Titanium-alloy high-pressure compressor arc rabbet working-blade processing technique

A processing technology, titanium alloy technology, which is applied in the field of processing technology of titanium alloy high-pressure compressor arc tenon working blades, can solve the problems of increasing measurement error, poor straightness, and affecting the detection results of node sizes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 Machining process of arc-shaped tenon blades of titanium alloy high-pressure compressor

[0058] The processing technology of titanium alloy high-pressure compressor arc-shaped tenon blades is processed by a combination of the following three innovative methods:

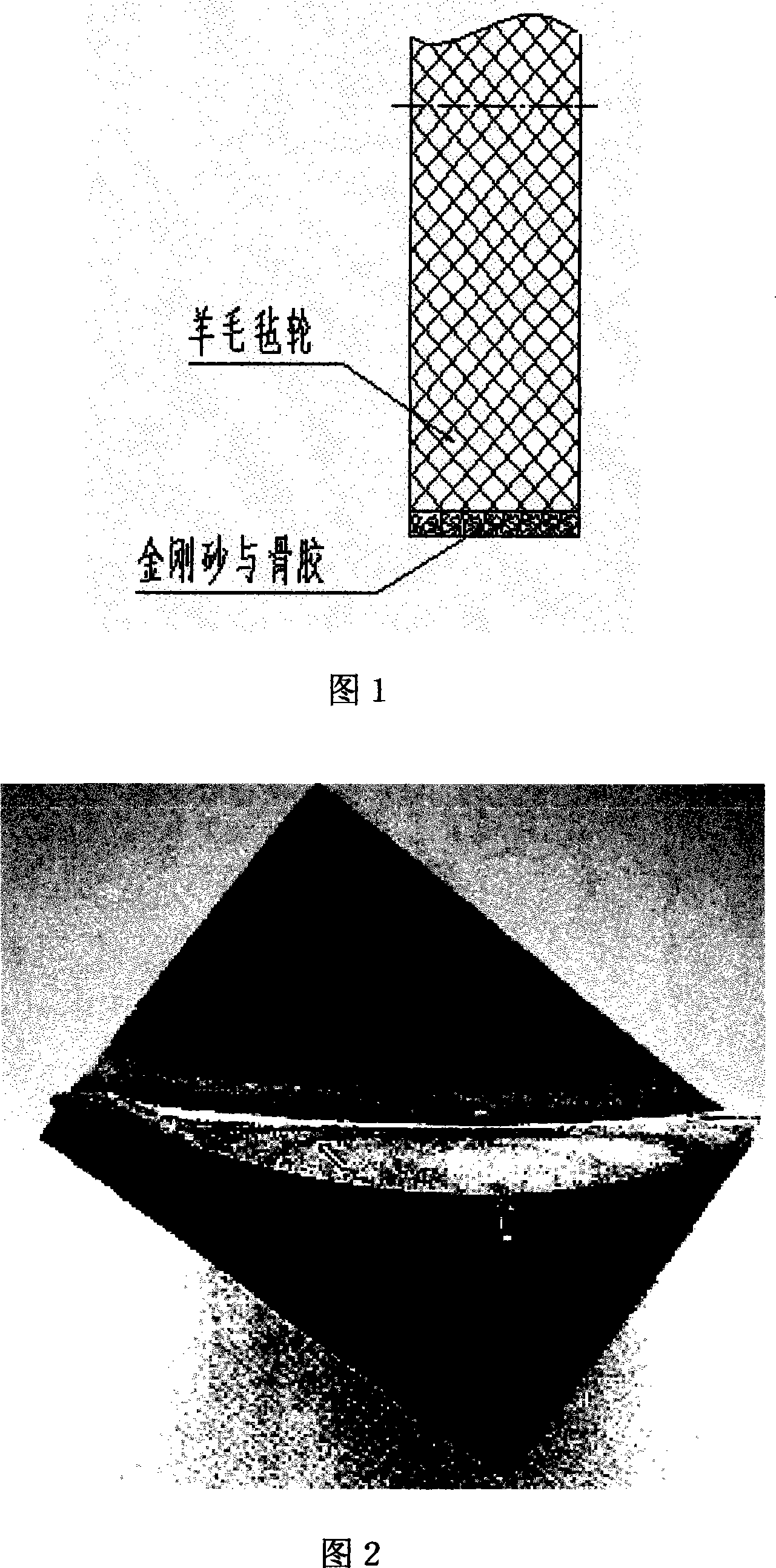

[0059] First, the method of using a felt wheel and a polishing wheel to polish the titanium alloy blade;

[0060] Second, the method of "CNC turning + forming knife precision turning" is used to process titanium alloy blade double arc tenon;

[0061] Third, use a special measuring tool for online measurement during the tenon processing; the special measuring tool includes the following structures: base (1), sliding block (2), measuring pin (3), positioning block (4), positioning Pin (5); Among them: slider (2), positioning block (4), positioning pin (5) are all arranged on the base (1), the measuring pin (3) is arranged on the sliding block (2), and the measuring pin ( 3) and the positioning pins (5) are re...

Embodiment 2

[0088] The content of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

[0089] The processing technology of the arc-shaped tenon working blade of the titanium alloy high-pressure compressor adopts one of the following three innovative methods for processing:

[0090] First, the method of using a felt wheel and a polishing wheel to polish the titanium alloy blade;

[0091] Second, the method of "CNC turning + forming knife precision turning" is used to process titanium alloy blade double arc tenon;

[0092] Third, use a special measuring tool for online measurement during the tenon processing; the special measuring tool includes the following structures: base (1), sliding block (2), measuring pin (3), positioning block (4), positioning Pin (5); Among them: slider (2), positioning block (4), positioning pin (5) are all arranged on the base (1), the measuring pin (3) is arranged on the sliding block (2), and the measuring pin ( 3) and the posit...

Embodiment 3

[0106] The content of this embodiment is basically the same as that of embodiment 1, and the difference lies in:

[0107] Titanium alloy high-pressure compressor arc-shaped tenon working blade processing technology, which uses a felt wheel and polishing wheel to polish the titanium alloy blade; in the tenon processing process, a special measuring tool is used for online measurement; the special measuring tool includes The following structures: base (1), sliding block (2), measuring pin (3), positioning block (4), positioning pin (5); among them: sliding block (2), positioning block (4), positioning pin (5) ) Are arranged on the base (1), the measuring pin (3) is arranged on the sliding block (2), the measuring pin (3) and the positioning pin (5) are respectively arranged on both sides of the positioning block (4), The axes are parallel or substantially coincident; the sliding block (2) can slide on the base (1) along the direction substantially parallel to the axis of the measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com