Gear transmission swinging pressing mechanism

A technology of gear transmission and compression mechanism, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of manual adjustment, unfavorable production efficiency, time-consuming and labor-intensive, etc., and achieve reliable compression, simple structure, and labor-saving hydraulic drive Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

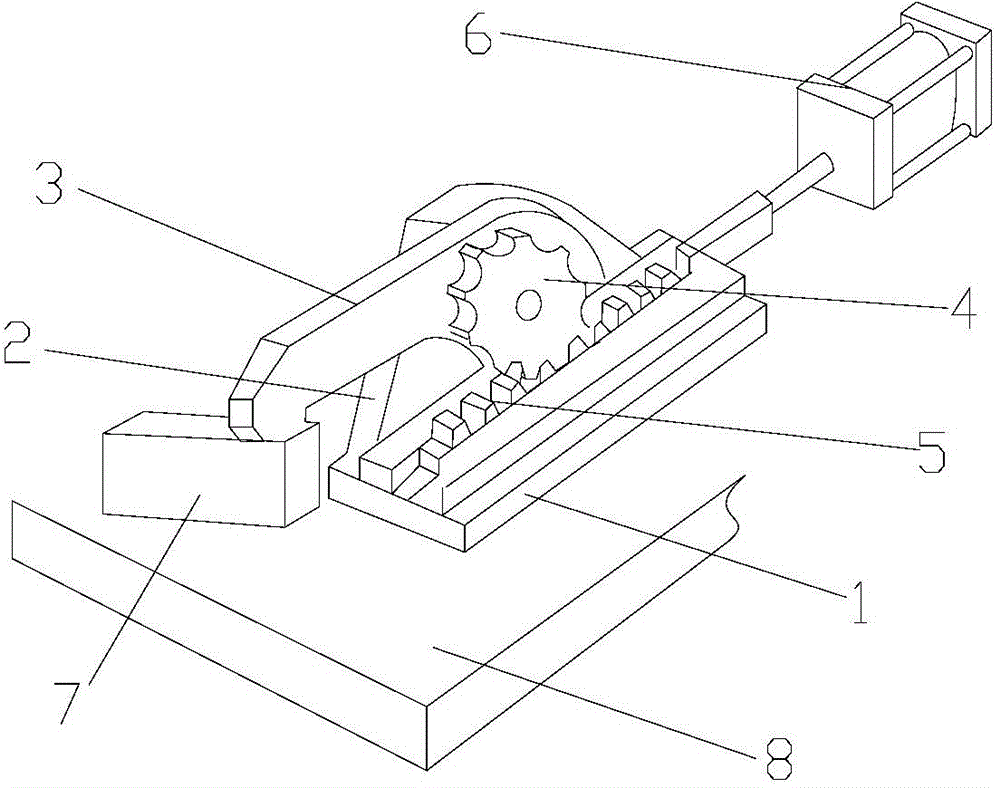

[0013] Such as figure 1 The gear-driven oscillating compression mechanism shown includes a fixed plate 1, a hydraulic cylinder 6, a pressure plate 3 and a gear 4. The fixed plate 1 is provided with a vertical vertical plate 2. The front end of the pressure plate 3 is straight and the rear end is bent downward. The front end of the pressing plate 3 is provided with a downward raised pressing block, and the surface of the raised pressing block is provided with anti-skid lines. The arc-shaped rear end of the pressing plate 3 is hinged with the vertical plate 2, and the gear 4 is fixed on the corresponding At the joint with the vertical plate 2, the axis of the gear 4 is in line with the axis of the joint. The gear 4 controls the pressure plate 3 to rotate synchronously. The fixed plate 1 corresponding to the bottom of the gear 4 is provided with a rack 5 meshing with the gear 4. Slidingly connected with the fixed plate 1, the hydraulic cylinder 6 is set on the rear side of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com