Circumferential water supply mechanism capable of running at high speed

A technology of water supply mechanism and high-speed rotation, which is applied to the parts of grinding machine tools, grinding machines, grinding drive devices, etc., can solve the problems of waste of water resources, failure of smooth water supply to cool mechanical equipment, and mechanical equipment unable to rotate normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

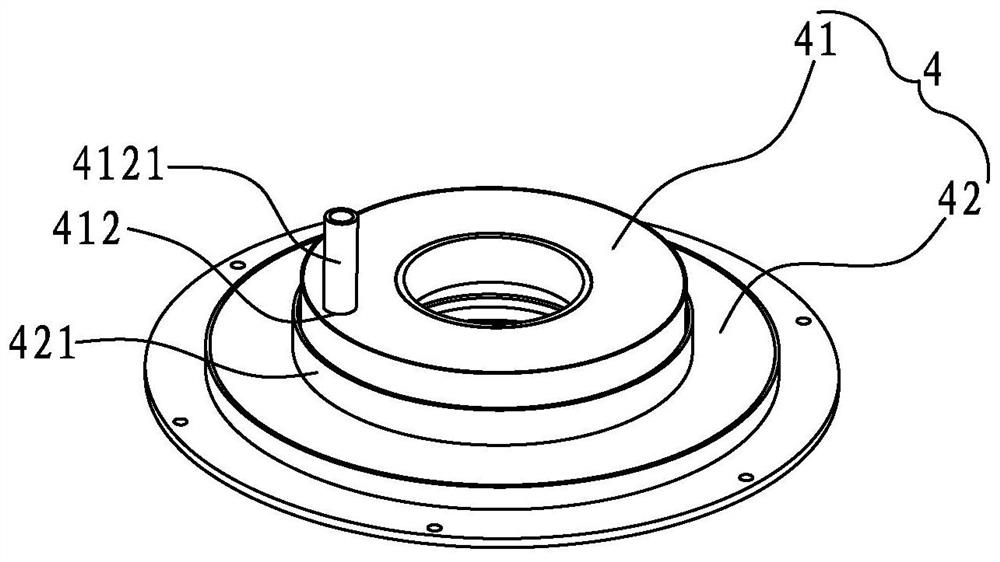

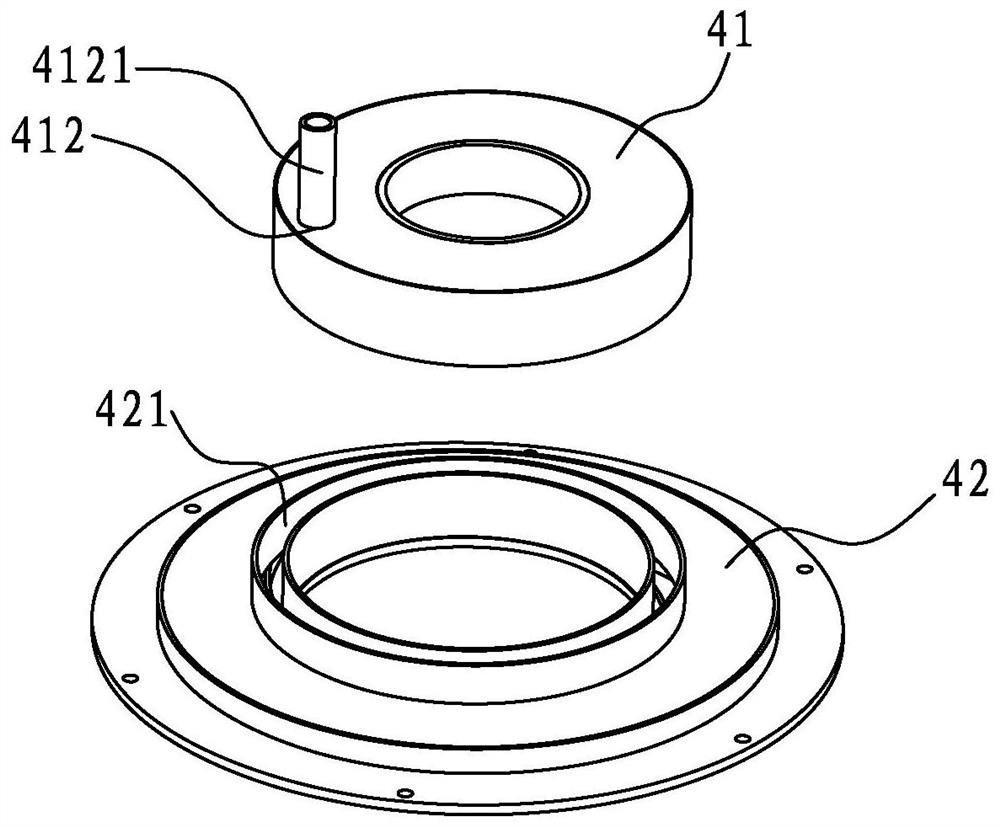

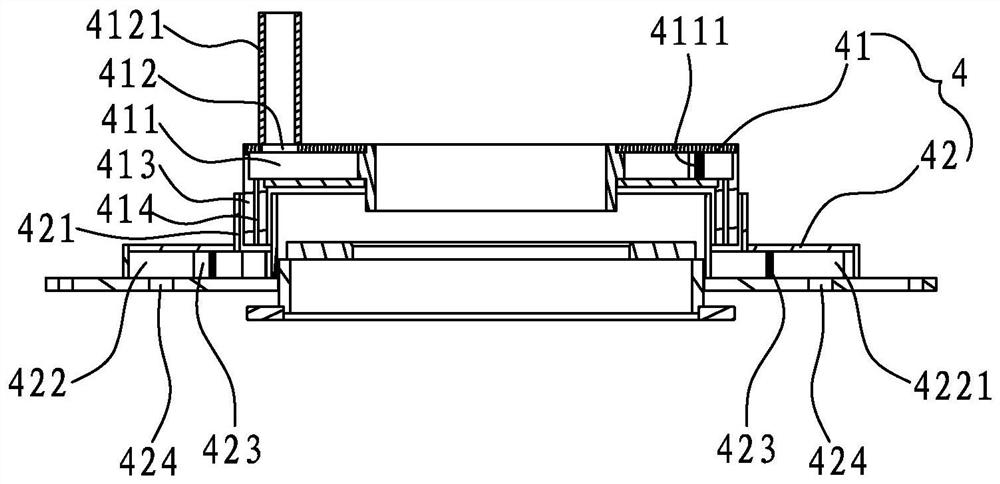

[0051] see Figure 1 to Figure 7 , the present invention discloses a circular water supply mechanism 4 capable of high-speed operation, including a lower water tray 41 and a water diversion tray 42 capable of high-speed operation; The water inlet 412 of the chamber 411, the water protruding ring 413 extending downward from the bottom wall of the water receiving chamber 411, and a plurality of circles evenly distributed on the water protruding ring 413 and communicating with the water receiving through holes 414 of the water receiving chamber 411; The water diversion plate 42 is provided with a water guide ring 421, a water diversion chamber 422, a plurality of water diversion blades 423 and a plurality of water diversion holes 424; And the lower end of the water guide ring 421 communicates with the water divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com