hsk tool system handle processing technology

A processing technology and tool shank technology, which is applied in the processing field of HSK tool system tool shank, can solve the problems such as the inability to achieve mass production and the incomplete grasp of the processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

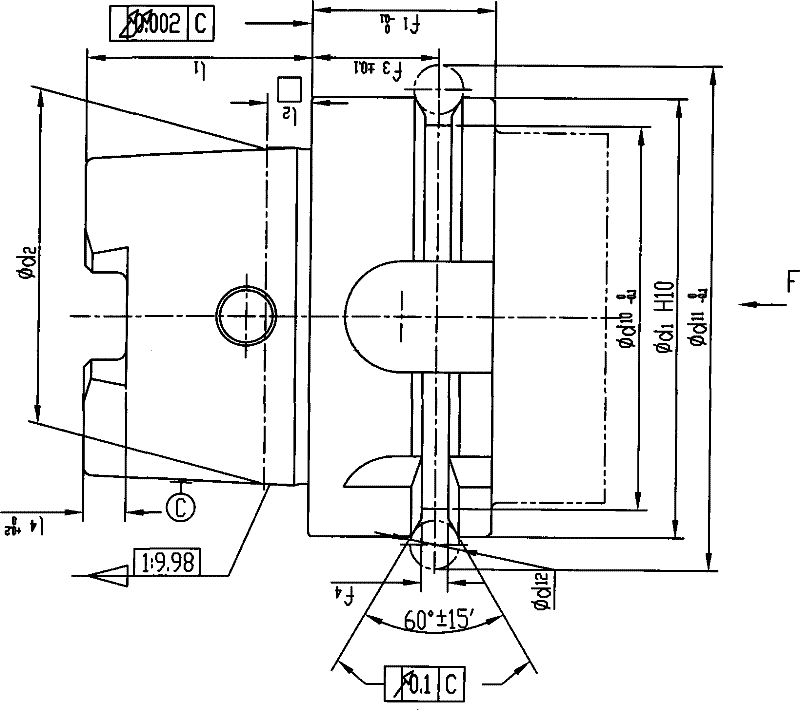

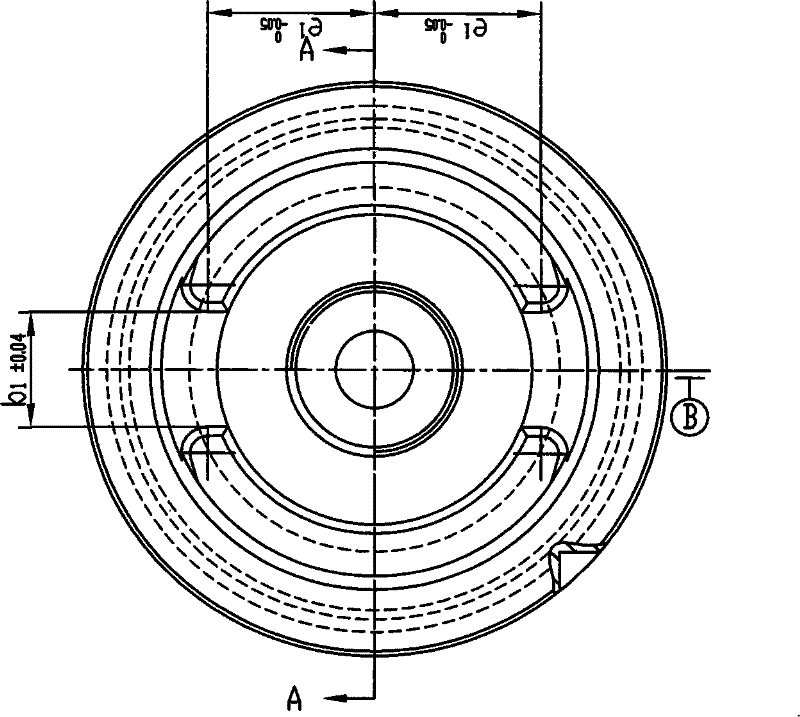

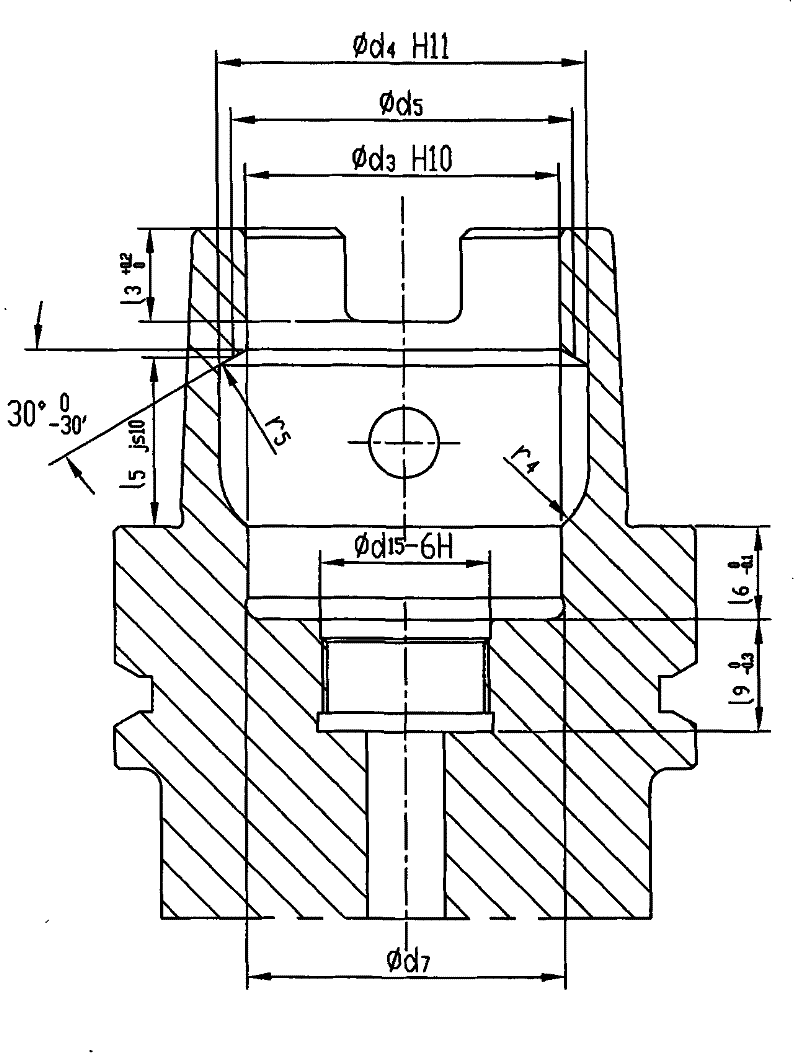

[0016] HSK tool system tool handle processing technology, its composition includes: take the tool handle blank, pretreat the said tool handle blank, then perform soft processing according to the determined soft processing process parameters, then perform heat treatment, and finally internally Bore and outer cone are finished.

[0017] In the HSK tool handle processing technology, the pretreatment is quenching and tempering the blank of the handle, and the heat treatment is firstly carburized and quenched, the quenching temperature is 800-950°C, and the time is 5-8 hours; Then oil quenching, the temperature is 800-900 ° C, and then vacuum tempered at 320 ° C, and finally blackened.

[0018] The products processed by the HSK tool system handle processing technology, the products processed by this method meet the requirements of the HSK handle for connecting handles stipulated in the ISO12164-1:2001 standard.

[0019] This product adopts HSK special inspection tooling to inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com