Rapidly-and-evenly-pressing pressing plate

A pressure plate, balanced technology, applied in the direction of clamping, support, positioning device, etc., can solve the problems of inconvenient operation, affecting processing accuracy, and poor balance of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

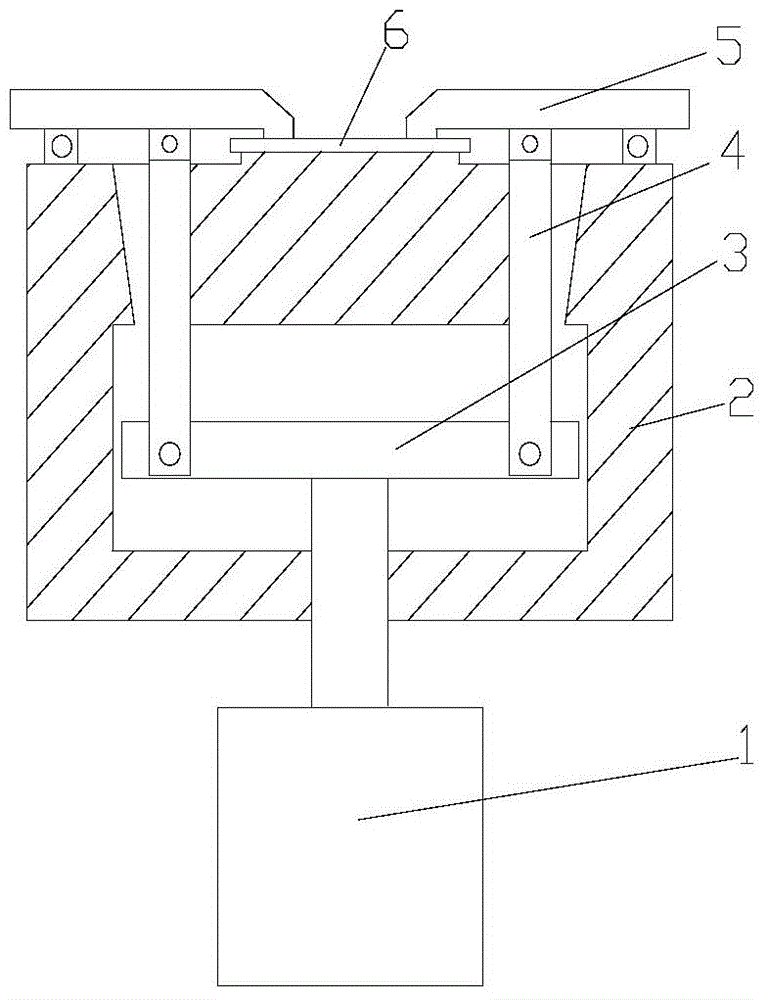

[0012] Such as figure 1 A pressure plate capable of fast and balanced compression, including a base body 2, a pressure plate 5, an equilibrating lever 3, and a hydraulic cylinder 1, the base body 2 is arranged on the upper end of the hydraulic cylinder 1, and the piston rod of the hydraulic cylinder 1 penetrates into the interior of the base body 2 , the piston rod is connected with the middle part of the equal arm lever 3, and the connecting rod 4 is symmetrically arranged in the seat body 2 corresponding to the two ends of the equal arm lever 3, and is in a vertical state when pressing, and the bottom end of the link rod 4 is connected to the equal arm lever 3 The end of the top is hinged, the top protrudes from the upper part of the seat body 2, and is hinged with the middle part of the pressure plate 5 arranged on the top of the seat body 2, the pressure plate 5 corresponds to the connecting rod 4, the rear end of the pressure plate 5 is hinged with the seat 2, and the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com