Focusing and levelling device with expandable measuring range and focusing and levelling method

A technology of focusing and leveling device and measuring range, which is applied to the exposure device of photo-engraving process, photo-engraving process of pattern surface, optics, etc. The effect of measuring intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

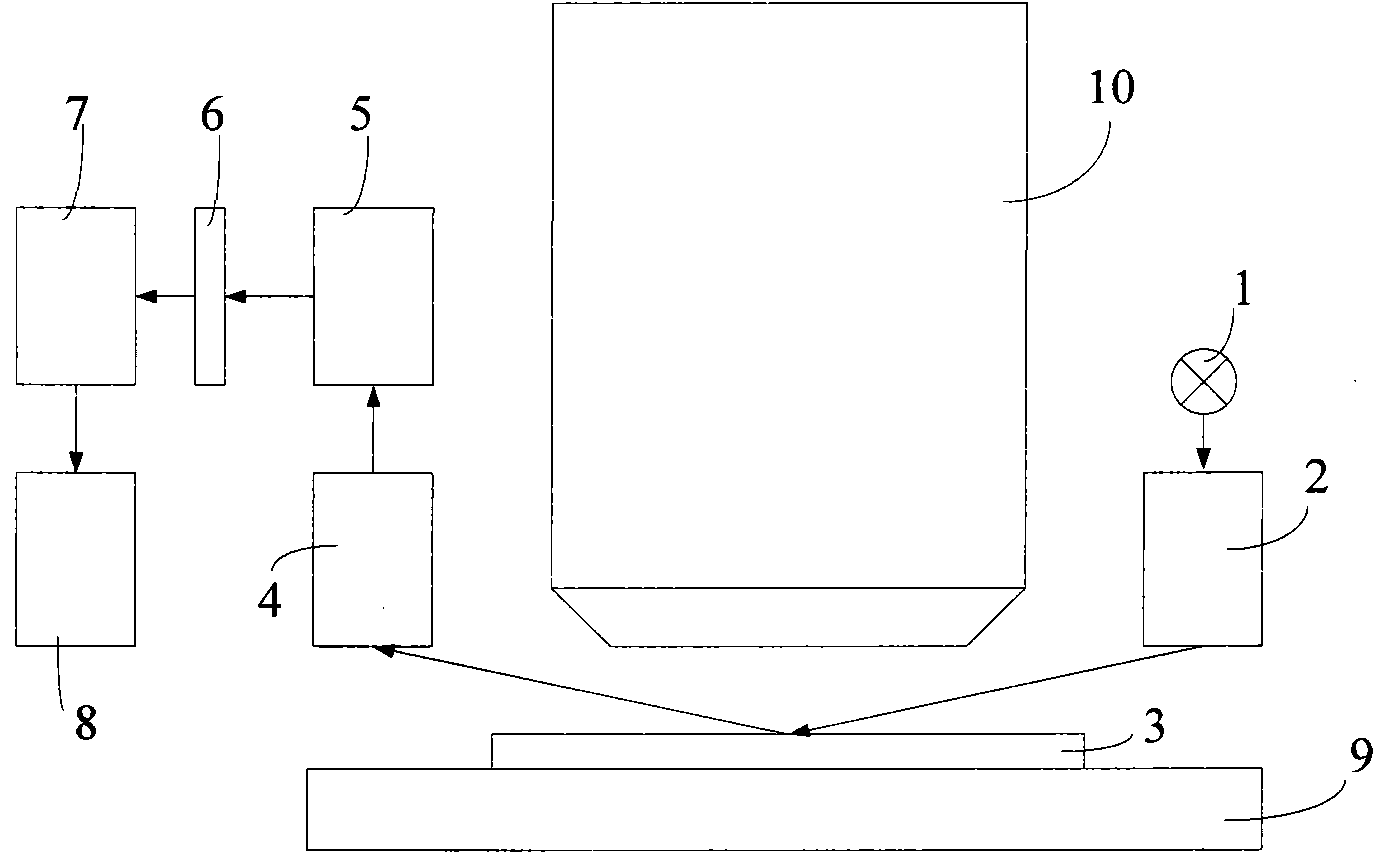

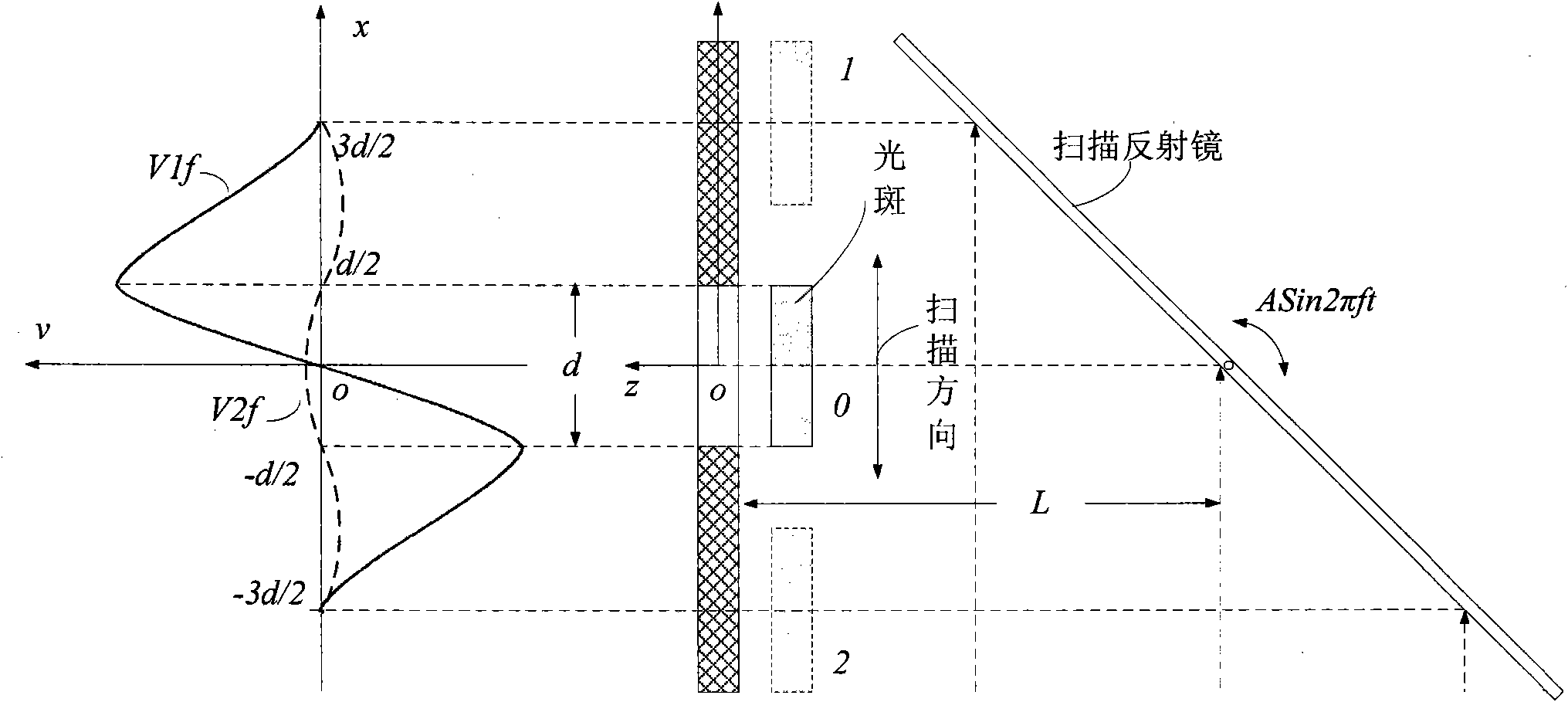

[0054] figure 1Shown is a structural diagram of a focusing and leveling measurement device used in projection lithography equipment according to the present invention. Wherein the measured silicon wafer 3 is located directly below the projection objective lens 10 and is supported by the workpiece table 9 . The light source 1, the optical projection unit 2, the tested silicon wafer 3, the optical receiving unit 4, the optical modulation unit 5, the receiving slit surface 6, the photodetector 7 and the control unit 8 constitute a focusing and leveling device. The device is used to realize the measurement of the surface height and inclination information of the silicon wafer 3 . The probe light emitted by the light source 1 irradiates the surface of the silicon wafer 3 through the optical projection unit 2 to form a measurement spot, and is reflected from the surface of the silicon wafer 3, passes through the optical receiving unit 4 and the optical modulation unit 5, and is fin...

no. 2 example

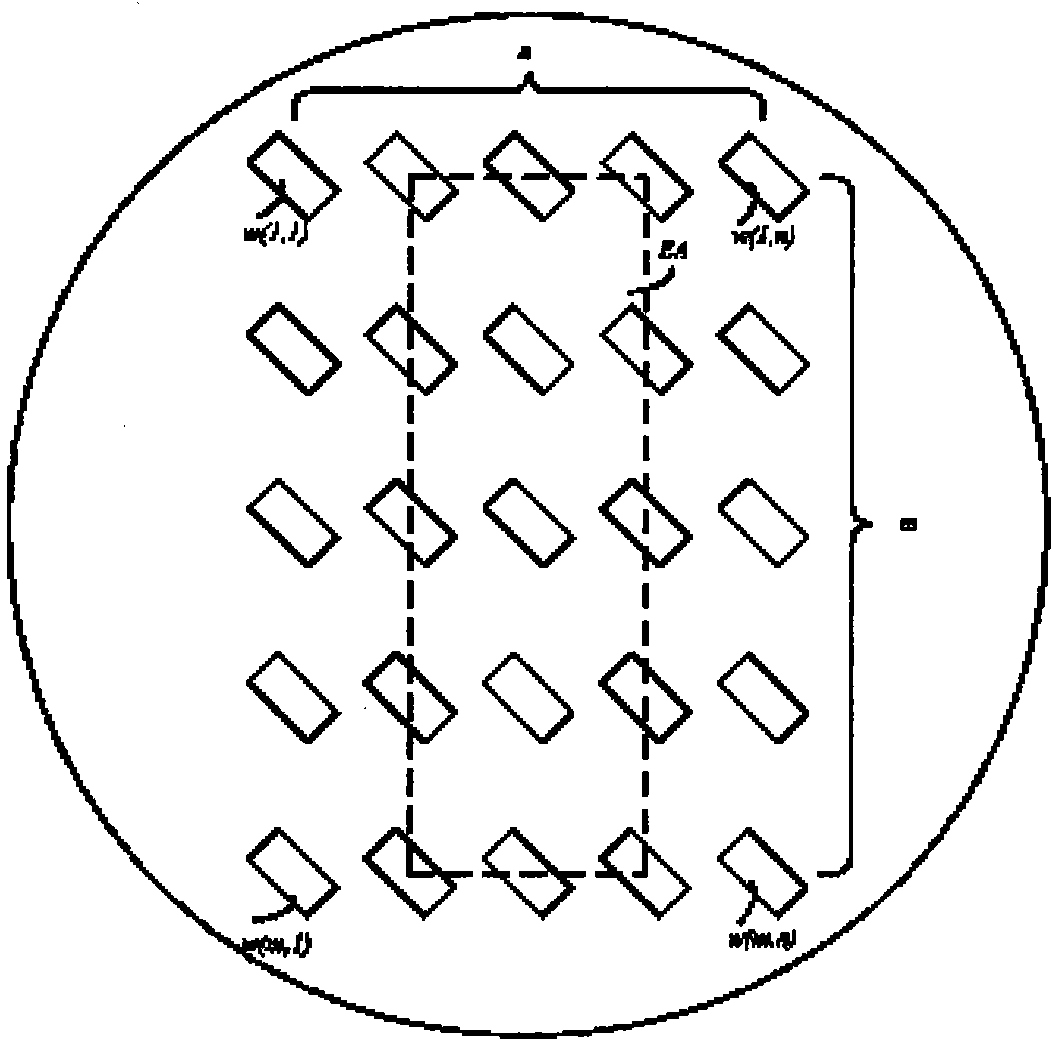

[0060] In the first embodiment, only the measurement range of two points (s(m, 1) and s(1, n)) is extended, and only the height value of the measured surface can be given within the extended range, and the inclination cannot be adjusted , so there are certain requirements for the inclination range of the silicon wafer. If the inclination of the silicon wafer is relatively large, it is difficult to level the silicon wafer using the process of Embodiment 1, and a pre-step is required to level the silicon wafer to a certain extent. In order to obtain inclination information within the extended measurement range, a group of extended slits can be added on the receiving slit plane. Figure 8 Shown is a distribution diagram of the slit matrix on the receiving slit plane in the focusing and leveling device according to the second embodiment of the present invention. By adding slits sx5 and slits sx6 on both sides of the slit s(m, 3) in the area C, the height values of three points c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com