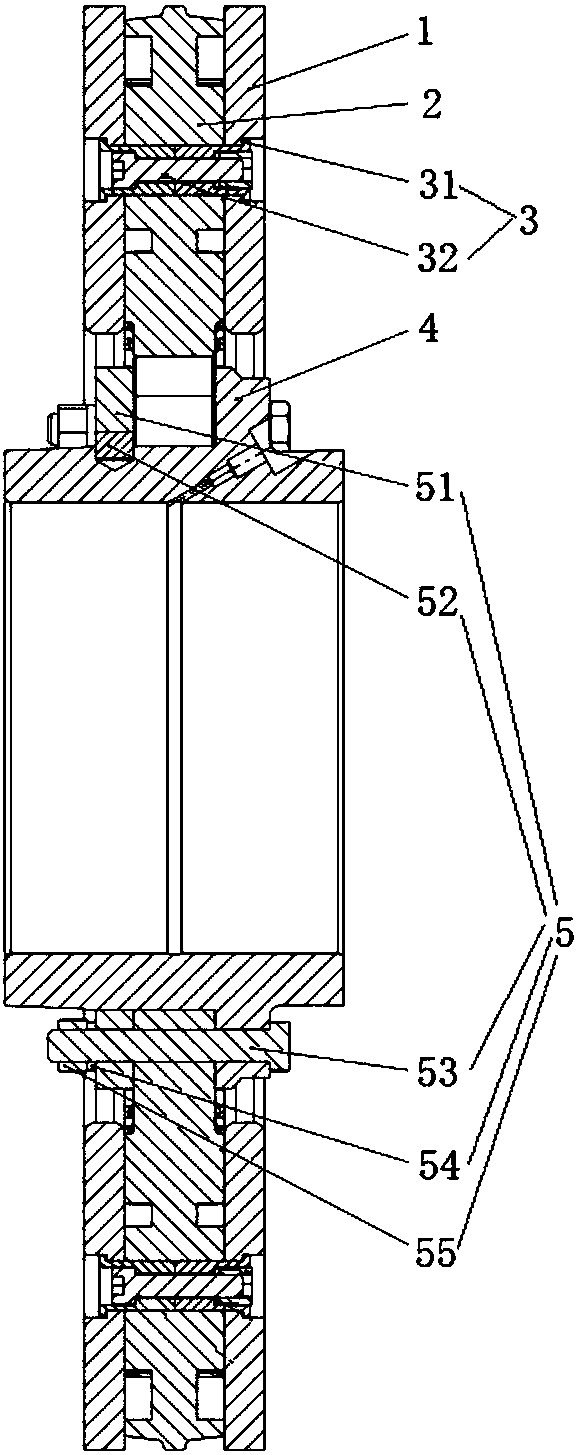

[0051] see figure 1 and figure 2 , the shaft-mounted brake disc assembly for high-speed trains in the illustration is one of the preferred solutions of the present invention, specifically including a brake disc 1, a support disc 2, a first connection structure 3, a hub 4 and a second connection structure 5 , two sets of disc-shaped brake discs 1 are coaxially stacked on both sides of the support disc 2, the brake disc 1 and the support disc 2 are clamped and locked by the first connection structure 3, and the support disc 2 is also Ring disc shape, the heat dissipation structure is processed and set in the ring area where the disc surface on both sides of the support disc 2 overlaps with the friction disc, the disc surfaces on both sides of the brake disc 1 are processed flat, so that the stacked brake disc 1 and support disc 2 The heat dissipation structure forms the heat dissipation channel inside the brake disc. The inner ring of the support disc 2 is processed with a co...

Embodiment 2

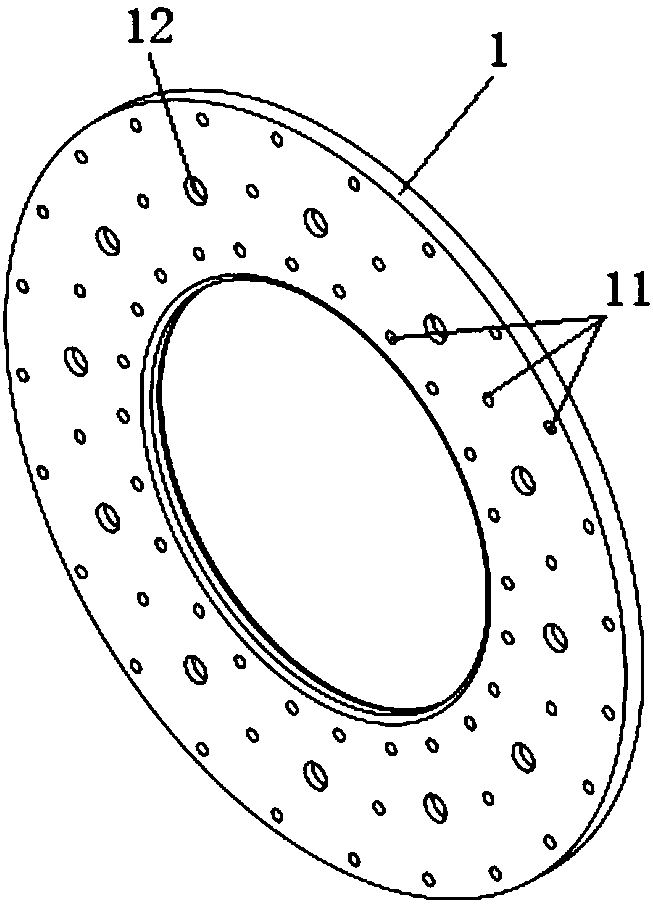

[0065] see in conjunction Figure 9 and Figure 10 , the shaft-mounted brake disc assembly for high-speed trains in the illustration is a further preferred solution of Embodiment 1. In Embodiment 1, the brake disc 1 is an integral circular disc-shaped structure, and two groups of brake discs are stacked separately Locked on both sides of the support disc 2, the brake disc 1 can be disassembled from the support disc 2 for maintenance.

[0066] In the second embodiment, in order to further reduce the maintenance cost of the brake disc 1, the brake disc 1 is spliced with several split brake discs 1' that are radially divided along the disc surface, such as Figure 10 In the semi-circular disc structure, each split brake disc 1' is stacked and locked with the support disc through an independent first connection structure 3, and the two split brake discs 1' are stacked and locked on the support disc 2, then splice to form a complete circular brake disc. In this way, when a cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com