Sintered finished ore unloading system and brake

A technology for finished mines and brakes, which is applied to brakes where braking elements interact with tracks, railway braking systems, loading/unloading, etc. It can solve problems such as the inability of mobile unloading trucks to stop effectively, and avoid inaccurate parking. The effect of accurate parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] An embodiment of the present invention provides a sintered finished ore unloading system and a brake, so as to implement effective braking on a mobile unloading vehicle of the sintered finished ore unloading system.

[0042] In order to enable those skilled in the art to better understand the technical solutions in the embodiments of the present invention, and to make the above-mentioned purposes, features and advantages of the embodiments of the present invention more obvious and understandable, the technical solutions in the embodiments of the present invention are described below in conjunction with the accompanying drawings The program is described in further detail.

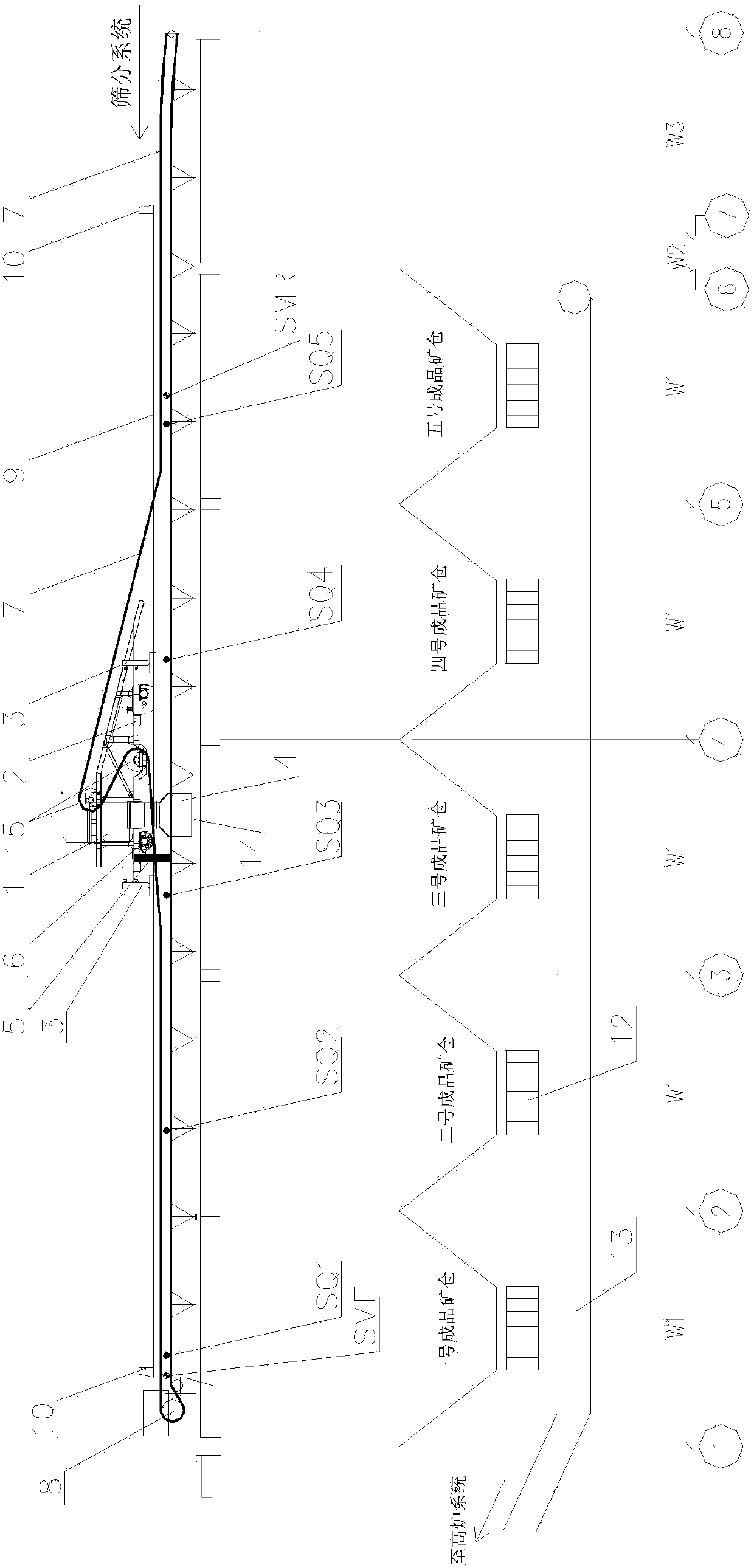

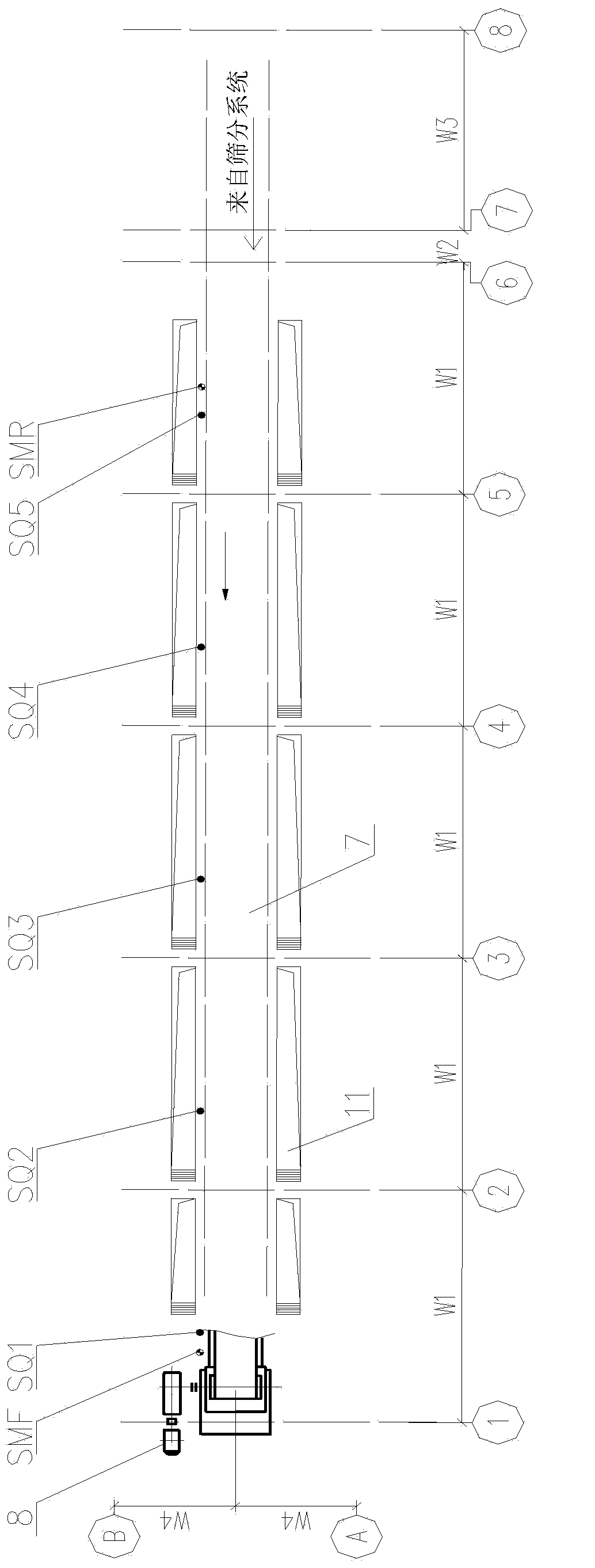

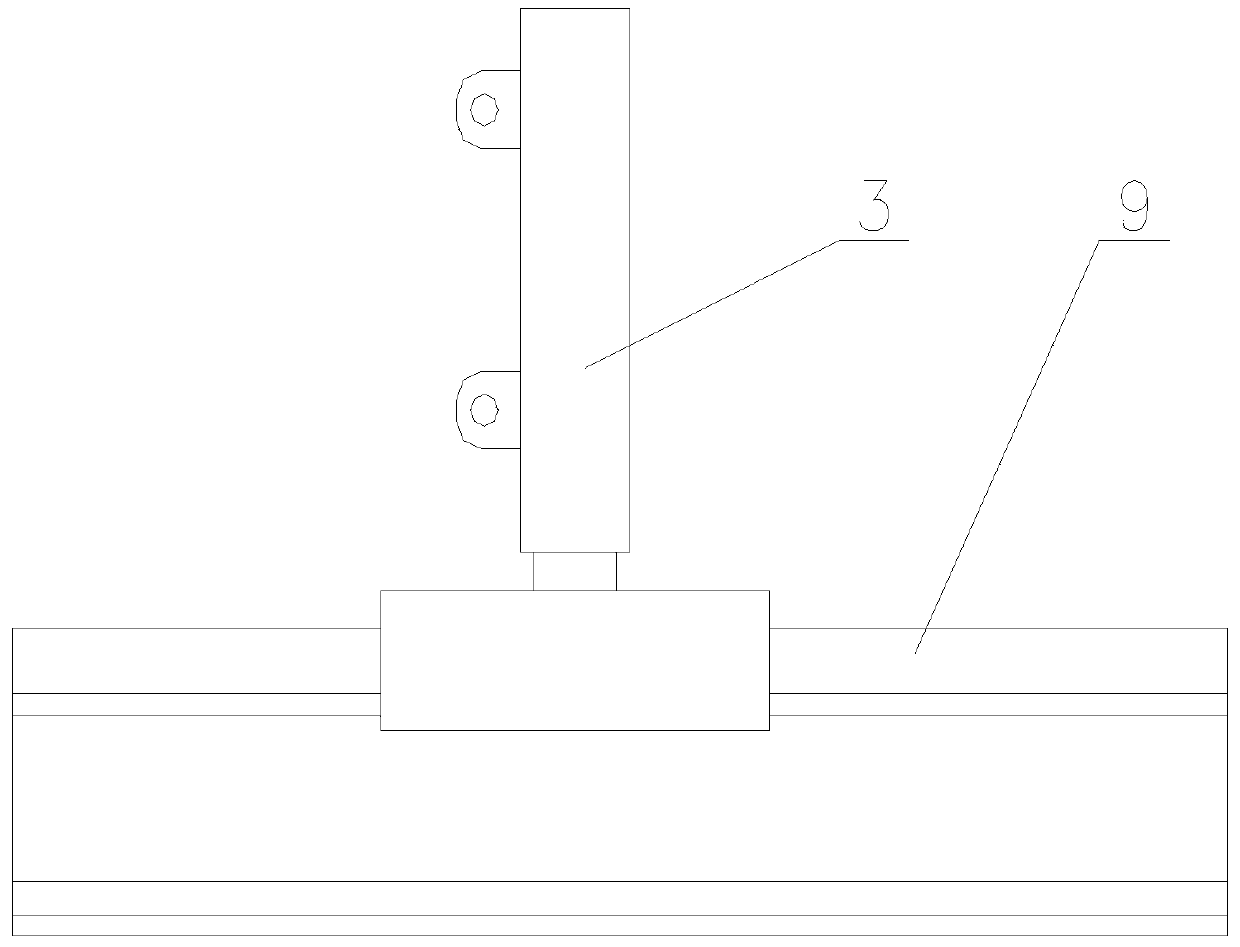

[0043] Please refer to the attached Figure 1-2 , figure 1 and figure 2The structure of the sintered product unloading system provided by the embodiment of the present invention is shown. The sintered product unloading system provided by the embodiment of the present invention includes a horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com