Method of forming isolation membrane in semiconductor device

A semiconductor and isolation film technology, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve the problems of rounded top corners of difficult trenches and lack of polymer carbon sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals designate like or like parts.

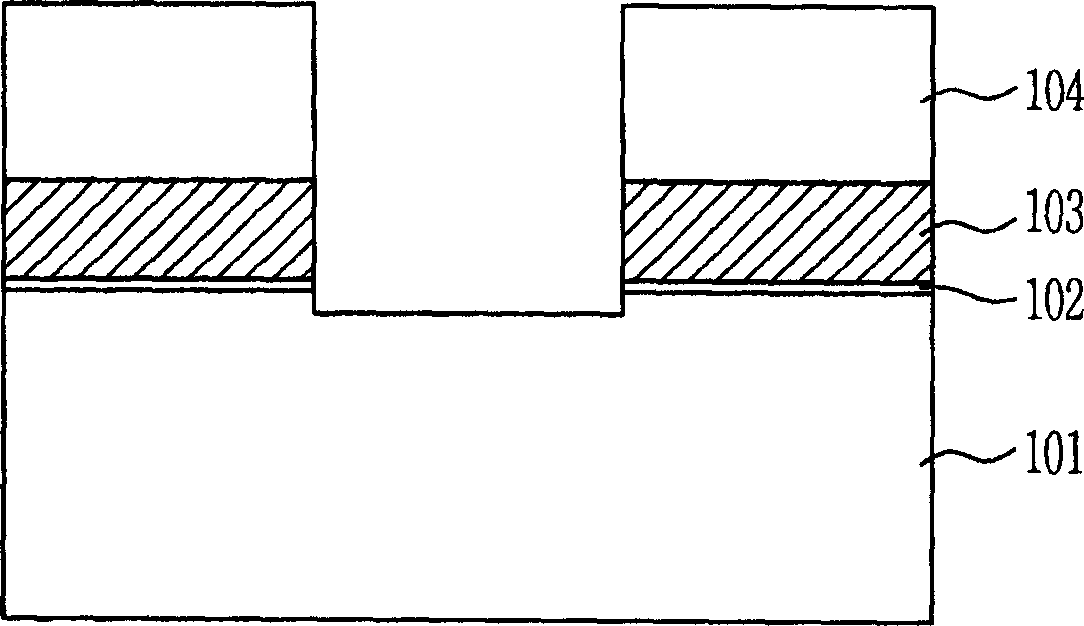

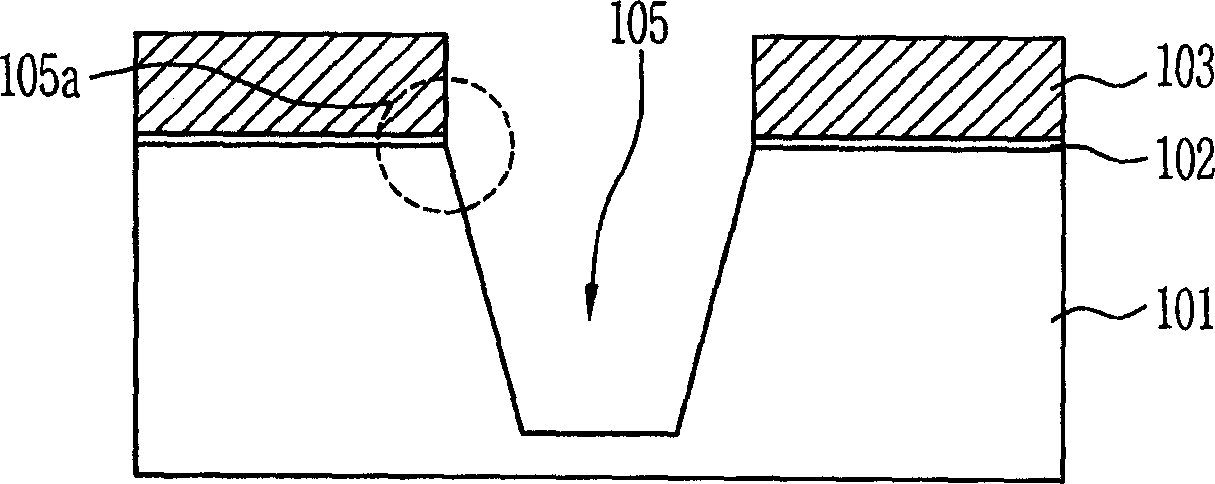

[0037] Figures 2A to 2E A cross-sectional view of a semiconductor device for explaining a method of forming an isolation film in a semiconductor device of a preferred embodiment of the present invention.

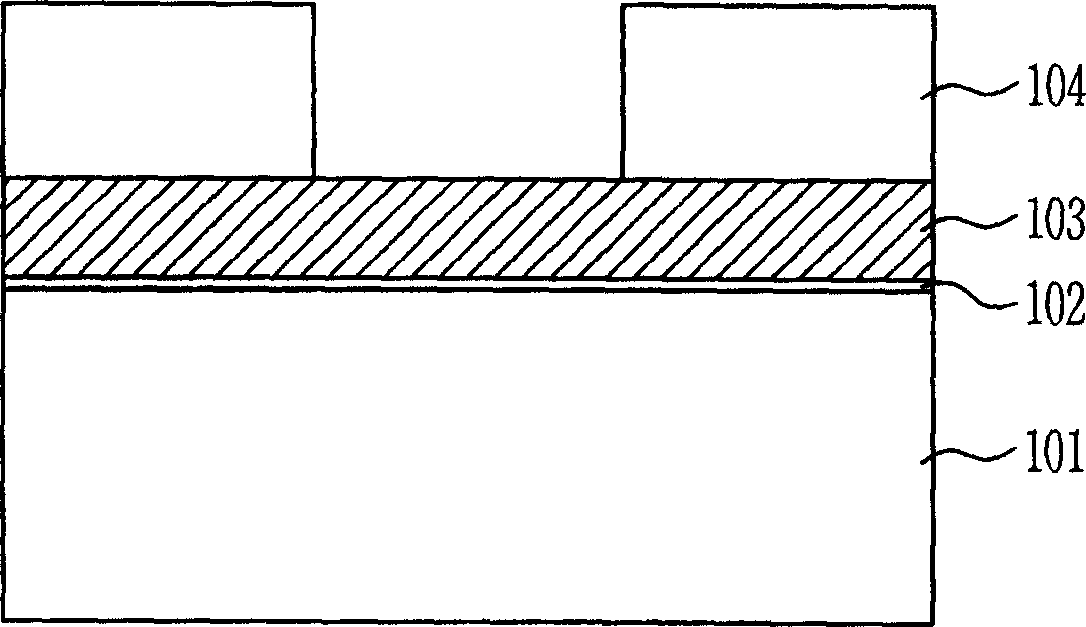

[0038] refer to Figure 2A A pad oxide film 202 and a pad nitride film 203 are sequentially formed on the semiconductor substrate 201 . Then photoresist covers the pad nitride film 203 . Next, exposure and development processes are performed to form a photoresist pattern 204, which defines an isolation region where an isolation film will be formed. Thereby, the pad nitride film 203 is exposed in the region where the isolation film is to be formed. At this time, the thickness of the pad nitride film 203 formed is preferably 1500 Å or less.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com