Process for manufacturing arc moldable mold-pressing door

A manufacturing process and membrane pressing technology, which is applied in the manufacturing process of arc shapeable membrane pressing doors, can solve problems such as difficulty in making door panels, achieve the effect of solving processing technology problems, enriching structure and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

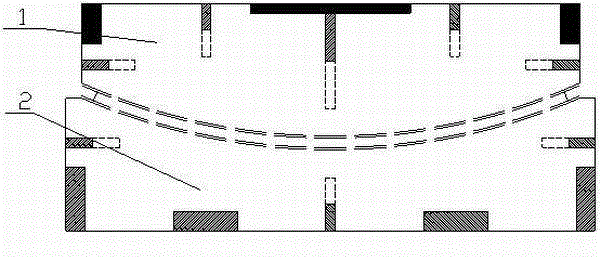

[0022] like Figure 1-5 As shown, a manufacturing process of an arc shapeable membrane pressure door comprises the following steps:

[0023] Step 1, divide the thickness of the door panel into several layers;

[0024] Step 2, making a bending die with a target curvature;

[0025] Step 3, glue each layer of the door panel with glue, and place the door panel on the lower membrane part 2 of the bending mold;

[0026] Step 4, adjust the parameters of the bending machine to bend the door panel, where the screen electrode current is 1.6A, the grid current is 0.3A, the heating time is 80 seconds, and the setting time is 2 hours;

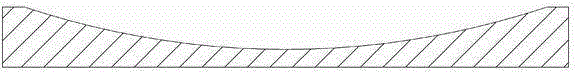

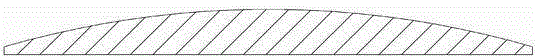

[0027] Step five, making a pair of concave-convex molds matching the radian of the door panel;

[0028] Step 6, first put the concave mold on the membrane press, put the door panel on the concave mold for peritoneal, then put the convex mold on the membrane press, put the door panel on the convex mold for another peritoneum, that is, forming.

[0029] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com