A method of manufacturing elastic fabric for low-relaxation and low-hysteresis sensors

A technology of elastic fabric and manufacturing method, which is applied in the combined field of textile and smart wear, can solve the problems of lack of wearability, limited use performance and application range of flexible fabric sensors, and lack of wearable mechanical properties, etc. The effect of measuring range and reducing test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

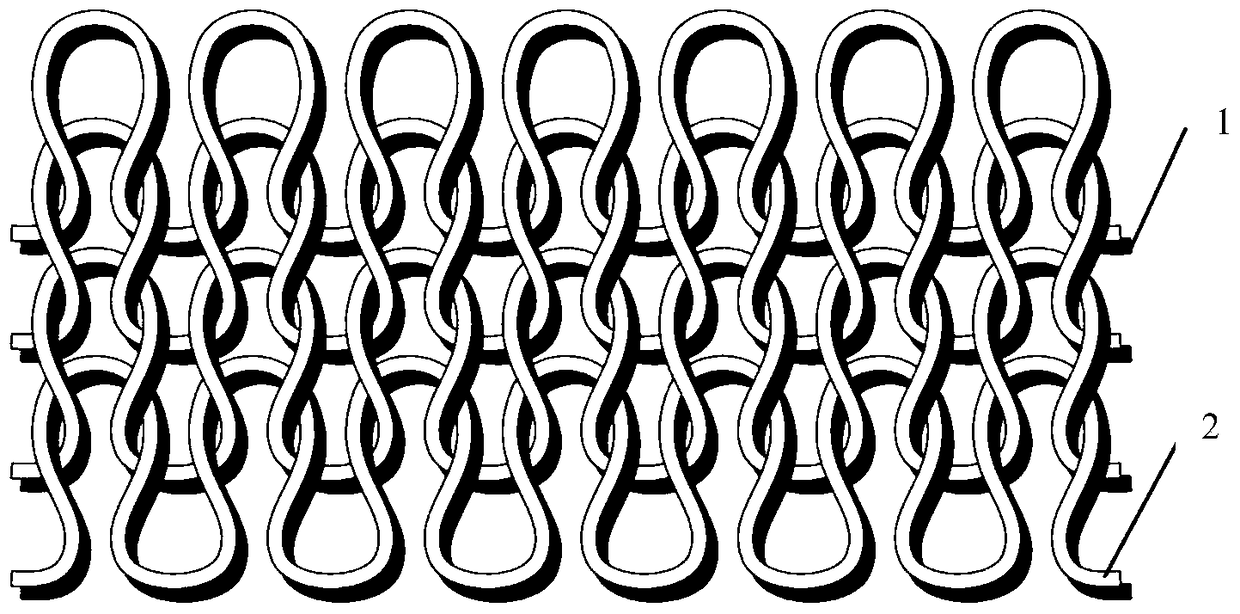

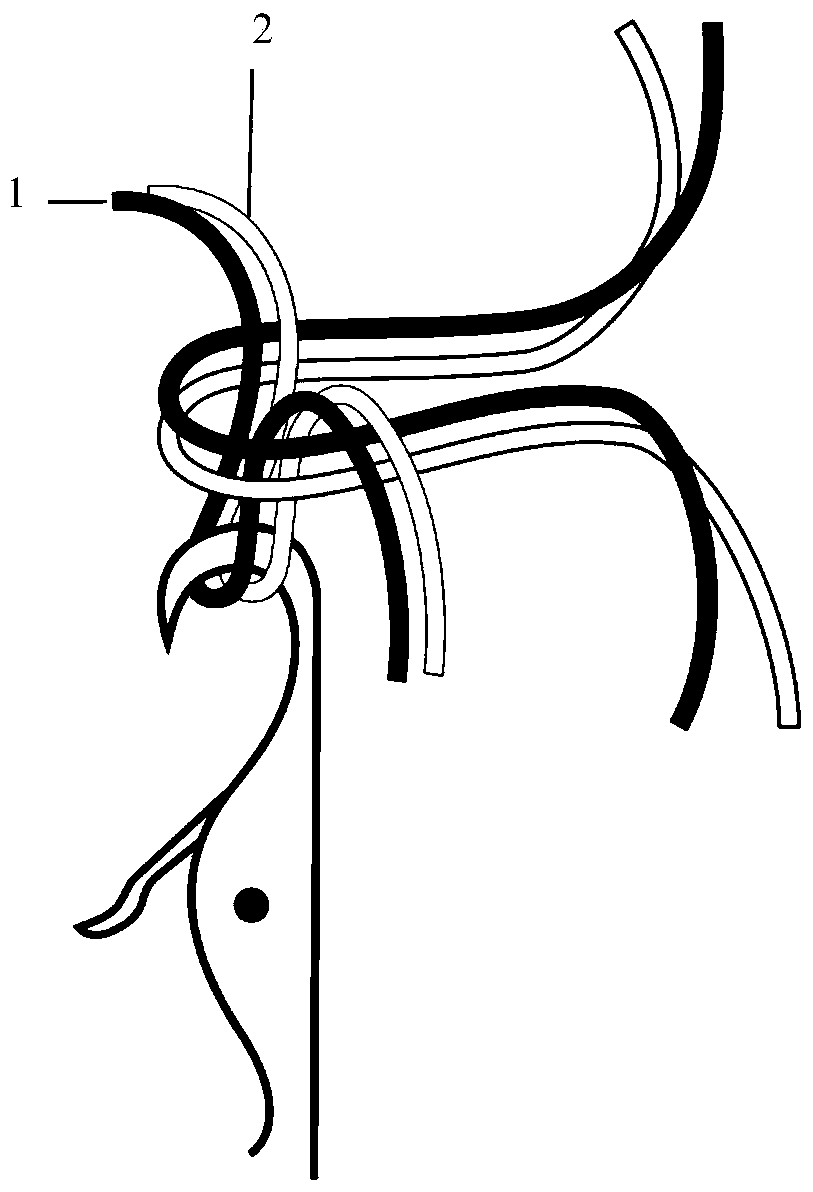

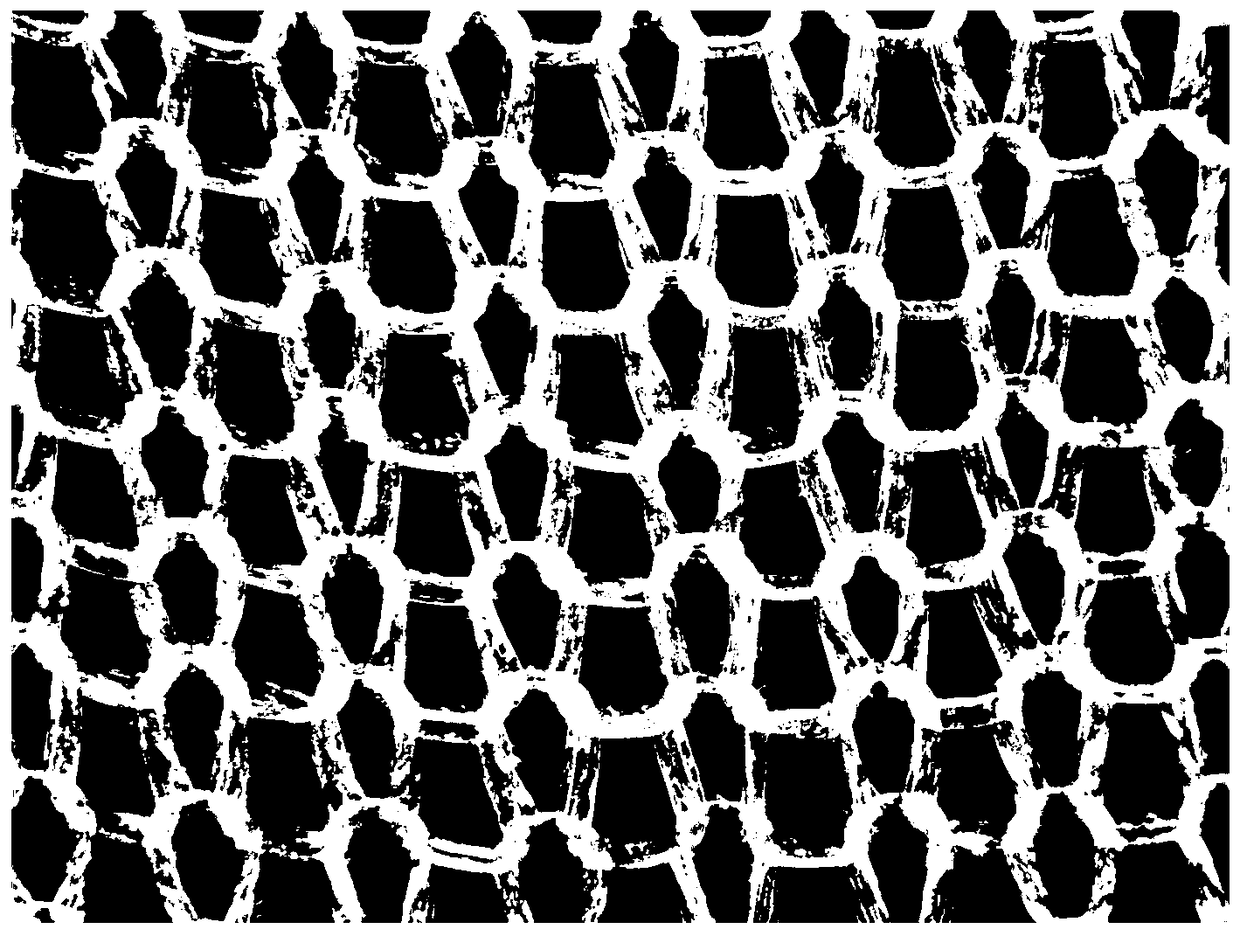

[0032] see Figure 1 to Figure 5 , This embodiment provides a low-relaxation and low-hysteresis elastic knitted fabric for sensors, which is processed by a circular weft knitting machine, and the fabric structure is plain weave with spandex plating. Spandex as ground yarn, namely figure 1 Among them, the black line 1 is spandex filament as elastic yarn; nylon filament is plating yarn, that is figure 1 Among them, the white thread 2 is a nylon filament as a non-elastic yarn; the nylon filament 2 is located on the surface of the fabric, and the spandex filament 1 is located inside the fabric. Among them, nylon filament 2 has a linear density of 70D, and spandex filament 1 has a linear density of 40D (Nylon filament 2 uses Tactel nylon filament, and spandex filament 1 uses Lycra spandex filament); the fiber composition is 83% by weight of nylon, and the weight of spandex is 83%. Percentage 17%; the square meter weight of the fabric is 200g / m 2 , fabric width 135cm, thickness 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com