Method and device for smelting molten salt during aluminum oxide production

A melting device and alumina technology, applied in the direction of alumina/hydroxide, etc., can solve the problems of short service life, difficult maintenance, resource waste, etc., and achieve the effects of long service life, flexible start-up, and easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

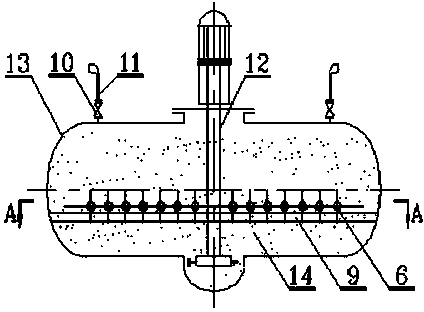

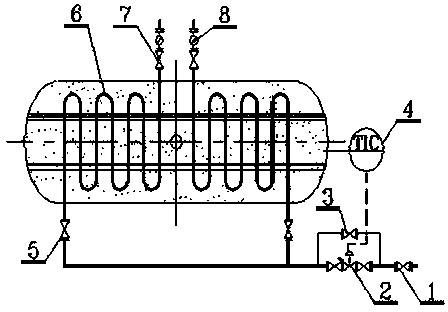

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0016] Embodiment of the present invention: When molten salt heating is carried out in the existing pipeline dissolution production alumina system, a molten salt melting method in alumina production of the present invention is adopted for implementation, that is, the solid molten salt at normal temperature is sent to Into the molten salt storage tank, a steam heater is installed in the molten salt storage tank, and the steam with a pressure of 3MPa~4MPa and a temperature of 250℃~270℃ is introduced into the steam heater, so that the heated The molten salt reaches a temperature above 142°C and melts, and then the molten salt is pumped into the next process.

[0017] When implementing the above-mentioned method of the present invention, adopt the molten salt melting device in a kind of alumina production of the present invention to implement, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com