Super magnetostrictive actuator driving single-stage direct-acting jet pipe servo valve

A giant magnetostrictive and actuator technology, applied in the direction of servo motor components, fluid pressure actuators, mechanical equipment, etc., can solve the problems of low natural frequency of torque motors, limited response speed capability, large inertia of jet tubes, etc., to achieve The effect of strong driving ability, large output force and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

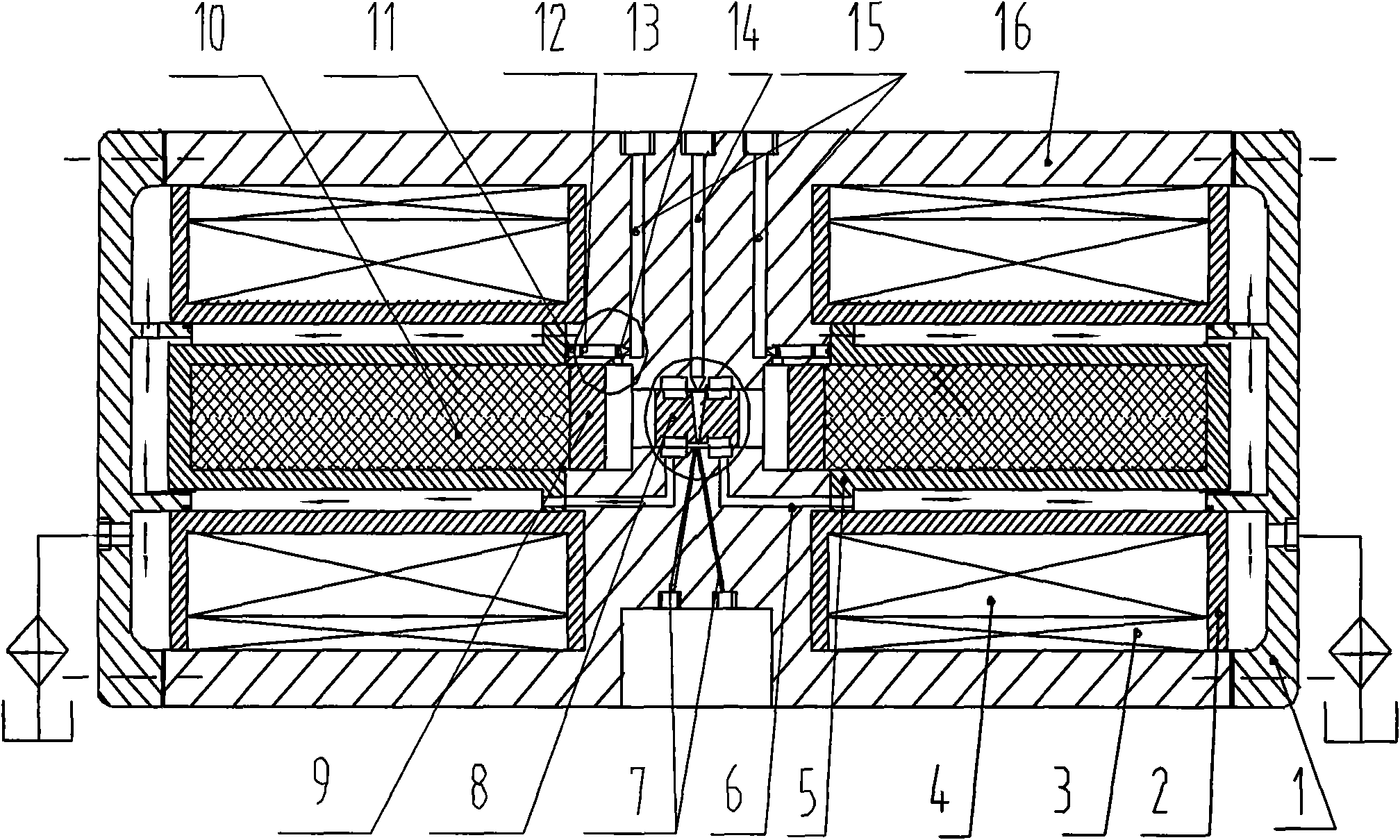

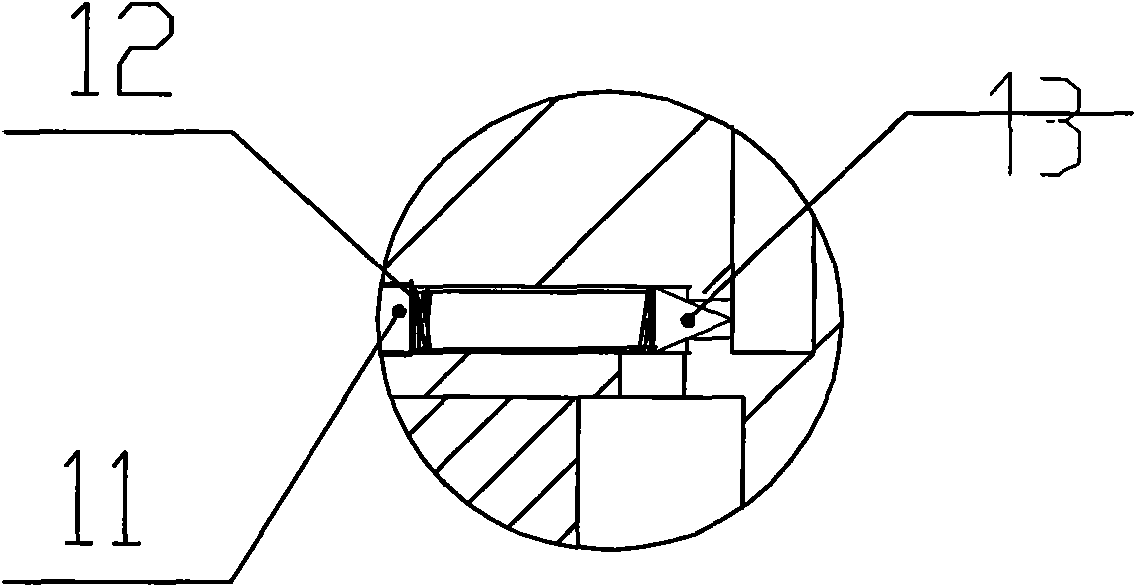

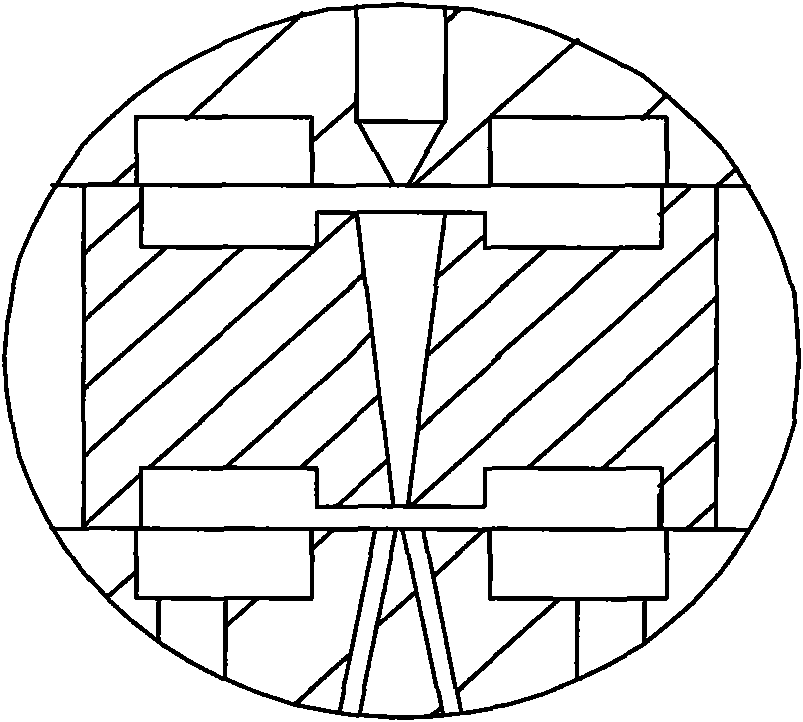

[0025] Such as figure 1 , 2, 3, the new jet tube servo valve is designed to design a new type of giant magnetostrictive actuator between the nozzle and the receiver of the traditional deflector type jet tube servo valve, and the actuator drives the distributor to replace the original deflected jet The torque motor of the tube servo valve and the flow deflector driven by it, the new flow distributor is directly driven by the giant magnetostrictive actuator and designed as an integral structure with it, and the jet nozzle and the jet receiver are fixed at the same time, so the dynamic response of the jet hydraulic amplifier is completely determined by the The giant magnetostrictive actuator is determined to avoid the restriction of the dynamic response of the system by directly driving the jet tube with large inertia. At the same time, because the giant magnetostrictive actuator has the advantages of faster response speed and stronger load capacity than the torque motor, so Whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com