High-pressure conveyed continuous powder body quantitative feeding device

A technology of quantitative supply and supply device, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of air leakage, the reduction of the air locking capacity of the screw pump, and the failure of the powder quantitative supply machine to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

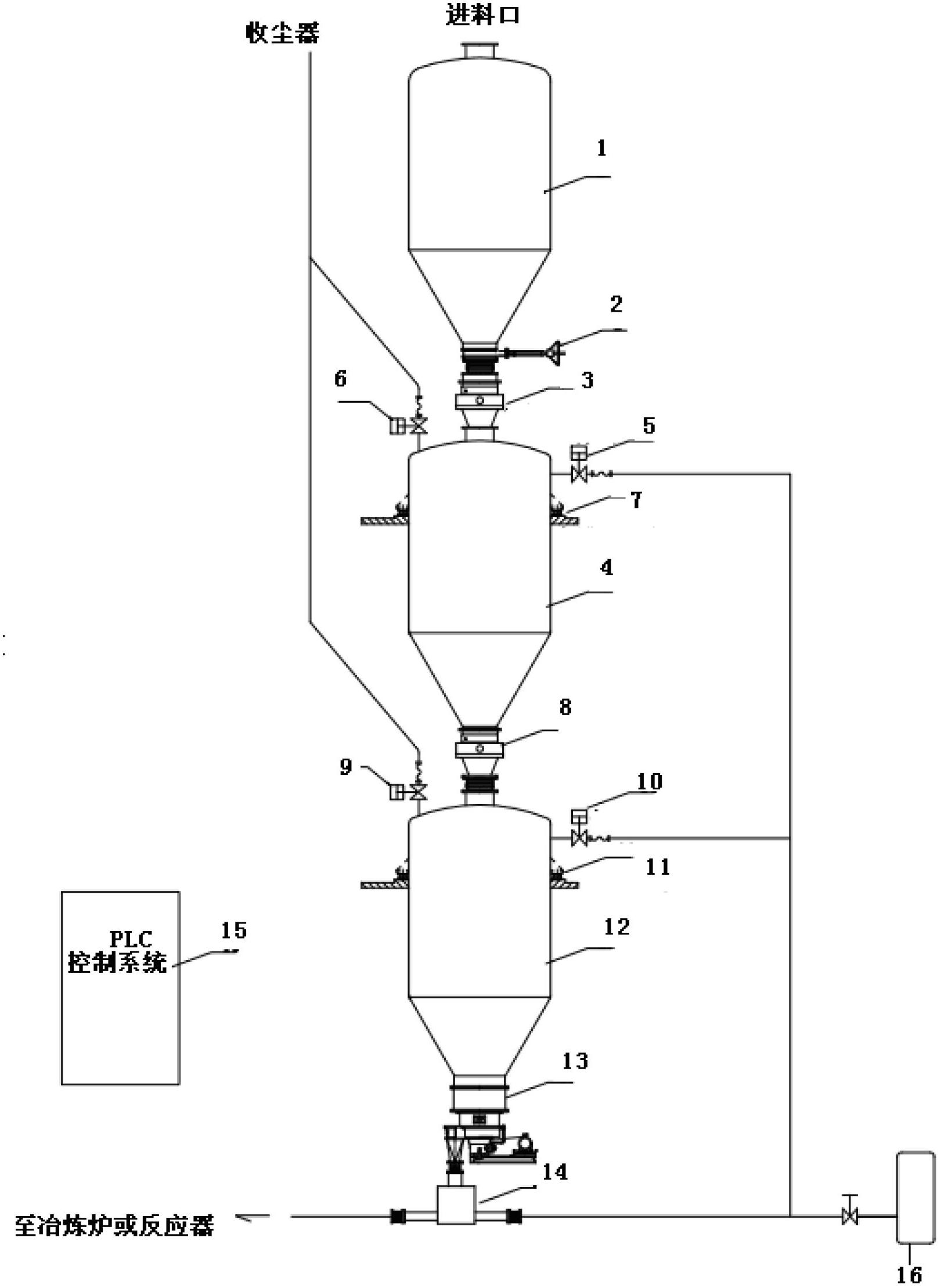

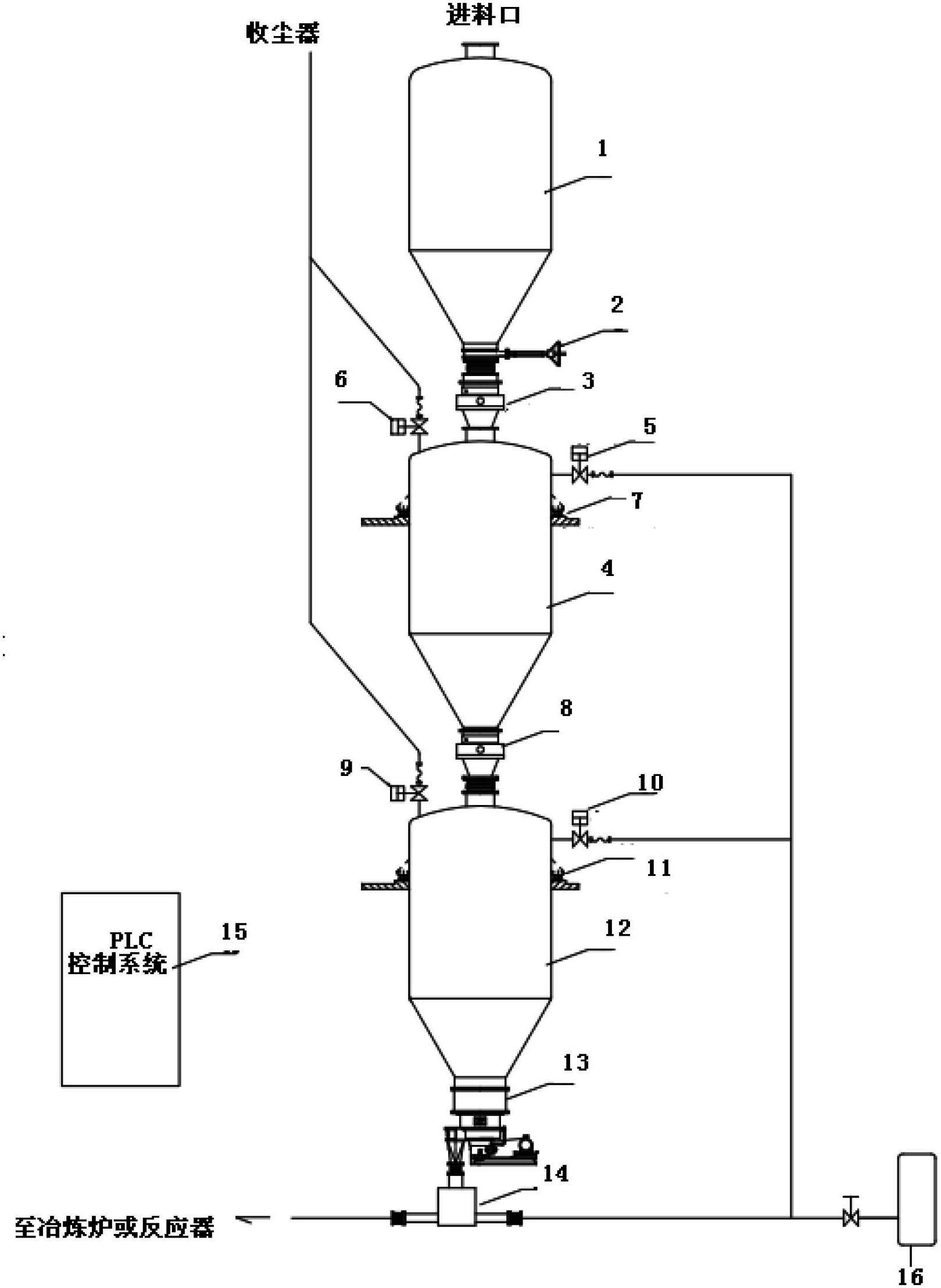

[0011] The following is attached figure 1 The specific embodiment of the present invention will be described in detail. Such as figure 1 As shown, a high-pressure conveying loss-in-weight powder quantitative supply device includes a powder feeding bin (1), a gate valve (2), a pneumatic valve (3, 5, 6, 8, 9, 10), a calibration bin (4 ), weighing sensor (7, 11), weighing bin (12), rotary feeder (13), Venturi tube (14), PLC control system (15).

[0012] The weighing bin (12) and the rotary feeder (13) constitute a weightless powder quantitative feeding machine. The Venturi tube (14) is conducive to the smooth entry of the powder into the pneumatic conveying pipeline. The calibration bin (4) is used for the weighing bin (12) ) to replenish materials and isolate the high pressure in the weighing chamber (12) from the normal pressure in the powder feeding chamber (1). Under working conditions, since the pneumatic valve (9) is always closed and the pneumatic valve (10) is always op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com