A control system for preventing malfunction of emergency stop device

A control system and misoperation technology, applied in the direction of control/regulation system, device for preventing/limiting/recovering the movement of parts of the control mechanism, mechanical control device, etc., can solve problems affecting the production safety performance of enterprises, and avoid downtime , Accurate tight stop, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

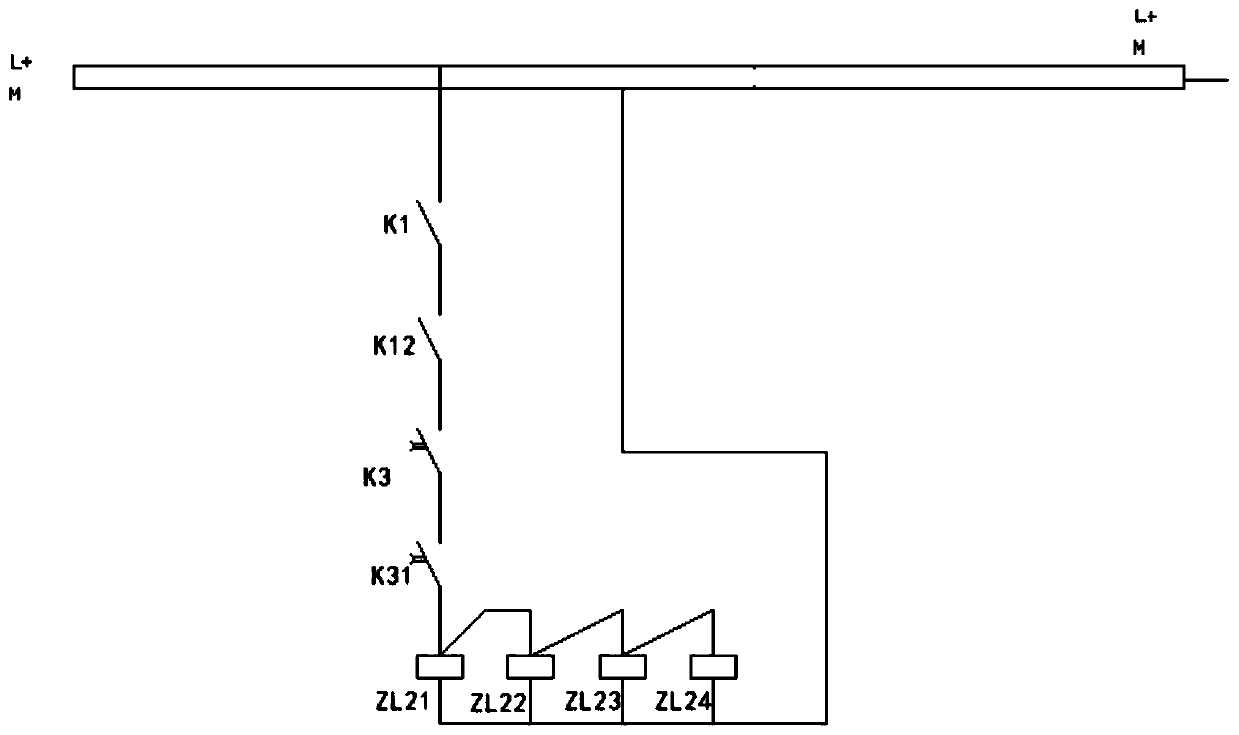

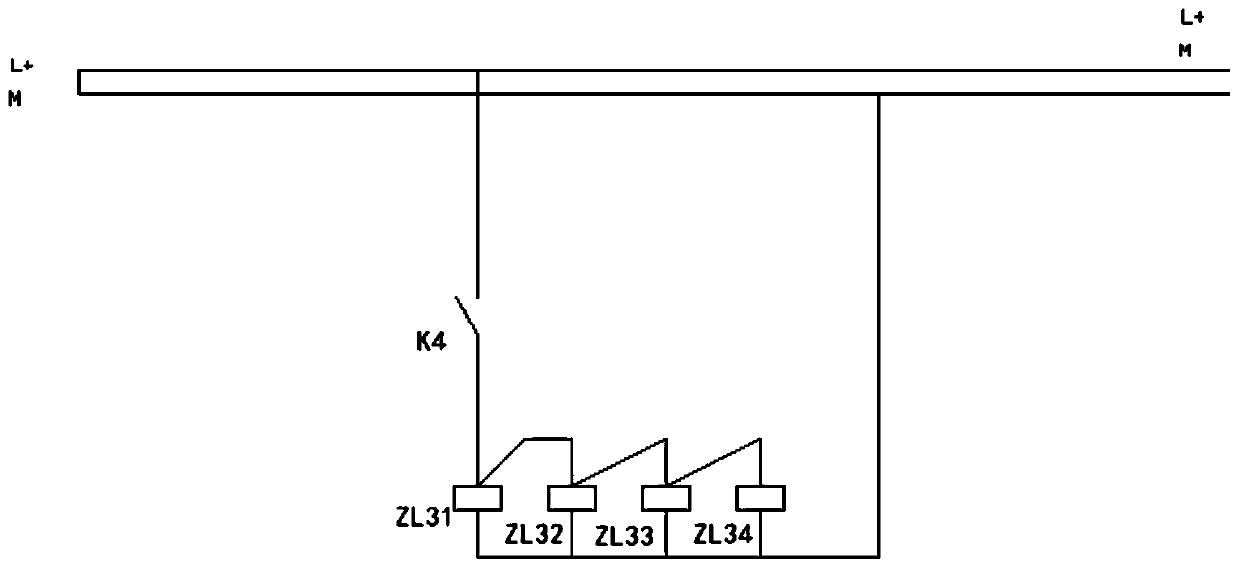

[0016] Under the premise of ensuring the normal use of the existing emergency stop function, the identification of malfunction signals is realized, and the judgment cut or delay filter is performed in both software and hardware to avoid production accidents.

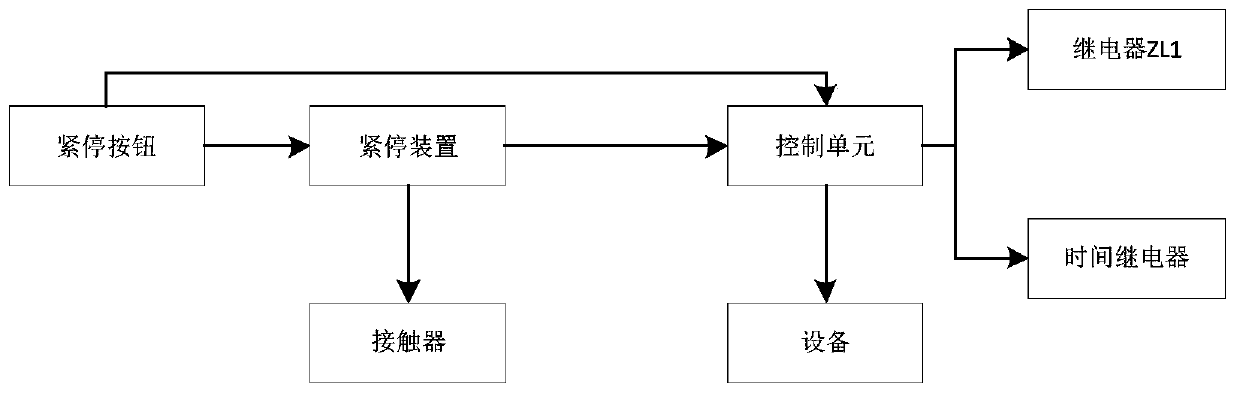

[0017] The emergency stop principle includes that the emergency stop device sends a control signal to the control unit, and the control unit sends a control signal to the controller of the equipment, and the controller software shuts down and emergency stops; the output of the emergency stop device simultaneously disconnects the power supply of the device through the power-off drive module to achieve The purpose of simultaneous tight stop of software and hardware.

[0018] The present invention makes improvements on this basis to avoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com