Pressure heavy load sensor of concrete filled steel tube

A technology of concrete filled steel tubes and sensors, which is applied in the field of heavy-load sensors, can solve the problems of inconvenient processing and manufacturing, increase the cost of the sensor, reduce the stiffness of the sensor, etc., and achieve the effects of simple and reasonable structure, reliable performance and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

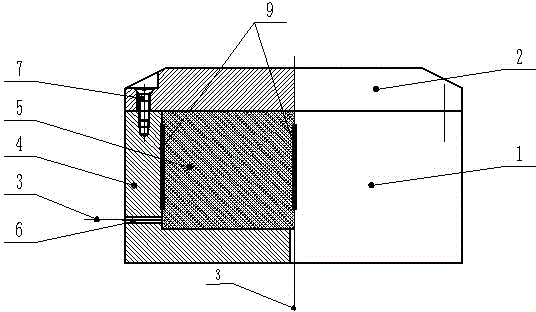

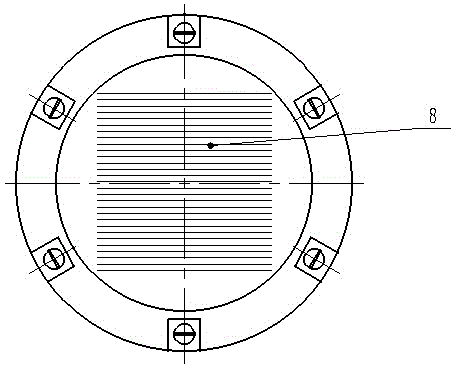

[0010] See attached figure 1 , figure 2 , the invention provides a weighing and pressure sensor with high rigidity and large bearing capacity. It is composed of 2 end caps, 3 wires, 4 steel pipes, 5 concrete, 6 through holes, 7 fastening screws, 8 non-slip threads, and 9 resistance strain gauges.

[0011] See attached figure 1 , figure 2 , the sensor is in the shape of a short cylinder. After the end cover 2 is coated with sealant, it is fixed on the sensor carrier by six fastening screws 7. The six fastening screws are evenly distributed on the end cover. There is a boss on the end cover. With anti-skid pattern 8

[0012] See attached figure 1 , the carrier of the sensor is composed of steel pipe 4 and concrete 5 . Two groups of strain gauges 9 are evenly arranged in the steel tube concrete, the first group includes four strain gauges, which are evenly distributed on the contact surface between the concrete and the steel pipe, and the direction is vertical, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com