Test device for working pressure inspection of thin hydraulic rubber capsule and test method thereof

A technology of working pressure and testing device, applied in the direction of using stable tension/pressure to test material strength, measuring device, using liquid/vacuum for liquid tightness measurement, etc. Sealing quality inspection and other issues, to achieve the effect of filling the gap in quality inspection technology, convenient fixing, and uniform pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

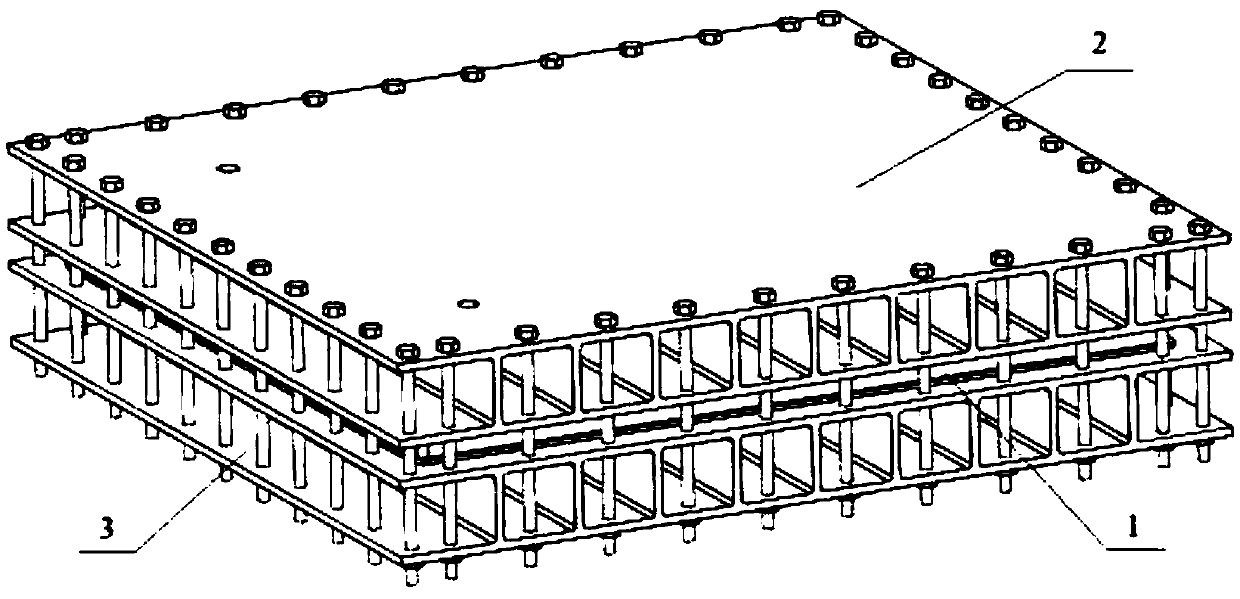

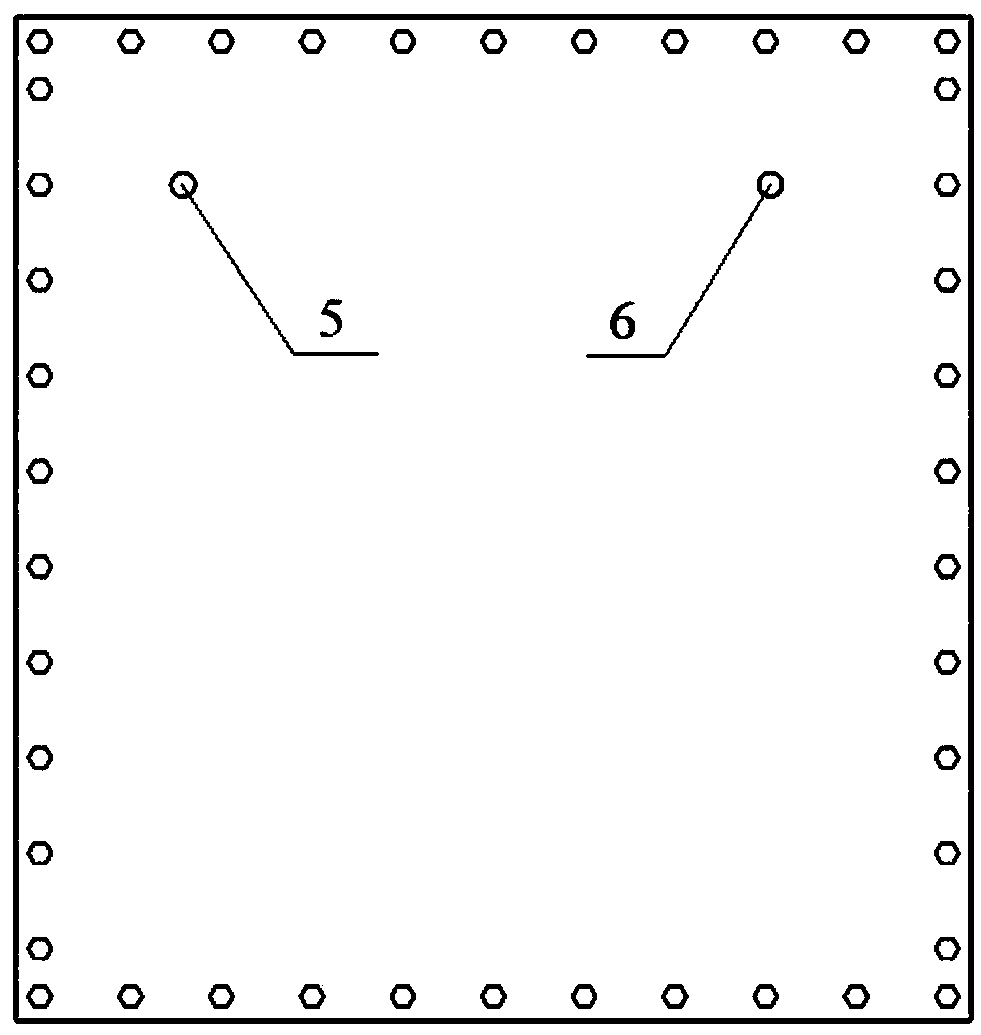

[0034] Embodiment 1: as figure 1 , 9 As shown, the test device for the working pressure test of the thin hydraulic rubber capsule includes a pressure box 1, a top cover splint 2, a base splint 3, an auxiliary device 8 and an automatic pressure calibration device;

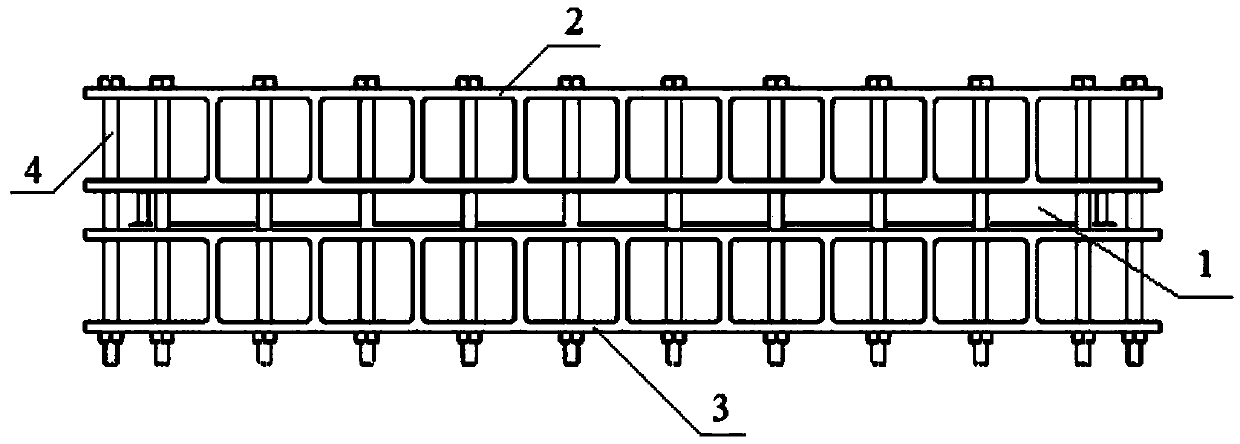

[0035] Such as figure 2 , 4 As shown, the pressure box 1 is placed between the base splint 3 and the top cover splint 2, and the bolt fastener 4 passes through the top cover splint 2 and passes through the bolt hole 7 corresponding to the base splint 3 to connect and lock the pressure box 1 ;

[0036] Such as Figure 6 , 7 As shown, the bottom center of the top cover splint 2 is provided with a limit boss 21, the outer diameter of the limit boss 21 is equal to the open inner diameter of the pressure box 1, and the top center of the base splint 3 is provided with a limit recess. groove 31, the inner diameter of the limiting groove 31 is equal to the outer diameter of the bottom of the pressure box 1;

[0037]...

Embodiment 2

[0048] Embodiment 2: The difference from Embodiment 1 is that Embodiment 2 also includes an automatic pressure calibration device, which is connected to a pressure gauge externally connected to the pressure test hole 5 . The automatic pressure calibration device is also connected with a pressure generator and a pressure transmitter. The pressure generator provides and outputs a predetermined pressure for parallel calibration pressure, and the automatic pressure calibration device outputs 22-25mA / 6- to the pressure transmitter. With a 10V drive signal, the pressure transmitter outputs the measured value of the predetermined pressure input from the pressure generator to the 22-25mA DC current superimposed on the current and return flow, and then sends it to the automatic pressure calibration device.

[0049] The method for testing the working pressure of a thin hydraulic rubber capsule by using the test device for testing the working pressure of the thin hydraulic rubber capsule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com