Precision matched bearing rapid adjustment device and usage method thereof

A technology of bearing and assembly, applied in the direction of measuring devices, adopting mechanical devices, mechanical measuring devices, etc., can solve the problems of affecting life, affecting accuracy, wasting time, etc., and achieves saving production costs, improving production efficiency, and simple device structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

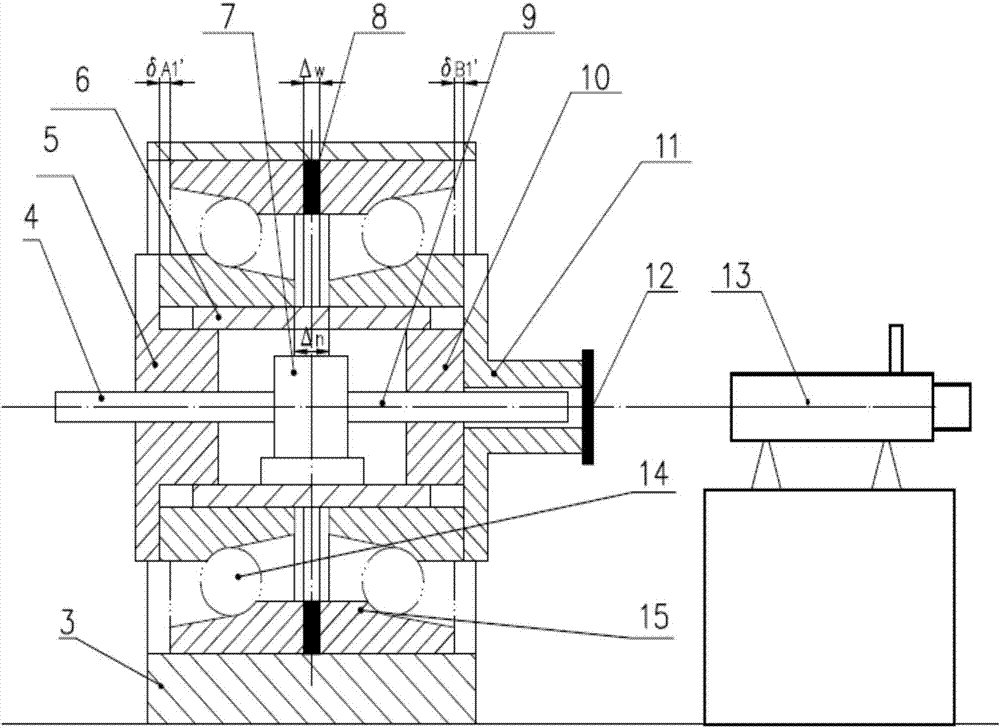

[0045] The present invention is described in detail below in conjunction with the embodiment that accompanying drawing provides:

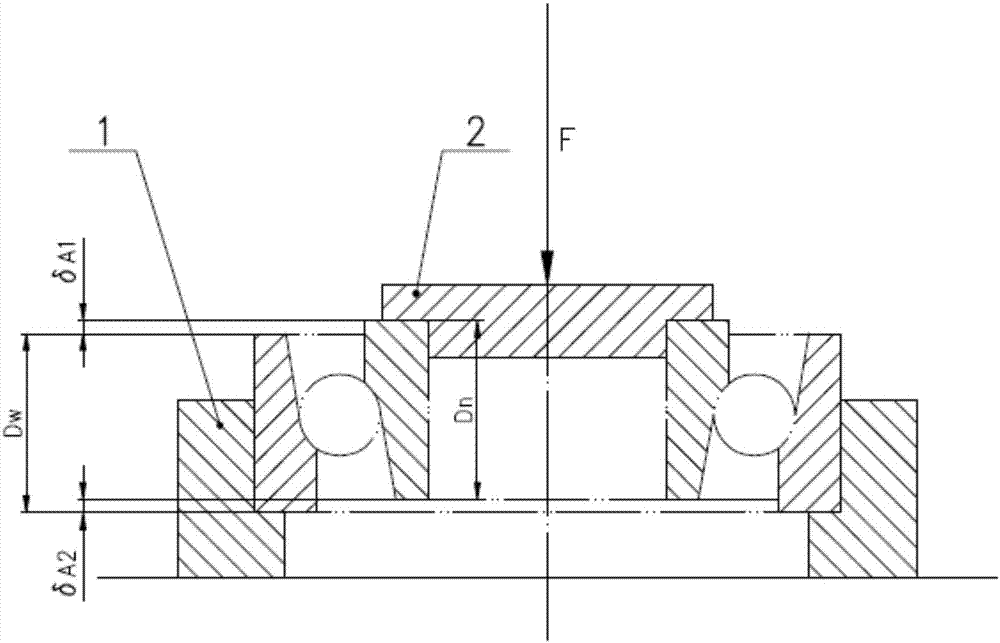

[0046] see figure 1, a single bearing clearance measuring device includes a bearing outer ring support seat 1 and a bearing inner ring pressure plate 2 . Bearing outer ring support seat 1 includes a cylindrical support seat body. One end of the support seat body is provided with a concave step. The bearing outer ring support seat 1 is processed into a concave step form. The concave step is used to support the bearing outer ring. The surface on the concave step parallel to the end surface of the bearing seat body is used for axially limiting the end surface of the bearing outer ring, and the surface perpendicular to the end surface of the supporting seat body on the concave step is used for radially limiting the bearing outer ring. The ring pressing plate 2 is formed by concentrically stacking two cylinders with different diameters, and the side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com