Space flexible arm tail end tool box pressing and anti-radiation protection mechanism

A technology of end tool and protection mechanism, which is applied in the field of space flexible arm end tool box compression and anti-radiation protection mechanism, which can solve the problems of satellites not entering orbit correctly, satellites not working normally, economic losses, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

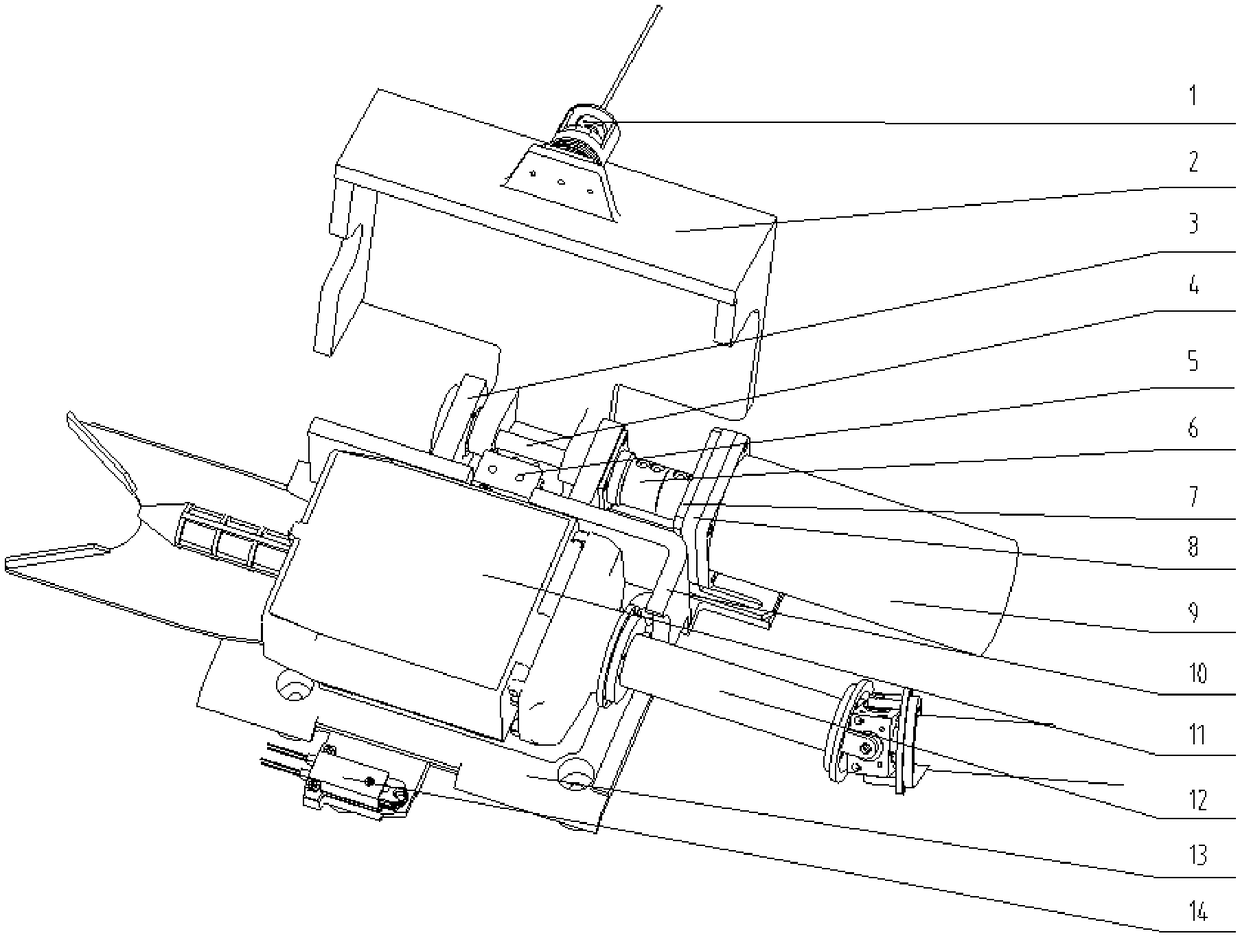

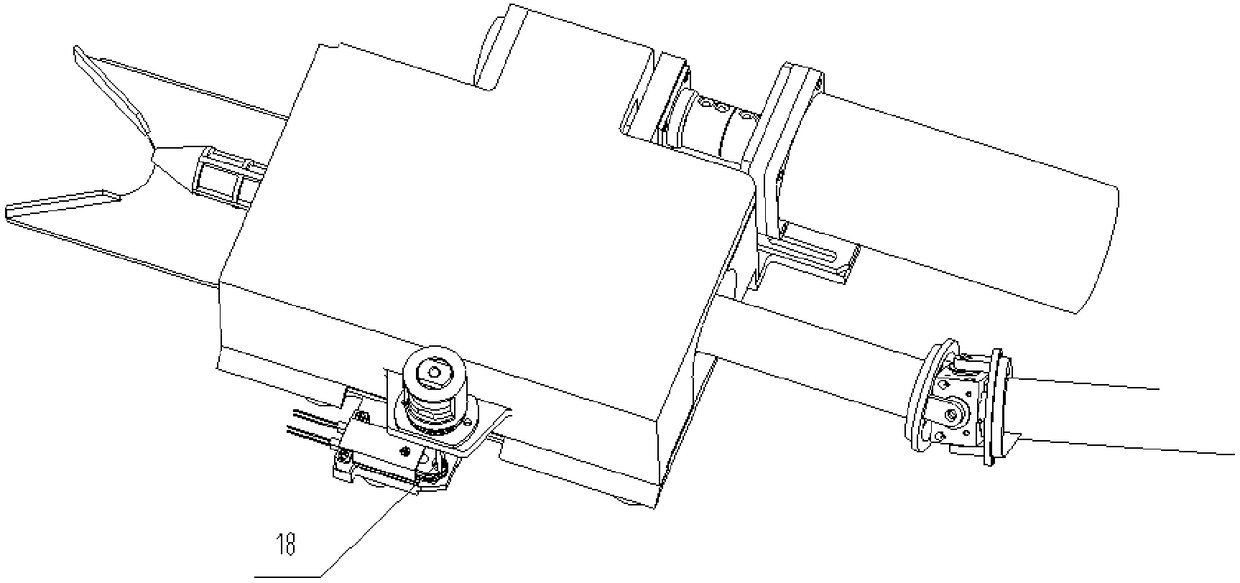

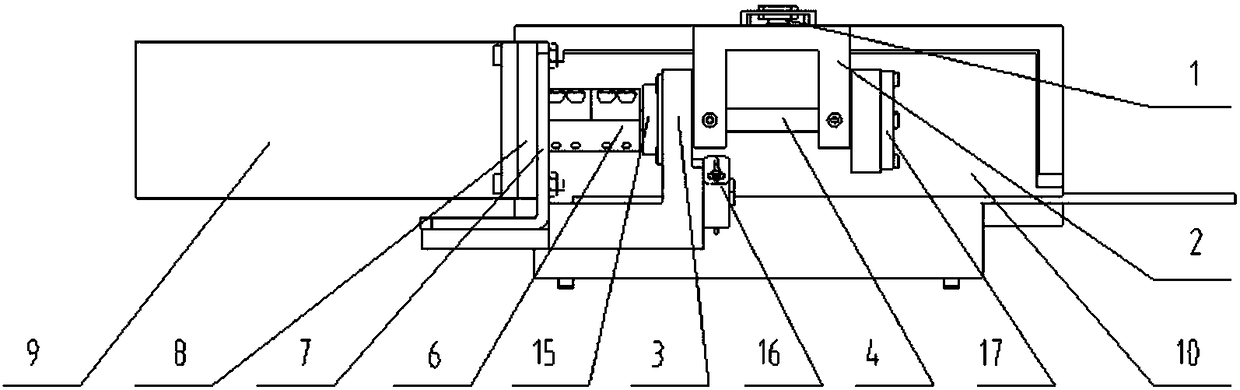

[0030] Such as figure 1 , figure 2 and image 3 As shown, the fixed base 10 is connected to the satellite cabin board by screws, the cutter 14, the position detection microswitch 5 and the bearing seat 3 are connected to the fixed base 10 by screws, and the limit microswitch 16 is connected to the satellite cabin by screws. On the bearing block 3, deep groove ball bearings are installed above the bearing block 3, and the power transmission shaft 4 is installed on the bearing by positioning parts such as the left bearing end cover 15, the right bearing end cover 17 and the axle sleeve. The part of the transmission shaft 4 between the two bearing seats is connected with the radiation shielding cover 2 through screws, and the left end of the transmission shaft 4 is connected with the driving motor and the reducer assembly 9 through a coupling 6 . The drive motor and reducer assembly 9 is connected with the L-shaped motor base 7 by bolts through the heat insulating pad 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com