Double-layer sealing bypass valve with air-tight device

A double-layer sealing and bypass valve technology, which is used in the field of air pollutant treatment and environmental protection, can solve the problems of easy dust accumulation on the sealing surface, large space occupation, short service cycle, etc., and can increase the sealing contact area and the sealing contact area. The effect of increasing and improving the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

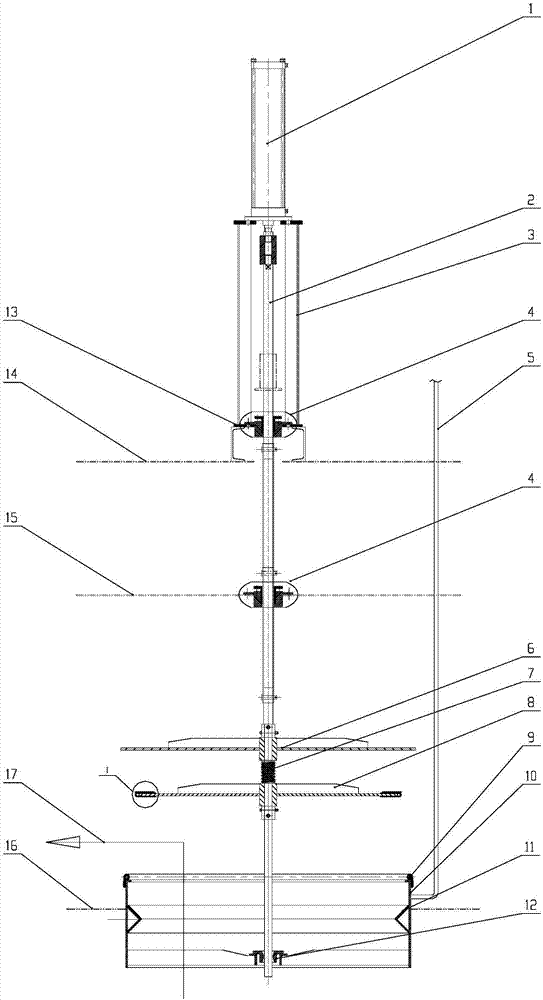

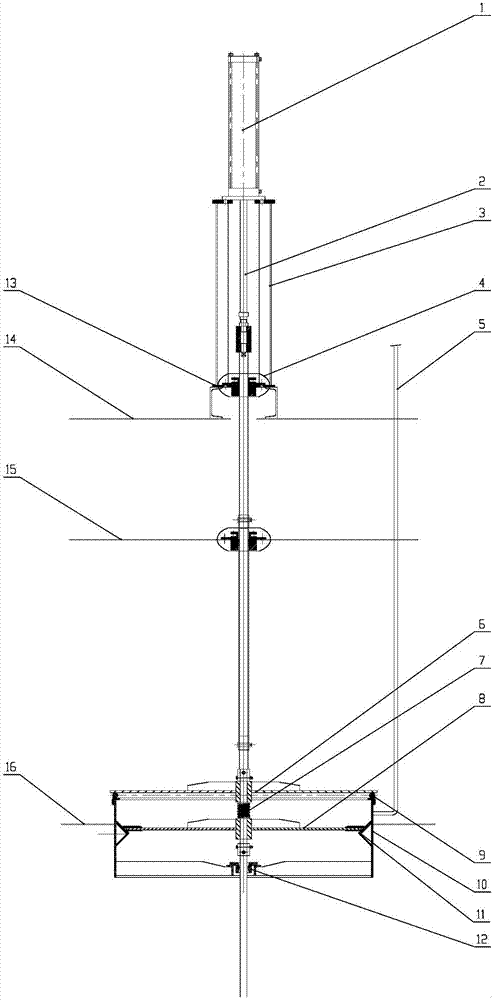

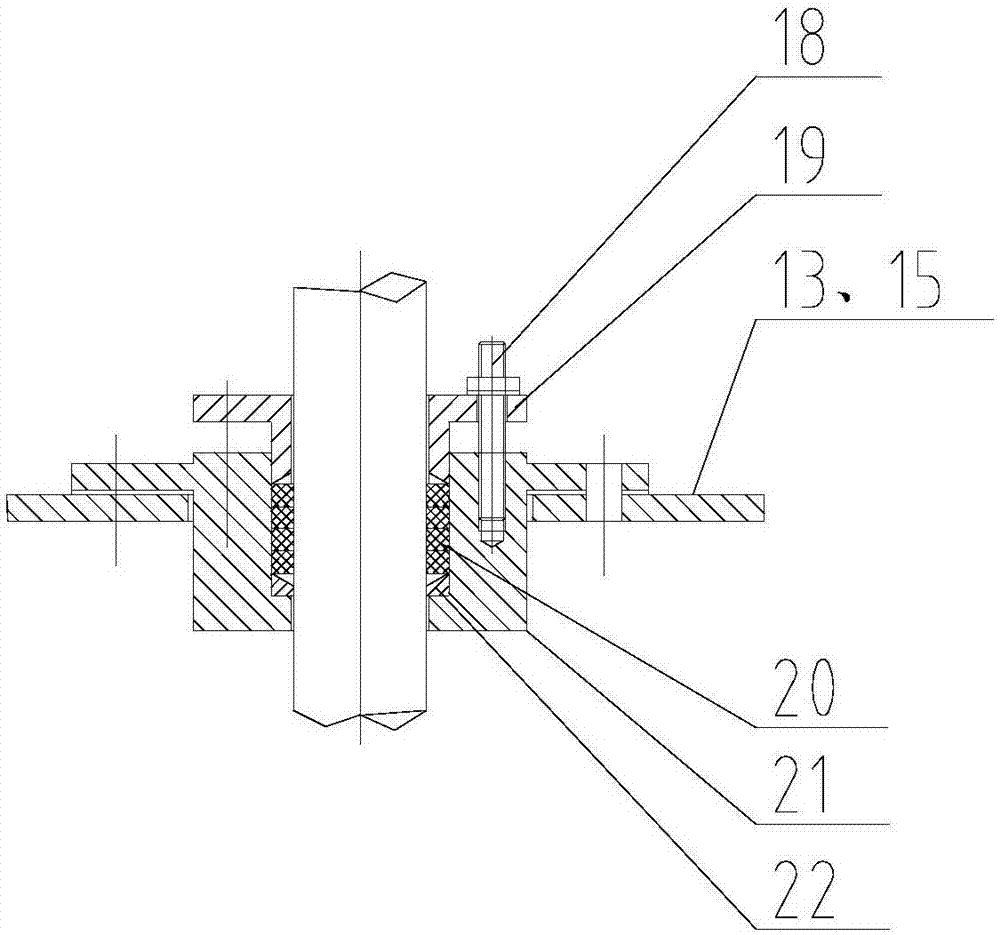

[0040] Such as Figure 1-4As shown, a double-layer sealed bypass valve with an airtight device includes a cylinder 1, a connecting rod 2, a valve body 3, an airtight pipeline 5, a valve plate 6, and a compression elastic element 7, preferably a compression spring , valve plate two 8, hollow sealing ring 9, air duct 10 and inclined plane sealing surface 11; wherein, valve body 3 is installed on the air duct top plate 14 through valve base 14, valve plate one 6, compression elastic element 7 and valve plate two 8 is installed on the connecting rod 2, the cylinder 1 is installed on the valve body 3, the connecting rod 2 is connected with the cylinder 1, and the connecting rod 2 drives the valve plate 1 6, the compression elastic element 7 and the valve plate 2 under the force of the cylinder 1 8 moves up and down, the hollow sealing ring 9 and the inclined sealing surface 11 are installed on the air duct 10, the valve plate 1 6 can cooperate with the hollow sealing ring 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com